| Author |

Topic Search Topic Search  Topic Options Topic Options

|

DaveKamp

Orange Level Access

Joined: 12 Apr 2010

Location: LeClaire, Ia

Points: 6036

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jul 2020 at 2:54pm Posted: 16 Jul 2020 at 2:54pm |

well... a guy could chuck them in a cordless drill, clamp it in a vise, duct-tape the trigger ON, and use a fine, well-worn flap-disk in a 4" grinder...

Or better yet, put a cheap speed controller on the 4" grinder, dial the speed way down, and smear the worn-out flap disk with some fine valve grinding garnet mixed with axle grease....

making them convex and PRECISE is simply a matter of having a radius to work on...

If you were a Kiwi, you'd cut a broomstick off at whatever that convex radius is, mark a spot on your shop floor just below where your cordless drill chuck spins, and use that as a 'swinging radius' rest for your 4" grinder as you made that dressing pass...

..If you were a Scotsman, you'd find a much harder way to do it...

(This, by the way, is a tip-of-my hat to all the Kiwis, Scotsman, and Russians out there who live amidst, and solve real-world problems and are NOT encumbered by the Proper Gentleman's Rules Of Machine Rebuilding Propriety (PGROMRP)

Edited by DaveKamp - 16 Jul 2020 at 2:59pm

|

|

Ten Amendments, Ten Commandments, and one Golden Rule solve most every problem. Citrus hand-cleaner with Pumice does the rest.

|

|

|

Sponsored Links

|

|

|

garden_guy

Orange Level

Joined: 05 Jul 2013

Location: Illinois

Points: 1146

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jul 2020 at 3:15pm Posted: 16 Jul 2020 at 3:15pm |

|

As a not-motor guy, I am not quite sure what I am looking at. Is this something that yields motor "clicking" when running? Or some other "noise"?

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5087

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Jul 2020 at 6:12am Posted: 17 Jul 2020 at 6:12am |

|

A hollow or wore lifter will increase the camshaft lobe ware to decrease the opening of the valve. Valves not opening will decrease fuel entering the firing chamber as well as allowing proper exhaust which can cause burning of a valve. If you only using the tractor for puttering around you most likely will never know the difference.

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 24531

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Jul 2020 at 8:02am Posted: 17 Jul 2020 at 8:02am |

I had a B&S Vtwin Intek apart the other day and gee, when you consider it runs at 3600RPM for hours, weekly, the 'valve train' is well..kind of a joke compared to a 'tractor'. I'm thinkin you could 'mismatch' a tractor valvetrain and never notice anything chuggin along at 1500-2000 rpms.... While it would be nice to properly rebuild and get it 'tight' and up to 'factory specs', overall, it probably doesn't really matter....

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5087

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Jul 2020 at 11:39am Posted: 17 Jul 2020 at 11:39am |

jaybmiller wrote: jaybmiller wrote:

I had a B&S Vtwin Intek apart the other day and gee, when you consider it runs at 3600RPM for hours, weekly, the 'valve train' is well..kind of a joke compared to a 'tractor'. I'm thinkin you could 'mismatch' a tractor valvetrain and never notice anything chuggin along at 1500-2000 rpms.... While it would be nice to properly rebuild and get it 'tight' and up to 'factory specs', overall, it probably doesn't really matter....

|

In most cases today for sure. 10 hours a day on a plow or fitting ground in making a living with a tractor that is less than full power would make a difference and make for tiring days.

|

|

wjohn

Orange Level

Joined: 19 Jan 2010

Location: KS

Points: 2184

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Jul 2020 at 6:08pm Posted: 17 Jul 2020 at 6:08pm |

DrAllis wrote: DrAllis wrote:

I'd be shocked if AGCO even has any available. |

Turns out they don't, but I lucked out and my dealer has a NOS one at a different location that I'm supposed to pick up next week when it comes in.

|

|

1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45

|

|

wjohn

Orange Level

Joined: 19 Jan 2010

Location: KS

Points: 2184

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Jul 2020 at 6:10pm Posted: 17 Jul 2020 at 6:10pm |

garden_guy wrote: garden_guy wrote:

As a not-motor guy, I am not quite sure what I am looking at. Is this something that yields motor "clicking" when running? Or some other "noise"?

|

This engine wasn't making any odd noises and ran pretty well. I think it must have had almost no oil pressure or got a bunch of junk in the cam area at one point because in addition to the worn lifters, the camshaft journals were also very worn.

|

|

1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45

|

|

wjohn

Orange Level

Joined: 19 Jan 2010

Location: KS

Points: 2184

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Jul 2020 at 6:21pm Posted: 17 Jul 2020 at 6:21pm |

DaveKamp wrote: DaveKamp wrote:

well... a guy could chuck them in a cordless drill, clamp it in a vise, duct-tape the trigger ON, and use a fine, well-worn flap-disk in a 4" grinder... |

I have to admit I'm not ballsy enough to try any of these, which may mostly be me overthinking it combined with not having enough nice ($$$) equipment... I sure couldn't meet the radius that is presumably specified on the print from AC. Or, it could be too much German in me vs. the Scottish. We will see what the new part looks like when it arrives and I'll proceed from there.

Certainly spinning the lifter while removing material is the way to go. The chuck on my valve grinder won't quite open up enough to fit these. I've been drill press shopping for other reasons already.

|

|

1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45

|

|

wjohn

Orange Level

Joined: 19 Jan 2010

Location: KS

Points: 2184

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Jul 2020 at 11:30pm Posted: 25 Jul 2020 at 11:30pm |

I picked up the new lifter today and it is actually very flat - not at all convex. Unless AGCO changed this more recently for service parts, I assume this is how they came from the factory for at least the 201 engines. As Butch said these engines should be happy with flat lifters - that appears to be how they were designed. I will use the valve end grinding attachment on my Sioux and clean up my old lifters with a nice flat surface and be able to sleep at night.

I am thinking that I will call around and ship my camshaft out to have the lobes reground. Jacob's right - not worth risking it at this point with the rest of the money I am putting into the engine. A couple lobes have enough pitting that they definitely need attention. Hopefully it will be good for 40 or 50 years.

|

|

1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5087

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Jul 2020 at 5:43am Posted: 26 Jul 2020 at 5:43am |

wjohn wrote: wjohn wrote:

I picked up the new lifter today and it is actually very flat - not at all convex. Unless AGCO changed this more recently for service parts, I assume this is how they came from the factory for at least the 201 engines. As Butch said these engines should be happy with flat lifters - that appears to be how they were designed. I will use the valve end grinding attachment on my Sioux and clean up my old lifters with a nice flat surface and be able to sleep at night.

I am thinking that I will call around and ship my camshaft out to have the lobes reground. Jacob's right - not worth risking it at this point with the rest of the money I am putting into the engine. A couple lobes have enough pitting that they definitely need attention. Hopefully it will be good for 40 or 50 years.

|

I will stand corrected! I received the convex information from the shop that did my crankshaft grinding.

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8448

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Jul 2020 at 5:49am Posted: 26 Jul 2020 at 5:49am |

John, Good information! Thanks for sharing. It is nice to have the real part in your hand to get good data from. Nice picture! Get that old cam tuned up and you will be good to go. Hey I way over think stuff too. Then have to get a reality check when I actually have the items in my hand and the work needs to get done! German and Swedish on this end.:) Regards, Chris

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

wjohn

Orange Level

Joined: 19 Jan 2010

Location: KS

Points: 2184

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Jul 2020 at 9:00am Posted: 26 Jul 2020 at 9:00am |

Dick L wrote: Dick L wrote:

I will stand corrected! I received the convex information from the shop that did my crankshaft grinding.

|

Well, that's not to say that the B/C/CA engines didn't have convex lifters, but I would be surprised if they were any different. Convex lifters seem to have been very common in automotive engines which is probably why the machine shop said that.

|

|

1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45

|

|

wjohn

Orange Level

Joined: 19 Jan 2010

Location: KS

Points: 2184

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Jul 2020 at 9:05am Posted: 26 Jul 2020 at 9:05am |

Sugarmaker wrote: Sugarmaker wrote:

John, Good information! Thanks for sharing. It is nice to have the real part in your hand to get good data from. Nice picture! Get that old cam tuned up and you will be good to go. Hey I way over think stuff too. Then have to get a reality check when I actually have the items in my hand and the work needs to get done! German and Swedish on this end.:) Regards, Chris |

No problem Chris. I wanted to solve this mystery. Thankfully they should be easy to clean up.

|

|

1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45

|

|

wjohn

Orange Level

Joined: 19 Jan 2010

Location: KS

Points: 2184

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Feb 2021 at 8:42pm Posted: 09 Feb 2021 at 8:42pm |

I wanted to follow up after resurfacing my lifters in my Sioux 645L valve grinder/resurfacer. I used the valve stem end attachment and took a bunch of light passes to get to a completely new, flat surface. The company I sent my cam off to (Delta Camshaft in Tacoma, WA) could've resurfaced them for several bucks each + shipping but the guy there I talked to said this method would be good for anything like this WD engine that has flat lifter faces. Anything with convex lifter faces (i.e. most automotive applications) would probably need a special tappet/lifter grinder that can give you a consistent radius, and I'd have to send those out to a shop like them. My valve grinder was in need of a new end wheel, which was about $30 and should last me through a lot of lifters and valve stem ends. I figure it has paid for itself already. I still need to put the engine back together and hope this was a successful project, but I learned a lot about lifters and camshaft grinding between the forum and Delta Camshaft.

Very worn lifter as removed from the engine:

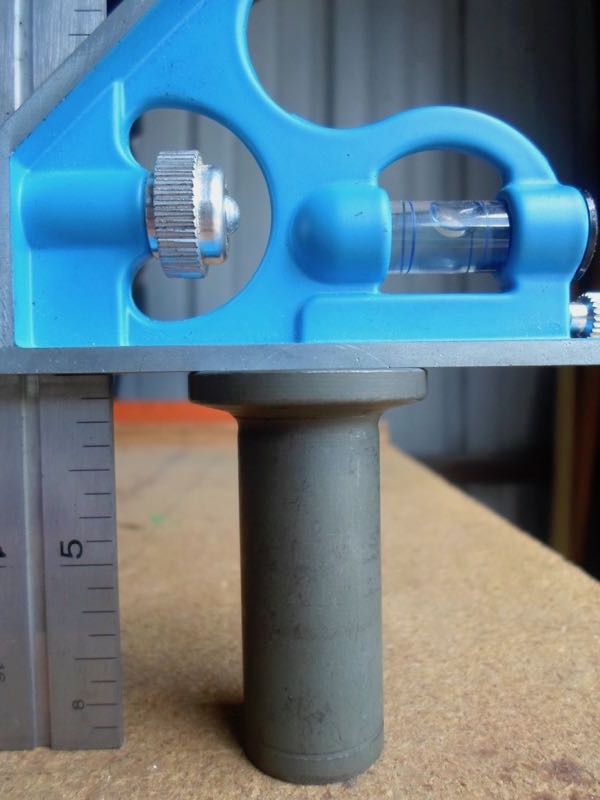

Showing the attachment that holds the lifter, which is rotated up and down in and out of contact with the grinding wheel. Then you slowly turn the red wheel in the lower RH of the picture to feed the lifter closer to the grinding wheel with each pass, to take more and more material off of the face.

Here you can really see how the lifters had worn so that the face was concave - the freshly machined surface is a high spot only around the outer edge, where there is no wear from the cam lobe:

And done:

|

|

1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

jaybmiller wrote:

jaybmiller wrote: