Ca hydraulic pump

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=169275

Printed Date: 18 Dec 2025 at 8:52pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Ca hydraulic pump

Posted By: Hunt4Allis

Subject: Ca hydraulic pump

Date Posted: 20 Mar 2020 at 3:32pm

| If I were to order a new rebuilt hydraulic pump for a c a model 1953, and just pulled my malfunctioning one off and put one on is it possible that the problem lies somewhere else or with a direct replacement like this what kind of confidence is in the pump working like new? I have already tried to reset all of the bolts and set screws to get it adjusted and in working order but none of that has worked. Thanks Matt |

Replies:

Posted By: jaybmiller

Date Posted: 20 Mar 2020 at 3:43pm

|

It took me 3 tries to 'rebuild' the pump on my '51 CA. It was easy ONCE I found the check ball that went 'walkabout' on the garage floor...hmm..grey ball, grey floor, 2hrs later I found it... EVERY bit of the pump needs to come off or out ! ANY gunk or sludge can ause it to 'fail'. Odds are it's never been cleaned and ,yeesh, yours is 67 years old..same as me. With a good 'exploded' diagram, lots of light and really,really good cleaning of everything, my pump worked when bolted back on. I took a LOT of sludge out of the pump sump and used 1000gr paper to 'hone' shafts and such. It should only be a pleasent afternoon task.......so I suggest cleaning yours up before ordering a rebuilt unit. I'm betting it's a $100 order ?? Jay ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: DennisA (IL)

Date Posted: 20 Mar 2020 at 4:37pm

|

I rebuilt mine about 20 years ago and stilling working great. If it has hydraulic oil and the PTO is engaged the pump should work. If not it must be the pump. Could be as simple as the pickup tube not in place to a broken spring in the pump or a plunger stuck. A rebuilt pump should work well if done right. The one you have mite just need a simple fix. What is it doing or not doing? ------------- Thanks & God Bless Dennis |

Posted By: Gerald J.

Date Posted: 20 Mar 2020 at 5:44pm

|

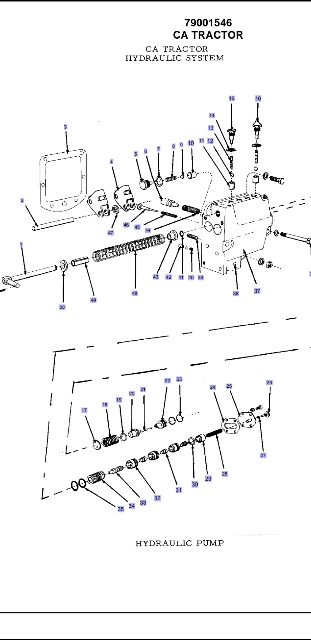

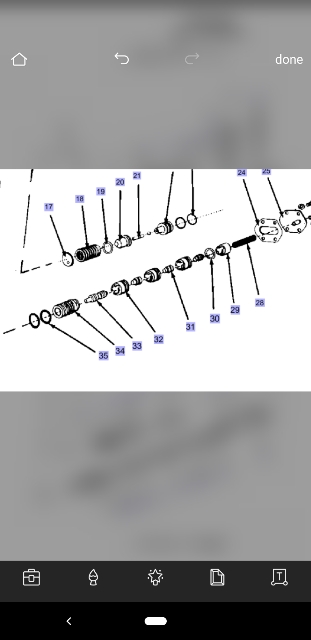

The shop manual has some details around page CA-51 http://geraldj.networkiowa.com/Trees/Allis-Chalmers-G-B-C-CA-Service.pdf" rel="nofollow - http://geraldj.networkiowa.com/Trees/Allis-Chalmers-G-B-C-CA-Service.pdf And a lot more pump details in the b-c section. Gerald J. |

Posted By: Larry in NC

Date Posted: 20 Mar 2020 at 6:18pm

| I assume the lift is not working. What does the oil look like? If it is milky, you have water which can make the pump stick. Changing the oil could help. The last one I had problems with, I hit the pump lightly with a hammer and it starting working. No guarantee that will work, but who knows. |

Posted By: Hunt4Allis

Date Posted: 20 Mar 2020 at 6:34pm

|

Already changed oil.( Works worse now...) It actually worked better with milky looking oil. It usually lifts extremely slow it seems until everything gets warmed up and then it won't stay raised up but it's not the adjustments I've already gone through it twice. |

Posted By: MACK

Date Posted: 20 Mar 2020 at 9:36pm

| Have yet to see one could not be fixed for a few dollars. MACK |

Posted By: jaybmiller

Date Posted: 21 Mar 2020 at 5:35am

|

re: t usually lifts extremely slow it seems until everything gets warmed up and then it won't stay raised up slow... not enough oil being pumped falls... check balls not checking drain oil, remove pump, tear down, clean real good, reassemble, bolt on,add new oil should be good to go.... be sure to keep parts in a baking tray,with white towel on bottom. keeps things like balls and springs from 'leaving the jobsite'...... ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Alvin M

Date Posted: 21 Mar 2020 at 6:56am

| What oil Are You Using |

Posted By: jaybmiller

Date Posted: 21 Mar 2020 at 7:51am

|

I use 'universal tractor hydraulic fluid' from Walmart, black pail, yellow lid. Might be different colours south of the 49th though. ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Hunt4Allis

Date Posted: 21 Mar 2020 at 10:32am

| I used super 303 hydraulic fluid |

Posted By: CTuckerNWIL

Date Posted: 21 Mar 2020 at 1:27pm

303 fluid is about the WORST thing you could put in it for fluid. I guess straight water may be worse.Here is an article on the waste oil you are using. https://www.tractorlife.com/2018/06/19/perilously-obsolete-the-dangers-of-303-tractor-hydraulic-fluids/" rel="nofollow - https://www.tractorlife.com/2018/06/19/perilously-obsolete-the-dangers-of-303-tractor-hydraulic-fluids/ Go to your local farm store and buy Universal Transdraulic fluid. If it pumps slow, you may either have a check ball and seat leaking or, one or more of the plungers is stuck in, and not pumping oil. When you take it apart and clean it, get 2 new balls for each one you take out of the assembly. When it is all cleaned up and ready to re assemble, take one new ball, place it on the seat, and stick a punch up against the ball and smack it with a hammer. That reforms the seat, but can damage the punched side of the ball, so throw it out. Put the second new ball in place and assemble. ------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: Bill Long

Date Posted: 21 Mar 2020 at 2:30pm

|

Listen closely to what is said above. I always have to remember that when I worked on the pumps we had all the parts we wanted and the equipment was relatively new. Now some 60 plus years later lots of things have happened that can cause the problems your are experiencing. Be sure to clean the pump thoroughly getting every bit of crud out. When we sold them we used 20w non detergent oil. Worked fine and provided lubrication for the transmission and gear box. Again, worked fine. Occasionally when the transmission got dirty we would fill it with kerosene, run it some - no hydraulic action - drain it and put new oil in. Some of these units have been sitting outside for years and god knows what has gotten into the hydraulic - transmission system. There is a rack of valves that run the length of the pump. Be certain they are carefully cleaned and move. Wish you the very best. When they work they are fine. Let us know how it goes. Good Luck! Bill Long

|

Posted By: Hunt4Allis

Date Posted: 22 Mar 2020 at 7:48am

|

Wow I had no idea that what I bought and put in their would be that low-quality and I appreciate the time you spent two educate me on this because I have three Allis-Chalmers tractors that I probably would have put it in all of them without knowing... When I bought this tractor a few years ago the hydraulics actually worked better with the milky white looking hydraulic fluid I drained out of it than what it does now with new 303 fluid that's in it now. I'm kind of wondering if I drain it out and get a higher quality oil if it will start to work again without cleaning at this point. I am tempted to remove it and clean it out but have zero experience with hydraulic pumps, I am mechanically minded as I've been electrician almost 25 years so I know I can do it. Last year I had saved a post from here about how to go about disassembling one of these from the tractor and rebuilding it but have since lost it. Any information that you can share will be greatly appreciated and I guess I will go to a specific tractor service and sales place I have locally instead of the big box store to get some better hydraulic fluid. (I really thought what I was buying was fine because reading on the label it actually points out that it's made for 1960s and older Allis Chalmers tractors) |

Posted By: jaybmiller

Date Posted: 22 Mar 2020 at 7:58am

|

I'd drain it, then refill, see what happens....can't do no harm , might get lucky !!! you've got the skills to clean/rebuild the pump..turnin wrenches...cuttin wires...all the same....'handy' and patience... I use the Wallmart 'universal tractor hydraulic oil', up here black pail, yellow lid. a LOT cheaper than a 'farm dealer place'.... jay ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Hunt4Allis

Date Posted: 23 Mar 2020 at 5:08am

|

Ok, I think I'm going to try drain/fill before rebuilding it( mostly because it worked pretty good before I drained it out, and the only reason I drained it is because it looked milky and foamed out the fill plug when it got hot) Thanks Matt |

Posted By: MACK

Date Posted: 23 Mar 2020 at 7:01am

| The cheaper fluid you used is not the problem. The 303 may not be the best oil, but is better than what came in it XX years ago. Your problem may have come from something that was in the XX year old oil, but changing it will not fix the problem. Take it apart, clean, replace springs, seals or anything else that is worn. Anything stuck, free it up. MACK |

Posted By: Hunt4Allis

Date Posted: 23 Mar 2020 at 7:17am

|

Ok, can I order a kit for this pump? It's a 1953 CA. Any info appreciated. Thanks Matt |

Posted By: Dakota Dave

Date Posted: 23 Mar 2020 at 7:51am

| No such thing as a kit for this pump. It only has two O rings for soft parts the shaft seals and they never go bad unless you tear them. Take it off the tractor put on the bench it's best to use something like a cake sheet to disassemble on. Each of the 4 Pistons has a small spring behind them. Each of the 4 plugs on the top has a ball behind it pull the control back part off . Slide out the pins that hold the actuating levers in place and remove the Pistons and springs make sure the springs aren't broke 3 Are the same the 4th is smaller diameter. Now carefully clean out the passages from the piston there are no seals just metal to metal the seats up top and the balls need to be clean and not deformed. Keep track of the 4 little slugs that slide in from the back they need to go back in the same order. There is a spring behind them that pushes against the feel after valve adjuster screw. More than 90 % of these pumps can be repaired by simple good cleaning. The pump Pistons get stuck and the cheek balls get crud in them. I've had 2 pumps that needed a spring and one I had to repair the linkage in the cap it was wore out. I assume it ran a long time without oil as it was all rusty. This pump should have oil in it. I've only ever seen one with rust. Once you get it on the bench an take it apart it's pretty apparent how it goes back together. You can look up the parts diagram on the AGCO parts site. |

Posted By: Hunt4Allis

Date Posted: 23 Mar 2020 at 8:05am

|

Ok thanks for the info 👍 If springs or other parts is broken or worn then there available from agco parts website? What size are the o rings/ springs? |

Posted By: Hunt4Allis

Date Posted: 23 Mar 2020 at 10:22am

I'm not sure if this is correct but it looks like there might be a kit from agco?

|

Posted By: MACK

Date Posted: 23 Mar 2020 at 9:17pm

| Don't buy the kit. It has a lot of parts you don't need plus expensive. Replace the 4 springs above check balls, as they break and stick spool valve. 4 big orings in body and one small one between hold poison valve and pump body. There are 3 in hold poison valve that won't be needed unless it is leaking. 3 gaskets you will need. Good luck. MACK |

Posted By: Hunt4Allis

Date Posted: 24 Mar 2020 at 8:37am

|

Ok, so correct me if I'm wrong... 1) drain trans/ hydraulic oil 2)fix pump 2.5)any way to flush system out before I reinstall clean pump to minimize contamination back into pump from transmission/ shared area that may have junk in it? 3) reinstall pump 4)fill with better oil than 303😜 5) adjustments need done again?( Or once the process of adjustments are done before no need to readjust?) 6)start next project on CA ( wide front end and trip loader bucket) 7) brings up another question, if all is working good with clean hydraulic system can adding/ introducing new hydraulic components put bad oil left in old cylinders and lines get into my pump and possibly cause another system failure?( I'm thinking answer is yes but my hydraulic knowledge is minimal) |

Posted By: jaybmiller

Date Posted: 24 Mar 2020 at 8:46am

|

2) probably only needsa good tear dow/clean/reassemble unless theres a busted spring. 2.5 ) I used brake cleaner and rags to mop up 99.44% of the 'crud' 4) any 'universal tractor hydraulic oil' will be fine 7) disconnect hose, push ram to spray old oil all over the floor and new jeans.....yeah THAT I remember doin.... 6) drive CA around for a day or two in the sunshine THEN start next project ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Hunt4Allis

Date Posted: 24 Mar 2020 at 11:44am

|

So to clean out the transmission area you sprayed brake cleaner into housing area once pump was removed through the hole created by removing the pump? I don't know if I'm thinking about it correct but I'm wanting to remove/disassemble pump and then clean everything else possible so when I reinstall the clean pump gunk doesn't get back into my pump and clog it up again... |

Posted By: Hunt4Allis

Date Posted: 25 Mar 2020 at 5:35pm

|

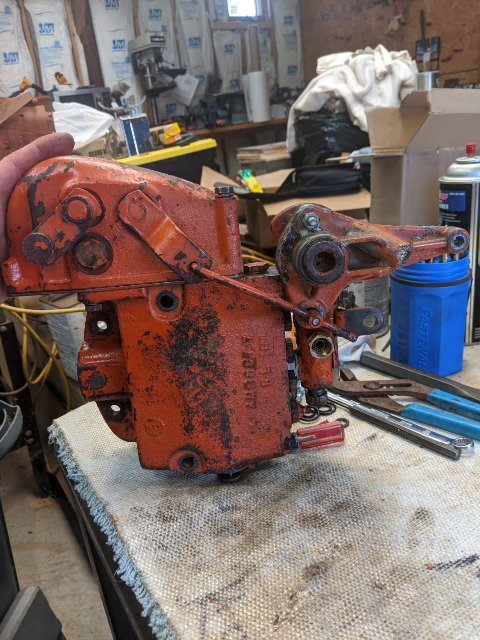

Well, there's no turning back now... Removed pump( pictures to come) |

Posted By: Hunt4Allis

Date Posted: 25 Mar 2020 at 6:33pm

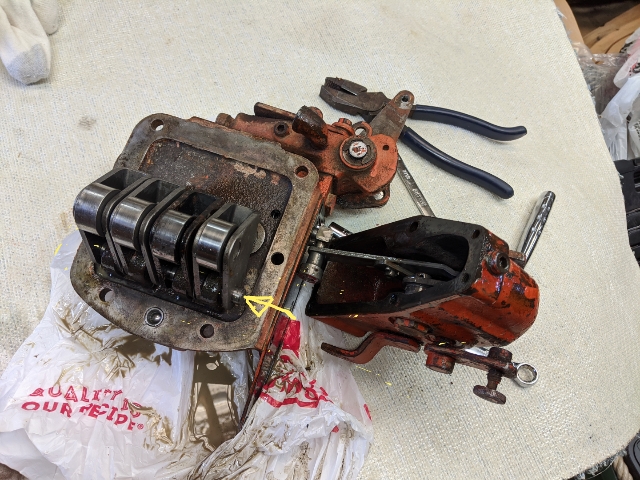

Here we are, 3 of hydraulic pump and 1 of the oil I drained out(303 super that was only used about 6 hours to brush hog the end a few hours with a post hole auger)    I'm not sure why but the one cam follower is a darker color then the other three and has some discoloration compared to the others? I'm not sure why but the one cam follower is a darker color then the other three and has some discoloration compared to the others?Thanks Matt 👍 |

Posted By: jaybmiller

Date Posted: 25 Mar 2020 at 6:44pm

|

mmmmm...chocolate milk !!! Leave the jug sitting for a couple days, it'll separate into oil on water..... be sure to disconnect cylinder hose and push ram to get rid of the oilywater in it as well..... yes I sprayed BC in the cavity,drained and wiped it out, several times I'm kinda sure my 'cavity' was painted with 'Glyptol' or some other weird spelt product that sealed the cast iron. The 'knowledge base' will know..... Jay ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Dave(inMA)

Date Posted: 25 Mar 2020 at 8:08pm

|

Great pictures! In your top left photo you can see the hydraulic pump drawbar control unit attached to the pump. I'm having fun tearing it down. Nasty looking oil! I am working up the courage to drain the rear end and remove the pump so I can clean it. Helps to see someone else doing the same! Please keep the pictures coming. And thanks. Dave ------------- WC, CA, D14, WD45 |

Posted By: Hunt4Allis

Date Posted: 25 Mar 2020 at 9:27pm

| I was shocked that there isn't a gasket on the mating face of tractor rear end to pump?!? |

Posted By: MACK

Date Posted: 25 Mar 2020 at 10:07pm

| There should be a gasket. MACK |

Posted By: jaybmiller

Date Posted: 26 Mar 2020 at 5:29am

|

ah, there's supposed to be a gasket ! I know , mine came off is 87,654,321 pieces.... ..not that I was counting...  I made my own as I had a sheet of gasket material and some proper hole punches. I'm wondering is the discoloration of part is really rust from having sat 'forever and a day' without oil ? I KNOW the diff gears of Troy were RUSTY. ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Hunt4Allis

Date Posted: 26 Mar 2020 at 6:29am

| Hmmmmmm, so someone else had this apart before and did not put a gasket back on?Do I need to drain oil from anywhere else, another words is it shared to any where else that I cannot see right now with the pump off I can see it's completely drained where the camshaft and couple of gears are in my pictures? |

Posted By: Dave(inMA)

Date Posted: 26 Mar 2020 at 8:12am

|

I'll be interested to hear what you find inside the drawbar control housing! When I pulled mine off yesterday, there was an ample supply of goopy thick old oil in there. [See Drawbar Control Repair thread for pics.] ------------- WC, CA, D14, WD45 |

Posted By: Hunt4Allis

Date Posted: 26 Mar 2020 at 8:13am

| Just getting ready to... |

Posted By: Hunt4Allis

Date Posted: 26 Mar 2020 at 10:59am

Just quick update, Well I'm glad I took the time to remove the entire thing and disassemble because I found two cotter pins that had fallen out of the two yellow circled areas in drawbar control assembly and as I'm going through the entire thing I'm finding bits and pieces of those cotter pins (the linkages that these pins were supposed to be in could be why i had intermittent control because after looking at how the linkages work and react to other parts inside) More to come after lunch Matt |

Posted By: Dave(inMA)

Date Posted: 26 Mar 2020 at 11:08am

|

Matt, so the broken cotter pins might have jammed the linkage now and then? Could be. I also am seeing what looks like rust on a few of the parts in there....some water ran out the drain hole when I took mine apart, but I didn't find any rust. Also, I'm wondering how much oil is supposed to be lurking in the control unit when everything is working properly? Dave ------------- WC, CA, D14, WD45 |

Posted By: Hunt4Allis

Date Posted: 26 Mar 2020 at 11:25am

|

Jammed/ not worked properly b/c they weren't making contact with other points when they should have been...( The cotter pins keep everything aligned to one another) And actually the reason I noticed is because of your other post showing your drawbar control unit that has a cotter pin in the picture and I was looking at my same part and there wasn't one that's when I realized a couple of them were missing and ground up inside (it's the picture that shows how you got the drawbar control apart from the hydraulic pump) Thanks Matt |

Posted By: Hunt4Allis

Date Posted: 26 Mar 2020 at 12:01pm

|

My tractor's are always parked under roof so it makes me wonder how I obviously got water mixed back in with the oil that I just replaced in this tractor last spring? I did drain the oil from both the drawbar drain plug end the rear diff but I did not drain anyting out of the hoses or cylinders which I'm guessing is how the new oil which I now know was low quality 303 oil became so milky looking again... |

Posted By: Dave(inMA)

Date Posted: 26 Mar 2020 at 12:03pm

|

Cool. Glad one of my pictures helped. Have you removed the arm/shaft that the control connecting link slides onto? It has a funky rectangular head that that slides onto the shaft that comes out of the pump. Curious as to how the head is locked onto the pump shaft - maybe a woodruff key? Dave ------------- WC, CA, D14, WD45 |

Posted By: NE GA Allis

Date Posted: 26 Mar 2020 at 12:13pm

|

Don’t be afraid of these pumps but definitely use caution when testing. Whatever you do stand clear of anything that might be a “weak” link. Here’s my story: Bought a CA and changed the gear oil since it was pretty milky. Probably used a trans-hydraulic fluid from tractor supply but can’t remember for sure. Well after getting that all done, I managed to get the pump working but I’ve always been weary of these pumps if I have not tore them down. That being said I never usually let the pump kick out when it brings the cylinders up all the way, I’ll stop the pump when the arms raise up to the top. Well by mistake I did not stop the pump one day when I raised the arms and BAM the pump blew one of the cylinders apart. Luckily I was sitting on the tractor so the platform protected me from getting high speed fluid from piercing the skin. So I did the usual thing checked out the cylinder and thought that it looked like it may have had previous damage. Ok I’ll put another cylinder on. Then same thing happened again, forgot to stop the pump and it blew another cylinder. Needless to say I have not changed out that cylinder as a reminder to not use the hydraulics on that tractor. Long story short, try to use some sort of protection if possible while testing a pump, they put out some serious PSI. You don’t need steel or fluid under the skin if something fails. ------------- Keeping Allis alive with: 2 B’s, 1 C, 6 CA’s, 2 WD’s, 1 WD45, 3 D15D’s, 1 D17 |

Posted By: Hunt4Allis

Date Posted: 26 Mar 2020 at 6:22pm

Having a hard time figuring out how to get yellow circled item out? On exploded view of it components it shows a snap ring on opposite side of yellow circled item inside hole which I can't even see to remove never mind actually getting a snap ring off inside a 3-4" deep area that's only 3/8" diameter... I keep removing other easier parts hoping it will somehow come out as a whole unit or something but no luck yet. Info appreciated, thanks Matt |

Posted By: MACK

Date Posted: 26 Mar 2020 at 8:59pm

| You need to pull the plate off the yellow circle is on. MACK |

Posted By: Hunt4Allis

Date Posted: 26 Mar 2020 at 9:45pm

|

Hmmm, ok I've done that a few times but it wouldn't budge... Maybe it's hung up by my ground up cotter pins or spring parts I've been finding in it. So it will come out( yellow circled part) with the plate that's behind it and the components attached to it stay on it all the way out and then I can remove the "c"clip after it's out? |

Posted By: Dave(inMA)

Date Posted: 26 Mar 2020 at 9:54pm

|

Wouldn't the shaft that extends through the plate need to be attached to something behind that plate in order to link the pump to the control unit? ------------- WC, CA, D14, WD45 |

Posted By: SteveM C/IL

Date Posted: 26 Mar 2020 at 10:12pm

| That shaft pushes on the valves to shift them in "pump" mode...just setting in a hole. |

Posted By: Hunt4Allis

Date Posted: 26 Mar 2020 at 10:26pm

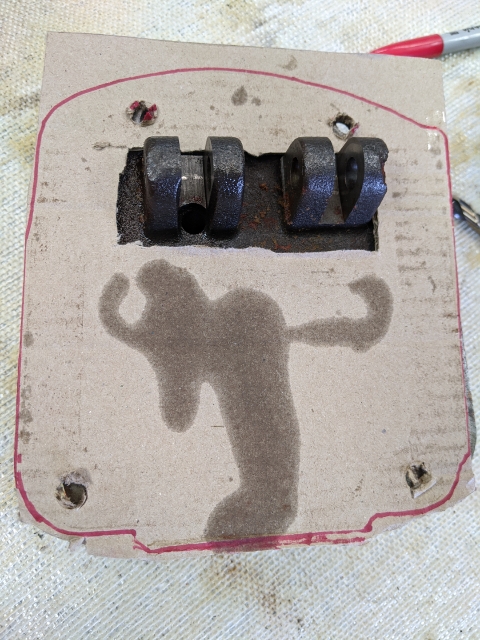

Came off with a putty knife It doesn't look like the rest of it can easily come apart? I've gone this far and I believe I found some small chunks of spring in passageways and wonder if it's from the under side of the rollers that is a bit lower in this picture than the other 3 rollers?(can't tell what's normal height from exploded view I have)  The left one is lower than other 3 to right, so what I've found small chunks of what seams to be spring material could be part of left spring which is why it's shorter now so the left one is lower? Thanks Matt |

Posted By: MACK

Date Posted: 27 Mar 2020 at 6:30am

| The spools that the small spools came out of, need to come out and be cleaned. MACK |

Posted By: Hunt4Allis

Date Posted: 27 Mar 2020 at 6:44am

| Not sure I'm understanding correctly mack |

Posted By: jaybmiller

Date Posted: 27 Mar 2020 at 6:56am

|

The 'spools' or 'plungers' are the 3 'big slugs of steel' that the 'cam followers' push upon to make the oil move. They're 11/16" in diameter according to the AGCO picture, online. In your picture, you can see 'ridges' or lines around them. Once you remove them, use 1000g autobody sandpaper to 'hone' or clean them up. To cleanup the cavities where they sit in, I wrapped 1000g paper on a pencil and twirled it in the holes. Everything should be nice and shiny and smoooooth. Jay ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Hunt4Allis

Date Posted: 27 Mar 2020 at 7:03am

|

Ok thanks I'm not sure how these three large plugs and one smaller one come out because the cam followers do not move back away enough for them to come out (in my limited experience) The long pin that goes through all of the cam followers opposite the roller (where they attached to the body of the pump) seems like it is pressed in with Force because I tapped on it lightly and it did not seem to want to move? Here's the pin( yellow arrow pointing to the end of it.

|

Posted By: Dave(inMA)

Date Posted: 27 Mar 2020 at 2:39pm

|

Matt - sent you a PM. Dave ------------- WC, CA, D14, WD45 |

Posted By: MACK

Date Posted: 27 Mar 2020 at 8:46pm

| No, the small and large spools lay length ways of pump. You have the small ones out, the large ones are what the small ones came out of. The end one will have two orings on it. Replace the orings along with the two on unloading value. MACK |

Posted By: Dartguy

Date Posted: 27 Mar 2020 at 9:12pm

Dave, my 1951 CA has 3 pistons which are stuck in the down position. I have no idea how to get them unstuck. Can you suggest what I need to do please? Thanks, Steve

|

Posted By: Hunt4Allis

Date Posted: 28 Mar 2020 at 6:46am

| Start digging 😜into into her |

Posted By: MACK

Date Posted: 28 Mar 2020 at 7:12am

| Use some penetration oil around them. With a small hammer, a quick rap will some times bounce them up enough to get ahold of them. Have had to weld a nut to them and twist them out. MACK |

Posted By: Dartguy

Date Posted: 28 Mar 2020 at 12:06pm

I have it submerged in diesel fuel right now. I thought it odd that 1 out of 4 was not stuck! Thank you

|

Posted By: Hunt4Allis

Date Posted: 28 Mar 2020 at 4:32pm

|

I'm wondering if I could make a temporary plate to go over where the hydraulic pump normally sits. refill the transmission with fluid drive the tractor around a bit then drain it so that I do not get any of the leftover junk from my transmission or anywhere else that I cannot get to to flush out of it back into my pump that's super clean now...Does it sound like a feasible plan or not?( Also trying to come up with a way to completely clean out the two hydraulic cylinders for the three-point?) I've lowered and raised the 3-point arms manually and got a lot of milky watery leftover hydraulic fluid out of the hoses and cylinders but I'm wondering if I put the hydraulic lines in a bucket of fluid and manually move the 3-point if I could suction up enough hydraulic fluid to clean it all out? I'm mostly thinking of doing all of the flushing because of the metal filings I found on the magnetic drain plug (that was the 2 cotter pins from the drawbar control linkage that were ground up and then recirculated through the whole system I'm sure?) |

Posted By: jaybmiller

Date Posted: 28 Mar 2020 at 4:48pm

|

I've made temporary plates from 1/4" finished plywood( mahogany flooring plywood). Actually sealed up pretty good without a gasket. Use 'fender' washers to spread the load from the bolts and nuts. Your bucket cleaning idea will work, not too sure how much more 'milk' you'll get out, but heck, better to do it now than ,arrghhh...later ! Jay ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Dave(inMA)

Date Posted: 28 Mar 2020 at 4:51pm

|

I really like the idea of a temporary plate. I think you should make one and then rent it out to guys like me! I removed my hydraulic pump this afternoon - happily only getting what appears to be hydraulic oil dripping out of the cylinder hoses. But flushing everything would be a good idea....surely can't hurt! Dave ------------- WC, CA, D14, WD45 |

Posted By: Hunt4Allis

Date Posted: 28 Mar 2020 at 5:32pm

| If I do the temp plate I know I have some cheap supers 303 oil to get rid of...🤪( To use to flush transmission out) |

Posted By: Dartguy

Date Posted: 28 Mar 2020 at 5:40pm

Mack, is the shaft that holds the cam followers pressed in? I cannot see any clips or pins securing it into place. Thanks.

I did go ahead and tap it out with a long drift punch. I wanted to make sure it wasn't locked in place somehow and end up breaking something. thanks to all

|

Posted By: Hunt4Allis

Date Posted: 28 Mar 2020 at 5:49pm

| They are not hard to remove ( I used a 3lb hammer and a large punch, just a little tappy,tap) |

Posted By: MACK

Date Posted: 29 Mar 2020 at 8:00am

| Drive it out with a hammer and soft punch. MACK |

Posted By: SteveM C/IL

Date Posted: 29 Mar 2020 at 1:02pm

| Just the pressure of springs against the lever keeping pin in place..Inside housing it is "captured" and cant get our of place. |

Posted By: Hunt4Allis

Date Posted: 29 Mar 2020 at 5:21pm

|

Made a temporary cover What would be best to put in and let slosh around for a short drive up and back on driveway?( Trans/ hydraulic oil or diesel fuel)?    Nothing fancy but just want the cleanest area I can get with all the time and effort and small money amount invested to limit re contamination...( Plan on driving 300' total to help wash any remaining junk out of areas I can't spray brake cleaner, like the differential area I'm thinking...) Thanks Matt |

Posted By: Hunt4Allis

Date Posted: 30 Mar 2020 at 11:38am

|

Ended up getting this sealer and I'm wondering if I should even use any? If using this in conjunction with the gaskets provided by Sandy lake where do I apply it( it says the sealer is to be used to hold gaskets in place while reassembling but I don't really see the need for that as I can tell where these will be sitting and how they look before I completely tighten everything down)

|

Posted By: Dave(inMA)

Date Posted: 30 Mar 2020 at 1:50pm

|

Matt - nifty temporary plate! Let us know how the cleanup goes. I asked Bill at Sandy Lake about that question this morning. He uses copper spray on gasket sealer. Otherwise you get leaks...... Dave ------------- WC, CA, D14, WD45 |

Posted By: Hunt4Allis

Date Posted: 30 Mar 2020 at 2:31pm

| Copper spray on gasket sealer?( You mean copper spray on gasket?) |

Posted By: Dave(inMA)

Date Posted: 30 Mar 2020 at 3:54pm

Yup. Like this: http://www.permatex.com/products/gasketing/gasket-sealants/permatex-copper-spray-a-gasket-hi-temp-sealant/" rel="nofollow - http://www.permatex.com/products/gasketing/gasket-sealants/permatex-copper-spray-a-gasket-hi-temp-sealant/ Don't think we need the hi-temp version, but I'm not seeing a low-temp option!  ------------- WC, CA, D14, WD45 |

Posted By: Hunt4Allis

Date Posted: 30 Mar 2020 at 4:35pm

|

Ok thanks for info on spray Here's my "temporary plate" made from an old piece of pine board(it actually did not even drip from anywhere around this board) sealed up real nice... So I refilled with the super 303 junk just to get rid of it since I won't be using it anymore in any of my tractor's after reading how bad it is of an oil, drove it up and back my driveway about 3 or 400 ft hit all the gears including reverse just to really try to clean it up inside the best I could (I will admit in 4th gear it's a scary feeling on a bumpy gravel driveway and the neighbors probably think I'm crazy now but it doesn't matter!!!) Backed the tractor into my shop and drained oil and it still looks this bad...(I'm now tempted to fill it with either diesel fuel or kerosene like somebody had recommended they did when they used to work on these old tractors to really give it a good washing inside so to speak) The third picture is my gasket kit that just came as I was finishing all that up from Sandy lake ( thanks Brenda and Bill!)

|

Posted By: Dave(inMA)

Date Posted: 30 Mar 2020 at 5:08pm

|

Maybe try it again with the 303 oil and see if it improves? How does the inside of the pump reservoir look now? Do you know how much water was hiding in the tranny? Might help to know how much water has to be added to the oil to turn it brown....take a known amount of the oil and start adding water to it and shake it each time to see when it starts to turn brown. One other thought: there may be pockets in the tranny that are hold oil/water but not draining. You could pull the side cover off tranny case and wash it down with something that will dissolve the oil, then carefully use compressed air to blow liquid out of the hidey holes.

------------- WC, CA, D14, WD45 |

Posted By: Hunt4Allis

Date Posted: 30 Mar 2020 at 5:42pm

|

Before I came in the house curiosity got to me and I had to dump some cleaned oil in there to see what came out with the drain plug out. at first it was milky and then it turned to more clear looking oil... I may pull the side cover just to have a look at other area in differential. I did not pull my temporary cover off so I don't know what is left in that area yet because like I say I'm tempted to put something else in there that would act more as a flush but I'm not sure what would be the correct thing to use? I could spend a couple days cleaning all the oil and crud off of underneath the plate but it's just not my main concern just yet...(I think this hydraulic leak has been going on for about 30 years by the way everything is covered on the outside at the rear of the tractor) I bought this tractor 2 years ago and so far I've put new spin-out rims on the rear tires and got all of them operating with my old parts.(also got two good front tires on it that hold air) Thanks Matt |

Posted By: Dave(inMA)

Date Posted: 31 Mar 2020 at 5:41am

|

Sounds as though the tranny case is getting clean. I think you'd be fine using diesel to rinse the tranny case as long as the tractor isn't running. You can remove the side cover to give you access. The shift forks are attached to that cover. Have the tractor in neutral when you remove the cover and make sure that you know where the gears and collars are in neutral in case you move something while flushing the case and contents. Use a spray bottle to flush. Have the collars lined up correctly when reinstalling the side cover and shift forks....the forks need to engage the shift lever so it needs to be in neutral position when you do this. I'm remembering all this from when I worked on the tranny years ago - it was popping out of third back then. ------------- WC, CA, D14, WD45 |

Posted By: jaybmiller

Date Posted: 31 Mar 2020 at 5:59am

|

re: make sure that you know where the gears and collars are in neutral THAT's why digital cameras where invented !!! clean your hands THEN take lots of pictures, some from different angles. I like the srpay bottle of diesel to clean idea ! When I rebuilt a JD HST, I left the 'drained' case over a pan with some paper towels in it overnight. Next day the towels were SOAKED in 'extra' oil that had slooooooowly seeped out of the case. The problem with oil and 'watery oil' is it takes a lot of time to drain. if you can, keep bucket under it for 2-3 days..longer is better. Jay ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Hunt4Allis

Date Posted: 31 Mar 2020 at 6:57am

| I had a reply on here or a different thread and it may have been yours Dave m, that said they used to put kerosene in when they were really dirty and I thought he said drive them around the yard at his shop. I could not find this post again. I'm wondering if driving around a short distance would hurt anything or if just putting it in leaving it sit overnight and then emptying it would be the best thing? |

Posted By: Dave(inMA)

Date Posted: 31 Mar 2020 at 10:27am

Not sure whose post that might have been - but not mine!  ------------- WC, CA, D14, WD45 |

Posted By: cdsloop

Date Posted: 31 Mar 2020 at 11:36am

| Forgive me for asking, but you are pulling all three plugs and draining each well when you are changing the fluid, correct? It surprises me that you are getting such contaminated fluid after the first complete drain. It will cross contaminate if you don't drain all three cavities... |

Posted By: Dave(inMA)

Date Posted: 31 Mar 2020 at 11:44am

|

I'm sure that Hunt4Allis will forgive you, cdsloop. That could be the issue..are you referring to tranny, differential, and pto housing? Thanks. Dave

------------- WC, CA, D14, WD45 |

Posted By: Hunt4Allis

Date Posted: 31 Mar 2020 at 11:53am

|

I removed the rearmost drain plug that is a magnetic type I believe and one other one that is at the very lowest point that I could find. Where is the third drain plug that I need to drain from? |

Posted By: cdsloop

Date Posted: 31 Mar 2020 at 12:16pm

| It has been 20 years or more since I have been close to a CA, my most recent experience is with a B. But there should be a drain on the PTO, the transmission, and near the rearmost section of the torque tube. |

Posted By: Hunt4Allis

Date Posted: 31 Mar 2020 at 2:00pm

Okay so I got the larger sections removed from my pump which is the very last thing that I can take apart to ensure everything is as clean as I can get it shown in the pictures above... You can see the slots that I'm referring to that are cut into the sleeves (above the majic marker#18 picture)they are perpendicular to how the plungers run through the length of them along with the various holes that are perpendicular.(you need to zoom in to see what I'm talking about) they look like keyways on the end of each sleeve... my question is does it matter the orientation/ "rotation wise speaking" of the slots and holes that are in these plugs that the smaller plugs go inside of or will the hydraulic pressure find and Orient these the way they need to be?(the parts I'm referring to our number 34 which there's only one of, and number 32 with there are three of on the exploded view I'm showing below) Thanks Matt 👍

|

Posted By: Hunt4Allis

Date Posted: 31 Mar 2020 at 6:27pm

Here's hopefully a clear picture so you can actually see the part numbers I'm referring to because once I posted the previous about the exploded view I tried viewing it and it's all blurry...

|

Posted By: Hunt4Allis

Date Posted: 31 Mar 2020 at 6:37pm

Thank you so much CDsloop!!! Because of your reply I realized I was not removing the farthest most forward drain plug and that's where all of the milky looking oil was left when I pulled it out there was a lot of nasty-looking oil that came out today. So now again I will add more oil end drive it around a bit and drain again but now this time will be three plugs that get removed 🤪 Thanks Matt |

Posted By: MACK

Date Posted: 31 Mar 2020 at 9:14pm

| It shouldn't matter where the slot is turned, I've always turned them to top from habit. MACK |

Posted By: Hunt4Allis

Date Posted: 31 Mar 2020 at 9:23pm

|

Ok, it just seamed like these slots lined up with holes drilled through pump housing that connected other portions of the pump. Thanks Matt |

Posted By: Hunt4Allis

Date Posted: 01 Apr 2020 at 4:47pm

|

I made some progress today getting my pump back together and may be able to bolt everything back up to the tractor and see how it works over the next couple days. Thanks for everyone's help and information! |

Posted By: cdsloop

Date Posted: 01 Apr 2020 at 7:21pm

| I thought that oil was terribly dirty to have just been changed. Glad to help! Sounds like you are making some progress now. |

Posted By: Hunt4Allis

Date Posted: 01 Apr 2020 at 7:36pm

|

Yup, and after all back together I then need to swap my NF to a WF end then install the trip loader to help clean up the pasture... ( Just a constantly evolving project it seams, but fun) I wouldn't do any of this if I didn't enjoy making old things work again 😉 |

Posted By: SteveM C/IL

Date Posted: 01 Apr 2020 at 8:04pm

Yep. That doesn't matter

|

Posted By: Hunt4Allis

Date Posted: 02 Apr 2020 at 4:33pm

|

Well that was fun. It's all cleaned with new o-rings and a couple other worn parts replaced (including the two cotter pins that had fallen out inside the drawbar control linkage) Now just two get it put back on tractor tomorrow with new hydraulic trans fluid and hopefully everything works as it should. I was a little apprehensive to do this but I think I did okay because at the end I didn't have any spare parts on the bench 😉 Here's a couple of pictures of it all back together although it doesn't look like very much from the outside there's a ton of parts inside of one of these that I hopefully will never need to mess with in my lifetime again.    Thanks for everyone chipping in information in the process, Matt 👍 |

Posted By: jaybmiller

Date Posted: 02 Apr 2020 at 6:25pm

|

If it takes you less than 3 tries to get her 'up and running', then 'you're a better man than me, Gunga Din'.  With hydraulics, cleanliness is CRITCAL, so clean, clean and clean some more.....I was in too much of a hurry the 1st time, even more of a hurry the 2nd time, 3rd time I took a whole day.....THEN it was 'happy'. ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Hunt4Allis

Date Posted: 04 Apr 2020 at 1:16pm

|

Well just got pump reinstalled and all filled with clean oil and I hit a homerun everything works! Now I just need to know when 2 take the dipstick reading for the full line with Rams extended? Another words is the full line with Rams extended with the PTO engaged and everything running or is it after it rest for a bit with Rams extended and not running or engaged? |

Posted By: CTuckerNWIL

Date Posted: 04 Apr 2020 at 2:47pm

I don't check mine with the rams extended, because I have a pin hitch CA and they don''t extend when the drawbar is on. If SC, I would check them with rams extended and the pump off.I doubt it matters much. I don't check mine with the rams extended, because I have a pin hitch CA and they don''t extend when the drawbar is on. If SC, I would check them with rams extended and the pump off.I doubt it matters much.

------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: Hunt4Allis

Date Posted: 04 Apr 2020 at 2:58pm

I have a snap coupler drawbar/ 3 point combo unit

|

Posted By: Dave(inMA)

Date Posted: 04 Apr 2020 at 6:37pm

Excellent news, Matt! Glad to hear that everything works as it should.  When I was topping off the oil level in my CA I saw that there was a measurable difference in the dipstick reading between lift arms down vs up (ie, cylinders extended). Maybe 3/16" or so on the dipstick. Dave ------------- WC, CA, D14, WD45 |

Posted By: Hunt4Allis

Date Posted: 04 Apr 2020 at 7:35pm

|

Ok,I'll top off fluid with cylinders extended and tractor not running now that I'm confident in when the measurement should be done... Dave, did you feel the need to completely reset all the settings on your hydraulics after your install?( I need to look back in my manual to see what the knobs are for and see if varying them actually does what there supposed to do now that pump is rebuilt and system is clean) |

Posted By: Dave(inMA)

Date Posted: 04 Apr 2020 at 9:05pm

|

Matt, I will need to reset the controls to (I think) "drawbar" to invoke the traction boast system as I'm sure that I have disturbed how they were set before I started working on the pump. Time to read the manual! I haven't reinstalled the pump yet - waiting on one more part and also want to flush the cylinders. Once that's all done, I'm hoping to report good results! ------------- WC, CA, D14, WD45 |

Posted By: jaybmiller

Date Posted: 04 Apr 2020 at 9:10pm

|

pretty sure you measure with it in the up position. That's how the D14 is done. Similar pump/cylinder system. It should be in the manual..somewhere..... I recall having to go up/down a few times to 'burb' the trapped air out, after that it was fine. ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Hunt4Allis

Date Posted: 04 Apr 2020 at 9:37pm

|

Right, I'm thinking I'll need to reset it too I've done it 2 times before so you'd think I'd have it memorized by now |

Hunt4Allis wrote:

Hunt4Allis wrote: