| Author |

Topic Search Topic Search  Topic Options Topic Options

|

MACK

Orange Level

Joined: 17 Nov 2009

Points: 7664

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jan 2022 at 8:39pm Posted: 03 Jan 2022 at 8:39pm |

|

Put a good pin in vice that will go through wrist pin (3/8 extenson). Put pin through wrist pin and torque. MACK

|

|

|

Sponsored Links

|

|

|

ac55tractor

Silver Level

Joined: 20 Oct 2012

Location: Raymond, Maine

Points: 240

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jan 2022 at 9:01pm Posted: 03 Jan 2022 at 9:01pm |

Oh, okay, I get it. Thanks Mack.

I realized earlier that even though the connecting rod is off center, the piston is not. So I should be able to center the pin inside the piston and tighten it down.

Mack,

I was wondering If I would hear back from you. I had never heard of a fire ring, so I looked it up. That is a great idea for creating a seal in a cylinder head.

My family and I go to the Cumberland Fair here in Maine every September. I have been known to sneak off with my grandson to watch the tractor pulls. It's amazing, the horse power that those tractors can create. Thanks again for the idea.

Steve

|

|

Lonn

Orange Level

Joined: 16 Sep 2009

Location: Назарово,Russia

Points: 29817

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 05 Jan 2022 at 5:28pm Posted: 05 Jan 2022 at 5:28pm |

|

One important reason for bearing crush is heat dissipation. The bearing could burn out without the bearing crush because the back of the bearing surface needs to be in tight contact with the rod and cap to take away the heat.

Edited by Lonn - 05 Jan 2022 at 5:29pm

|

|

-- --- .... .- -- -- .- -.. / .-- .- ... / .- / -- ..- .-. -.. . .-. .. -. --. / -.-. .... .. .-.. -.. / .-. .- .--. .. ... -

Wink

I am a Russian Bot

|

|

ac55tractor

Silver Level

Joined: 20 Oct 2012

Location: Raymond, Maine

Points: 240

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Jan 2022 at 7:02pm Posted: 05 Jan 2022 at 7:02pm |

Thank you for that. It only adds to the fact that bearing crush is absolutely necessary.

I have a question.

Does the bearing have to extend out of both the cap and the

rod, or will it work with having the extension come out of the cap only?

Thanks

Steve

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8684

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jan 2022 at 1:58pm Posted: 06 Jan 2022 at 1:58pm |

|

I don't think it matters....have messed with some rebuild rods an know the shell stuck out a little but can't tell you whether rod or cap.My belief is as long as you have crush you're ok. I am no authority.....

|

|

JK in Pa

Bronze Level

Joined: 12 Sep 2009

Location: Dushore, Pa.

Points: 164

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jan 2022 at 2:05pm Posted: 06 Jan 2022 at 2:05pm |

|

The wrist pins cannot be centered. Directions will get you there. Many rebuilds were ruined in a mater of hours.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88605

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jan 2022 at 3:28pm Posted: 06 Jan 2022 at 3:28pm |

|

John, on the smaller B/ C motor , i think the pin is centered in the piston... Its the CRANK end of the rod you have to watch how you install........ Now the WC / WD motor I believe is not centered on the piston end ??? ......... and all the rods go in the same way on the CRANK end ??

|

|

Like them all, but love the "B"s.

|

|

JK in Pa

Bronze Level

Joined: 12 Sep 2009

Location: Dushore, Pa.

Points: 164

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jan 2022 at 3:42pm Posted: 06 Jan 2022 at 3:42pm |

|

Steve, you are right. I was thinking he was working on a WD Motor. Sorry for the confusion.

|

|

ac55tractor

Silver Level

Joined: 20 Oct 2012

Location: Raymond, Maine

Points: 240

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jan 2022 at 3:46pm Posted: 06 Jan 2022 at 3:46pm |

Thank you SteveM C/L, Thank you JK in PA. and Thank you Steve (ill)

I am going over the service manual right now. The pins are centered.

No problem, I know that I have the best guidance on this overhaul.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88605

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jan 2022 at 3:55pm Posted: 06 Jan 2022 at 3:55pm |

|

just watch the CRANK END of the rod... they dont all go in the same way.

|

|

Like them all, but love the "B"s.

|

|

ac55tractor

Silver Level

Joined: 20 Oct 2012

Location: Raymond, Maine

Points: 240

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jan 2022 at 4:15pm Posted: 06 Jan 2022 at 4:15pm |

Joke here

I can always use the ball pean to get them to fit.

Truth here.

But Steve, they all came out aiming the same direction.

You know that I will be sure that they get reinstalled properly. Something tells me that there was side play inside the piston at the wrist pin to allow the incorrect offset. That may explain the broken piston ring. Not sure, who knows?

I have a whole list of questions. I Just want to get through fitting these rods first.

Here is one for you all.

The floating oil pickup is attached to the pipe that goes to the block. The pickup is attached with one tube going into another and held in with a cotter pin. Is it possible, that along with the oil that is being pulled up, if air being pulled up as well.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88605

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jan 2022 at 4:51pm Posted: 06 Jan 2022 at 4:51pm |

|

the screen should be well BELOW the oil line.. should not suck air.

|

|

Like them all, but love the "B"s.

|

|

ac55tractor

Silver Level

Joined: 20 Oct 2012

Location: Raymond, Maine

Points: 240

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 06 Jan 2022 at 6:47pm Posted: 06 Jan 2022 at 6:47pm |

|

It was something that I noticed, I was curious about it. Thanks.

|

|

ac55tractor

Silver Level

Joined: 20 Oct 2012

Location: Raymond, Maine

Points: 240

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Jan 2022 at 3:49pm Posted: 11 Jan 2022 at 3:49pm |

Over last weekend, I was able to get in contact with the son of the original owner of my Allis B. I asked him if he knew anything about the engine being worked on in the past. He said that he remembered that his father was getting lower end noise from the engine. He said his father worked on the crankshaft. He pulled shims out, and ground the flats of the connecting rods to get the connecting rods to fit. He remembered that they squeezed the rods in a vice at the parting lines because he removed too much from the flats on the rods to get them to fit.

That explained to me how the bores on the connecting rods became egged.

I finished the rods today. I am very happy with they way that they spin freely on the crankshaft.

|

|

BrianC

Orange Level Access

Joined: 16 Jun 2011

Location: New York

Points: 1619

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Jan 2022 at 5:22pm Posted: 11 Jan 2022 at 5:22pm |

Does it make sense to balance the rods? Pistons?

I lost track of what all you are doing.

Maybe you can recap the scope of the rebuild? I know you worked on the main journal bearings

and end play.

New pistons, rings and liners? Rings- end gap and clearance/fit to grooves in pistons. Liners- protrusion and o-ring sealing. If the block's

sealing surface is corroded they might leak. The camshaft, you should put the lifters back to the lobe where they came from.

From my experience the top problems of rebuilds are crank/rod bearing issues, wet liner leak, head gasket leak. Another is the darn rear main seal leaking. Interesting to me, I have a '48 C needing an engine rebuild.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88605

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Jan 2022 at 6:28pm Posted: 11 Jan 2022 at 6:28pm |

He remembered that they squeezed the rods in a vice at the parting lines because he removed too much from the flats on the rods to get them to fit.

well........... i dont remember reading that one in the service manual !!

|

|

Like them all, but love the "B"s.

|

|

ac55tractor

Silver Level

Joined: 20 Oct 2012

Location: Raymond, Maine

Points: 240

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Jan 2022 at 6:32pm Posted: 11 Jan 2022 at 6:32pm |

I have a new

set of pistons, rings, and liners. I checked the block closely and it seems to be in great shape. I

checked the top of the bare block with a straight edge. There was no deviation

or uneven areas. I spent a lot of time cleaning the oil sludge out of the block

and getting the dirt out of the coolant chamber.

I purchased

an oil pump rebuild kit and have lapped the back plate flat. That Is ready to

go.

I rebuilt

the governor assembly.

At first the

liners would not go all the way down into the block. I lightly honed the lower

liner diameter with a small wheel cylinder hone and some light oil, and the

liners slide right in now, without the “O” rings attached.

After

setting the liners into place, (without “O” rings), I checked the protrusion

for the liners. They sit cleanly in the block with a .002 - .004 protrusion.

The camshaft

lifters were pulled, cleaned, numbered, tagged, and bagged. I have installed

new cam bearings, and I purchased a remanufactured cam shaft.

After

measuring the cam all the cam lobes are the same height, and the 3 bearing

journals each measure 1.749.

After getting

the cylinder head milled flat. I have rebuilt the cylinder head with new

valves, springs, and valve guides. Lapped the valves to the new valve seats.

That’s all I

can think of right now. I haven’t gotten to setting the gap on the rings yet. I

was wondering if it was necessary for me to make a ring squaring tool to

seat the piston ring squarely in the bore, to use a feeler gauge to check its

gap.

I have a

better idea how to maintain bearing crush and how shimming the split line

works. I have never heard of ether of these.

I am not an

engine rebuilder. I feel that I do have enough common sense to assemble this

engine into spec. Having the service manual and a parts number book has been a

big help as well.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88605

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Jan 2022 at 6:40pm Posted: 11 Jan 2022 at 6:40pm |

sounds like you are building a RACE CAR !!!............... 125 cubic inch / 20 HP..

|

|

Like them all, but love the "B"s.

|

|

ac55tractor

Silver Level

Joined: 20 Oct 2012

Location: Raymond, Maine

Points: 240

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Jan 2022 at 6:40pm Posted: 11 Jan 2022 at 6:40pm |

I had to get an answer on those rods. I contacted the guy who sold me the tractor. (He was the builder of my house and my former neighbor.) He was easy to find. He said that he traded an old station wagon for the tractor in the late 80's. Unfortunately the original owner had passed away over 10 years ago, but he was able to get in touch with his son for me. We spoke on the phone for almost an hour. He seemed happy to hear that Wendy and I were taking good care of his fathers Allis B.

|

|

ac55tractor

Silver Level

Joined: 20 Oct 2012

Location: Raymond, Maine

Points: 240

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Jan 2022 at 6:47pm Posted: 11 Jan 2022 at 6:47pm |

|

Oh, I forgot to mention that I took the plunge, and got oversize pistons, rings, and sleeves. Got to have that extra 1 or 2 horsepower when I really need it.

|

|

MACK

Orange Level

Joined: 17 Nov 2009

Points: 7664

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Jan 2022 at 8:06pm Posted: 11 Jan 2022 at 8:06pm |

|

Use your pistons to square the rings. MACK

|

|

ac55tractor

Silver Level

Joined: 20 Oct 2012

Location: Raymond, Maine

Points: 240

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Jan 2022 at 8:32pm Posted: 11 Jan 2022 at 8:32pm |

Thanks Mack That's a good Idea. That will save me some time.

|

|

ac55tractor

Silver Level

Joined: 20 Oct 2012

Location: Raymond, Maine

Points: 240

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Jan 2022 at 8:44pm Posted: 11 Jan 2022 at 8:44pm |

Just after Christmas, I tried to place a ring into the (bottom) of one of the sleeves. As it went in, it made a short scratch in the liner. I looked at the gap, it looked at the gap by eye, close to .010, maybe less. I pulled the ring out and put it back in the package. Before I place another ring in a sleeve, I am going to check it for burrs, Clearly, I have a lot of work ahead of me. The engine is in the cellar. I work on it for a few hours every day. Some days I don't go near it at all.

|

|

wjohn

Orange Level

Joined: 19 Jan 2010

Location: KS

Points: 2263

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Jan 2022 at 11:00pm Posted: 12 Jan 2022 at 11:00pm |

ac55tractor wrote: ac55tractor wrote:

The camshaft

lifters were pulled, cleaned, numbered, tagged, and bagged. I have installed

new cam bearings, and I purchased a remanufactured cam shaft. |

Are you going to resurface the lifters since the reman camshaft had the lobes ground (I presume)? The guidance I got and info I found around the internet suggested this was a good idea when installing a reground cam.

Here's a thread I started where I asked the question and ended up resurfacing my WD lifters myself once I discovered that a brand new lifter for that engine was flat. I do not know for certain if the B engine lifters were flat or slightly convex when new. Another potential risk is that I do not know if they are hardened to a certain depth that I might have gotten into. Other members had done this before so I thought it was low risk. I still have not gotten my engine back together yet unfortunately.

Just wanted to bring this up if you hadn't thought about it yet.

|

|

1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45

|

|

ac55tractor

Silver Level

Joined: 20 Oct 2012

Location: Raymond, Maine

Points: 240

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jan 2022 at 8:04pm Posted: 13 Jan 2022 at 8:04pm |

wjohn, I want to thank you for sending out that link to me. I read it over and the last thing that I need is chunks of chipped up lifters in the oil pan. I checked a couple of lifters and they were flat on the bottom. Then I picked up a third one. It was #5. It was concave. That was the lobe number that was warn out on the cam that I pulled. I am going to fix the lifters here at the house. Thanks again for the heads up. Steve (inME)

|

|

ac55tractor

Silver Level

Joined: 20 Oct 2012

Location: Raymond, Maine

Points: 240

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jan 2022 at 1:34pm Posted: 15 Jan 2022 at 1:34pm |

|

|

|

ac55tractor

Silver Level

Joined: 20 Oct 2012

Location: Raymond, Maine

Points: 240

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jan 2022 at 1:35pm Posted: 15 Jan 2022 at 1:35pm |

|

|

|

ac55tractor

Silver Level

Joined: 20 Oct 2012

Location: Raymond, Maine

Points: 240

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jan 2022 at 1:36pm Posted: 15 Jan 2022 at 1:36pm |

|

|

|

ac55tractor

Silver Level

Joined: 20 Oct 2012

Location: Raymond, Maine

Points: 240

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jan 2022 at 1:37pm Posted: 15 Jan 2022 at 1:37pm |

|

|

|

BrianC

Orange Level Access

Joined: 16 Jun 2011

Location: New York

Points: 1619

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jan 2022 at 4:04pm Posted: 15 Jan 2022 at 4:04pm |

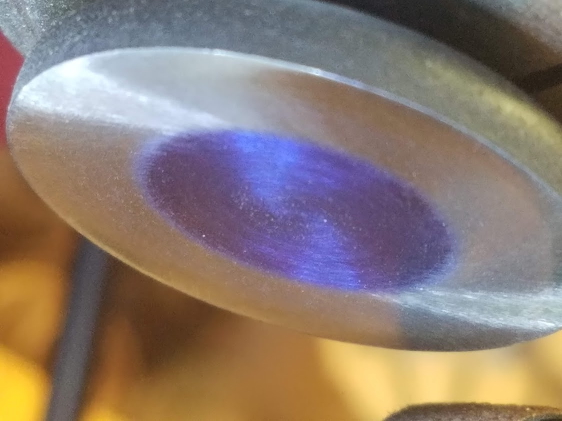

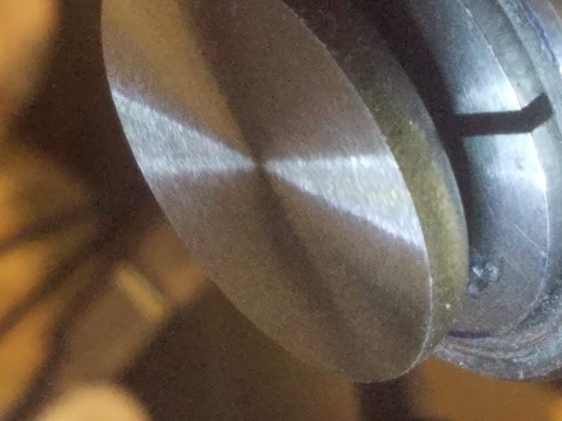

That looks nice. In the last picture it looks finer, I guess you lapped it. The camshaft makers are fanatically adamant about the proper assembly lube and break-in oil, and priming the oil system for first start up.

That is for high revving latter day engines. Yours is 1600 rpm, low spring pressure. Still, I would get some of that camshaft assembly lube.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

ac55tractor wrote:

ac55tractor wrote: