D-17 XT

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=170049

Printed Date: 05 Feb 2026 at 11:58pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: D-17 XT

Posted By: coggonobrien

Subject: D-17 XT

Date Posted: 11 Apr 2020 at 8:57pm

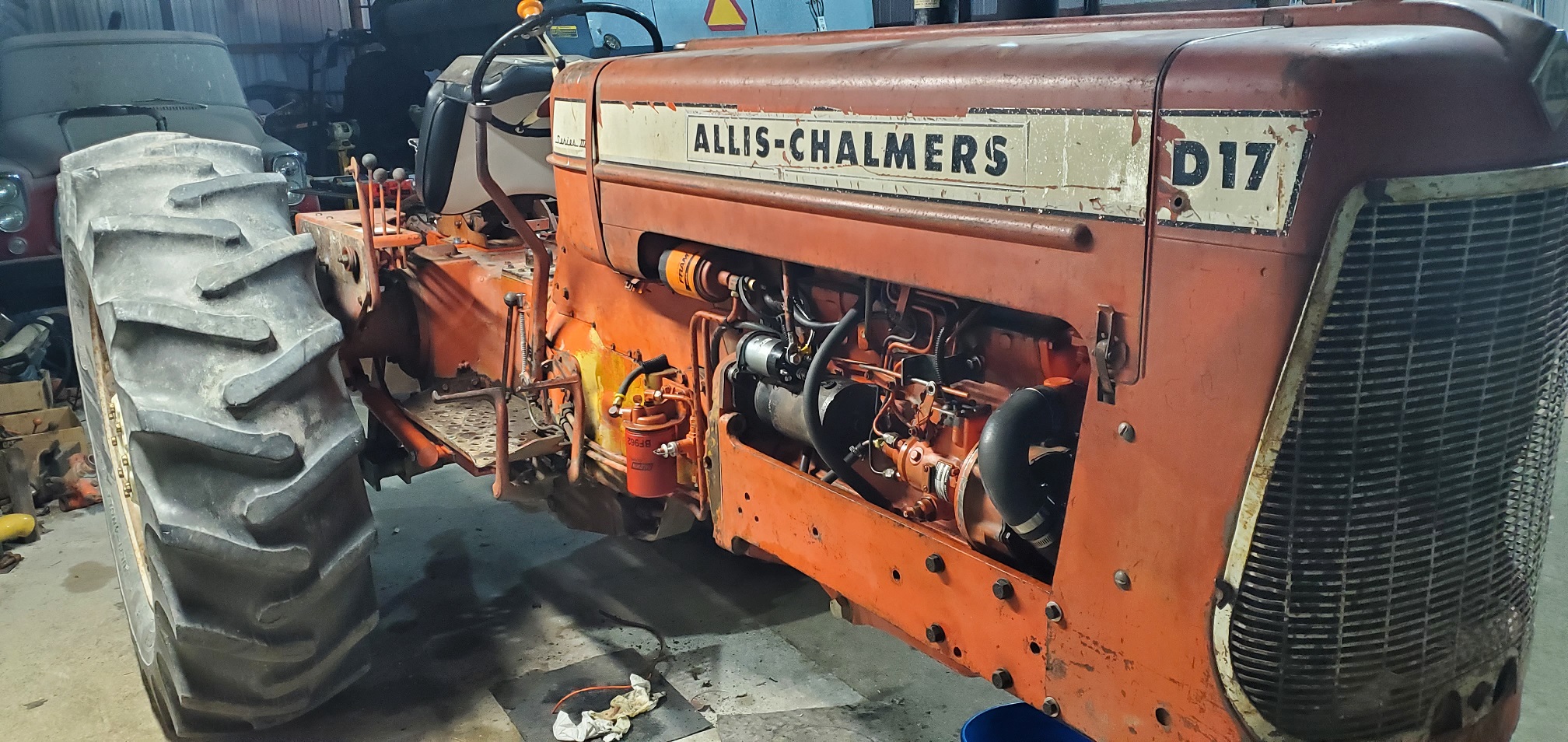

The Dr's. Look Ma', careful planning means you don't butcher sheetmetal.           |

Replies:

Posted By: Nathan (SD)

Date Posted: 11 Apr 2020 at 9:03pm

| Check out a muffler for a JD 830. Offset might be close enough for the hole. |

Posted By: DrAllis

Date Posted: 11 Apr 2020 at 9:07pm

| And lose the turbo whistle ?? No way !! |

Posted By: AC7060IL

Date Posted: 11 Apr 2020 at 10:05pm

| Nice D17 diesel. Is it a 443T or 433I? How many more days til it’s plow day? |

Posted By: MACK

Date Posted: 11 Apr 2020 at 10:08pm

| Like it. MACK |

Posted By: JC-WI

Date Posted: 11 Apr 2020 at 10:25pm

|

Are you using an orbit motor on the original front steering box and pedestal and control under the dash? ------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |

Posted By: DrAllis

Date Posted: 12 Apr 2020 at 5:24am

| Char-Lynn orbit motor connected directly to the steering worm gear in front. A regular A-C 100 series orbitrol under the fuel tank to send the signal to the orbit motor. This was a big deal and just barely enough room for the orbit motor. It is a gas chassis with the shorter hoods and side frames. There is clearance to remove the crank pulley without pulling the front end out from under it. The diesel engine is about 3 inches shorter than the gas engine overall. I thought I was going to be forced into using a wide front axle and somehow mounting an external steer cylinder crossways on the tie rods. This way either front end will work. Go to: D17 project-Google photos to see an album my son created. I still have some 1/2" thick rub plates to make for the 3-point lower arms and remote outlets and fender repairs, but it's getting close. Sad to think the 190XT engine existed in 1965 and this engine didn't get used on the Ag side until 1978 in the F-2 combine. It is a 433-I that the intercooler has been removed to fit under the hood. |

Posted By: DrAllis

Date Posted: 12 Apr 2020 at 5:41am

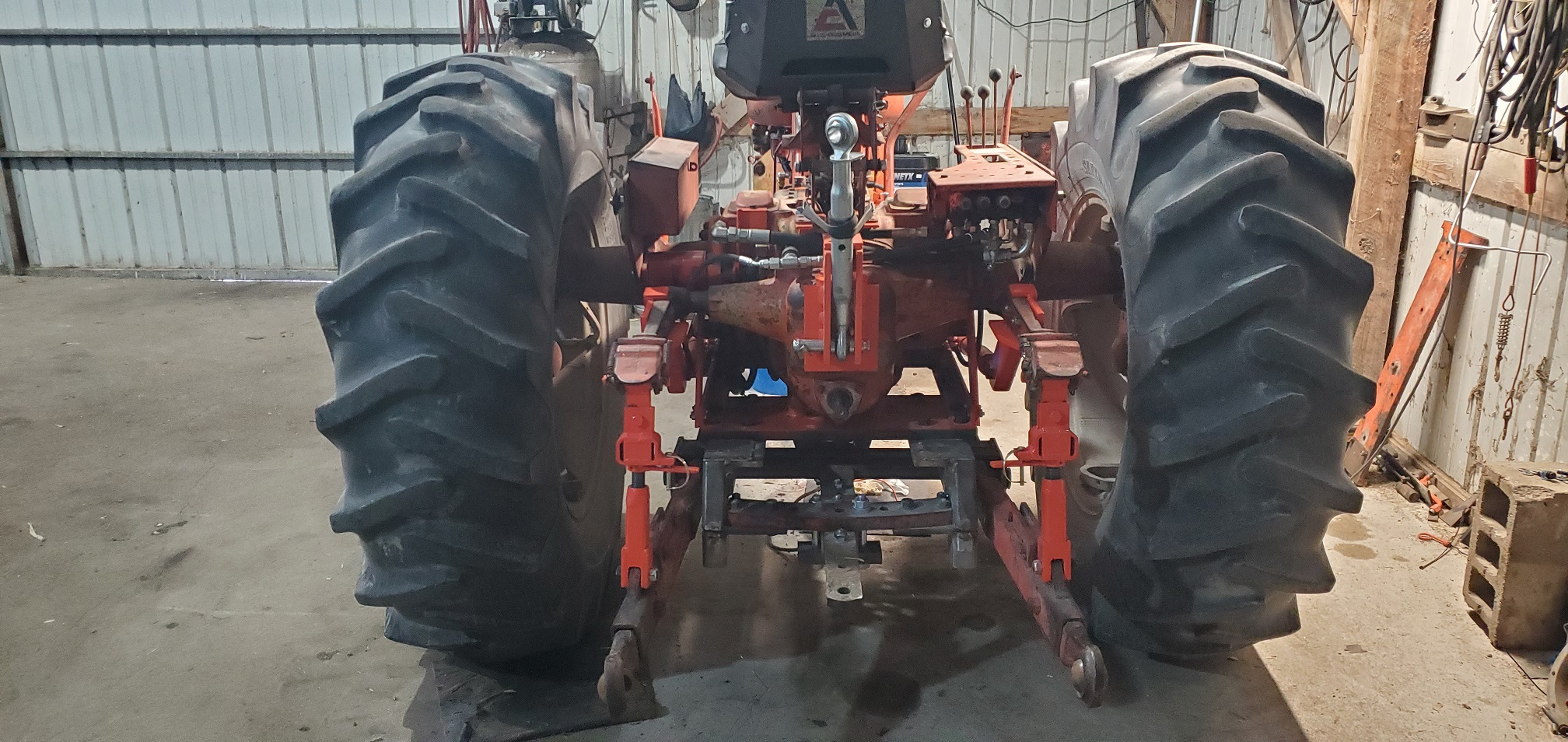

| Plow day ?? My brother has 3 acres of sod to do maybe this Summer. The design of the 3-point hitch is such that, after dropping the draft arms/lift links (a 2 minute job), I can unbolt each side frame, the drawbar bail and then pull the drawbar out of the snap-coupler bell and this tractor still works with snap-coupler equipment. The heavy base plate and braces and auxiliary lift cylinders stay on the tractor. |

Posted By: Kenny L.

Date Posted: 12 Apr 2020 at 7:38am

| I'm looking forward to see it in person one of these day when the kido take me off being grounded. (I thought it was supposed to be the other way a round) Stay safe and Happy Easter |

Posted By: DrAllis

Date Posted: 12 Apr 2020 at 8:13am

| Just be sure all your ground connections are clean and tight. We don't want there to be a spark of any kind...……….!! |

Posted By: m16ty

Date Posted: 12 Apr 2020 at 8:37am

| What is the reasoning behind the external lift cylinders? More lift power than the internal cylinder offers? |

Posted By: IBWD MIke

Date Posted: 12 Apr 2020 at 8:40am

|

I like it! |

Posted By: DrAllis

Date Posted: 12 Apr 2020 at 8:56am

| Original internal lift cylinder operates at 3700 psi and 4.5 GPM's. The new "live" hydraulic system (with the pump on the engine) operates at 2200 psi and 12 GPM's, so it takes more cubic inches of cylinders to lift that 4-bottom plow or anything else that is heavy. |

Posted By: m16ty

Date Posted: 12 Apr 2020 at 9:27am

Ok, I overlooked the fact that you went from high pressure to low pressure, via the new hyd pump on the side of the engine. The original system was “live”, you now have “independent” hydraulics. |

Posted By: coggonobrien

Date Posted: 12 Apr 2020 at 9:28am

| He has both systems intact and fully functional |

Posted By: AC7060IL

Date Posted: 12 Apr 2020 at 3:56pm

|

Thanks for posting all the excellent photos. The fact that it’s hood panels easily lift off is so cool for that early era. AC lost that during the D21-100 series era. But glad it got revived or the 7000 & 8000 series. I also appreciate where you mounted the 433T’s fuel filter & hand primer. Great job! Did the engine plate to clutch housing give you a challenge? |

Posted By: Keith M

Date Posted: 12 Apr 2020 at 6:15pm

| I love what you did. I’m more of a parts changer than a mechanic. My Dad is a mechanic but sees no reason to change things. So projects like this I get no help on. If you could send detailed instructions I’d love to do this to my D-17. If too involved I understand. Thanks, Keith from Kentucky |

Posted By: Carl(NWWI)

Date Posted: 12 Apr 2020 at 6:29pm

| That will be a fun toy!! Well done Dr |

Posted By: DrAllis

Date Posted: 12 Apr 2020 at 6:38pm

| The rear plate mounting and flywheel/clutch were almost as much of a challenge as the power steering. The chassis was a gasser, so that means the clutch shaft is an 1 1/4" or so LONGER than a diesel chassis. Spacing the engine forward that much wasn't an option because of the power steering design. I cut off the nose of the clutch shaft where the pilot bearing goes. I found a metric bearing that would slide onto the splined part of the now shortened clutch shaft. I used a 7000 tractor clutch disc, a 180-200 pressure plate, a D17 diesel throwout bearing shifter, and some machining of the flywheel to get that 100 HP clutch assembly in the 55 HP bellhousing. When complete, the wheelbase of the tractor was 1/8" longer, so sheet metal wasn't any problem. If the chassis had been a diesel to begin with, this part of the project would have been much easier. The only Sheetmetal change made was the air cleaner stack hole in the hood was opened up about 1/4" to make room for the larger diameter tube. |

Posted By: DrAllis

Date Posted: 12 Apr 2020 at 6:40pm

| A working and fun toy, Carl. I can see hay making, grain augering and many miles of 18+ MPH tractor riding !! |

Posted By: HD6GTOM

Date Posted: 12 Apr 2020 at 6:47pm

| Like it. Looks like a lot of thinking to put her together. |

Posted By: Gatz in NE

Date Posted: 12 Apr 2020 at 7:13pm

|

Dr's D17 XTreme make-over (with permission...) https://nam03.safelinks.protection.outlook.com/?url=https%3A%2F%2Fphotos.google.com%2Fshare%2FAF1QipMo_srQs3nQ64NjssN84MhtyP9h8I6mkXIuiGvY2J5VcnMOYvtM7s6osgp3IBqd-A%3Fkey%3DSkQ4NzlsazB3QWt3TUhLRmFBWXh4TVJIWVdsYW1R&data=02%7C01%7Ctom.obrien%40altorfer.com%7C2a5f3ad9046046144f0c08d7df3cd10e%7C2c491e7949634c00b2ab1426e1ab7841%7C0%7C0%7C637223324611112782&sdata=XHjbtdg0GTB1%2F6NJJqt0kBLBt1mzR2ufXBuj9oihRY8%3D&reserved=0Disclaimer/Confidentiality" rel="nofollow - https://nam03.safelinks.protection.outlook.com/?url=https%3A%2F%2Fphotos.google.com%2Fshare%2FAF1QipMo_srQs3nQ64NjssN84MhtyP9h8I6mkXIuiGvY2J5VcnMOYvtM7s6osgp3IBqd-A%3Fkey%3DSkQ4NzlsazB3QWt3TUhLRmFBWXh4TVJIWVdsYW1R&data=02%7C01%7Ctom.obrien%40altorfer.com%7C2a5f3ad9046046144f0c08d7df3cd10e%7C2c491e7949634c00b2ab1426e1ab7841%7C0%7C0%7C637223324611112782&sdata=XHjbtdg0GTB1%2F6NJJqt0kBLBt1mzR2ufXBuj9oihRY8%3D&reserved=0Disclaimer/Confidentiality

|

Posted By: DSeries4

Date Posted: 12 Apr 2020 at 8:12pm

|

You did an excellent job fitting that engine in there and keeping the sheet metal intact, even all the hydraulic hoses are nicely secured in place and don't sag. These are the things I look for. You took the time to make it fit and you didn't hack everything up with a cutting torch. Anyone would be proud to have a D17 like that! ------------- '49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080 |

Posted By: JohnColo

Date Posted: 12 Apr 2020 at 8:59pm

|

That is one beautiful piece of work. When I saw the first picture I didn't even realize it wasn't just another stock D17, then I noticed the manifold and, wait, what did he do! I'll bet there were some cold days working in that uninsulated shop! What year is that Binder pickup in the background?

|

Posted By: DrAllis

Date Posted: 12 Apr 2020 at 9:03pm

| 1960 Farmall pickup. It runs and drives 40K miles. |

Posted By: JoeO(CMO)

Date Posted: 14 Apr 2020 at 8:11am

|

I like it!👍 That is the best looking, thought out, functional 3-point conversion I have seen and can be easily used!! When is production starting on a “kit”? I don’t have a 17 now but one can be found. ------------- |

Posted By: 190xt MN

Date Posted: 14 Apr 2020 at 6:04pm

| Very good engineering. Looks like a stock d 17. Both hydraulic systems are still fully functional? |

Posted By: Calvin Schmidt

Date Posted: 14 Apr 2020 at 7:13pm

|

Nice job ! Friend is finishing up a 301 in a D-19. It will be his corn planting tractor and a little fun tractor pulling. Cant beat fun and work. ------------- Nothing is impossible if it is properly financed |

Posted By: DrAllis

Date Posted: 15 Apr 2020 at 7:18am

| Both hydraulic systems are fully functional, YES. The new "live" hyd system auxiliary external lift cylinders simply plug into the OEM high pressure coupler outlet, so all three cylinders work together. When I go to plow with the 4-bottom snap-coupler fully mounted plow, I will unplug that connection and use the internal pump and ram for lift/lower and Traction Booster. I intend to eventually connect the position control lever to the new hydraulic system console to be able to control 3-point hitch depth, but doubt that I will go so far as to fabricate Traction Booster linkage. We'll see. |

Posted By: DrAllis

Date Posted: 15 Apr 2020 at 7:19am

| Calvin, how is your friend doing his steering ?? |

Posted By: Brian F(IL)

Date Posted: 15 Apr 2020 at 12:43pm

| Is the base tractor a Series III or Series IV? |

Posted By: DrAllis

Date Posted: 15 Apr 2020 at 12:50pm

| Series 3 late 1963 version. That's the reason for the new added on "live" hydraulic system and a home-made 3-point hitch. The rest of the tractor is identical to a Series 4. |

Posted By: Brian F(IL)

Date Posted: 15 Apr 2020 at 12:56pm

I thought the hydraulic bank of levers looked like a Series IV. But I also noticed it didn't have the hydraulic pump in the belt pulley hole, hence Series III. Nice work.

|

Posted By: JC-WI

Date Posted: 15 Apr 2020 at 1:59pm

|

Sure liked the attaching of the control valve under the fuel tank,

and the orbit on the steering gear box. More than likely, you will be

filling in the muffler hole with a piece of metal formed and fitted

there... and if you don't want it permanent, as in forever, put a few

tack welds on the under side. Was thinking about the 3pt.

draft and started to wonder if you could have just adapted the torsion

assembly from the original 3pt over to your sub frame? and then bring

the linkage up from there for your control? It is a slick looking outfit now for sure. mmm, wonder what a 170/175 would have looked like with the engine in them... instead of the Perkins.170XT / 175XT  ------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |

Posted By: DrAllis

Date Posted: 15 Apr 2020 at 2:12pm

| All the torsion bar tube does is give you a place for the draft arms to attach and pull from. Thru the twisting of the internal torsion bar, you get the Traction booster to work thru linkage from there to the valve block. I'm pulling from the snap coupler bell and using the large coil spring underneath for the Traction Booster sensing and have fabbed a pull frame that is attached to the regular snap coupler drawbar. The OEM set-up wouldn't be nearly as easy to drop off to use the snap-coupler feature as this is. |

Posted By: HudCo

Date Posted: 15 Apr 2020 at 4:14pm

| man alive !!!!!!! this is everything i have been dreaming of doing to the series i d17d as soon as i get it back, be cause most of the enginge is missing . your three point hitch looks almost identical to the one that i fabbed for my wd about 20 years ago except my arms were off of a case eagle hitch i was thinking of a cummins 4bt or a ad4 perkins for mine any allis parts in my area are very far between . that is a totaly cool very usable work tractor you have built |

Posted By: DrAllis

Date Posted: 18 Jun 2020 at 9:16am

| Thinking about taking the D-17 XTD to the Amana Show for Saturday only, but the weather isn't sounding too dry at this time...…. |

Posted By: tbran

Date Posted: 18 Jun 2020 at 10:12pm

|

ok , I can see this, it is the year 2040, a customer has obtained Doc's tractor, he pops open his G13 Iphonelaptoptabletcombo and a virtual AGCO parts man scratch that parts person, hologram pops up and the customer asks for an overhaul kit for this D17, and a clutch and pilot brg and a rear lift cyl packing kit and oh yes a power steering quad ring.... the supporting computer goes up in smoke.... :-) ------------- When told "it's not the money,it's the principle", remember, it's always the money.. |

Posted By: wade89

Date Posted: 18 Jun 2020 at 11:00pm

| Dr, You mentioned the length of input shaft being different between gas and diesel D-17. Is that because of the bellhousing adapter ring? I assumed they were same minus frame rails and tin. I have a diesel chassis in need of motor swap and I'm curious now. (Don't mean to hijack You. Very nice job with yours) 👍 |

Posted By: HudCo

Date Posted: 18 Jun 2020 at 11:16pm

| what is the hp. for that engine and can the drive train still handle heavy tillage |

Posted By: DrAllis

Date Posted: 19 Jun 2020 at 7:12am

| Clutch shaft on a gasser is longer than a diesel. That thick cast iron adapter ring/spacer moves the gas engine forward approximately how much longer the clutch shaft really is. I believe the engineers were trying to make the gas engine look longer as compared to the diesel engine, and even at that, the diesel side frames and hoods are 2.75" longer than a gasser. Engine has been dyno'd and makes 85 HP @ 2300 RPM's. At 1650 RPM's (540 PTO speed) the engine develops 67 HP. The actual engine torque is 240 ft lbs versus 210 on the gas engine, so 10% or so increase on the driveline. The D-19 transmission/ring and pinion and diff are the same and seemed to hold up. The key would be not weighing the chassis down any heavier than most field working D-17's should be, which is less than 6500 lbs. Many of them are at 6000 lbs and with the new (removeable) heavy-duty 3-point hitch and turbo diesel engine, this one tips the scales at 6200 with NF end. Wide front is another 250 lbs. The top engine speed of 2500 RPM makes high third a really nice gear and fills in that speed gap between hi 3rd and low 4th. The turbo is spooled up at 1400 RPM, so running anything at 1650 PTO speed (thus far) is no problem. A couple weeks ago it saw square baling duty and mowing/conditioning the hay to be able to bale. All good. |

Posted By: DrAllis

Date Posted: 19 Jun 2020 at 7:23am

| To do this transplant into a diesel would be easy compared to the gas chassis. The steering orbit motor will have 2.75" more inches of room. To make the fan reach the radiator might be best dealt with by extending the shroud back towards the engine ?? You'll have lots of room to play with for sure. Tbran, I tried very hard to utilize parts that came from an A-C tractor, at least any of the wear/maintenance items. The tachometer is truly odd-ball as my son found it on the internet for $17, so I told him to get two. It is powered by the Delco 10-SI alternator and is rated for Marine use, so I figured that meant it could stand getting rained on. Whomever winds up with this tractor after I'm gone shouldn't have any problems coming up with repair parts to keep her earning her keep for many years. |

Posted By: wade89

Date Posted: 19 Jun 2020 at 8:12am

| Thanks for the info. Friend of mine has a military aircraft tug with 433T in it. American Coleman brand. Hasn't moved in years. Only a matter of time before I talk him into selling it to me. |

Posted By: Ted J

Date Posted: 21 Jun 2020 at 11:40am

|

All I can say is WOW!! Dr, were you an engineer at Allis? You sure have a knack for it! BEAUTIFUL engineering and ideas. ------------- "Allis-Express" 19?? WC / 1941 C / 1952 CA / 1956 WD45 / 1957 WD45 / 1958 D-17 |

Posted By: DrAllis

Date Posted: 21 Jun 2020 at 6:10pm

| Thank you, Ted J. No official engineering degree, that is for sure. Just self-taught application of experience. I always thought they (AC) should have asked me for advice from teenage years onward. When I was 16, Oliver had come out with the Over-under-hydraul shift transmission, which gave 3-speeds on-the-go. I had that in my head while baling hay one day, that if AC expanded the Power Director on a 190XT to include an over-drive position, they could have 12-speeds instead of 8-speeds with an overdrive for each of the 4 transmission gears. This would have closed the speed gap between 6th and 7th gears and provided a real road gear. My design however included a neutral between each speed range, still utilizing the live PTO thru the Power Director clutch, which would have been a bad idea. Anyway, AC finally did do what I thought was a good idea 5 years later, when they introduced the model 7000, and they actually had a truly "live" PTO, which I didn't. |

DrAllis wrote:

DrAllis wrote: