| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Braswell

Bronze Level

Joined: 14 Feb 2024

Location: North Carolina

Points: 16

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: 7gb track loader fuel timing 3500 engine Topic: 7gb track loader fuel timing 3500 engine

Posted: 28 Feb 2024 at 5:55am |

|

I have the 3500 engine, can anyone tell me what the injection timing should be . I need a service manual if anyone has one forsale .. my loader has one top track roller thanks!!

Drbraswell@triad.rr.com

|

|

|

Sponsored Links

|

|

|

DMiller

Orange Level Access

Joined: 14 Sep 2009

Location: Hermann, Mo

Points: 29492

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Feb 2024 at 8:56am Posted: 28 Feb 2024 at 8:56am |

These engines did not have an advance system, the Stanadyne Pump has a small rectangular cover to the side held by two screws, get the Crankshaft damper slot aligned to the front cover pin and the timing line inside that pump window case edge should be set to the associated mark on the rotating member. If the line in the pump does not show will have to rotate the engine one full turn as are 180 degrees out. If does not line up then loosen the mount nuts, and rotate the pump case until does.

3500 is common to many Allis tractors and all have the Stanadyne Roosa Master style pump.

Edited by DMiller - 28 Feb 2024 at 8:59am

|

|

Braswell

Bronze Level

Joined: 14 Feb 2024

Location: North Carolina

Points: 16

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Feb 2024 at 9:41am Posted: 28 Feb 2024 at 9:41am |

|

Mr. DMiller… thanks for your response!!!

This engine has two timing pointers and that’s where I’m a little stumped. The only manual I have is for a genset showing 24 deg. BTDC as a beginning of injection. I’m hoping for someone with a manual that will show injection timing for a track loader with the 3500 inline 6 turbo engine. I’m guessing it’s 10-14 degrees BTDC but I would like to know what the book says. I have not been able to locate a manual (so far) on this track loader with this engine. THANKYOU for your response is an understatement!!

Randy from the Tarheel State (NC)

|

|

Braswell

Bronze Level

Joined: 14 Feb 2024

Location: North Carolina

Points: 16

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Mar 2024 at 6:23am Posted: 01 Mar 2024 at 6:23am |

|

Mr.Miller,

Do you have a book that shows the degree injection begins. The only book I can find on this 3500 is for a generator application. Mine is in a track loader. Oddly this engine has two pointers on the front cover and the pointer cast in the front cover (shown in this book) is not correct for this application because, set by the book, the intake valve is still open at the beginning of injection (24deg.btdc) I stumbled on this and this is why they have not been able to crank this engine without a lot of ether. The other pointer is the one accurate at TDC but so far I can find a book that shows this one and the correct injection timing btdc. This is a good one for shop class !!!

|

|

AC Mel

Orange Level Access

Joined: 23 Jan 2010

Location: N.Ca.

Points: 1099

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 01 Mar 2024 at 10:24am Posted: 01 Mar 2024 at 10:24am |

Randy....This is out of the service manual for the 3500 engine in the 7GB.....i have not studied it.

|

|

DMiller

Orange Level Access

Joined: 14 Sep 2009

Location: Hermann, Mo

Points: 29492

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Mar 2024 at 10:42am Posted: 01 Mar 2024 at 10:42am |

|

Even on my 180 or the several other of this type engine have looked at, none had two Timing Cover pointers. Something seems amiss.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 19508

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Mar 2024 at 6:13pm Posted: 01 Mar 2024 at 6:13pm |

|

Let's try and help you with some insight. IF, your pump is currently timed at 24 degrees BTDC (which is a COMMON number for a 3500 mark 2 engine) and has been running just fine for years, THAT IS CORRECT AND DO NOT THINK ABOUT CHANGING IT FROM THAT SETTING !! I could find you specs from a service manual for 24 degrees and if for some reason the inj pump was ever overhauled, it may now be timed at 16 or 18 degrees because of an update to the inj pump. Sooo, you think it should be at 24 degrees (as per the book) and change it ??? you will burn all six pistons doing this. Whatever it is LEAVE IT ALONE !! Pump timing doesn't "change" itself or EVER need to be altered !!!!

|

|

woynpoint

Bronze Level

Joined: 27 Feb 2024

Location: Antalya

Points: 1

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Mar 2024 at 12:15am Posted: 02 Mar 2024 at 12:15am |

Thanks for information

Edited by woynpoint - 02 Mar 2024 at 12:16am

|

|

Braswell

Bronze Level

Joined: 14 Feb 2024

Location: North Carolina

Points: 16

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Mar 2024 at 4:48pm Posted: 02 Mar 2024 at 4:48pm |

|

THANKYOU for the responses. Somethings is “amiss” for sure!! I recently purchased this machine, it did run but they used a significant amount of either to get it started . Using that mark set on 24 deg. BTDC I noticed the intake valve still open. I removed the radiator to get a better look and found another factory pointer and this pointer is correctly pointing to TDC whereas the other one is not. They were frustrated with it after pulling the pump multiple times as how I ended up with it. I can get all the marks to line up but I’m at 14 degrees BTDC so I was hoping for a book to support my efforts before reinstalling the pump/lines

Thanks for talking to me about it….

PS .. I have the 3500mark11 book and it says it’s for a “generator drive engine”

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 19508

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Mar 2024 at 5:32pm Posted: 02 Mar 2024 at 5:32pm |

|

It is probably a 16 degree engine. What is the inj pump full number?? DM4 629 XXXXX

|

|

Braswell

Bronze Level

Joined: 14 Feb 2024

Location: North Carolina

Points: 16

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Mar 2024 at 6:13am Posted: 03 Mar 2024 at 6:13am |

|

DCGF0631-4GR

A note: the gentleman I purchased this loader from sent the pump off for resealing etc. and also the injectors he purchased new somewhere. The injectors were set at 4000 psi opening and I had the fuel shop lower them to 3100 psi.

Thanks for the responses!!!

|

|

AC Mel

Orange Level Access

Joined: 23 Jan 2010

Location: N.Ca.

Points: 1099

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Mar 2024 at 3:18pm Posted: 03 Mar 2024 at 3:18pm |

Ok.....Just a follow up on my earlier post....I did finally stop and read it....looks pretty simple to me. It's either 22 degrees or 24 degrees depending on the engine serial number

|

|

Codger

Orange Level

Joined: 23 Dec 2020

Location: Illinois

Points: 1785

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Mar 2024 at 6:19pm Posted: 03 Mar 2024 at 6:19pm |

|

|

|

A career built on repairing and improving engineering design deficiencies, shortcomings, and failures over 50 years now.

|

|

Braswell

Bronze Level

Joined: 14 Feb 2024

Location: North Carolina

Points: 16

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Mar 2024 at 5:26am Posted: 04 Mar 2024 at 5:26am |

|

Thank you so much for taking time to send me this!!!!

Have you ever seen on of these engines with 2 timing pointers, one cast in the front cover on the left side of the front pully and one bolted on the front cover on the right side of the pully. I’ve confirmed the right side pointer to be accurate with TDC mark on the pully

|

|

Braswell

Bronze Level

Joined: 14 Feb 2024

Location: North Carolina

Points: 16

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Mar 2024 at 6:34am Posted: 04 Mar 2024 at 6:34am |

|

Can you call me about this machine??? You obviously have a deeper understanding of this unit than anyone I’ve found so far. I’m in North Carolina

336-451-5881

Thanks Randy

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 19508

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Mar 2024 at 8:15am Posted: 04 Mar 2024 at 8:15am |

|

A model "DC" pump would never have been a 16 degree pump, but 24 degrees is all I ever remember. 4000 psi on the injectors is insane. 2800 psi on injectors is better yet for starting.

|

|

Braswell

Bronze Level

Joined: 14 Feb 2024

Location: North Carolina

Points: 16

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Mar 2024 at 7:37pm Posted: 04 Mar 2024 at 7:37pm |

|

Gentlemen, I’m grateful for all the input!!! Today after many attempts I have reinstalled the pump @24dbtdc, the marks in the pump window aligned and my back is give out. I did use the pointer on the right side of the crank pully… right or wrong I’m putting the lines back on and going to find out.

Many thanks again for all y’all’s efforts!!

Randy from N.C.

|

|

AC Mel

Orange Level Access

Joined: 23 Jan 2010

Location: N.Ca.

Points: 1099

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Mar 2024 at 11:34am Posted: 11 Mar 2024 at 11:34am |

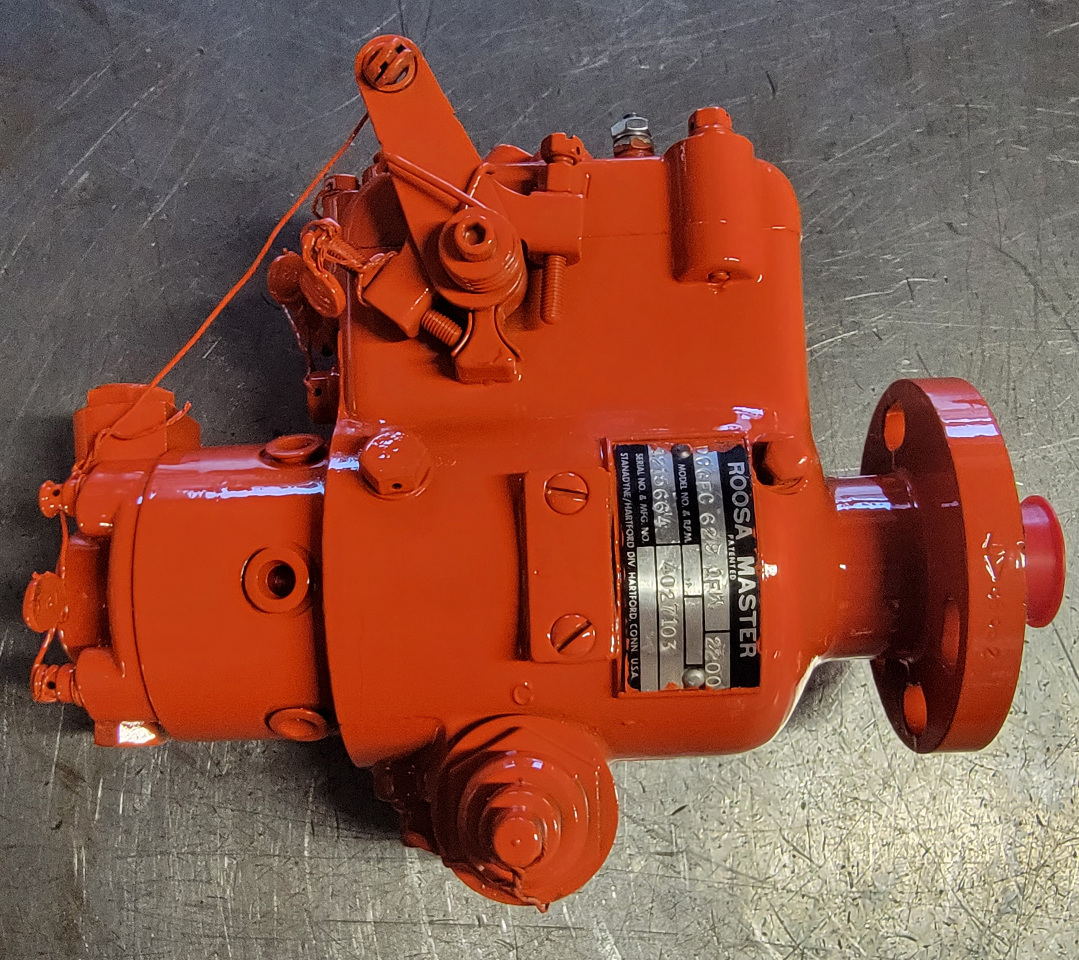

Ok....Been talking....texting..and emailing with Randy...he got the tractor running...I sent him links to the necessary parts and service manuals on ebay. He was struggling with pictures to post....so he text them to me ...I resized them ..hoping they will work...looks like a nice specimen. He could jump in now and answer question..or comment.

|

|

Codger

Orange Level

Joined: 23 Dec 2020

Location: Illinois

Points: 1785

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Mar 2024 at 12:19pm Posted: 11 Mar 2024 at 12:19pm |

|

Really needs the missing fastener in the Roosa-Master pump flange.

|

|

A career built on repairing and improving engineering design deficiencies, shortcomings, and failures over 50 years now.

|

|

Braswell

Bronze Level

Joined: 14 Feb 2024

Location: North Carolina

Points: 16

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Mar 2024 at 12:42pm Posted: 11 Mar 2024 at 12:42pm |

|

Very observant Mr. Codger!!!!

There are only two trades holes in the pump adapter , I thought the same…

|

|

Braswell

Bronze Level

Joined: 14 Feb 2024

Location: North Carolina

Points: 16

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Mar 2024 at 12:44pm Posted: 11 Mar 2024 at 12:44pm |

|

Sorry, I meant threaded holes,

|

|

Codger

Orange Level

Joined: 23 Dec 2020

Location: Illinois

Points: 1785

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Mar 2024 at 2:35pm Posted: 11 Mar 2024 at 2:35pm |

That would be the first two fastener mounting for the Roosa-Master style pumps I've seen and I've been around a lot of them; though not Allis-Chalmers in design

I'd wager you are correct in the two fastener mounting scenario. I've never seen a flange with the four mounting holes/slots in the past. All have been the three slots only. This pump is for a 3500 Allis engine and you can plainly see the 180 degrees opposed mounting slot:

Edited by Codger - 11 Mar 2024 at 2:50pm

|

|

A career built on repairing and improving engineering design deficiencies, shortcomings, and failures over 50 years now.

|

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 50528

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Mar 2024 at 4:36pm Posted: 11 Mar 2024 at 4:36pm |

One thing that stands out in the pump picture on the tractor is the soft copper line with the kink in the line. Should have a rubber fuel line there to keep the lines from rubbing a hole in each other...

|

|

Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need!

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)