| Author |

Topic Search Topic Search  Topic Options Topic Options

|

WeisAC2

Bronze Level

Joined: 02 Feb 2017

Location: Aiken SC

Points: 112

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: D15 Power Director Topic: D15 Power Director

Posted: 10 Oct 2021 at 3:11pm |

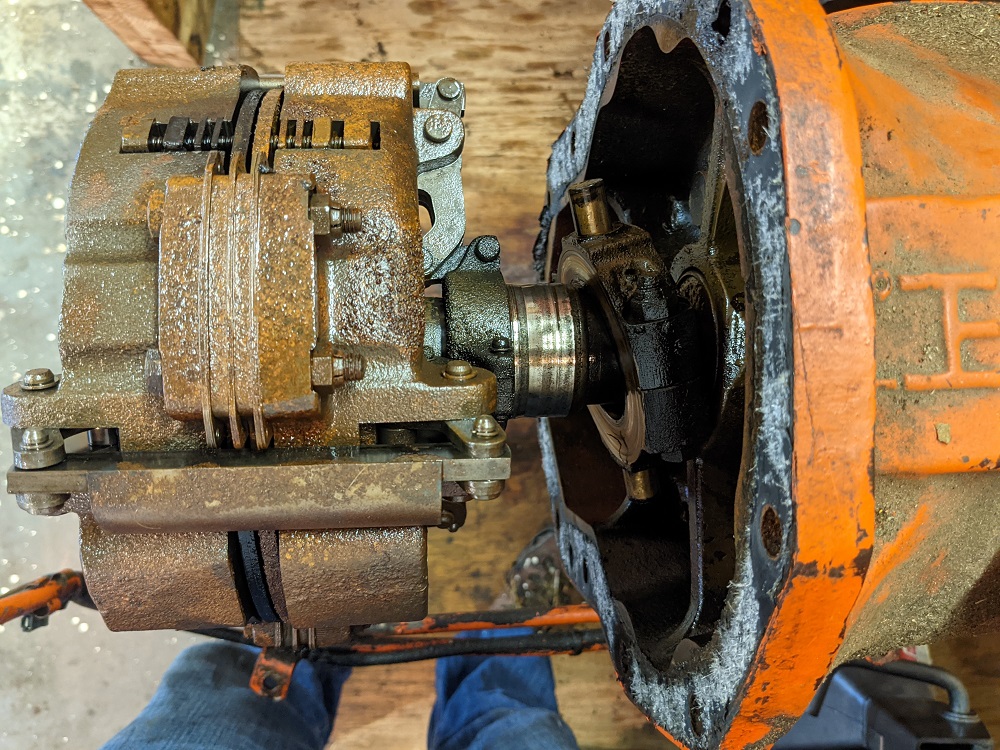

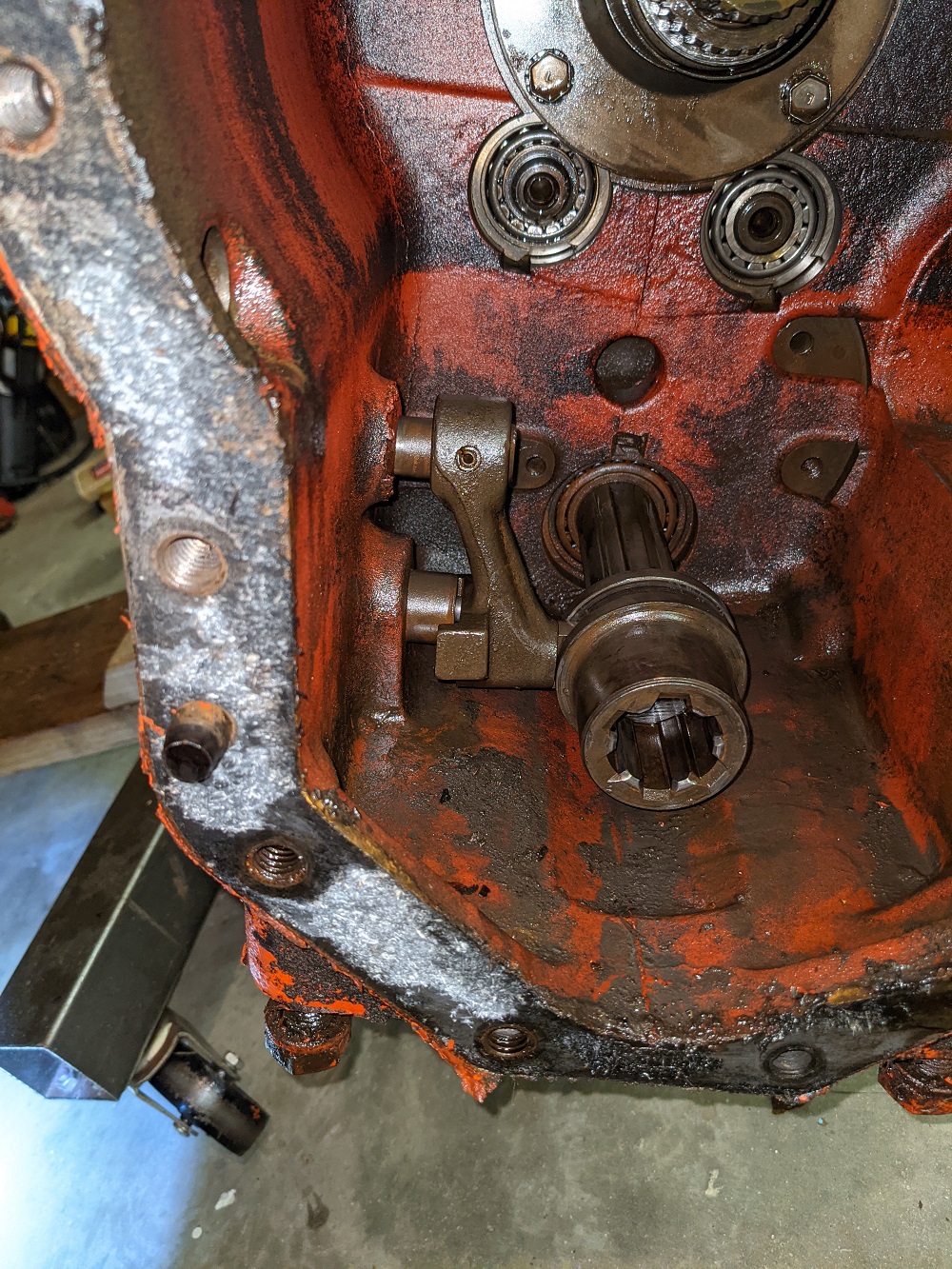

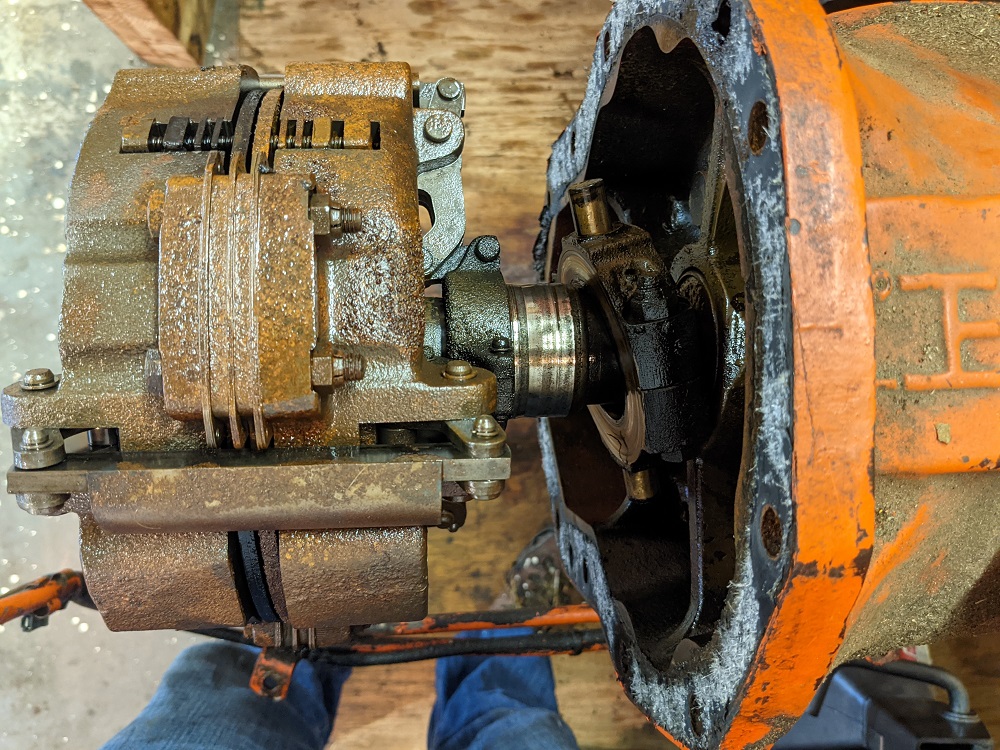

I'm in the process of addressing several issues within the torque tube of my D15 Diesel (1961, Series 1). One problem is that the power director has never worked. The tractor has been in the family since the 80's and we've always only had high range. The power director lever just feels loose as you move it front to back. The set screw at the base of the lever has been checked but that's all we've ever done. This winter I've decided to finally get this fixed (as well as replacing seals and bearings within torque tube, and PTO lever o-ring). I thought I would start off by looking in the power director access panel to see what I can find out. It appears that the brass collar is broken/loose. It's kind of hard to see but I wanted to see if you guys can tell anything...

Green arrow is to the collar that just flops around while lever is moved front to back. The black arrow is where I suppose it should be seated???

|

|

|

Sponsored Links

|

|

|

John m

Silver Level

Joined: 11 Apr 2020

Location: Wetmore, Mi

Points: 278

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Oct 2021 at 3:56pm Posted: 10 Oct 2021 at 3:56pm |

|

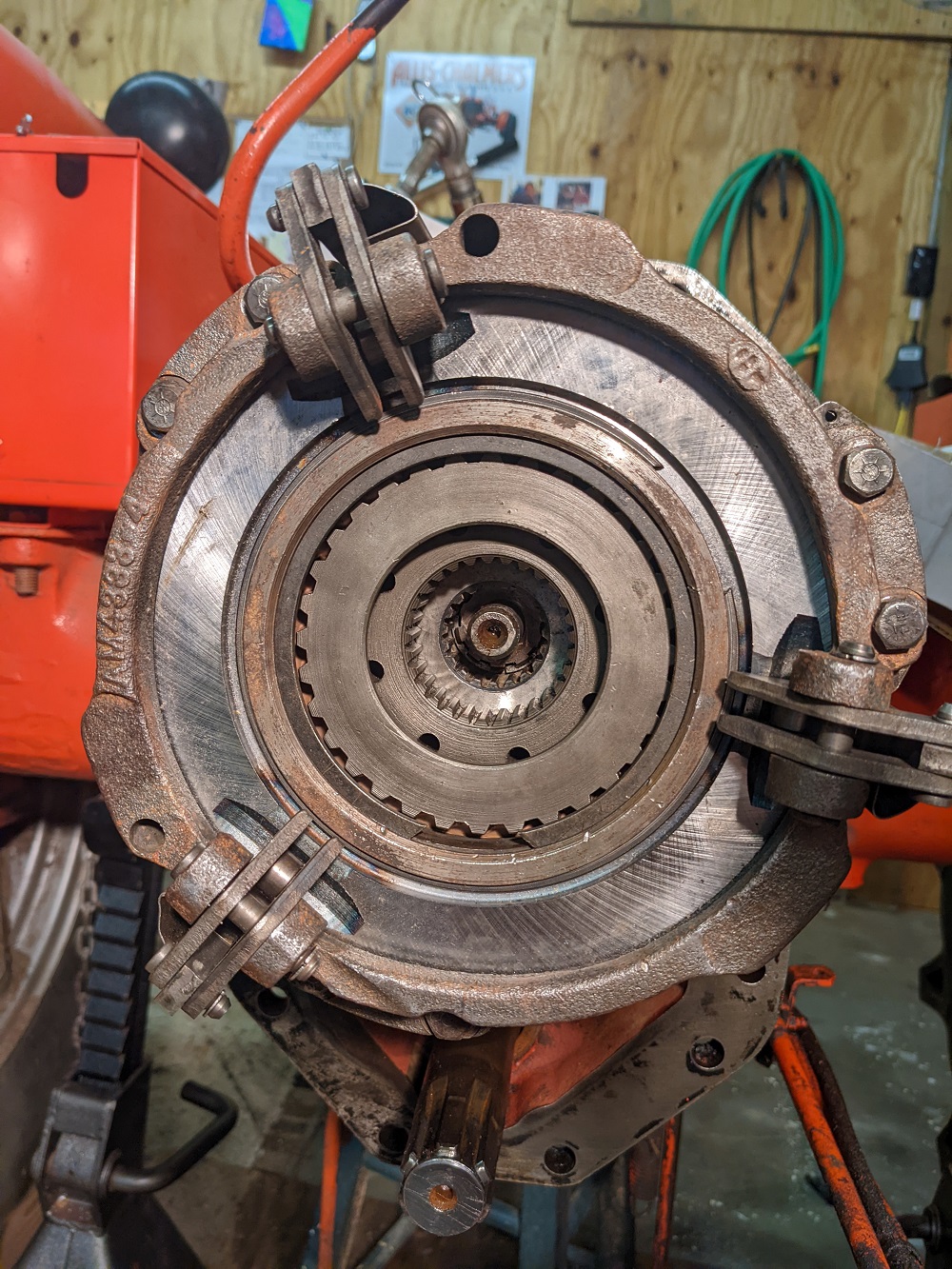

Why does the clutch pack look rusty. My 190 is oil filled I believe. Do they run dry clutches?

|

|

WeisAC2

Bronze Level

Joined: 02 Feb 2017

Location: Aiken SC

Points: 112

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Oct 2021 at 4:18pm Posted: 10 Oct 2021 at 4:18pm |

|

The tractor gets less than 10 hours of use per year. It's stored inside but still very humid here. There was oil in the power director compartment. I'm not sure how wet the clutch pack is supposed to stay.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 21709

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Oct 2021 at 5:35pm Posted: 10 Oct 2021 at 5:35pm |

|

A badly worn out brass bearing and shifter collar usually is caused by very low oil levels at sometime in its past service life. Nothing a split and new parts can't fix. 2 1/2 gallons of oil when completed.

|

|

WeisAC2

Bronze Level

Joined: 02 Feb 2017

Location: Aiken SC

Points: 112

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Oct 2021 at 5:41pm Posted: 10 Oct 2021 at 5:41pm |

|

Thanks for the info. I'll post some pictures of her split in the next day or so. Will keep you guys updated with my progress. Appreciate the help!

|

|

WeisAC2

Bronze Level

Joined: 02 Feb 2017

Location: Aiken SC

Points: 112

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Oct 2021 at 2:02pm Posted: 11 Oct 2021 at 2:02pm |

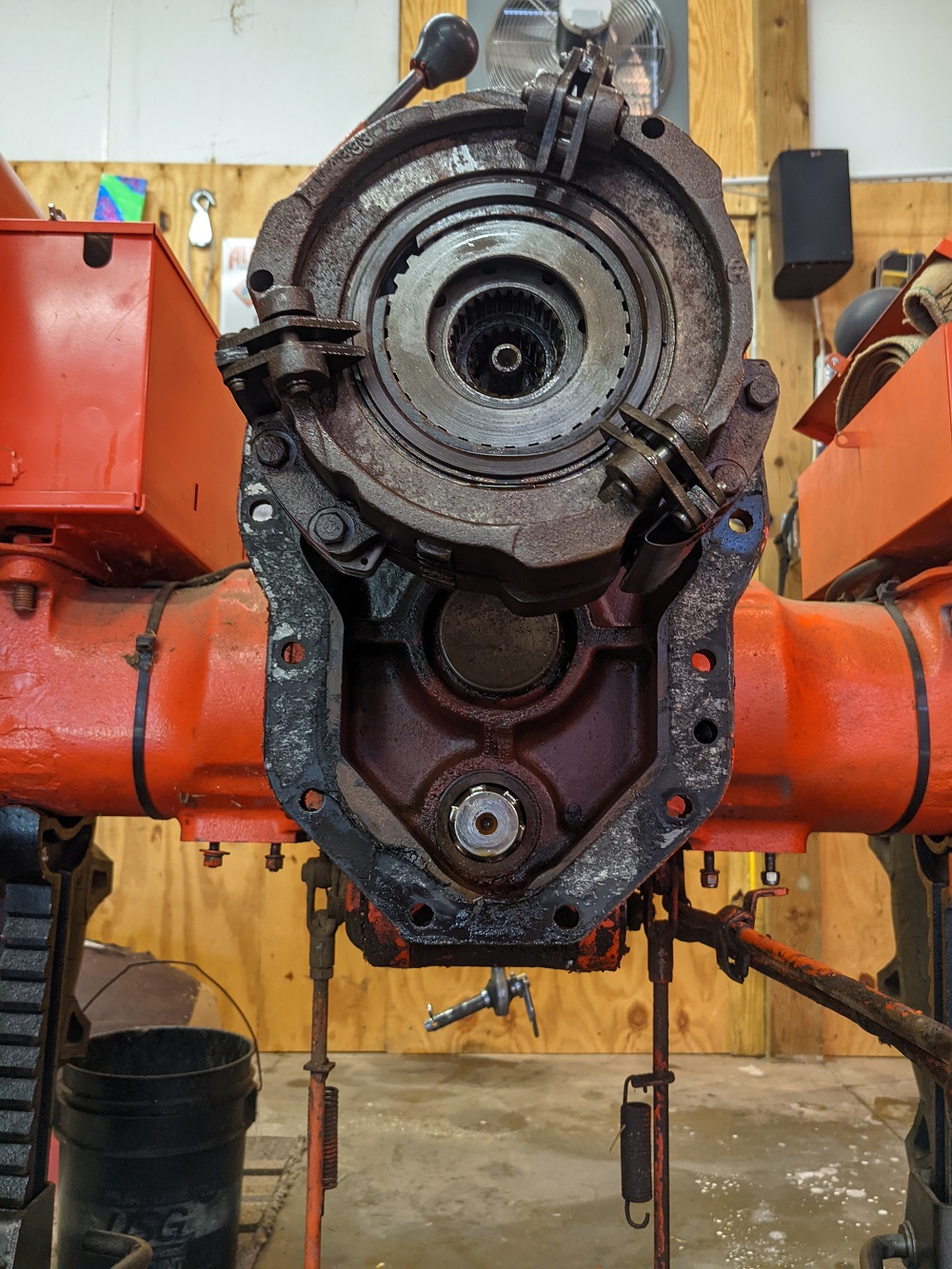

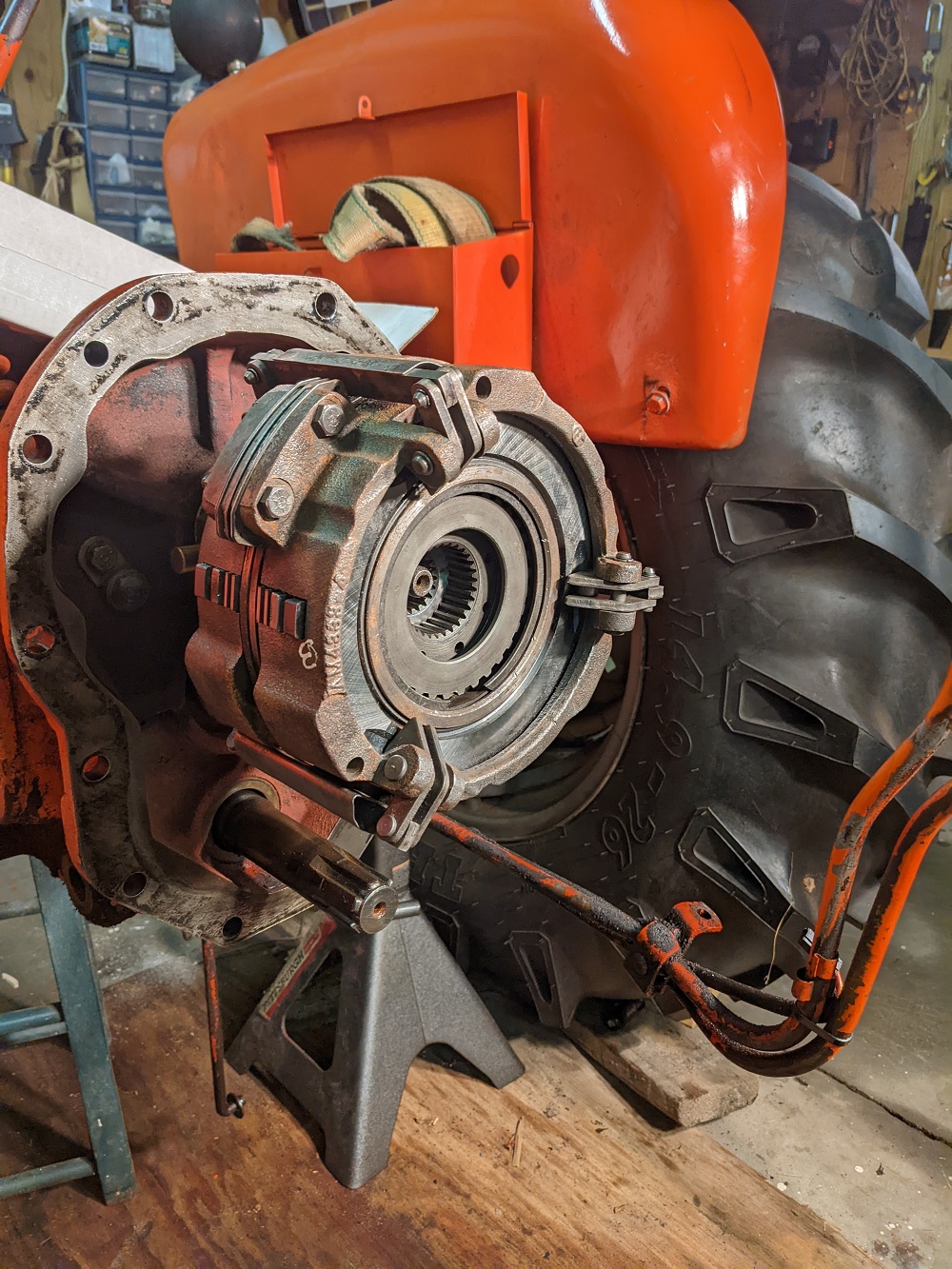

Been making some progress with the tractor. Since I'm replacing the seals and bearing inside the torque tube I decided to completely remove it instead of just splitting at the transmission. So far, I've split the tractor at the rear of the engine. Will use an engine hoist to help finish removing the rest of the torque tube.

|

|

DonDittmar

Orange Level

Joined: 15 Sep 2009

Location: MIllersburg, MI

Points: 2513

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Oct 2021 at 7:57pm Posted: 11 Oct 2021 at 7:57pm |

|

nice stand.

|

|

Experience is a fancy name for past mistakes. "Great moments are born from great opportunity"

1968 D15D,1962 D19D

Also 1965 Cub Loboy and 1958 JD 720 Diesel Pony Start

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 5186

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Oct 2021 at 8:46pm Posted: 11 Oct 2021 at 8:46pm |

|

I will second the nice stand, that would have worked great on my 160 rebuild 2 months ago. Nice, its a diesel. Defiantly been low on oil for a good while it appears.

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

WeisAC2

Bronze Level

Joined: 02 Feb 2017

Location: Aiken SC

Points: 112

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Oct 2021 at 12:28pm Posted: 13 Oct 2021 at 12:28pm |

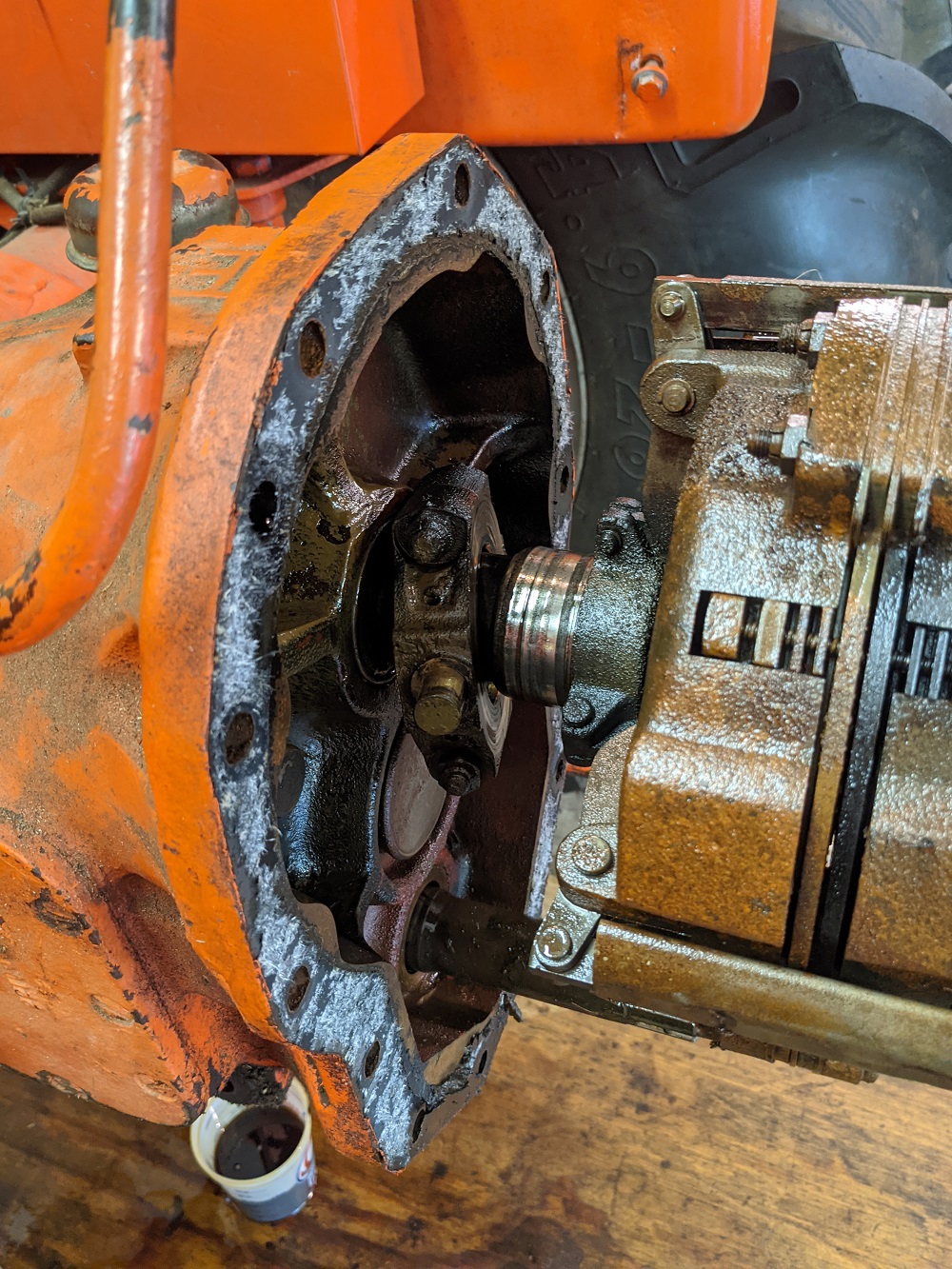

Been making steady progress with getting the torque tube ready for removal. I think all I have left to do is to remove the dip sticks and the power director shaft that the fork mounts to.

|

|

ACinSC

Orange Level

Joined: 16 Dec 2015

Location: South Carolina

Points: 2934

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Oct 2021 at 2:46pm Posted: 13 Oct 2021 at 2:46pm |

|

Power director lever in the floor was my contribution today . Try to help my fav son out , but we're getting in uncharted waters . THANKS !!

|

|

John m

Silver Level

Joined: 11 Apr 2020

Location: Wetmore, Mi

Points: 278

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Oct 2021 at 4:43pm Posted: 13 Oct 2021 at 4:43pm |

|

Nice. Headed down that road shortly with my 190. I'm actually quite anxious to do it. Keep us updated, I will surely be watching for the updates.

|

|

Alex09(WI)

Orange Level

Joined: 15 Mar 2012

Location: CECIL WI

Points: 1739

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Oct 2021 at 9:30pm Posted: 14 Oct 2021 at 9:30pm |

Doing well so far! I went through a d15 torque tube this year to install shuttle clutch gears. There are some pics at this link that may help: https://www.facebook.com/awtractorrepair/posts/1367701396958709

|

|

www.awtractor.com

A&W TRACTOR 920-598-1287

KEEPING ALLIS-CHALMERS IN THE FIELDS THROUGH THE 21ST CENTURY

|

|

Alex09(WI)

Orange Level

Joined: 15 Mar 2012

Location: CECIL WI

Points: 1739

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Oct 2021 at 9:32pm Posted: 14 Oct 2021 at 9:32pm |

|

And make sure to remove the power director oil dipstick! Otherwise you'll split it 1" apart and you'll wonder why it wont go any further

|

|

www.awtractor.com

A&W TRACTOR 920-598-1287

KEEPING ALLIS-CHALMERS IN THE FIELDS THROUGH THE 21ST CENTURY

|

|

WeisAC2

Bronze Level

Joined: 02 Feb 2017

Location: Aiken SC

Points: 112

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Oct 2021 at 8:21am Posted: 16 Oct 2021 at 8:21am |

Thanks for the pictures Alex! I was trying to find some to reference and really appreciate the link you sent. I'll start another thread when I get to rebuilding the torque tube. I've gotten all the bolts out and the dip stick removed but struggling to get the torque tube to separate from the transmission. It's stuck on there pretty good. Guess that makes sense since it been since '61. May have to get a porta power to "break the seal"... |

|

WeisAC2

Bronze Level

Joined: 02 Feb 2017

Location: Aiken SC

Points: 112

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Oct 2021 at 7:57pm Posted: 16 Oct 2021 at 7:57pm |

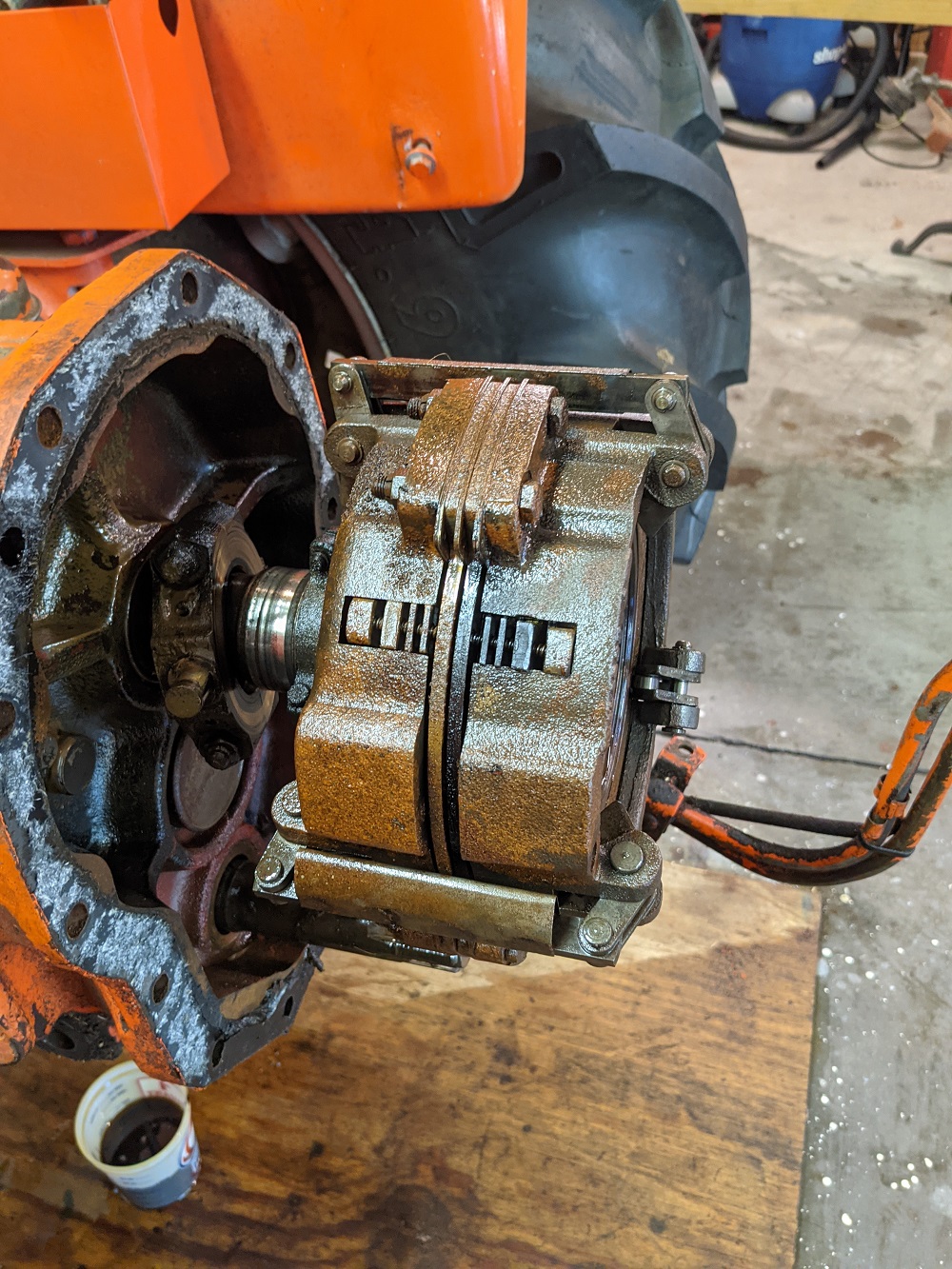

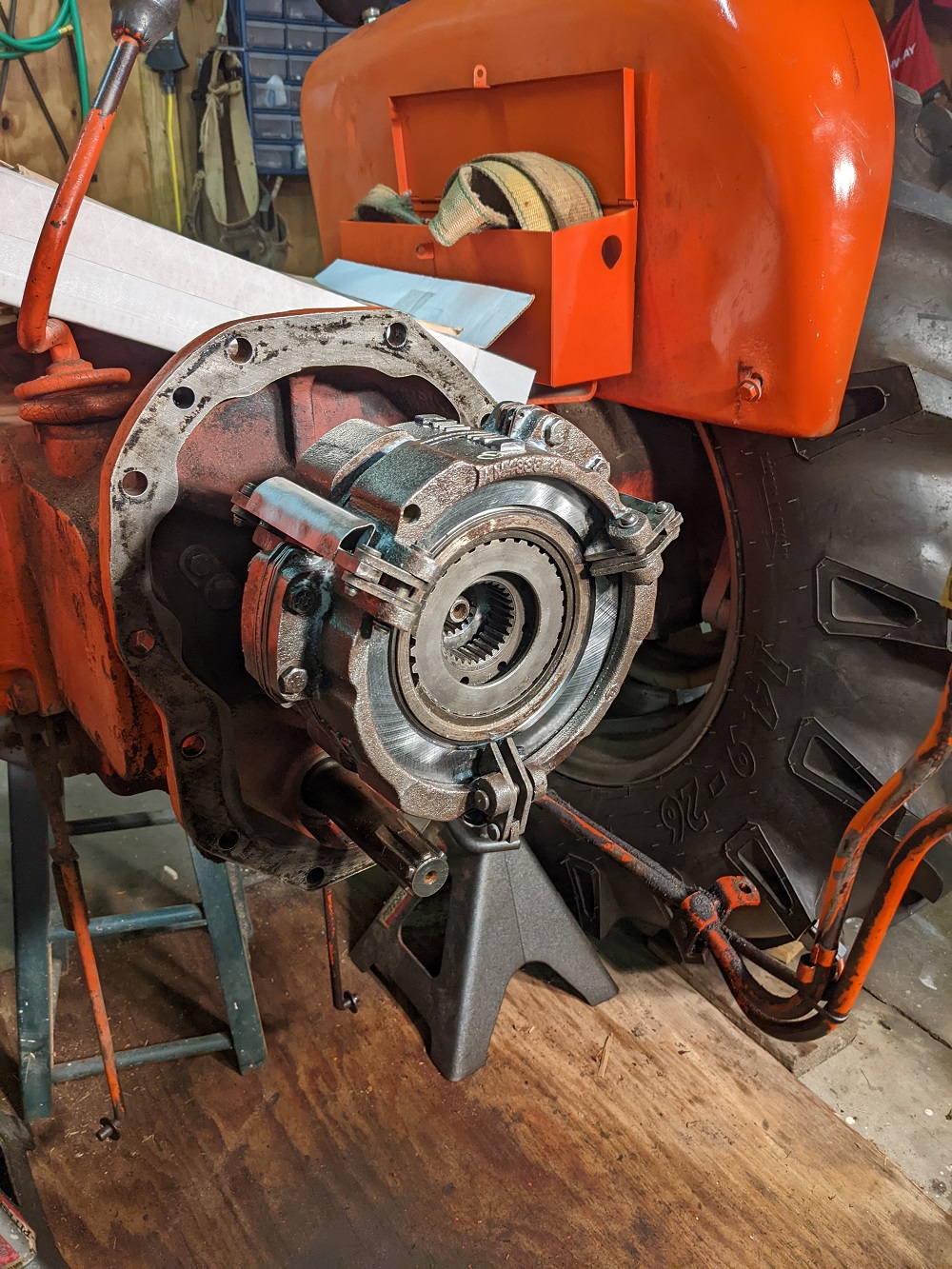

I was able to get the torque tube separated from the transmission today. Thought I would include a few pictures for you guys. I think I see the source of the rattling when the tractor was at a low idle...

|

|

Mikez

Orange Level Access

Joined: 16 Jan 2013

Location: Usa

Points: 8689

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Oct 2021 at 8:04pm Posted: 16 Oct 2021 at 8:04pm |

|

interesting. Could you post some pictures of the torque tube

|

|

John m

Silver Level

Joined: 11 Apr 2020

Location: Wetmore, Mi

Points: 278

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Oct 2021 at 9:17pm Posted: 16 Oct 2021 at 9:17pm |

|

What are you thinking is the source of the rattle?

|

|

John m

Silver Level

Joined: 11 Apr 2020

Location: Wetmore, Mi

Points: 278

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Oct 2021 at 9:27pm Posted: 16 Oct 2021 at 9:27pm |

|

Looking at the pictures it kinda looks like some black sludge in the front of power director and some of the other pieces. Maybe got hot at one time. Just guessing about that. Keep us updated, looking good.

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 5186

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Oct 2021 at 9:56pm Posted: 16 Oct 2021 at 9:56pm |

|

Lots of rust, low fluid level and a moisture issue. Did this tractor sit outside? At least you know what’s wrong at this point. I would rebuild the power director after seeing the damage.

Edited by AC720Man - 16 Oct 2021 at 10:01pm

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

Alex09(WI)

Orange Level

Joined: 15 Mar 2012

Location: CECIL WI

Points: 1739

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Oct 2021 at 1:33pm Posted: 17 Oct 2021 at 1:33pm |

If you need replacement parts, we can help you

|

|

www.awtractor.com

A&W TRACTOR 920-598-1287

KEEPING ALLIS-CHALMERS IN THE FIELDS THROUGH THE 21ST CENTURY

|

|

WeisAC2

Bronze Level

Joined: 02 Feb 2017

Location: Aiken SC

Points: 112

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Oct 2021 at 7:10pm Posted: 17 Oct 2021 at 7:10pm |

|

Tractor sat outside for many years prior to me getting it. Since then it is stored in a shop.

The tractor developed a rattle from the torque tube when idling in neutral with foot clutch out. It would go away if you bumped up the RPMs a little. Foot clutch was rebuilt a couple years back. I was assuming I also had a bad bearing in the torque tube, but it may have been the brass collar.

I'll post pictures of the torque tube soon. Need to decide where it will live while I take it apart. Will probably do another thread on it too.

Alex, thanks for the video! Very helpful. Yes the power director will be rebuilt.

|

|

WeisAC2

Bronze Level

Joined: 02 Feb 2017

Location: Aiken SC

Points: 112

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Oct 2021 at 7:15pm Posted: 17 Oct 2021 at 7:15pm |

|

Yes the black sludge has a hint of metallic grit to it. Good catch John.

|

|

WeisAC2

Bronze Level

Joined: 02 Feb 2017

Location: Aiken SC

Points: 112

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Oct 2021 at 8:22am Posted: 21 Oct 2021 at 8:22am |

I had a little time last night to get the power director off. Thanks again Alex as the video helped. Definitely having it in low range made things easier! The power director clutch pack will be rebuilt. I also have a few pictures of the torque tube below for you guys. Somehow... the PTO collar or shaft or detent ball has become warped and the PTO will periodically get stuck engaged. It's stuck at the moment and will not disengage or move back. I also need to figure that one out while all of this is apart.

|

|

polarbear

Silver Level

Joined: 05 Jul 2016

Location: addieville il

Points: 331

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Oct 2021 at 10:31am Posted: 21 Oct 2021 at 10:31am |

|

WOW great and informative pictures just absolutely a good job

THANK YOU EVERYONE

|

|

WeisAC2

Bronze Level

Joined: 02 Feb 2017

Location: Aiken SC

Points: 112

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Oct 2021 at 12:49pm Posted: 21 Oct 2021 at 12:49pm |

|

Thanks polarbear. I'm just learning as I go. Using this forum and my service manual as a resource. Taking pictures anyway so thought I would post them on the forum for others to see. Somebody may spot a problem that I would have missed!

Edited by WeisAC2 - 21 Oct 2021 at 12:49pm

|

|

polarbear

Silver Level

Joined: 05 Jul 2016

Location: addieville il

Points: 331

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Oct 2021 at 8:05am Posted: 26 Oct 2021 at 8:05am |

|

I'M WAITING TO SEE SOMEONE DO A TRANSMISSION AND SHOW PICTURES

|

|

WeisAC2

Bronze Level

Joined: 02 Feb 2017

Location: Aiken SC

Points: 112

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Dec 2021 at 1:07pm Posted: 21 Dec 2021 at 1:07pm |

Well's it's been a group effort, but I got the rebuilt power director reinstalled. Thought I would post some pic's for you guys. I'm ready to put this to use! I still got a little ways to go on the torque tube.

|

|

tbran

Orange Level

Joined: 14 Sep 2009

Location: Paris Tn

Points: 3507

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Dec 2021 at 6:36pm Posted: 21 Dec 2021 at 6:36pm |

|

The issue I fear is why did the shifter collar wear like that... make sure the thrust plate ramps and roller allow the clutch to 'snap' in . Some cut notches in the neutral locator plate where the button has to be pressed to shift to low or high to hold the clutch in and not have it pop out - this will wear out the brass collars and locating ridge on the shifter.

|

|

When told "it's not the money,it's the principle", remember, it's always the money..

|

|

WeisAC2

Bronze Level

Joined: 02 Feb 2017

Location: Aiken SC

Points: 112

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Dec 2021 at 7:41am Posted: 22 Dec 2021 at 7:41am |

|

Thanks tbran. The thrust plates were replaced along with all new clutch discs. This tractor came with the power director broken. I'm thinking that it was run low on oil which is what caused the problem.

|

|

ac160

Silver Level

Joined: 02 Dec 2010

Points: 402

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Dec 2021 at 9:57am Posted: 22 Dec 2021 at 9:57am |

|

Where did you get a stand like that? Or is it homemade?

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)