| Author |

Topic Search Topic Search  Topic Options Topic Options

|

wjohn

Orange Level

Joined: 19 Jan 2010

Location: KS

Points: 2165

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Gleaner Concave Bar Offset Hole Direction Topic: Gleaner Concave Bar Offset Hole Direction

Posted: 14 May 2025 at 9:52pm |

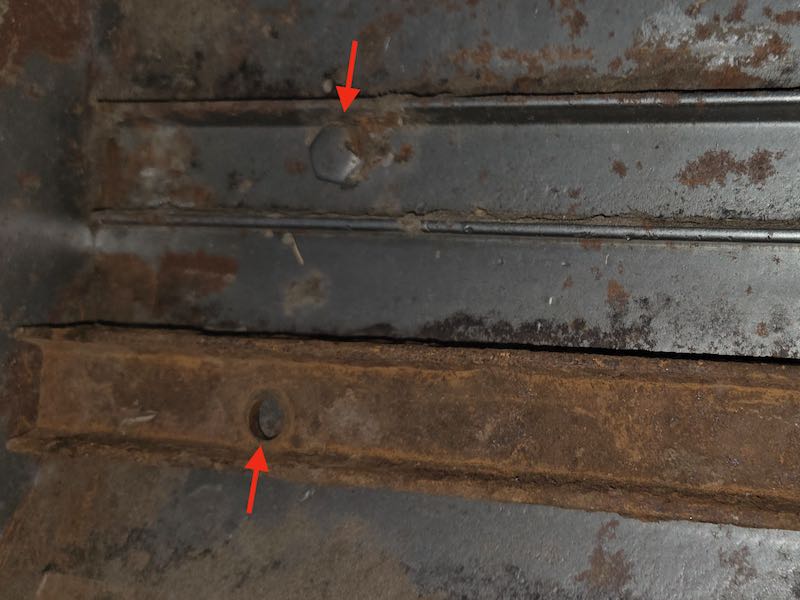

On the older gleaners with the bolt-in channel style concave bars, does it matter which direction they're installed? The holes are offset to one side.

The concave on the door looks like it only clears some nearby screw heads by flipping it one direction, so I am planning on carrying that over to the other concaves. My CII manual says nothing about it so it must not be important?

Picture of one concave one direction, and the other concave with the holes opposite.

|

|

1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45

|

|

|

Sponsored Links

|

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 21442

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 May 2025 at 9:59pm Posted: 14 May 2025 at 9:59pm |

|

Short side forward so the channel doesn't get lifted up off the floor.

|

|

tbran

Orange Level

Joined: 14 Sep 2009

Location: Paris Tn

Points: 3490

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 hours 23 minutes ago at 8:30am Posted: 19 hours 23 minutes ago at 8:30am |

|

They look a tad worn... From the factory they had 5 concaves - for hard to thresh crops - we always pulled #2 and #5 out for corn and soybeans. The beauty of the conventional Gleaner - can run 1 2 3 4 or 5 bars depending on degree of threshing needed. CII and M/M2 same cylinder.

|

|

When told "it's not the money,it's the principle", remember, it's always the money..

|

|

wjohn

Orange Level

Joined: 19 Jan 2010

Location: KS

Points: 2165

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 5 hours 49 minutes ago at 10:04pm Posted: 5 hours 49 minutes ago at 10:04pm |

DrAllis wrote: DrAllis wrote:

Short side forward so the channel doesn't get lifted up off the floor. |

That logic makes sense. I can't do that with the one on the rock door though due to clearance to the nearby screws (picture below). I will flip the other ones on the concave door the way you describe.

|

|

1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 21442

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 5 hours 41 minutes ago at 10:12pm Posted: 5 hours 41 minutes ago at 10:12pm |

|

Cut off the concave ends just enough so you can. You do not want to run them backwards

|

|

wjohn

Orange Level

Joined: 19 Jan 2010

Location: KS

Points: 2165

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 5 hours 32 minutes ago at 10:21pm Posted: 5 hours 32 minutes ago at 10:21pm |

tbran wrote: tbran wrote:

They look a tad worn... From the factory they had 5 concaves - for hard to thresh crops - we always pulled #2 and #5 out for corn and soybeans. The beauty of the conventional Gleaner - can run 1 2 3 4 or 5 bars depending on degree of threshing needed. CII and M/M2 same cylinder. |

They are slightly worn. I got a set of 5 new ones from my dealer and mine are down a good 1/16" or so, but the owner/manager said they still had life in them and I should just run them.

They're chewed up in a few spots from rocks too. The owner of the combine before me had concaves 3, 4, and 5 in... Nothing on the rock door, so it probably wasn't kicking open as often as it should and the rest of the concaves took the brunt of it when he was combining soybeans. I'm putting them back in the 1, 3, and 5 positions since a few guys around here have said they don't have issues with wheat left in heads, and then they leave can just use the 1,3, and 5 positioning for soybeans. If it doesn't work out I'll have to install the new set of 5. I assume mixing and matching new/worn concave bars wouldn't be ideal with the varying cylinder clearance.

|

|

1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45

|

|

wjohn

Orange Level

Joined: 19 Jan 2010

Location: KS

Points: 2165

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 5 hours 31 minutes ago at 10:22pm Posted: 5 hours 31 minutes ago at 10:22pm |

DrAllis wrote: DrAllis wrote:

Cut off the concave ends just enough so you can. You do not want to run them backwards |

Interesting and thanks for the insights. I can probably take just enough off of the corner with a grinder to clear the screw heads.

|

|

1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

DrAllis wrote:

DrAllis wrote: