| Author |

Topic Search Topic Search  Topic Options Topic Options

|

coggonobrien

Orange Level Access

Joined: 14 Nov 2010

Location: Eastern Iowa

Points: 1877

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: D-17 XT Topic: D-17 XT

Posted: 11 Apr 2020 at 8:57pm |

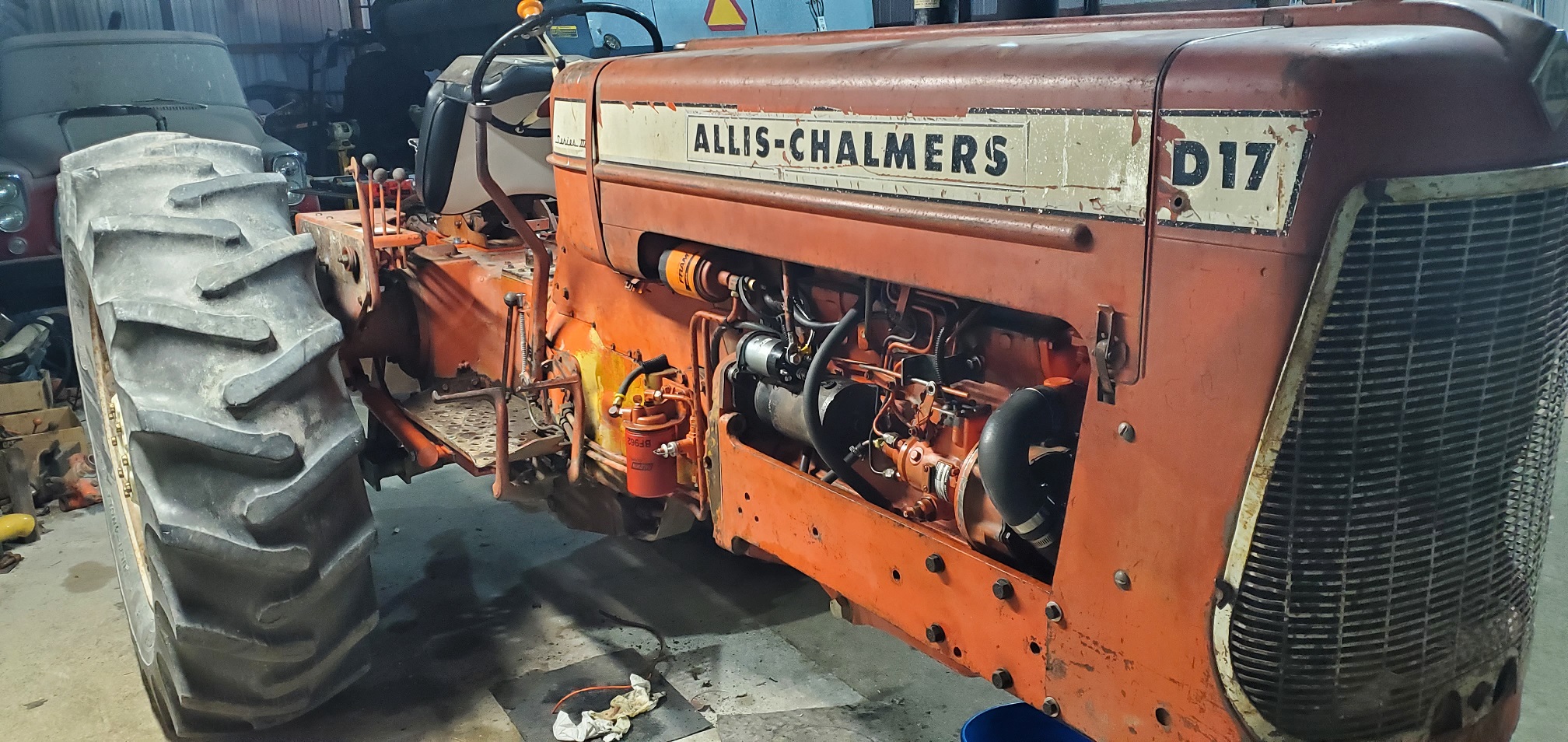

The Dr's. Look Ma', careful planning means you don't butcher sheetmetal.

|

|

|

Sponsored Links

|

|

|

Nathan (SD)

Orange Level

Joined: 11 Sep 2009

Location: Day County SD

Points: 1299

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Apr 2020 at 9:03pm Posted: 11 Apr 2020 at 9:03pm |

|

Check out a muffler for a JD 830. Offset might be close enough for the hole.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22569

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Apr 2020 at 9:07pm Posted: 11 Apr 2020 at 9:07pm |

|

And lose the turbo whistle ?? No way !!

|

|

AC7060IL

Orange Level

Joined: 19 Aug 2012

Location: central IL

Points: 3631

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Apr 2020 at 10:05pm Posted: 11 Apr 2020 at 10:05pm |

|

Nice D17 diesel. Is it a 443T or 433I? How many more days til it’s plow day?

|

|

MACK

Orange Level

Joined: 17 Nov 2009

Points: 7664

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Apr 2020 at 10:08pm Posted: 11 Apr 2020 at 10:08pm |

|

Like it. MACK

|

|

JC-WI

Orange Level Access

Joined: 11 Sep 2009

Location: wisconsin

Points: 34556

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Apr 2020 at 10:25pm Posted: 11 Apr 2020 at 10:25pm |

|

Are you using an orbit motor on the original front steering box and pedestal and control under the dash?

|

|

He who says there is no evil has already deceived himself

The truth is the truth, sugar coated or not. Trawler II says, "Remember that."

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22569

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2020 at 5:24am Posted: 12 Apr 2020 at 5:24am |

|

Char-Lynn orbit motor connected directly to the steering worm gear in front. A regular A-C 100 series orbitrol under the fuel tank to send the signal to the orbit motor. This was a big deal and just barely enough room for the orbit motor. It is a gas chassis with the shorter hoods and side frames. There is clearance to remove the crank pulley without pulling the front end out from under it. The diesel engine is about 3 inches shorter than the gas engine overall. I thought I was going to be forced into using a wide front axle and somehow mounting an external steer cylinder crossways on the tie rods. This way either front end will work. Go to: D17 project-Google photos to see an album my son created. I still have some 1/2" thick rub plates to make for the 3-point lower arms and remote outlets and fender repairs, but it's getting close. Sad to think the 190XT engine existed in 1965 and this engine didn't get used on the Ag side until 1978 in the F-2 combine. It is a 433-I that the intercooler has been removed to fit under the hood.

Edited by DrAllis - 12 Apr 2020 at 5:50am

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22569

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 12 Apr 2020 at 5:41am Posted: 12 Apr 2020 at 5:41am |

|

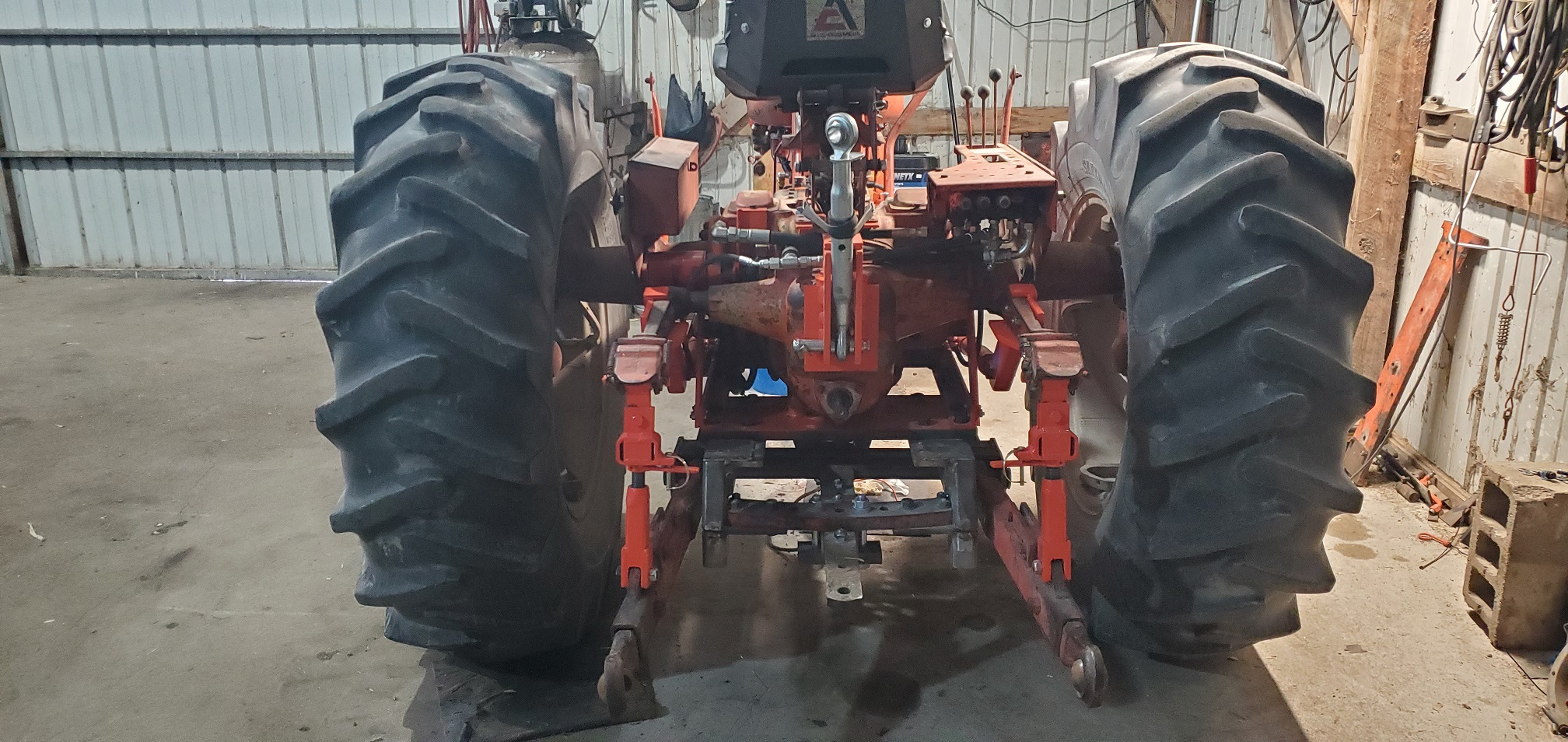

Plow day ?? My brother has 3 acres of sod to do maybe this Summer. The design of the 3-point hitch is such that, after dropping the draft arms/lift links (a 2 minute job), I can unbolt each side frame, the drawbar bail and then pull the drawbar out of the snap-coupler bell and this tractor still works with snap-coupler equipment. The heavy base plate and braces and auxiliary lift cylinders stay on the tractor.

|

|

Kenny L.

Orange Level Access

Joined: 12 Sep 2009

Location: NEIOWA

Points: 1397

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2020 at 7:38am Posted: 12 Apr 2020 at 7:38am |

|

I'm looking forward to see it in person one of these day when the kido take me off being grounded. (I thought it was supposed to be the other way a round) Stay safe and Happy Easter

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22569

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2020 at 8:13am Posted: 12 Apr 2020 at 8:13am |

|

Just be sure all your ground connections are clean and tight. We don't want there to be a spark of any kind...……….!!

|

|

m16ty

Orange Level

Joined: 28 Jan 2011

Location: TN

Points: 1480

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2020 at 8:37am Posted: 12 Apr 2020 at 8:37am |

|

What is the reasoning behind the external lift cylinders? More lift power than the internal cylinder offers?

|

|

IBWD MIke

Orange Level

Joined: 08 Apr 2012

Location: Newton Ia.

Points: 4237

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2020 at 8:40am Posted: 12 Apr 2020 at 8:40am |

|

I like it!

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22569

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2020 at 8:56am Posted: 12 Apr 2020 at 8:56am |

|

Original internal lift cylinder operates at 3700 psi and 4.5 GPM's. The new "live" hydraulic system (with the pump on the engine) operates at 2200 psi and 12 GPM's, so it takes more cubic inches of cylinders to lift that 4-bottom plow or anything else that is heavy.

|

|

m16ty

Orange Level

Joined: 28 Jan 2011

Location: TN

Points: 1480

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2020 at 9:27am Posted: 12 Apr 2020 at 9:27am |

DrAllis wrote: DrAllis wrote:

Original internal lift cylinder operates at 3700 psi and 4.5 GPM's. The new "live" hydraulic system (with the pump on the engine) operates at 2200 psi and 12 GPM's, so it takes more cubic inches of cylinders to lift that 4-bottom plow or anything else that is heavy. |

Ok, I overlooked the fact that you went from high pressure to low pressure, via the new hyd pump on the side of the engine. The original system was “live”, you now have “independent” hydraulics.

|

|

coggonobrien

Orange Level Access

Joined: 14 Nov 2010

Location: Eastern Iowa

Points: 1877

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2020 at 9:28am Posted: 12 Apr 2020 at 9:28am |

|

He has both systems intact and fully functional

|

|

AC7060IL

Orange Level

Joined: 19 Aug 2012

Location: central IL

Points: 3631

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2020 at 3:56pm Posted: 12 Apr 2020 at 3:56pm |

|

Thanks for posting all the excellent photos. The fact that it’s hood panels easily lift off is so cool for that early era. AC lost that during the D21-100 series era. But glad it got revived or the 7000 & 8000 series.

I also appreciate where you mounted the 433T’s fuel filter & hand primer. Great job! Did the engine plate to clutch housing give you a challenge?

Edited by AC7060IL - 12 Apr 2020 at 6:21pm

|

|

Keith M

Silver Level

Joined: 17 Mar 2020

Location: Kentucky

Points: 50

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2020 at 6:15pm Posted: 12 Apr 2020 at 6:15pm |

|

I love what you did. I’m more of a parts changer than a mechanic. My Dad is a mechanic but sees no reason to change things. So projects like this I get no help on. If you could send detailed instructions I’d love to do this to my D-17. If too involved I understand. Thanks, Keith from Kentucky

|

|

Carl(NWWI)

Orange Level

Joined: 13 Sep 2009

Location: NW WI

Points: 956

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2020 at 6:29pm Posted: 12 Apr 2020 at 6:29pm |

|

That will be a fun toy!! Well done Dr

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22569

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2020 at 6:38pm Posted: 12 Apr 2020 at 6:38pm |

|

The rear plate mounting and flywheel/clutch were almost as much of a challenge as the power steering. The chassis was a gasser, so that means the clutch shaft is an 1 1/4" or so LONGER than a diesel chassis. Spacing the engine forward that much wasn't an option because of the power steering design. I cut off the nose of the clutch shaft where the pilot bearing goes. I found a metric bearing that would slide onto the splined part of the now shortened clutch shaft. I used a 7000 tractor clutch disc, a 180-200 pressure plate, a D17 diesel throwout bearing shifter, and some machining of the flywheel to get that 100 HP clutch assembly in the 55 HP bellhousing. When complete, the wheelbase of the tractor was 1/8" longer, so sheet metal wasn't any problem. If the chassis had been a diesel to begin with, this part of the project would have been much easier. The only Sheetmetal change made was the air cleaner stack hole in the hood was opened up about 1/4" to make room for the larger diameter tube.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22569

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2020 at 6:40pm Posted: 12 Apr 2020 at 6:40pm |

|

A working and fun toy, Carl. I can see hay making, grain augering and many miles of 18+ MPH tractor riding !!

|

|

HD6GTOM

Orange Level

Joined: 30 Nov 2009

Location: MADISON CO IA

Points: 6627

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2020 at 6:47pm Posted: 12 Apr 2020 at 6:47pm |

|

Like it. Looks like a lot of thinking to put her together.

|

|

Gatz in NE

Orange Level

Joined: 11 Sep 2009

Location: Lincoln, NE

Points: 1064

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2020 at 7:13pm Posted: 12 Apr 2020 at 7:13pm |

Dr's D17 XTreme make-over

(with permission...)

|

|

DSeries4

Orange Level

Joined: 12 Sep 2009

Location: Ontario, Canada

Points: 7600

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2020 at 8:12pm Posted: 12 Apr 2020 at 8:12pm |

You did an excellent job fitting that engine in there and keeping the sheet metal intact, even all the hydraulic hoses are nicely secured in place and don't sag. These are the things I look for. You took the time to make it fit and you didn't hack everything up with a cutting torch.

Anyone would be proud to have a D17 like that!

|

|

'49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080

|

|

JohnColo

Orange Level

Joined: 03 Apr 2020

Location: Niwot, CO

Points: 1263

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2020 at 8:59pm Posted: 12 Apr 2020 at 8:59pm |

That is one beautiful piece of work. When I saw the first picture I didn't even realize it wasn't just another stock D17, then I noticed the manifold and, wait, what did he do!

I'll bet there were some cold days working in that uninsulated shop! What year is that Binder pickup in the background?

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22569

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2020 at 9:03pm Posted: 12 Apr 2020 at 9:03pm |

|

1960 Farmall pickup. It runs and drives 40K miles.

|

|

JoeO(CMO)

Orange Level

Joined: 11 Sep 2009

Location: Cent Missouri

Points: 2696

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Apr 2020 at 8:11am Posted: 14 Apr 2020 at 8:11am |

|

I like it!👍

That is the best looking, thought out, functional 3-point conversion I have seen and can be easily used!!

When is production starting on a “kit”?

I don’t have a 17 now but one can be found.

|

|

|

|

190xt MN

Bronze Level

Joined: 15 Sep 2019

Location: Minnesota

Points: 81

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Apr 2020 at 6:04pm Posted: 14 Apr 2020 at 6:04pm |

|

Very good engineering. Looks like a stock d 17. Both hydraulic systems are still fully functional?

|

|

Calvin Schmidt

Orange Level

Joined: 11 Sep 2009

Location: Ontario Can.

Points: 4577

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Apr 2020 at 7:13pm Posted: 14 Apr 2020 at 7:13pm |

|

Nice job ! Friend is finishing up a 301 in a D-19. It will be his corn planting tractor and a little fun tractor pulling. Cant beat fun and work.

|

|

Nothing is impossible if it is properly financed

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22569

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Apr 2020 at 7:18am Posted: 15 Apr 2020 at 7:18am |

|

Both hydraulic systems are fully functional, YES. The new "live" hyd system auxiliary external lift cylinders simply plug into the OEM high pressure coupler outlet, so all three cylinders work together. When I go to plow with the 4-bottom snap-coupler fully mounted plow, I will unplug that connection and use the internal pump and ram for lift/lower and Traction Booster. I intend to eventually connect the position control lever to the new hydraulic system console to be able to control 3-point hitch depth, but doubt that I will go so far as to fabricate Traction Booster linkage. We'll see.

Edited by DrAllis - 15 Apr 2020 at 9:16am

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22569

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Apr 2020 at 7:19am Posted: 15 Apr 2020 at 7:19am |

|

Calvin, how is your friend doing his steering ??

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

DrAllis wrote:

DrAllis wrote: