| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Ca hydraulic pump Topic: Ca hydraulic pump

Posted: 20 Mar 2020 at 3:32pm |

|

If I were to order a new rebuilt hydraulic pump for a c a model 1953, and just pulled my malfunctioning one off and put one on is it possible that the problem lies somewhere else or with a direct replacement like this what kind of confidence is in the pump working like new? I have already tried to reset all of the bolts and set screws to get it adjusted and in working order but none of that has worked. Thanks Matt

Edited by Hunt4Allis - 20 Mar 2020 at 3:33pm

|

|

|

Sponsored Links

|

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 24889

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Mar 2020 at 3:43pm Posted: 20 Mar 2020 at 3:43pm |

It took me 3 tries to 'rebuild' the pump on my '51 CA. It was easy ONCE I found the check ball that went 'walkabout' on the garage floor...hmm..grey ball, grey floor, 2hrs later I found it... EVERY bit of the pump needs to come off or out ! ANY gunk or sludge can ause it to 'fail'. Odds are it's never been cleaned and ,yeesh, yours is 67 years old..same as me.

With a good 'exploded' diagram, lots of light and really,really good cleaning of everything, my pump worked when bolted back on. I took a LOT of sludge out of the pump sump and used 1000gr paper to 'hone' shafts and such. It should only be a pleasent afternoon task.......so I suggest cleaning yours up before ordering a rebuilt unit. I'm betting it's a $100 order ?? Jay

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

DennisA (IL)

Orange Level

Joined: 11 Sep 2009

Location: Ridott IL.

Points: 2075

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Mar 2020 at 4:37pm Posted: 20 Mar 2020 at 4:37pm |

|

I rebuilt mine about 20 years ago and stilling working great.

If it has hydraulic oil and the PTO is engaged the pump should work. If not it must be the pump. Could be as simple as the pickup tube not in place to a broken spring in the pump or a plunger stuck. A rebuilt pump should work well if done right. The one you have mite just need a simple fix.

What is it doing or not doing?

|

|

Thanks & God Bless

Dennis

|

|

Gerald J.

Orange Level

Joined: 12 Sep 2009

Location: Hamilton Co, IA

Points: 5636

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Mar 2020 at 5:44pm Posted: 20 Mar 2020 at 5:44pm |

The shop manual has some details around page CA-51 http://geraldj.networkiowa.com/Trees/Allis-Chalmers-G-B-C-CA-Service.pdf And a lot more pump details in the b-c section. Gerald J.

|

|

Larry in NC

Orange Level

Joined: 09 Feb 2016

Location: NC

Points: 1050

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Mar 2020 at 6:18pm Posted: 20 Mar 2020 at 6:18pm |

|

I assume the lift is not working. What does the oil look like? If it is milky, you have water which can make the pump stick. Changing the oil could help. The last one I had problems with, I hit the pump lightly with a hammer and it starting working. No guarantee that will work, but who knows.

|

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Mar 2020 at 6:34pm Posted: 20 Mar 2020 at 6:34pm |

|

Already changed oil.( Works worse now...)

It actually worked better with milky looking oil.

It usually lifts extremely slow it seems until everything gets warmed up and then it won't stay raised up but it's not the adjustments I've already gone through it twice.

|

|

MACK

Orange Level

Joined: 17 Nov 2009

Points: 7664

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Mar 2020 at 9:36pm Posted: 20 Mar 2020 at 9:36pm |

|

Have yet to see one could not be fixed for a few dollars. MACK

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 24889

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Mar 2020 at 5:35am Posted: 21 Mar 2020 at 5:35am |

re: t usually lifts extremely slow it seems until everything gets warmed up and then it won't stay raised up

slow... not enough oil being pumped falls... check balls not checking

drain oil, remove pump, tear down, clean real good, reassemble, bolt on,add new oil should be good to go....

be sure to keep parts in a baking tray,with white towel on bottom. keeps things like balls and springs from 'leaving the jobsite'......

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

Alvin M

Orange Level

Joined: 24 Jun 2018

Location: PA

Points: 815

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Mar 2020 at 6:56am Posted: 21 Mar 2020 at 6:56am |

|

What oil Are You Using

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 24889

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Mar 2020 at 7:51am Posted: 21 Mar 2020 at 7:51am |

|

I use 'universal tractor hydraulic fluid' from Walmart, black pail, yellow lid. Might be different colours south of the 49th though.

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Mar 2020 at 10:32am Posted: 21 Mar 2020 at 10:32am |

|

I used super 303 hydraulic fluid

|

|

CTuckerNWIL

Orange Level

Joined: 11 Sep 2009

Location: NW Illinois

Points: 22825

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Mar 2020 at 1:27pm Posted: 21 Mar 2020 at 1:27pm |

Hunt4Allis wrote: Hunt4Allis wrote:

I used super 303 hydraulic fluid |

303 fluid is about the WORST thing you could put in it for fluid. I guess straight water may be worse.Here is an article on the waste oil you are using. https://www.tractorlife.com/2018/06/19/perilously-obsolete-the-dangers-of-303-tractor-hydraulic-fluids/ Go to your local farm store and buy Universal Transdraulic fluid. If it pumps slow, you may either have a check ball and seat leaking or, one or more of the plungers is stuck in, and not pumping oil. When you take it apart and clean it, get 2 new balls for each one you take out of the assembly. When it is all cleaned up and ready to re assemble, take one new ball, place it on the seat, and stick a punch up against the ball and smack it with a hammer. That reforms the seat, but can damage the punched side of the ball, so throw it out. Put the second new ball in place and assemble.

Edited by CTuckerNWIL - 21 Mar 2020 at 1:28pm

|

|

|

|

Bill Long

Orange Level

Joined: 12 Sep 2009

Location: Bel Air, MD

Points: 4556

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Mar 2020 at 2:30pm Posted: 21 Mar 2020 at 2:30pm |

Listen closely to what is said above. I always have to remember that when I worked on the pumps we had all the parts we wanted and the equipment was relatively new. Now some 60 plus years later lots of things have happened that can cause the problems your are experiencing. Be sure to clean the pump thoroughly getting every bit of crud out. When we sold them we used 20w non detergent oil. Worked fine and provided lubrication for the transmission and gear box. Again, worked fine. Occasionally when the transmission got dirty we would fill it with kerosene, run it some - no hydraulic action - drain it and put new oil in. Some of these units have been sitting outside for years and god knows what has gotten into the hydraulic - transmission system. There is a rack of valves that run the length of the pump. Be certain they are carefully cleaned and move. Wish you the very best. When they work they are fine. Let us know how it goes. Good Luck! Bill Long

Edited by Bill Long - 21 Mar 2020 at 2:31pm

|

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Mar 2020 at 7:48am Posted: 22 Mar 2020 at 7:48am |

|

Wow I had no idea that what I bought and put in their would be that low-quality and I appreciate the time you spent two educate me on this because I have three Allis-Chalmers tractors that I probably would have put it in all of them without knowing...

When I bought this tractor a few years ago the hydraulics actually worked better with the milky white looking hydraulic fluid I drained out of it than what it does now with new 303 fluid that's in it now.

I'm kind of wondering if I drain it out and get a higher quality oil if it will start to work again without cleaning at this point.

I am tempted to remove it and clean it out but have zero experience with hydraulic pumps, I am mechanically minded as I've been electrician almost 25 years so I know I can do it.

Last year I had saved a post from here about how to go about disassembling one of these from the tractor and rebuilding it but have since lost it.

Any information that you can share will be greatly appreciated and I guess I will go to a specific tractor service and sales place I have locally instead of the big box store to get some better hydraulic fluid. (I really thought what I was buying was fine because reading on the label it actually points out that it's made for 1960s and older Allis Chalmers tractors)

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 24889

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Mar 2020 at 7:58am Posted: 22 Mar 2020 at 7:58am |

I'd drain it, then refill, see what happens....can't do no harm , might get lucky !!!

you've got the skills to clean/rebuild the pump..turnin wrenches...cuttin wires...all the same....'handy' and patience...

I use the Wallmart 'universal tractor hydraulic oil', up here black pail, yellow lid. a LOT cheaper than a 'farm dealer place'....

jay

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Mar 2020 at 5:08am Posted: 23 Mar 2020 at 5:08am |

|

Ok, I think I'm going to try drain/fill before rebuilding it( mostly because it worked pretty good before I drained it out, and the only reason I drained it is because it looked milky and foamed out the fill plug when it got hot)

Thanks Matt

Edited by Hunt4Allis - 23 Mar 2020 at 5:09am

|

|

MACK

Orange Level

Joined: 17 Nov 2009

Points: 7664

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Mar 2020 at 7:01am Posted: 23 Mar 2020 at 7:01am |

|

The cheaper fluid you used is not the problem. The 303 may not be the best oil, but is better than what came in it XX years ago. Your problem may have come from something that was in the XX year old oil, but changing it will not fix the problem. Take it apart, clean, replace springs, seals or anything else that is worn. Anything stuck, free it up. MACK

|

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Mar 2020 at 7:17am Posted: 23 Mar 2020 at 7:17am |

|

Ok, can I order a kit for this pump?

It's a 1953 CA.

Any info appreciated.

Thanks Matt

|

|

Dakota Dave

Orange Level

Joined: 12 Sep 2009

Location: ND

Points: 3974

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Mar 2020 at 7:51am Posted: 23 Mar 2020 at 7:51am |

|

No such thing as a kit for this pump. It only has two O rings for soft parts the shaft seals and they never go bad unless you tear them. Take it off the tractor put on the bench it's best to use something like a cake sheet to disassemble on. Each of the 4 Pistons has a small spring behind them. Each of the 4 plugs on the top has a ball behind it pull the control back part off . Slide out the pins that hold the actuating levers in place and remove the Pistons and springs make sure the springs aren't broke 3 Are the same the 4th is smaller diameter. Now carefully clean out the passages from the piston there are no seals just metal to metal the seats up top and the balls need to be clean and not deformed. Keep track of the 4 little slugs that slide in from the back they need to go back in the same order. There is a spring behind them that pushes against the feel after valve adjuster screw. More than 90 % of these pumps can be repaired by simple good cleaning. The pump Pistons get stuck and the cheek balls get crud in them. I've had 2 pumps that needed a spring and one I had to repair the linkage in the cap it was wore out. I assume it ran a long time without oil as it was all rusty. This pump should have oil in it. I've only ever seen one with rust. Once you get it on the bench an take it apart it's pretty apparent how it goes back together. You can look up the parts diagram on the AGCO parts site.

|

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Mar 2020 at 8:05am Posted: 23 Mar 2020 at 8:05am |

|

Ok thanks for the info 👍

If springs or other parts is broken or worn then there available from agco parts website?

What size are the o rings/ springs?

Edited by Hunt4Allis - 23 Mar 2020 at 8:07am

|

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Mar 2020 at 10:22am Posted: 23 Mar 2020 at 10:22am |

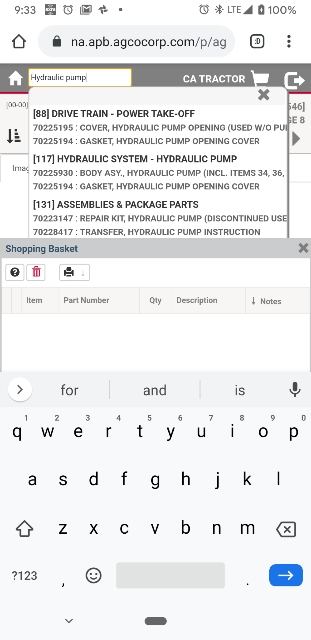

I'm not sure if this is correct but it looks like there might be a kit from agco?

|

|

MACK

Orange Level

Joined: 17 Nov 2009

Points: 7664

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Mar 2020 at 9:17pm Posted: 23 Mar 2020 at 9:17pm |

|

Don't buy the kit. It has a lot of parts you don't need plus expensive. Replace the 4 springs above check balls, as they break and stick spool valve. 4 big orings in body and one small one between hold poison valve and pump body. There are 3 in hold poison valve that won't be needed unless it is leaking. 3 gaskets you will need. Good luck. MACK

|

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Mar 2020 at 8:37am Posted: 24 Mar 2020 at 8:37am |

|

Ok, so correct me if I'm wrong...

1) drain trans/ hydraulic oil

2)fix pump

2.5)any way to flush system out before I reinstall clean pump to minimize contamination back into pump from transmission/ shared area that may have junk in it?

3) reinstall pump

4)fill with better oil than 303😜

5) adjustments need done again?( Or once the process of adjustments are done before no need to readjust?)

6)start next project on CA ( wide front end and trip loader bucket)

7) brings up another question, if all is working good with clean hydraulic system can adding/ introducing new hydraulic components put bad oil left in old cylinders and lines get into my pump and possibly cause another system failure?( I'm thinking answer is yes but my hydraulic knowledge is minimal)

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 24889

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Mar 2020 at 8:46am Posted: 24 Mar 2020 at 8:46am |

2) probably only needsa good tear dow/clean/reassemble unless theres a busted spring.

2.5 ) I used brake cleaner and rags to mop up 99.44% of the 'crud' 4) any 'universal tractor hydraulic oil' will be fine

7) disconnect hose, push ram to spray old oil all over the floor and new jeans.....yeah THAT I remember doin....

6) drive CA around for a day or two in the sunshine THEN start next project

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Mar 2020 at 11:44am Posted: 24 Mar 2020 at 11:44am |

|

So to clean out the transmission area you sprayed brake cleaner into housing area once pump was removed through the hole created by removing the pump?

I don't know if I'm thinking about it correct but I'm wanting to remove/disassemble pump and then clean everything else possible so when I reinstall the clean pump gunk doesn't get back into my pump and clog it up again...

|

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Mar 2020 at 5:35pm Posted: 25 Mar 2020 at 5:35pm |

|

Well, there's no turning back now...

Removed pump( pictures to come)

|

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Mar 2020 at 6:33pm Posted: 25 Mar 2020 at 6:33pm |

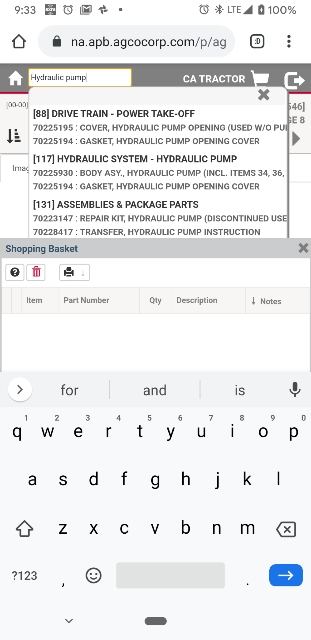

Here we are, 3 of hydraulic pump and 1 of the oil I drained out(303 super that was only used about 6 hours to brush hog the end a few hours with a post hole auger)     I'm not sure why but the one cam follower is a darker color then the other three and has some discoloration compared to the others? Thanks Matt 👍

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 24889

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Mar 2020 at 6:44pm Posted: 25 Mar 2020 at 6:44pm |

mmmmm...chocolate milk !!! Leave the jug sitting for a couple days, it'll separate into oil on water.....

be sure to disconnect cylinder hose and push ram to get rid of the oilywater in it as well.....

yes I sprayed BC in the cavity,drained and wiped it out, several times

I'm kinda sure my 'cavity' was painted with 'Glyptol' or some other weird spelt product that sealed the cast iron. The 'knowledge base' will know.....

Jay

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Mar 2020 at 8:08pm Posted: 25 Mar 2020 at 8:08pm |

Great pictures! In your top left photo you can see the hydraulic pump drawbar control unit attached to the pump. I'm having fun tearing it down.

Nasty looking oil! I am working up the courage to drain the rear end and remove the pump so I can clean it. Helps to see someone else doing the same!

Please keep the pictures coming. And thanks.

Dave

|

|

WC, CA, D14, WD45

|

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Mar 2020 at 9:27pm Posted: 25 Mar 2020 at 9:27pm |

|

I was shocked that there isn't a gasket on the mating face of tractor rear end to pump?!?

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

Hunt4Allis wrote:

Hunt4Allis wrote:

I'm not sure why but the one cam follower is a darker color then the other three and has some discoloration compared to the others?

I'm not sure why but the one cam follower is a darker color then the other three and has some discoloration compared to the others?