| Author |

Topic Search Topic Search  Topic Options Topic Options

|

HudCo

Orange Level

Joined: 29 Jan 2013

Location: Plymouth Utah

Points: 4051

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: d15 series ii three point on series i d17 Topic: d15 series ii three point on series i d17

Posted: 03 Oct 2025 at 1:24pm |

|

i have a d15 17278 sn at the shop to re pack some loader cylinders and was looking at the factory three point hitch has any one tryed putting that setup on the d17

Edited by HudCo - 03 Oct 2025 at 1:34pm

|

|

|

Sponsored Links

|

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22569

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Oct 2025 at 2:51pm Posted: 03 Oct 2025 at 2:51pm |

|

Some things to consider: #1. A 4500 lb D-15 series 2 can destroy one of those category 1 hitches if used heavily. How long would it last on a 5500 lb D-17 ?? #2. I think the torsion bar and draft arms would bolt right on, but how do you intend to get the splined lift arms off the splined shaft?? You could remove the lift arm housing and remove both shafts with the lift arm still attached, I guess. It would mean removing the lift arm housing on both tractors to get it done.

|

|

Tracy Martin TN

Orange Level Access

Joined: 11 Sep 2009

Location: Gallatin,TN

Points: 10889

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Oct 2025 at 9:09pm Posted: 03 Oct 2025 at 9:09pm |

|

The D10,D12 and D15 3 point hitches were too light!The mounting bolts were placed incorrectly. JMHO, Tracy

|

|

No greater gift than healthy grandkids!

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 5400

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Oct 2025 at 11:00am Posted: 04 Oct 2025 at 11:00am |

|

Dad pulled a heavy Oliver 3 bottom plow with his series II D15 for over 30 years and never had issues with the 3 point lift. Staying within the limits of the 46hp tractor or any tractor for that matter, is key to not overloading it causing breakage. Working outside of its designed load is asking for problems. Dad’s D15 sees a lot of 3 point work till this day on our farm, mainly sickle mower and blade work. Other than the garden it hasn’t plowed for 20 years.

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

Tracy Martin TN

Orange Level Access

Joined: 11 Sep 2009

Location: Gallatin,TN

Points: 10889

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Oct 2025 at 5:33pm Posted: 04 Oct 2025 at 5:33pm |

|

AC720Man, only one in existence then, my apologies! Tracy

|

|

No greater gift than healthy grandkids!

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 5400

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Oct 2025 at 7:38pm Posted: 04 Oct 2025 at 7:38pm |

|

I guess we should feel lucky, but again we don’t abuse our equipment. No hurt feelings here.

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

Tracy Martin TN

Orange Level Access

Joined: 11 Sep 2009

Location: Gallatin,TN

Points: 10889

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Oct 2025 at 8:08pm Posted: 04 Oct 2025 at 8:08pm |

|

We don't abuse equipment ever! They were a piss poor design from the get go. Crawl under one and study the mounting holes, you will see what I mean! Tracy

|

|

No greater gift than healthy grandkids!

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22569

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Oct 2025 at 7:54am Posted: 05 Oct 2025 at 7:54am |

|

Don't know if this still exists or not, but years ago you could always purchase Ford/Massey lower 3-point hitch draft arms at your local Tractor Supply. Why ??? I guess because they frequently broke !!

|

|

PaulB

Orange Level

Joined: 12 Sep 2009

Location: Rocky Ridge Md

Points: 5226

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Oct 2025 at 11:08am Posted: 05 Oct 2025 at 11:08am |

DrAllis wrote: DrAllis wrote:

Don't know if this still exists or not, but years ago you could always purchase Ford/Massey lower 3-point hitch draft arms at your local Tractor Supply. Why ??? I guess because they frequently broke !! |

Look closely at my ad in the classified of used and NOS parts. There is a pair of Ford type lift arm and pull arms that I acquired on a tractor that I got with a cobbled up 3pt. They will soon be heading back to China unless someone wants them first.

Edited by PaulB - 05 Oct 2025 at 7:00pm

|

|

If it was fun to pull in LOW gear, I could have a John Deere.

Real pullers don't have speed limits.

If you can't make it GO... make it SHINY

|

|

Leadoff

Silver Level

Joined: 14 Oct 2016

Location: Calgary

Points: 309

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Oct 2025 at 3:03pm Posted: 05 Oct 2025 at 3:03pm |

D15 TPH Owners/Commenters

I would like to cast my vote/opinion on this very interesting topic..........

We operated a D15 Series II (factory TPH) from 1967 (new) on our 100 milking cow/600 acre dairy farm to 1981 when it was traded in on a new Ford 7700. It joined a D17 Series I and Ford 8n, and later in 1975 a 185.

The D15 took over a lot of the Ford 8n TPH duties adding a bit mor HP/weight. The D17 could not help out because of Snap Coupler !!!!!!!!! The 185 was a great transition to heavier TPH duties over time

1. The D15 will always be IMHO one of the best tractors ever 2. The TPH worked fine for plowing, blade work, snow blower, all well within the allowable limits of the design - never an issue. 3. The Drawbar cast iron support (unique to TPH option) broke when we overloaded the drawbar tongue allowable weight and we replaced the broken cast iron support with a new part and installed additional support bars up to the Top Link connection to prevent failure again. The root cause of the failure was too much weight on the drawbar - the four bolts holding the support to the tractor rear area were solid tight. An excellent thread on the cast iron Drawbar saga if you are interested

Numerous times I have visitors look at my humble collection (see below) and ask if the D15 would be available for sale - of course the answer is always no!! The other tractors are in great shape, but the D15 is almost always the one favored

PS - a fabricated steel Drawbar support vs cast iron would have been stronger - reciprocating/vibratory loading on the four bolts holding the TPH assembly not good, maybe not best application for larger recip machines like Bush Hog etc - TPH lift arms very similar to Ford 8n

Hope this adds some interesting perspective to the discussion

|

|

1963 D17D Series III. 1965 D15 Series II. 1965 D17 Series IV. 1975 185. 1978 716H. 1979 716H. 1965 780 Harvester/1R&DC. 1957 Model 73 SC 4 Furrow Plow

|

|

HudCo

Orange Level

Joined: 29 Jan 2013

Location: Plymouth Utah

Points: 4051

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Oct 2025 at 7:16pm Posted: 05 Oct 2025 at 7:16pm |

|

thats whats bad about all these three point hitches that mount to thoes four bolts on the rear end and lift houseing that is just not much to be pulling from on those lift arms my d17 that i am rebiulding right now has to have the lift arm housing replaced from the bolts being striped out on is already a 1inch bolt the wd wd45 arnot any differant and atleast be tied into the snap coupler bolts and only thing that was ever hooked to my d17 lift arms was a two bottom rollover snap coupler plow

|

|

Gary Burnett

Orange Level Access

Joined: 11 Sep 2009

Location: Virginia

Points: 3164

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Oct 2025 at 9:12pm Posted: 05 Oct 2025 at 9:12pm |

|

Most of the problems on the D15 3pt comes from the bolts holding the main bracket in the housing getting loose and wallowing out.Here is how I solved the problem.Two of the bolts in a D15 out of the 4 had some play so I took all the bolts out and dropped the housing.Come the find out the housing has a little over 2 inches of threads but AC for some reason only put 1 inch bolts to hold the housing.So I ordered 4 grade 8 all thread rods from McMaster Carr,cleaned up the threads real good,covered the all thread rods in Red Loctite.Nothing moves at all.Used self locking nuts with a couple grade 8 flat washer to secure the housing nothing ever moved and I checked the nuts from time to time but they never needed any more tightening.

|

|

Leadoff

Silver Level

Joined: 14 Oct 2016

Location: Calgary

Points: 309

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Oct 2025 at 10:31pm Posted: 05 Oct 2025 at 10:31pm |

Gary Burnett

An excellent solution. Thank-you for sharing

|

|

1963 D17D Series III. 1965 D15 Series II. 1965 D17 Series IV. 1975 185. 1978 716H. 1979 716H. 1965 780 Harvester/1R&DC. 1957 Model 73 SC 4 Furrow Plow

|

|

Jordan(OH)

Orange Level

Joined: 11 Sep 2009

Location: Celina, OH

Points: 1579

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Oct 2025 at 3:36am Posted: 06 Oct 2025 at 3:36am |

DrAllis wrote: DrAllis wrote:

Don't know if this still exists or not, but years ago you could always purchase Ford/Massey lower 3-point hitch draft arms at your local Tractor Supply. Why ??? I guess because they frequently broke !! |

And those broke all the time because they weren’t spring steel like the originals.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22569

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Oct 2025 at 6:21am Posted: 06 Oct 2025 at 6:21am |

|

But, the originals must have broke too !!! That's why they were so easily purchased in the after-market world.

|

|

DSeries4

Orange Level

Joined: 12 Sep 2009

Location: Ontario, Canada

Points: 7600

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Oct 2025 at 3:00pm Posted: 06 Oct 2025 at 3:00pm |

|

The D15 3 points were too weak from the factory. Hard to find one that hasn't been welded up. Putting one on a D17 would kill it in no time!

Lots of good quality aftermarket 3 point assemblies out there. That's the route I would go if I needed one.

|

|

'49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22569

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Oct 2025 at 3:29pm Posted: 06 Oct 2025 at 3:29pm |

|

I'm going from memory here, but I'd say those four 3/4" bolts are about 8 inches wide c to c. But, the torsion bar bracket (the one that loosens up or breaks) must be 18 to 20 inches wide. All the push or pull from the draft arms get transmitted into that torsion bar bracket twisting it and jamming it and trying to loosen it because the mounting bolts are so far from the end where the shock is coming from. A steel bracket versus cast would have been nice. Bolts/studs long enough to utilize the full thread hole depth would have been nice. A couple of simple braces from each end of the torsion bar bracket going forward to the snap coupler bell 3/4" bolts mounting holes would have been really nice.

|

|

Leadoff

Silver Level

Joined: 14 Oct 2016

Location: Calgary

Points: 309

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Oct 2025 at 12:59pm Posted: 11 Oct 2025 at 12:59pm |

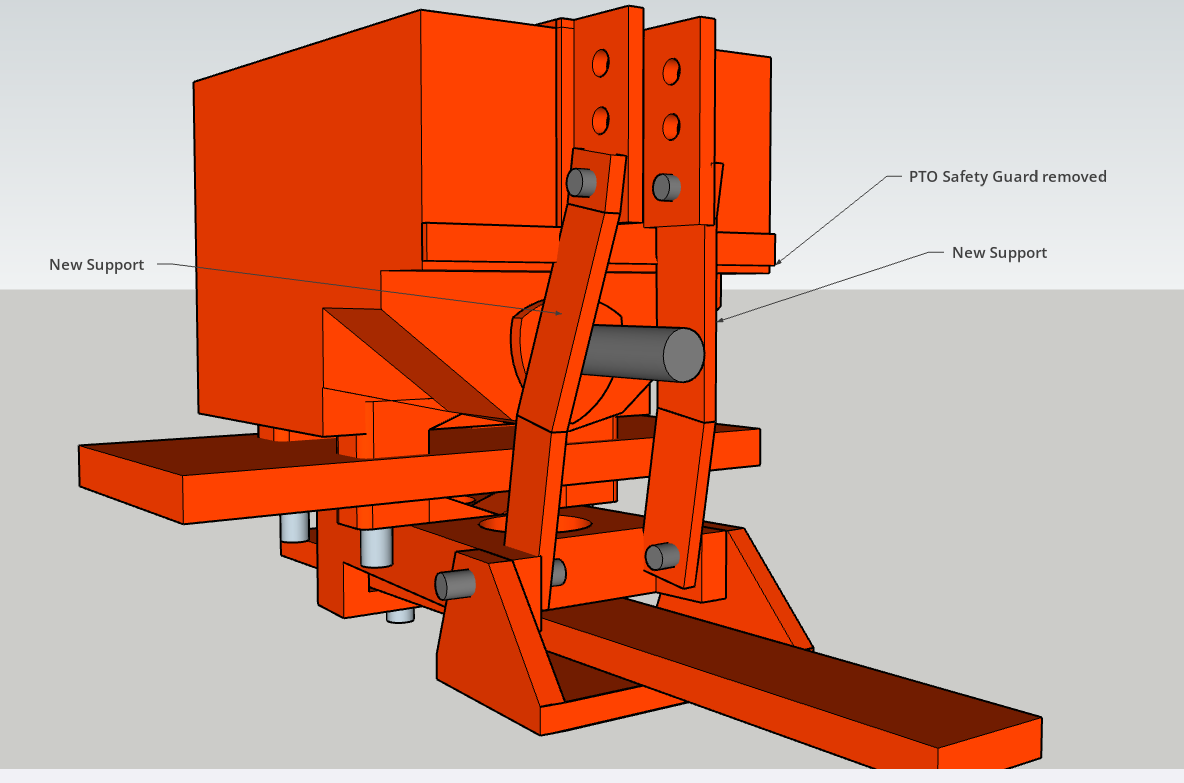

D15 Series II factory TPH Drawbar

Here is an improvement to the Drawbar support we implemented on our D15 II after overloading with the manure spreader, the rear tractor wheel hit a pothole shocking the system and breaking one of the four mounting feet that bolt up into the main frame. We replaced the broken main support with a new factory part (back in mid 1970's when parts were available) and added the support bars shown below

The improvement worked for many years after - solved our overload problem

Key Notes: - not to scale, drawn from memory, basic model to show new supports location - new support bars 1/2" thickness, regular carbon steel - PTO Guard removed (cut out new support bar opening and reinstall if desired) - new support bars need to be very tight fit, to carry load - no slack in holes/bolts - support bar bends required to allow access to PTO

Hope this helps some D15 owners

PS there are several excellent Drawbar Support design solutions available. This one was very simple, we did it ourselves on the farm, and it worked!!!!

|

|

1963 D17D Series III. 1965 D15 Series II. 1965 D17 Series IV. 1975 185. 1978 716H. 1979 716H. 1965 780 Harvester/1R&DC. 1957 Model 73 SC 4 Furrow Plow

|

|

HudCo

Orange Level

Joined: 29 Jan 2013

Location: Plymouth Utah

Points: 4051

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Oct 2025 at 3:39pm Posted: 11 Oct 2025 at 3:39pm |

|

|

|

HudCo

Orange Level

Joined: 29 Jan 2013

Location: Plymouth Utah

Points: 4051

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Oct 2025 at 3:43pm Posted: 11 Oct 2025 at 3:43pm |

|

cant see the draw bar good, arms off of a case

|

|

Leadoff

Silver Level

Joined: 14 Oct 2016

Location: Calgary

Points: 309

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Oct 2025 at 4:43pm Posted: 11 Oct 2025 at 4:43pm |

HudCo

You developed a very substantial design, and has done the job for a very long time

Congratulation on a low cost, effective solution

|

|

1963 D17D Series III. 1965 D15 Series II. 1965 D17 Series IV. 1975 185. 1978 716H. 1979 716H. 1965 780 Harvester/1R&DC. 1957 Model 73 SC 4 Furrow Plow

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

DrAllis wrote:

DrAllis wrote:

this is what i biult on on my wd about twenty five years ago its had alot of heavy loads on the three point and drawbar

this is what i biult on on my wd about twenty five years ago its had alot of heavy loads on the three point and drawbar