Matching Used Camshaft and Lifters

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=172539

Printed Date: 19 Dec 2025 at 7:21pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Matching Used Camshaft and Lifters

Posted By: wjohn

Subject: Matching Used Camshaft and Lifters

Date Posted: 02 Jul 2020 at 11:06pm

|

There's plenty of discussion about this on automotive forums, but I'm curious what the guys who deal with low-speed low spring pressure Allis-Chalmers engines think. The lobes on the camshaft out of my WD look decent, but the middle journal is worn way out of spec, so I'm looking for a replacement camshaft. Do the original lifters from whatever camshaft I buy need to go with it, on their original matched lobes? The concern is that mismatched lobes and lifters would start wearing rapidly and wipe out the lobes. All of my lifters are worn slightly concave, and a couple of them have more serious wear patterns on them that concern me. I haven't priced new lifters at AGCO but I doubt they're cheap. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Replies:

Posted By: jaybmiller

Date Posted: 03 Jul 2020 at 5:29am

|

I'd like to think you could take parts from 4-5-6 engines, mix and match and Frankenengine would start right up an last 30-40-50 years. Sure it'd be nice if evrything was 'within spec' but... reality is things wear over time and STILL perofrm reasonably well. I KNOW that a certain lil English Austin never had all the 'head parts' put back 'in order' and it ran GREAT.... dang that was 1/2 century ago. ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Butch(OH)

Date Posted: 03 Jul 2020 at 5:35am

| The old rule of thumb is old cam/new lifters is OK but new cam/old lifters is not OK. If your going to the expence of a new or reground cam get the lifters refaced. If that expence causes your wallet to empty out then don't get a new cam and find a used one and put it back together. As the other poster said it will very likely run great tbe rest of your life. |

Posted By: Butch(OH)

Date Posted: 03 Jul 2020 at 5:36am

| Duplicate removed |

Posted By: allisbred

Date Posted: 03 Jul 2020 at 5:59am

| Well— I’m going through this same issue on an old Chrysler flat head that is soon to be rebuilt. Doesn’t seem new lifters are available and I‘m being told they reuse the old lifters on reground cams. |

Posted By: wjohn

Date Posted: 03 Jul 2020 at 9:52am

I will not be putting a new/reground cam in this tractor and valve springs will be stock. However, I should mention that this tractor will get some hours on it since I have about 20 acres of tillable I plan to mess around with. Sounds like I should just find the best looking used lifters I can and go with them. I think I read a DickL post somewhere that said the lifters should actually be slightly convex? ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: Boss Man

Date Posted: 03 Jul 2020 at 6:06pm

| Lifters have concave bottoms on them to help them turn as the cam rotates, which helps control wear |

Posted By: wjohn

Date Posted: 03 Jul 2020 at 6:52pm

WC/WD/WD-45 lifters should be concave when new? Most automotive examples I looked up have a convex surface. Mine from my WD are all slightly concave and definitely showing various levels of wear... If they were originally concave that would make me feel slightly better. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: HD6GTOM

Date Posted: 03 Jul 2020 at 7:58pm

| When I overhauled dads, I got new lifters at NAPA. |

Posted By: Tracy Martin TN

Date Posted: 03 Jul 2020 at 9:00pm

|

On the D 15 series and smaller AC engines,what turns the lifters are that they are off center to lobes on the cam, might be that way on larger engines too. Just the nature of cam rotating will turn the lifter. HTH Tracy ------------- No greater gift than healthy grandkids! |

Posted By: MACK

Date Posted: 03 Jul 2020 at 9:14pm

| If the lifters are concave, they are worn out. MACK |

Posted By: LeonR2013

Date Posted: 03 Jul 2020 at 9:28pm

| When I redid my 45 I straight edged the bottom of the lifter and found they were worn. So I just glued a piece of emery cloth to a very flat 2X10 and keeping the lifter as flat as possible began sanding and checking frequently with a straight edge. Worked for me. Leon |

Posted By: wjohn

Date Posted: 03 Jul 2020 at 9:50pm

Any way you'd have the part number somewhere? I've searched NAPA's website with no luck for anything tied to a WD. The only new ones I can find are from Reliance and they're in the $50 each range. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: DrAllis

Date Posted: 03 Jul 2020 at 9:52pm

| Some valve grinders have an attachment to reface mushroom type lifters. |

Posted By: wjohn

Date Posted: 03 Jul 2020 at 9:53pm

|

Mack, thanks for the confirmation on concave being worn out. Leon I will be tempted to attempt some cleanup on these if I can't find affordable new ones. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: Jacob (WI,ND)

Date Posted: 03 Jul 2020 at 9:57pm

|

There are a lot of variables, but I'll give you my two cents from my experience. On my 20-35 rebuild, we originally used the original worn cam, with resurfaced lifters. That is what people told us we should do, and we didn't know any better, so we did just that. That was NOT the thing to do! After minimal running we pulled the engine side covers to inspect, to find the edges of several of the lifters chipped up and you can guess where those chips go. Long story short, we SHOULD have had the cam ground as well as the lifters. The old funny worn cam was putting pressure on the edges of the new lifters and making them fail. Maybe it was a fluke, but I don't think so. Tore the engine all back down to have the cam ground, and new lifters AGAIN. Clean out entire engine. Very frustrating. Take the time and $ and have both reground. It really doesn't cost that much compared to fixing the carnage when something goes wrong. Now you know how I know. ------------- Jacob Swanson 1920 6-12; 1925,1926 20-35 longfenders; 1925,1926 15-25's; 1927,1929 20-35 shortfenders; C; B's; IB; WC's; WD; WD45 |

Posted By: KMAG

Date Posted: 03 Jul 2020 at 10:01pm

|

Vintage Power Wagons is your home for 218/230/265 Mopar flathead parts. https://drive.google.com/file/d/0BxzO_Oy1EMLIWVFzSHRzNjlOMWs/view" rel="nofollow - https://drive.google.com/file/d/0BxzO_Oy1EMLIWVFzSHRzNjlOMWs/view $25 per valve tappet. Loads of low mileage (under 30k) military 230 M37 engines out there for cheap parts. |

Posted By: wjohn

Date Posted: 03 Jul 2020 at 11:45pm

That would be slick. I have a Sioux 645L and it came with the rocker arm grinding attachment, but it doesn't look like they even made anything for lifters - at least for that model. I was trying to think of a way to rig it up but I'm not sure I could accurately do much other than grind the bottom of the lifter flat. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: SteveM C/IL

Date Posted: 03 Jul 2020 at 11:47pm

| From Briggs & Stratton on up, flat tappets run off center of lobe so they will rotate. |

Posted By: Butch(OH)

Date Posted: 04 Jul 2020 at 9:53am

My Black and Decker has that attachmemt. After using it I finish the lifter by placing it in a collar in the Bridgeport and lowering it on a lapping plate. |

Posted By: Butch(OH)

Date Posted: 04 Jul 2020 at 12:36pm

My Black and Decker has that attachmemt. After using it I finish the lifter by placing it in a collar in the Bridgeport and lowering it on a lapping plate. |

Posted By: wjohn

Date Posted: 04 Jul 2020 at 2:20pm

That flat grinds the surface, or gives you a slightly convex surface? I guess if these were flat from the factory I could handle that with my valve grinder.

------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: Dick L

Date Posted: 04 Jul 2020 at 3:37pm

Slight convex is the way I have always re conditioned. They will get concave after enough dirty oil and hours of run time. The lifters out of this engine was as bad as I had ever seen them. I used a spin index on a pivot with a surface grinder in my tool shop. I used new lifters when I put a Crane ground camshaft in my one C. However my wife says I am absent minded. I tell her she is silly because I can not for the life of me remember being absent minded.

|

Posted By: Butch(OH)

Date Posted: 04 Jul 2020 at 6:20pm

| Yes it grinds them flat, your engine will be happy with flat ground lifters |

Posted By: HD6GTOM

Date Posted: 05 Jul 2020 at 8:00am

| I do not have any numbers. I went to a NAPA that has been in business since the 1930's. They knew which catalogue to look in. They did not come from the NAPA warehouse. Good luck with your tractor. The WD45 we have is one dad bought new. Last time I worked on the hovenor for him, I put 170 governor springs in it. It was his favorite tractor. |

Posted By: wjohn

Date Posted: 05 Jul 2020 at 12:08pm

Awesome. I guess that makes sense... They start out convex, eventually get worn flat, and then wear in to concave. By at least making them flat they're probably at least half as good as new, and way better than what they look like now. These are samples of the ones I'm working with out of my WD. They're concave by 0.002-0.003 in the centers. Some have some pretty ugly wear patterns from the lobes at 90 degree angles which tells me they weren't or haven't been rotating at some point in their lives. Those spots are worn in a little deeper. I'll play around with grinding them flat on the valve end grinding attachment on my Sioux. No Bridgeport unfortunately but I can try hand finishing them.  ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: wjohn

Date Posted: 05 Jul 2020 at 12:10pm

Thanks Tom. I should price AGCO ones but I doubt they're much if any cheaper than the Reliance ones at $50 each. I wonder if the ones you got from NAPA were from Reliance or someone like Mahle, Sealed Power, etc. but I can't find them available anymore. As you are hinting at it might be worth stopping by a local NAPA in case they have a better way to look them up. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: DrAllis

Date Posted: 05 Jul 2020 at 5:05pm

| I'd be shocked if AGCO even has any available. |

Posted By: LeonR2013

Date Posted: 15 Jul 2020 at 9:16pm

| WJohn, yours are way worse than mine was. It had to be a noisy motor. I wouldn't attempt to do those by hand. But mine turned out good and still in there after several years of lite work. |

Posted By: LeonR2013

Date Posted: 15 Jul 2020 at 9:25pm

| In addition wjohn I glued a piece of I think it was 400 emery, to a flat board and used both hands to keep the lifter as square as possible sanded back and forth, finished with very fine emery. Guess I was to dumb not to try it, but so far so good. Leon |

Posted By: DaveKamp

Date Posted: 16 Jul 2020 at 2:54pm

|

well... a guy could chuck them in a cordless drill, clamp it in a vise, duct-tape the trigger ON, and use a fine, well-worn flap-disk in a 4" grinder... Or better yet, put a cheap speed controller on the 4" grinder, dial the speed way down, and smear the worn-out flap disk with some fine valve grinding garnet mixed with axle grease.... making them convex and PRECISE is simply a matter of having a radius to work on... If you were a Kiwi, you'd cut a broomstick off at whatever that convex radius is, mark a spot on your shop floor just below where your cordless drill chuck spins, and use that as a 'swinging radius' rest for your 4" grinder as you made that dressing pass... ..If you were a Scotsman, you'd find a much harder way to do it... ...and if you were Russian, you'd mix some vodka with the grease, and post a how-to video on Youtube!!!    (This, by the way, is a tip-of-my hat to all the Kiwis, Scotsman, and Russians out there who live amidst, and solve real-world problems and are NOT encumbered by the Proper Gentleman's Rules Of Machine Rebuilding Propriety (PGROMRP)

------------- Ten Amendments, Ten Commandments, and one Golden Rule solve most every problem. Citrus hand-cleaner with Pumice does the rest. |

Posted By: garden_guy

Date Posted: 16 Jul 2020 at 3:15pm

|

As a not-motor guy, I am not quite sure what I am looking at. Is this something that yields motor "clicking" when running? Or some other "noise"? |

Posted By: Dick L

Date Posted: 17 Jul 2020 at 6:12am

| A hollow or wore lifter will increase the camshaft lobe ware to decrease the opening of the valve. Valves not opening will decrease fuel entering the firing chamber as well as allowing proper exhaust which can cause burning of a valve. If you only using the tractor for puttering around you most likely will never know the difference. |

Posted By: jaybmiller

Date Posted: 17 Jul 2020 at 8:02am

|

I had a B&S Vtwin Intek apart the other day and gee, when you consider it runs at 3600RPM for hours, weekly, the 'valve train' is well..kind of a joke compared to a 'tractor'. I'm thinkin you could 'mismatch' a tractor valvetrain and never notice anything chuggin along at 1500-2000 rpms.... While it would be nice to properly rebuild and get it 'tight' and up to 'factory specs', overall, it probably doesn't really matter.... ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Dick L

Date Posted: 17 Jul 2020 at 11:39am

In most cases today for sure. 10 hours a day on a plow or fitting ground in making a living with a tractor that is less than full power would make a difference and make for tiring days.

|

Posted By: wjohn

Date Posted: 17 Jul 2020 at 6:08pm

Turns out they don't, but I lucked out and my dealer has a NOS one at a different location that I'm supposed to pick up next week when it comes in. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: wjohn

Date Posted: 17 Jul 2020 at 6:10pm

This engine wasn't making any odd noises and ran pretty well. I think it must have had almost no oil pressure or got a bunch of junk in the cam area at one point because in addition to the worn lifters, the camshaft journals were also very worn. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: wjohn

Date Posted: 17 Jul 2020 at 6:21pm

I have to admit I'm not ballsy enough to try any of these, which may mostly be me overthinking it combined with not having enough nice ($$$) equipment... I sure couldn't meet the radius that is presumably specified on the print from AC. Or, it could be too much German in me vs. the Scottish. We will see what the new part looks like when it arrives and I'll proceed from there. Certainly spinning the lifter while removing material is the way to go. The chuck on my valve grinder won't quite open up enough to fit these. I've been drill press shopping for other reasons already. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: wjohn

Date Posted: 25 Jul 2020 at 11:30pm

|

I picked up the new lifter today and it is actually very flat - not at all convex. Unless AGCO changed this more recently for service parts, I assume this is how they came from the factory for at least the 201 engines. As Butch said these engines should be happy with flat lifters - that appears to be how they were designed. I will use the valve end grinding attachment on my Sioux and clean up my old lifters with a nice flat surface and be able to sleep at night. I am thinking that I will call around and ship my camshaft out to have the lobes reground. Jacob's right - not worth risking it at this point with the rest of the money I am putting into the engine. A couple lobes have enough pitting that they definitely need attention. Hopefully it will be good for 40 or 50 years.  ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: Dick L

Date Posted: 26 Jul 2020 at 5:43am

I will stand corrected! I received the convex information from the shop that did my crankshaft grinding.

|

Posted By: Sugarmaker

Date Posted: 26 Jul 2020 at 5:49am

|

John, Good information! Thanks for sharing. It is nice to have the real part in your hand to get good data from. Nice picture! Get that old cam tuned up and you will be good to go. Hey I way over think stuff too. Then have to get a reality check when I actually have the items in my hand and the work needs to get done! German and Swedish on this end.:) Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: wjohn

Date Posted: 26 Jul 2020 at 9:00am

Well, that's not to say that the B/C/CA engines didn't have convex lifters, but I would be surprised if they were any different. Convex lifters seem to have been very common in automotive engines which is probably why the machine shop said that. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: wjohn

Date Posted: 26 Jul 2020 at 9:05am

No problem Chris. I wanted to solve this mystery. Thankfully they should be easy to clean up. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: wjohn

Date Posted: 09 Feb 2021 at 8:42pm

|

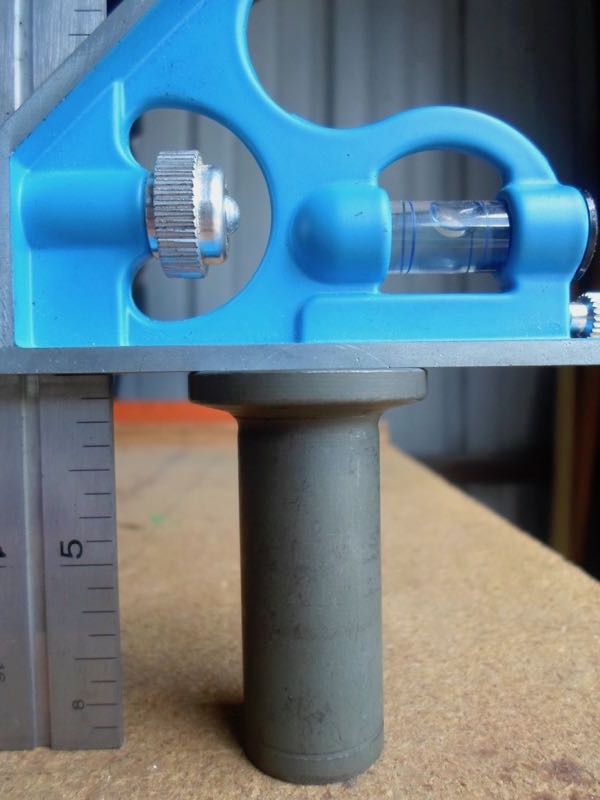

I wanted to follow up after resurfacing my lifters in my Sioux 645L valve grinder/resurfacer. I used the valve stem end attachment and took a bunch of light passes to get to a completely new, flat surface. The company I sent my cam off to (Delta Camshaft in Tacoma, WA) could've resurfaced them for several bucks each + shipping but the guy there I talked to said this method would be good for anything like this WD engine that has flat lifter faces. Anything with convex lifter faces (i.e. most automotive applications) would probably need a special tappet/lifter grinder that can give you a consistent radius, and I'd have to send those out to a shop like them. My valve grinder was in need of a new end wheel, which was about $30 and should last me through a lot of lifters and valve stem ends. I figure it has paid for itself already. I still need to put the engine back together and hope this was a successful project, but I learned a lot about lifters and camshaft grinding between the forum and Delta Camshaft. Very worn lifter as removed from the engine:  Showing the attachment that holds the lifter, which is rotated up and down in and out of contact with the grinding wheel. Then you slowly turn the red wheel in the lower RH of the picture to feed the lifter closer to the grinding wheel with each pass, to take more and more material off of the face.   Here you can really see how the lifters had worn so that the face was concave - the freshly machined surface is a high spot only around the outer edge, where there is no wear from the cam lobe:  And done:  ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Butch(OH) wrote:

Butch(OH) wrote: