| Author |

Topic Search Topic Search  Topic Options Topic Options

|

tbran

Orange Level

Joined: 14 Sep 2009

Location: Paris Tn

Points: 3539

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Mar 2021 at 9:30pm Posted: 08 Mar 2021 at 9:30pm |

|

Put compressed air in the oil galley and listen for a lot of air escaping in the front cover...after seeing this,,, looks like block has been changed- there is a allen headed plug with a hole drilled in it for gear lube - gotta be sure it is in. Unless I missed something 3500's did not have PC

|

|

When told "it's not the money,it's the principle", remember, it's always the money..

|

|

|

Sponsored Links

|

|

|

Agwilly

Bronze Level

Joined: 06 Mar 2021

Location: Central Ontario

Points: 20

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Mar 2021 at 9:33pm Posted: 08 Mar 2021 at 9:33pm |

|

I have to admit I don’t think there’s enough room for the drive gear as well.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22124

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Mar 2021 at 7:28am Posted: 09 Mar 2021 at 7:28am |

|

Piston cooling jets can be verified (or not) by using a mirror and looking in the correct places. If you see one, there are 5 more. Also, removing one main cap and sliding out an upper main brg shell will verify if the piston cooling jets can even work, if there are any drilled in the block. If that front block plug with the orifice was missing, I don't think it would have any oil pressure.

|

|

WD45Diesel57

Orange Level

Joined: 20 Jul 2010

Location: Varna, Ont. Can

Points: 646

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Mar 2021 at 7:36am Posted: 09 Mar 2021 at 7:36am |

Agwilly wrote: Agwilly wrote:

I have to admit I don’t think there’s enough room for the drive gear as well. |

Hi Bill im from south western ontario, and ive had good luck with Fawcett Tractor Supply in St. Marys Ont. for 7000 series parts they have a few around there!

|

|

1-B's, 2-C, 2-CA's,2-WF, 1-WC,1-G, 3-WD's, 2-WD45, 1-RC, 1-D17 Diesel, 1-D14, 2-D15,1-D17 row crop,1-D19 gas and All Crop 40,60,66,72,90 and 100

|

|

CDN 400

Bronze Level Access

Joined: 05 Apr 2014

Location: On. Canada

Points: 81

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Mar 2021 at 10:32am Posted: 09 Mar 2021 at 10:32am |

WD45Diesel57 wrote: WD45Diesel57 wrote:

Agwilly wrote: Agwilly wrote:

I have to admit I don’t think there’s enough room for the drive gear as well. |

Hi Bill im from south western ontario, and ive had good luck with Fawcett Tractor Supply in St. Marys Ont. for 7000 series parts they have a few around there!

|

Have you dealt there lately, that place has really changed. I will never darken their doorway again.

|

|

Agwilly

Bronze Level

Joined: 06 Mar 2021

Location: Central Ontario

Points: 20

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Mar 2021 at 9:07pm Posted: 10 Mar 2021 at 9:07pm |

|

I have found a combine 426 engine can you tell me if the oil pan will fit under my 220?

|

|

LeonR2013

Orange Level

Joined: 01 Jan 2013

Location: Fulton, Mo

Points: 3500

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Mar 2021 at 9:39pm Posted: 10 Mar 2021 at 9:39pm |

|

A hole drilled in the right place might just work. A long time ago I had to rebuild a Cummins 250 and the mountains of Colorado was to much for it with 80,000 lbs. So I drilled a 3/16 hole in the end of the rod, put 290 pistons in and turned her up, with a 400 turbo on it. Ran great, just had to watch the temps. a little bit. I don't know how many trips I made to Grand Junction and didn't have a problem. It can be done to any engine. Just be careful! Leon

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22124

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Mar 2021 at 10:33pm Posted: 10 Mar 2021 at 10:33pm |

|

Have you determined for absolute positive that this particular block has piston cooling jets or not??? because if it doesn't, your low oil pressure issue must be bearing clearance related. I think the combine oil pan and dual oil pump will fit on a 220, but you are not clear WHICH 426 combine engine it is. Clearance to the oil pan to front axle frame is of concern. Your engine is using the 210/220/D21 front engine plate which is thinner than a later model tractor or combine engine plate, which could complicate oil pan hole alignment to the timing cover. You need to determine if your front cover will work for the oil pump drive gear. You'd better make a lot of measurements and take pictures when you go to buy these parts and LOOK at the engine they came out of.

Edited by DrAllis - 11 Mar 2021 at 6:01am

|

|

Agwilly

Bronze Level

Joined: 06 Mar 2021

Location: Central Ontario

Points: 20

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Mar 2021 at 2:33pm Posted: 11 Mar 2021 at 2:33pm |

|

|

|

Agwilly

Bronze Level

Joined: 06 Mar 2021

Location: Central Ontario

Points: 20

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Mar 2021 at 2:35pm Posted: 11 Mar 2021 at 2:35pm |

|

|

|

Agwilly

Bronze Level

Joined: 06 Mar 2021

Location: Central Ontario

Points: 20

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Mar 2021 at 2:43pm Posted: 11 Mar 2021 at 2:43pm |

|

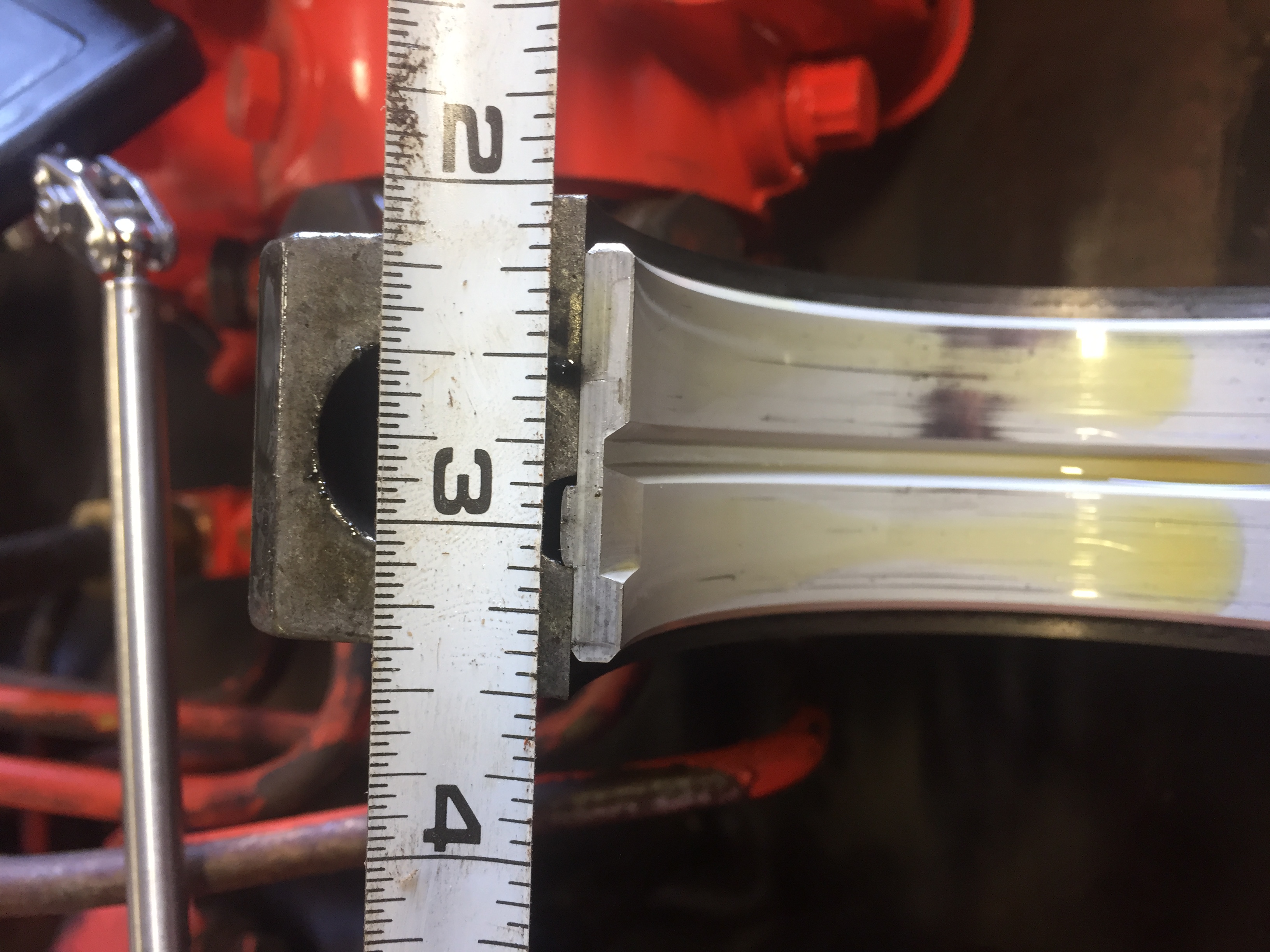

So i was able to get back to my tractor today. i have taken some pictures. On the very last pic you can see with a mirror that there is one hole drilled in the front main webbing of every cylinder. That's all there is. I also took pics of main bearings. The old ones that i took out went to the full width of the main bearing cap. I was told that this was all you can get now. also you can see not much clearance for the gear to drive the pump. So can you tell me please what i have here and how to proceed with this. I appreciate your time Bill.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22124

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Mar 2021 at 7:15pm Posted: 11 Mar 2021 at 7:15pm |

|

You have two choices: #1. find a salvage 210 or 220 that has the crankshaft driven oil pump and buy the pump, lines, oil pan and probably the timing cover. The combine engine parts may work, but I think the timing cover gear clearance will cause you problems and your old thin front plate will cause issues with the front oil pan bolts. #2. Pull the crankshaft out of the block and drive a small steel ball in each piston cooling jet to plug them. If you could find a set of old style main bearings, that would work too, but I don't think that will happen.

|

|

Agwilly

Bronze Level

Joined: 06 Mar 2021

Location: Central Ontario

Points: 20

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Mar 2021 at 7:22pm Posted: 11 Mar 2021 at 7:22pm |

|

Thanks I appreciate your help. Bill.

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8667

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Mar 2021 at 11:24pm Posted: 11 Mar 2021 at 11:24pm |

|

Wouldn't the front cover and oil pan off a 7000 426 work on a 3500 (220) and clear the axle? That way the pump would fit. The mount holes are already there in the block.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22124

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Mar 2021 at 6:02am Posted: 12 Mar 2021 at 6:02am |

|

The older generation 210/220- D21 engine has a couple of things going on. The front plate of the engine is 3/16" thick and all the 7000 series are 3/8" thick. Now, these numbers are from my memory, but it moves the front row of pan bolts forward about 1/2 hole or so. The oil pan is longer/shorter as a result. The 7000 series timing cover may not exactly be the shape of the 210-220 front plate, especially around the hydraulic pump drive and maybe the injection pump area too. Not saying it won't or can't, just know that it might be different.

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8667

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Mar 2021 at 6:21am Posted: 12 Mar 2021 at 6:21am |

|

Ah Hah!

|

|

injpumpEd

Orange Level Access

Joined: 13 Sep 2009

Location: Walnut IL

Points: 5115

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Mar 2021 at 7:16am Posted: 12 Mar 2021 at 7:16am |

|

If he had the old main bearings, he could roll in his old uppers, since they usually don't wear. While going to a crank drive oil pump is a better idea, it's kind of a pain on the 21 like Dr is mentioning. The 210/220/combine front timing cover is notched where the oil pump gear goes up to meet the crank gear. Plus the row of bolts is farther forward. I have located the oil pumps, pickups, and tubes on ebay from military surplus. Nothing was cheap though! Looks like his block has the oil pump bolt holes, so front cover and pan would need dealt with.

|

|

210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers!

|

|

pirlbeck

Silver Level

Joined: 01 Dec 2009

Location: West Central IA

Points: 233

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Mar 2021 at 7:31am Posted: 12 Mar 2021 at 7:31am |

|

The engine is already out of the tractor, why not just pull the crank and plug the piston cooling jet holes and be done with it. When the timing cover is off, make sure the timing gear lube orifice plug is in the front of the block. Also, I thought I read that he had a rear main seal leak too that needed addressed, so the flywheel end needs to come apart anyway too.

|

|

injpumpEd

Orange Level Access

Joined: 13 Sep 2009

Location: Walnut IL

Points: 5115

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Mar 2021 at 8:29am Posted: 12 Mar 2021 at 8:29am |

|

Pulling the crank involves pulling the front cover AND front plate, which means camshaft removal! Easy enough to roll his old uppers back in if he still has them. We really haven't determined if this is indeed his issue either have we? If a block plug was left out, it wouldn't have any oil pressure, as mentioned above. On my puller, I cut the front plate across the bottom, so I could pull crank a little easier. Probably sacrificed some strength, but it's a puller!

|

|

210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers!

|

|

tbran

Orange Level

Joined: 14 Sep 2009

Location: Paris Tn

Points: 3539

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Mar 2021 at 9:59pm Posted: 12 Mar 2021 at 9:59pm |

|

What 3500 had piston cooling? The 6.7 426 on the 7050 had PC the 7030 did not. That was 72...ish...

|

|

When told "it's not the money,it's the principle", remember, it's always the money..

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22124

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Mar 2021 at 6:24am Posted: 13 Mar 2021 at 6:24am |

|

I had a new replacement short block 30+ yrs ago that had the piston cooling jets on it. It was a Generation one block too. Also in a 220. It was a parts sale to an independent repair shop. I just can't remember what he wound up doing and he's no longer in business. All the Mark 2 blocks had it, except the 7030, which in hindsight was a bad idea on A-C's part.

** Ed, I pulled a crank out of an N-6 engine one time without having to remove the front plate. It took Mike an I both to position the crank throws just right with all the pistons shoved up to their tops and it just barely came by the plate. Now, that was the thicker/newer plate made for an early 80's combine engine, so maybe there was more room to do that.

Edited by DrAllis - 13 Mar 2021 at 6:28am

|

|

Agwilly

Bronze Level

Joined: 06 Mar 2021

Location: Central Ontario

Points: 20

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Mar 2021 at 7:46am Posted: 13 Mar 2021 at 7:46am |

|

I have one more question, like i said there is no serial plate in this block. if i was to get one made what should be put on it?

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8667

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Mar 2021 at 2:26pm Posted: 13 Mar 2021 at 2:26pm |

|

....just put "REPLACEMENT"....it's not a 3500 or a 3750...it's a combination that covers both bases... I wouldn't waste my time. Pretty sure my 220 has a replacement block only because it says MOD 3500 but no serial #. Has crank drive pump but is also a 70 model. No idea of history. Had around 3000hrs on a working tach. Why would it need fixed with that few hrs?

|

|

injpumpEd

Orange Level Access

Joined: 13 Sep 2009

Location: Walnut IL

Points: 5115

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Mar 2021 at 6:00pm Posted: 13 Mar 2021 at 6:00pm |

|

So not to derail this topic, but it still applies. Are the engines with big pin rods not drilled in the main saddle for the cooling passage? The block in my puller was a very late model block(4036952) that originally had big pin rods, and I never remember seeing any oil holes directed at the bottom of the pistons. Those used the rifled rod. I am using heat treated small pin rods. I have a couple of other blocks, one has the holes, it came out of a piece of construction equipment, tag does say 670T, 4035893, the other is same casting number, but still assembled so can't see inside, was non intercooled out of a uni.

|

|

210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers!

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22124

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Mar 2021 at 6:05pm Posted: 13 Mar 2021 at 6:05pm |

|

Pretty sure they are drilled and because the non-piston cooling upper main shells got discontinued 30 yrs ago, AC or DA or AGCO printed a bulletin telling you to plug those holes with a steel ball of a certain P/N. So, they made it impossible to do an in-frame quicky, unless you left the old upper shells in place. It was a bad idea to discontinue those old style upper shells.

|

|

Mikez

Orange Level Access

Joined: 16 Jan 2013

Location: Usa

Points: 8741

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Mar 2021 at 9:32pm Posted: 13 Mar 2021 at 9:32pm |

|

Is the part number for the old upper bearings you guys speak of different then the new ones. Just curious

|

|

Agwilly

Bronze Level

Joined: 06 Mar 2021

Location: Central Ontario

Points: 20

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 May 2021 at 4:04pm Posted: 01 May 2021 at 4:04pm |

|

Hello I got my tractor back together with a crank drive oil pump. Still having low oil pressure issues. Could someone please give me the part number on the ball bearings to plug the oil jets in the block please? Thanks Bill.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22124

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 May 2021 at 4:26pm Posted: 01 May 2021 at 4:26pm |

|

Hold on. You have a crankshaft driven oil pump from what? what engine? That pump has more volume than the old oil pump. You shouldn't need to plug the piston cooling jets. There must be bearing clearance issues. What is the oil pressure when hot?? 35 to 55 psi at full throttle is spec. What did the dry main bearings plasti-gauge at ??

You didn't have oil pressure issues until you replaced main and rod bearings, correct ??

Edited by DrAllis - 01 May 2021 at 4:27pm

|

|

DanWi

Orange Level Access

Joined: 18 Sep 2009

Location: wttn

Points: 1941

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 May 2021 at 5:40pm Posted: 01 May 2021 at 5:40pm |

|

Are you getting the oil pressure directly from a gauge screwed into the block? A gauge on the dash either mechanical or electric could read low.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22124

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 May 2021 at 6:40pm Posted: 01 May 2021 at 6:40pm |

|

210 and late 220 oil pumps are the exact same (74028052) pump that an early 7030 and 7050 had. The 7050 had piston cooling and a third oil filter and they never ever had oil pressure issues.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

Agwilly wrote:

Agwilly wrote: