| Author |

Topic Search Topic Search  Topic Options Topic Options

|

SC_MudDuck

Bronze Level

Joined: 24 May 2020

Location: Mullins, SC

Points: 41

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: 1950 B Hydraulic Cylinders Questions Topic: 1950 B Hydraulic Cylinders Questions

Posted: 01 Jun 2020 at 10:13am |

Hello again friends. Took the weekend to work on getting the B up to snuff to run a bush hog (SQ600). As I said in a different post, I have a hydraulic leak directly from the cylinder that needs to be repaired. Started my research, but cannot figure out which cylinders I have as I cannot find a matching 3pt hitch to reference to start comparing.

All the 3pt hitch I have been seeing for sale or on Google Images use 1 cylinder. My setup has 2 under the seat. Do I need both? Is one a drive and the other a slave? What I have been seeing for sale is a 2" x 8" stroke, is that enough? Trying to make a decision to either repack the current cylinders or buy new.

Has anyone else seen this on a B and can make some recommendations? If more information is needed, please let me know and I will get whatever I can.

I look forward to again learning from this massive knowledge base!

|

|

|

Sponsored Links

|

|

|

Larry in NC

Orange Level

Joined: 09 Feb 2016

Location: NC

Points: 1051

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Jun 2020 at 10:29am Posted: 01 Jun 2020 at 10:29am |

|

If you have two mounted cylinders, those are most likely original that were installed to operate two way plows. If this is the case, your tractor has a two position hydraulic control valve. You move the control lever to the right to operate one cylinder and to the left to operate the other. The after market three point hitches normally use one larger cylinder. You do not want two larger volume cylinders because the lift will be very slow. The B has a high pressure, low volume pump.

|

|

SC_MudDuck

Bronze Level

Joined: 24 May 2020

Location: Mullins, SC

Points: 41

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Jun 2020 at 10:37am Posted: 01 Jun 2020 at 10:37am |

Hmmm... That's pretty cool! I didn't know anything about the left to right action, I only used forward (down) and back (up). I'll have to give this a try when I get home.

Do you happen to know what the bore size would be or a part number?

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89941

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Jun 2020 at 1:45pm Posted: 01 Jun 2020 at 1:45pm |

|

the factory B cylinders are something like 1 inch size.. If it leaks at the packing nut on front, just try to tighten it with a pipe wrench another turn... That cylinder runs at 3200 psi so that is a LOT OF LIFT .... The larger 2 inch cylinders are normally rated for 2000 or 2500 psi... You can damage one or blow the packing if you run the higher pressure constantly... AS mentioned, the BIG cylinder takes a lot more oil to fill and will go a lot slower to lift.......... I actually used a cylinder off a CA when i converted by B... i think it is 1.5 inch.. Old WD cylinders are nice also, but kind of long to fit in the space.

|

|

Like them all, but love the "B"s.

|

|

SC_MudDuck

Bronze Level

Joined: 24 May 2020

Location: Mullins, SC

Points: 41

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jun 2020 at 11:35am Posted: 03 Jun 2020 at 11:35am |

Larry in NC wrote: Larry in NC wrote:

If this is the case, your tractor has a two position hydraulic control valve. You move the control lever to the right to operate one cylinder and to the left to operate the other. |

So, there is no left to right on my setup. There is 1 lever on the right hand seat that only moves up and down. How does this affect my setup?

I have on hose going from the cylinder into the control from the same orientation as the cylinder and the other cylinder is attached to the top of the control valve going to the other cylinder. Should my control valve be setup differently?

I also wish there was a way to set the lift so that it stays put.

|

|

SC_MudDuck

Bronze Level

Joined: 24 May 2020

Location: Mullins, SC

Points: 41

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jun 2020 at 11:37am Posted: 03 Jun 2020 at 11:37am |

steve(ill) wrote: steve(ill) wrote:

If it leaks at the packing nut on front, just try to tighten it with a pipe wrench another turn... |

Its pretty tough to tell exactly where the cylinder is leaking at this moment. I will try to take some degreaser and pressure washer to it this weekend to do some looking around.

|

|

SC_MudDuck

Bronze Level

Joined: 24 May 2020

Location: Mullins, SC

Points: 41

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jun 2020 at 11:54am Posted: 03 Jun 2020 at 11:54am |

This is what I see when I look at my hydraulic control lever.

|

|

Larry in NC

Orange Level

Joined: 09 Feb 2016

Location: NC

Points: 1051

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jun 2020 at 11:59am Posted: 03 Jun 2020 at 11:59am |

Yours is single action so the rams would have to work together if they are both hooked up. There would have to be a tee to connect them. Here are are pictures of the dual control.

Edited by Larry in NC - 03 Jun 2020 at 12:03pm

|

|

Bill Long

Orange Level

Joined: 12 Sep 2009

Location: Bel Air, MD

Points: 4556

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jun 2020 at 12:22pm Posted: 03 Jun 2020 at 12:22pm |

What is described above and shown is a control that directs the oil flow to either one or if the control is in the middle to both. As stated that is used for a two way plow whereby you lift one or the other. If you do not have that then check the plumbing to see exactly where the hoses from the rams connect. Also, when you call for lift do both rams expand. If you could post pictures of your system showing the rams and the plumbing so we can see how they are connected. Take good care of my favorite. Good Luck! Bill Long

|

|

SC_MudDuck

Bronze Level

Joined: 24 May 2020

Location: Mullins, SC

Points: 41

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jun 2020 at 7:05pm Posted: 03 Jun 2020 at 7:05pm |

|

|

|

SC_MudDuck

Bronze Level

Joined: 24 May 2020

Location: Mullins, SC

Points: 41

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jun 2020 at 7:08pm Posted: 03 Jun 2020 at 7:08pm |

|

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89941

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jun 2020 at 7:20pm Posted: 03 Jun 2020 at 7:20pm |

You have the standard B hyd pump with the standard single control handle.. Normally for two cylinders you would TEE them together and connect to port 8 coming out the BACK of the valve.. The port 6 on top is to measure the pressure output, but i guess its OK to connect the second hose to it... SEE BELOW....

Yes, everything is VERY DIRTY.. Dont blame the cylinder right off, it could be an old leaking hose or fitting... Pressure wash first, then look............ If your pump/valve is working correctly it should have a HOLD position when you let go of the lever.. If it is just dropping when you let go, then the round cam / spring on the side of the valve is STUCK or the spool inside the pump is STUCK.

Edited by steve(ill) - 03 Jun 2020 at 7:25pm

|

|

Like them all, but love the "B"s.

|

|

SC_MudDuck

Bronze Level

Joined: 24 May 2020

Location: Mullins, SC

Points: 41

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jun 2020 at 7:30pm Posted: 03 Jun 2020 at 7:30pm |

|

Awesome! I’ll give’r a good washing and top her off afterwards and see what we have going on. Maybe tomorrow after work...not very patient, can’t wait for the weekend! THANKS!!!

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89941

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jun 2020 at 7:36pm Posted: 03 Jun 2020 at 7:36pm |

You also have two standard B hydraulic cylinders. Nothing special.. Looks like someone has added a TOP LINK to make a 3 pt system.. I cant see the lower arms or how it is working. Normally the "B" cylinders will operate the rock shaft and arms that are mounted to the back of the seat frame.... i guess you have a couple LOWER ARMS that were added ?

Now i can see the round cam and spring area on your valve / pump... They are buried in CRUD.. that might keep it from working correctly... A good pressure was is in order... If you dont have that, a couple coatings for oven cleaner might work.......... I prefer to chip off everything ( crud) i can with a putty knife, then wash with gasoline and a brush to get deeper.

|

|

Like them all, but love the "B"s.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89941

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jun 2020 at 8:03pm Posted: 03 Jun 2020 at 8:03pm |

Ii dont have a real good photo of a B pump/ valve .... This is an IB so the seat is removed and the final drive housing is rotated... but look at the valve... Normally the HOSE comes out the BACK at a 45 degree angle... and to the side you can see the CAM and SPRING... that has to be FREE and operational if you want the system to HOLD when you let go of the control handle.

|

|

Like them all, but love the "B"s.

|

|

SC_MudDuck

Bronze Level

Joined: 24 May 2020

Location: Mullins, SC

Points: 41

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jun 2020 at 8:50pm Posted: 03 Jun 2020 at 8:50pm |

Thanks Steve, I am picking up what you’re throwing down with that illustration! I will try to take a photo of the lower before leaving for work. You helped me solve the problem of why my hitch didn’t look like any of the others I have seen on images. Crafty solution.  You gotta do what makes sense I reckon!

|

|

SC_MudDuck

Bronze Level

Joined: 24 May 2020

Location: Mullins, SC

Points: 41

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Jun 2020 at 9:03am Posted: 04 Jun 2020 at 9:03am |

I have attached a few photos of the lower lift arms to complete my setup.

|

|

SC_MudDuck

Bronze Level

Joined: 24 May 2020

Location: Mullins, SC

Points: 41

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Jun 2020 at 6:47pm Posted: 04 Jun 2020 at 6:47pm |

After the initial pressure wash.    I have a video I will try to upload if I can figure out how to turn it into a gif. More to come, stay tuned, if you will!

|

|

SC_MudDuck

Bronze Level

Joined: 24 May 2020

Location: Mullins, SC

Points: 41

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Jun 2020 at 7:46pm Posted: 04 Jun 2020 at 7:46pm |

|

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89941

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Jun 2020 at 8:14pm Posted: 04 Jun 2020 at 8:14pm |

Well, that valve looks a lot better... You can see the cam plate moving with the spring when you pull on the lever / arm.... I dont remember " exactly" how far it moves, etc, but your looking better.... Does the 3 point stay up when you let go of the lever now ? ... If not, you might WIGGLE that cam plate and spring a little... even soak it with Penetrant to make sure it is moving free..

Your 3 point is definitely home made... Someone bought a pair of 3 point lower arms and built brackets to bolt them to the final drives... The "upper arms" are home made and probably welded to a cross arm that is like 1-1/4 diameter pipe ? and the cylinders push on brackets attached to that cross arm also ?.... That 1-1/4 diameter pipe / bar is called a ROCK SHAFT.... Cant see the brackets that attach to the seat frame, but about half of the top is FACTORY and heavily modified..

Now find the leak... the HEAD of each cylinder should have a packing nut around the ROD shaft with a HEX nut like 1-1/4 diameter... You can tighten that 1 turn if the leak is around the ROD... If its the HOSE, they probably need replaced.

|

|

Like them all, but love the "B"s.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89941

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Jun 2020 at 8:24pm Posted: 04 Jun 2020 at 8:24pm |

Here is a picture of a FACTORY Rock Shaft setup with dual plows... You can see the ROCK SHAFT as the horizontal bar ( about 1-1/4 diameter) behind the seat... There are brackets on each end that bolt to the seat frame and allow the shaft to rotate.. There are a couple plates welded to the bar that the cylinders push on, and a couple plates that hold the UPPER ARMS .......... the factory setup is NOT a 3 point... It has UPPER ARMS and the LOWER is a BEAM that runs under the tractor and connects under the transmission area... This has been removed on yours and aftermarket 3 point arms made to fit.

|

|

Like them all, but love the "B"s.

|

|

SC_MudDuck

Bronze Level

Joined: 24 May 2020

Location: Mullins, SC

Points: 41

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Jun 2020 at 8:58pm Posted: 04 Jun 2020 at 8:58pm |

|

So, it holds as it did before. Have to find the sweet spot after setting height, but it takes some finagling. Just can’t pull it back, let it go, and it fall into a neutral position. It’s a manual shift to hold.

Watching the video the spring doesn’t compress and the screw above doesn’t seem to do anything. Should it do something and should it compress?

Also, if the cylinder is leaking behind the head, what does that mean?

|

|

SC_MudDuck

Bronze Level

Joined: 24 May 2020

Location: Mullins, SC

Points: 41

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Jun 2020 at 9:03pm Posted: 04 Jun 2020 at 9:03pm |

This becoming very interesting for sure. Knew I didn’t have a museum relic but wish I knew the story behind the mods. Pretty cool ingenuity, wonder when the mods happened? How many revisions were there to the design before completion, etc. I’ll assume it has a PE stamp or some other stamp of compliance!

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89941

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Jun 2020 at 9:24pm Posted: 04 Jun 2020 at 9:24pm |

YEA... Definitely a Professional Job !

You should be able to pull the lever UP and it raise, then LET GO and it pops back to the HOLD position.. You press DOWN if you want it to gravity drop... Normally STICKING in the cam plate / spring area can cause that "finding the sweet spot" .... i have not adjusted one for 10 years.. cant give you good directions now.... but your looking in the right area... You might soak with penetrant and see if that helps any.. If not , maybe someone turned the screw too far ? Turn it 2 turns ( measured) and see what happens.. you can always set it back to where it is now.... Spring can be broken, worn out, no tension, etc... i think the screw and small spring set the RATE or SPEED that the 3 point drops, not IF it drops... Still think you are looking at the BIGGER coil spring, cam, pinned to shaft properly, dragging between the plates, etc..... and in the end it is possible that something is worn slightly inside.

the cylinder ROD goes thru the barrel and then there are 3-4 pieces of packing of the VEE chevron type installed... The HEX nut screws in and compresses that packing.. If it leaks, you MIGHT be able to snug it up... If its 70 years old, it might be brittle and not help...... but leak could be the hose or fittings also.

Edited by steve(ill) - 04 Jun 2020 at 9:34pm

|

|

Like them all, but love the "B"s.

|

|

SC_MudDuck

Bronze Level

Joined: 24 May 2020

Location: Mullins, SC

Points: 41

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Jun 2020 at 8:04am Posted: 05 Jun 2020 at 8:04am |

steve(ill) wrote: steve(ill) wrote:

Normally for two cylinders you would TEE them together and connect to port 8 coming out the BACK of the valve.. The port 6 on top is to measure the pressure output, but i guess its OK to connect the second hose to it... SEE BELOW.... |

Is this the right way connect the hoses? If so, I would prefer to connect them properly such that I get the correct applied work out of the system.

Also, if the working pressure is 3200psi would I need a 4000 psi gauge or just plug port 6? I do like gauges...

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89941

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Jun 2020 at 8:23am Posted: 05 Jun 2020 at 8:23am |

|

"Normally" the hoses are TEE together... Looking at the print of the valve i dont see what it hurts to put one hose on the TEST port.. There does not seem to be a restriction or orifice in that line... but im not sure......i think best to have a TEE off one port..... The GAUGE is not standard, just for a test.. You remove the gauge when done and plug with a small pipe plug... You dont want a gauge to get SMACKED and break off when in the field.

|

|

Like them all, but love the "B"s.

|

|

SC_MudDuck

Bronze Level

Joined: 24 May 2020

Location: Mullins, SC

Points: 41

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Jun 2020 at 11:22am Posted: 05 Jun 2020 at 11:22am |

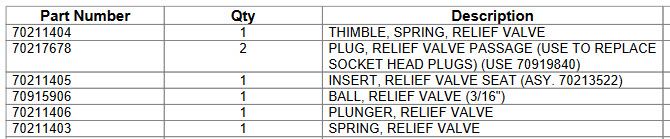

I have tracked down all the AGCO part numbers to turn this back to OEM, but have NO IDEA where to find them for purchase. Any thoughts?

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89941

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Jun 2020 at 1:03pm Posted: 05 Jun 2020 at 1:03pm |

|

there is a CLASSIFIED section on this FORUM... I would post that you have a B tractor and need ............ I dont know if your talking cylinder / rock shaft / or just hoses... NAPA or someone can make the hoses.. You can also buy small hoses at a lot of FARM STORES that have pipe thread ends...... Im sure there are several on this site that have "PARTS" for whatever you need.

|

|

Like them all, but love the "B"s.

|

|

SC_MudDuck

Bronze Level

Joined: 24 May 2020

Location: Mullins, SC

Points: 41

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Jun 2020 at 1:15pm Posted: 05 Jun 2020 at 1:15pm |

Was mainly talking all the parts shown in the schematic for the re-routing the lines with a Tee such as below. These part numbers came from the Agco Parts Book so trying to cross reference them is a little tough. Is there a real need to be this thorough for basically a plug using 1/2" NPT fittings?

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89941

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Jun 2020 at 3:43pm Posted: 05 Jun 2020 at 3:43pm |

|

No....... those parts are internal.. Not coming out.. Take off the hose and screw in a pipe plug with teflon tape to seal it....In the main port, you can run a TEE right off the valve, or run out a foot with a hose, then put a TEE and run each side... 3 hoses.

|

|

Like them all, but love the "B"s.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

Larry in NC wrote:

Larry in NC wrote:

You gotta do what makes sense I reckon!

You gotta do what makes sense I reckon!