| Author |

Topic Search Topic Search  Topic Options Topic Options

|

gman54313

Silver Level

Joined: 23 Nov 2019

Location: Green Bay WI

Points: 66

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Allis B Bearing Size Topic: Allis B Bearing Size

Posted: 21 Dec 2019 at 3:50pm |

I have measured the rod journals and came up with 1.916 the spec says 1.9365 to 1.9375 would it make more sense to go .030 instead of .020? My mains are 2.226 spec is 2.249- 2.250 I believe .030 because .020 doesn't get me there.

|

|

|

Sponsored Links

|

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89196

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Dec 2019 at 4:36pm Posted: 21 Dec 2019 at 4:36pm |

The mains definitely need to be turned .030 .... Why not let the Machinist check the ROUNDNESS of the rod journals and make a decision of they can be used as is, or need turned down another .010 .

.......... .... your still going to use the shim packs on the bearings for adjustment ?

If so, you have several thousandths of adjustment with the shims, as long as the journal is ROUND to start with. .......... you are at .024 clearance so .020 bearings and a shim adjustment "could" get you in the ball park.

Edited by steve(ill) - 21 Dec 2019 at 4:42pm

|

|

Like them all, but love the "B"s.

|

|

gman54313

Silver Level

Joined: 23 Nov 2019

Location: Green Bay WI

Points: 66

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Dec 2019 at 5:02pm Posted: 21 Dec 2019 at 5:02pm |

|

Thanks Steve, You bring up a good point, I forgot to mentioned I had a machinist check it for roundness and I was told all the journals are in spec for roundness.

|

|

Lon(MN)

Orange Level

Joined: 11 Sep 2009

Location: Merrill Wi

Points: 2043

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Dec 2019 at 7:41am Posted: 22 Dec 2019 at 7:41am |

|

I have three crankshafts, machined and ready to go if you are interested. email lselkriver@gmail.com

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22307

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Dec 2019 at 7:53am Posted: 22 Dec 2019 at 7:53am |

|

Look on the backside of each of your old bearing shells and they should be stamped -.020" or -.030" or whatever. They are probably -.020" and the crank is WORN, needing to be reground down to -.030" to accept new smaller brgs. Your Machinist wasn't much help.

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5093

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Dec 2019 at 8:52am Posted: 22 Dec 2019 at 8:52am |

If you decide not to grind the crankshaft and use .020 new bearing shells they would need to be filed as shown in my pictures and properly shimmed to get .002 clearance at the rod straight down after crush. The pictures show how I measured the difference. https://public.fotki.com/DickL/allis_chalmers_engi/filing-main-and-rod/

|

|

gman54313

Silver Level

Joined: 23 Nov 2019

Location: Green Bay WI

Points: 66

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Dec 2019 at 2:27pm Posted: 22 Dec 2019 at 2:27pm |

The rod bearings are all stampedJ745SB20 the mains just stamped FM 67

|

|

Alex09(WI)

Orange Level

Joined: 15 Mar 2012

Location: CECIL WI

Points: 1768

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 22 Dec 2019 at 2:43pm Posted: 22 Dec 2019 at 2:43pm |

Your rod bearings shoudl be good to go with new .020 bearings. The mains you could keep at .020 BUT it all depends on what the wear is like on the journals now. If they are feel uneven with the end of your finger, they should be ground. I they are scored around the circumference of the jounal, they should also be ground. If they are nice and smooth then I would think you could put .020 bearings in and get the proper clearance with removing a shim or 2.

Some bearings are not stamped with the size, such as your mains, but your rods are .020 from the -SB20 suffix of the bearings. Other time bearings are inked with the size and the ink will come off from being in the engine.

|

|

www.awtractor.com

A&W TRACTOR 920-598-1287

KEEPING ALLIS-CHALMERS IN THE FIELDS THROUGH THE 21ST CENTURY

|

|

gman54313

Silver Level

Joined: 23 Nov 2019

Location: Green Bay WI

Points: 66

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Dec 2019 at 8:53pm Posted: 22 Dec 2019 at 8:53pm |

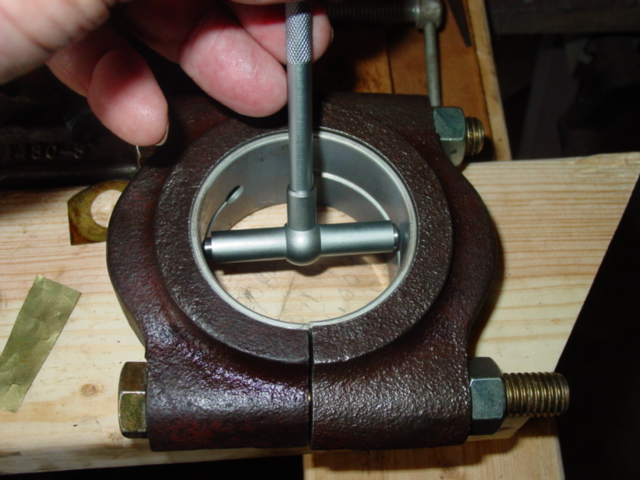

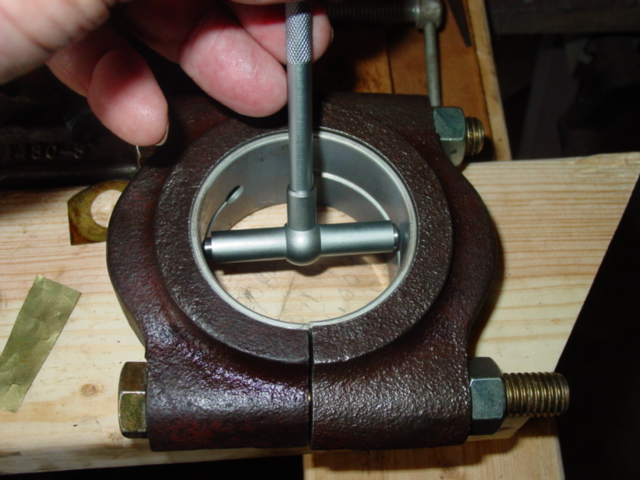

Alex, thank you for your input the pic below is of my main all three look pretty much the same, If I remove a shim or two I believe I would have to file the bearing shell correct?

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5093

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 23 Dec 2019 at 6:56am Posted: 23 Dec 2019 at 6:56am |

The first picture at the link is where you check for end play. That is between the crankshaft timing gear and the side of the first main journal. The clearance here is a minimum of .0015. The gear is moved in to correct this space by the crankshaft grinder when grinding the crankshaft inside surface where the thrust shell rides. https://public.fotki.com/DickL/allis_chalmers_engi/filing-main-and-rod/

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)