| Author |

Topic Search Topic Search  Topic Options Topic Options

|

McGatha185

Bronze Level

Joined: 10 Nov 2016

Location: Missouri

Points: 48

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Allis 185 Priming and Starting Topic: Allis 185 Priming and Starting

Posted: 10 Nov 2016 at 4:47pm |

Hey guys, thanks for helping. So here's the problem. I have a 1970 Allis 185 Crop Hustler. I've been beating my way through college and finally graduated this last spring, so now I'm finally starting to come back to life, and do some work around the farm, but it's been awhile since I started this tractor. I had 20 gallons of fuel in it with conditioner so it wouldn't go bad. It didn't go bad, it just isn't there anymore. It all leaked out. I didn't have the valve turned off at the sediment bowl and the priming pump was worn out, so it leaked around the priming pump and drained the entire system.

So trying to get it started, I have cleaned the sediment bowl, put on a new fuel filter filled with new fuel, I put new fuel in the tank and made sure the lines were clear. I then bought a new priming pump since mine would squirt back at me every time I pumped it... it works good now. I pumped the living crap out of it, making sure nothing but fuel is coming out of the petcock on the fuel filter, and only fuel is coming out of the feed line to the fuel pump. I pumped some more, making sure my throttle was set all the way open, and I pulled the timing plate from the fuel injector pump to make sure fuel was dripping good. All is well so far. I've never needed more than this for it to start, but it just won't. So I tried to loosen the feed line nuts on the injectors. Problem with this is that this dog has an old type of coupling system (??Ernesto...Ermesto...something like this??) that sticks hard. You need to pull them loose. I could only get two to pull loose while the rest wouldn't budge, and I was starting to bend the fuel lines trying! I even shot it down with blaster to try and loosen them up.

I pumped a ton more on it. Over a 1000 times and it still won't even try to hit. I never seen a drip come from the injector lines. I even had a friend hold an air nozzle in the fuel tank with a rag around it to artificially pressurize the system, and hopefully push some fuel through it. Didn't work. This was running just fine when I shut it down last. It should start! The engine turns free and nice. What else can I do? I've read several threads talking about this same subject but they're always for 160's or 175's and never quite relate to my fuel injection system. At least they don't seem to relate when I try to find what's being talked about. My dad used to own a 180 and the only time it didn't start the local mechanic used a shringe of diesel fuel and manually shot fuel into the injectors. Is that a way? How about taking loose the fuel return line so the air can pump out? I don't know. Maybe my throttle is stuck shut. I just don't know. Please help!!!

|

|

|

Sponsored Links

|

|

|

McGatha185

Bronze Level

Joined: 10 Nov 2016

Location: Missouri

Points: 48

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Nov 2016 at 4:54pm Posted: 10 Nov 2016 at 4:54pm |

Reading back through this, I want to point out for those who might misunderstand that I loosened the retaining nuts holding the fuel lines into the injectors, but the lines themselves will not pull out of the injector bodies. I could feel a slight pop when I pulled on two of these lines and they moved a tiny bit, indicating they came loose. The other four are stuck fast in the injectors, and I'm afraid of the damage I'll do trying to force them out. I'd hate to make a big problem out of a little one.

Thanks for helping!

|

|

injpumpEd

Orange Level Access

Joined: 13 Sep 2009

Location: Walnut IL

Points: 5156

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Nov 2016 at 5:32pm Posted: 10 Nov 2016 at 5:32pm |

|

most likely the pumping plungers in the pump are gummed up and stuck. If this is the case, the pump will need to be serviced, and for best results, the injectors also. I've seen this over and over. Today's fuel does not do well when left to sit.

|

|

210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers!

|

|

Tracy Martin TN

Orange Level Access

Joined: 11 Sep 2009

Location: Gallatin,TN

Points: 10875

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Nov 2016 at 6:50pm Posted: 10 Nov 2016 at 6:50pm |

|

Are you sure you have the fuel shut off out?

|

|

No greater gift than healthy grandkids!

|

|

McGatha185

Bronze Level

Joined: 10 Nov 2016

Location: Missouri

Points: 48

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Nov 2016 at 7:06pm Posted: 10 Nov 2016 at 7:06pm |

|

Yeah, I've opened it up. Every time I use the priming pump I can see the sediment in the bottom of the bowl stir up.

|

|

critter

Silver Level Access

Joined: 13 Nov 2013

Location: Ohio

Points: 254

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Nov 2016 at 7:54pm Posted: 10 Nov 2016 at 7:54pm |

Tracy Martin TN wrote: Tracy Martin TN wrote:

Are you sure you have the fuel shut off out? |

I think he meant the pull knob on the dash

|

|

McGatha185

Bronze Level

Joined: 10 Nov 2016

Location: Missouri

Points: 48

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Nov 2016 at 8:03pm Posted: 10 Nov 2016 at 8:03pm |

|

There is no pull knob on the dash. My dad's old 180 had one, I know, and there's a spot on this dash for one, but when I got it, there was no pull knob. I'm sure some farmer reworked it a long time ago. Mine is set up to flip a toggle and push the button. It's always worked fine, so I've never felt to need to change it. I'm just starting to fix this old guy up, so I'll probably put it back to factory stock.

|

|

Lynn Marshall

Orange Level Access

Joined: 13 Sep 2009

Location: Dana, Iowa

Points: 2446

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Nov 2016 at 8:25pm Posted: 10 Nov 2016 at 8:25pm |

|

If it doesn't have a manual shut off cable, it may have an electric one like a lot of the combines. Is there a wire on the top of the pump? If so, do you have power there when the toggle switch is turned on?

|

|

McGatha185

Bronze Level

Joined: 10 Nov 2016

Location: Missouri

Points: 48

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Nov 2016 at 8:27pm Posted: 10 Nov 2016 at 8:27pm |

|

It does have a wire on top of the pump. I never thought of checking it. I'll go see right now what my meter says.

|

|

McGatha185

Bronze Level

Joined: 10 Nov 2016

Location: Missouri

Points: 48

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Nov 2016 at 8:36pm Posted: 10 Nov 2016 at 8:36pm |

|

Ok, I checked the battery and it was showing almost 15 volts. I flipped the toggle and checked the little wire coming into the top of the pump and it says 0 volts. But when I tried to turn the engine over with the toggle off it won't do it but it will spin free with it on. Is the little wire a ground maybe? It goes up to the hood and then snakes its way under the hood by the fuel tank before I lose it. I'd have to pull the hood. Isn't there some sort of switch on the clutch to stop it from starting in gear?

|

|

MACK

Orange Level

Joined: 17 Nov 2009

Points: 7664

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Nov 2016 at 8:58pm Posted: 10 Nov 2016 at 8:58pm |

|

Unhook the wire at pump, then run a jumper wire from battery or starter to that post. Be sure to unhook it when you are done. When you hook and unhook wire to terminal, you should hear a click in pump if it is working. MACK

|

|

McGatha185

Bronze Level

Joined: 10 Nov 2016

Location: Missouri

Points: 48

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Nov 2016 at 9:04pm Posted: 10 Nov 2016 at 9:04pm |

Ok, I'll do this but it'll have to be tomorrow. I'm going to work now.

Thanks a ton!!!

|

|

McGatha185

Bronze Level

Joined: 10 Nov 2016

Location: Missouri

Points: 48

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Nov 2016 at 12:25pm Posted: 11 Nov 2016 at 12:25pm |

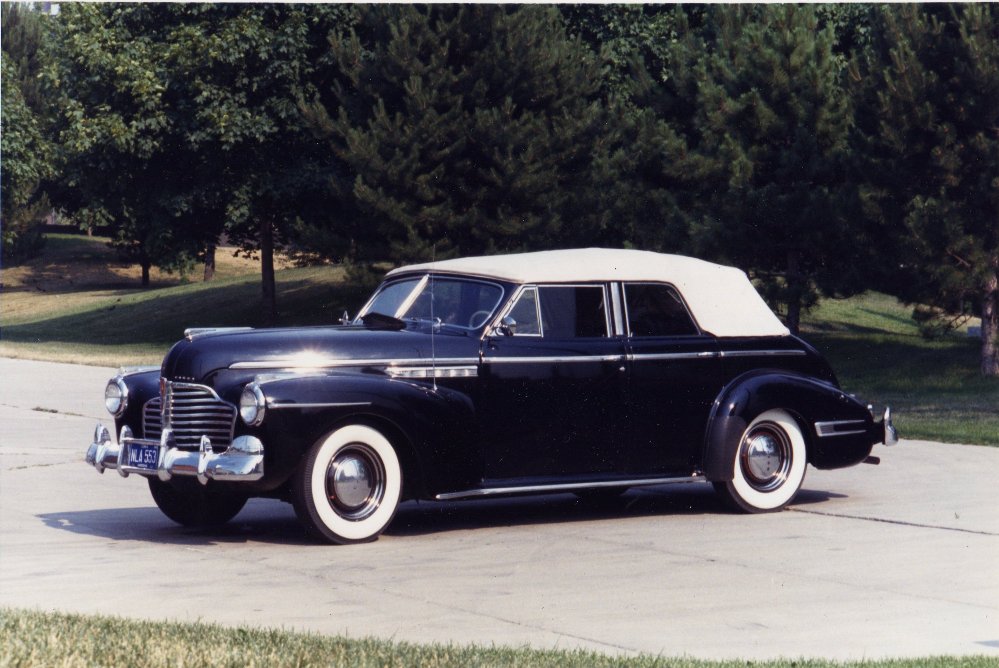

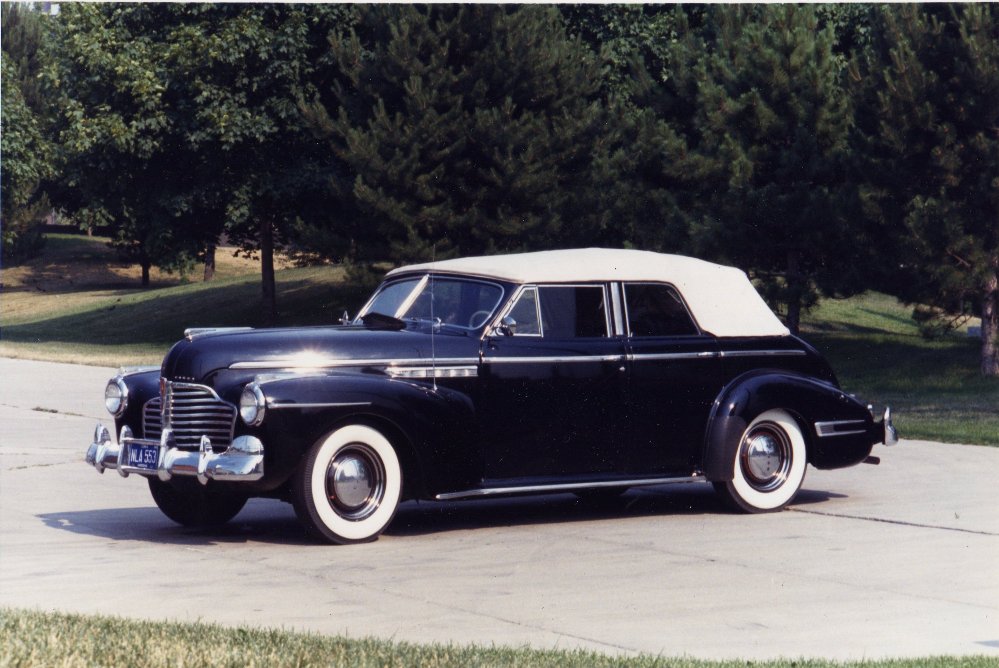

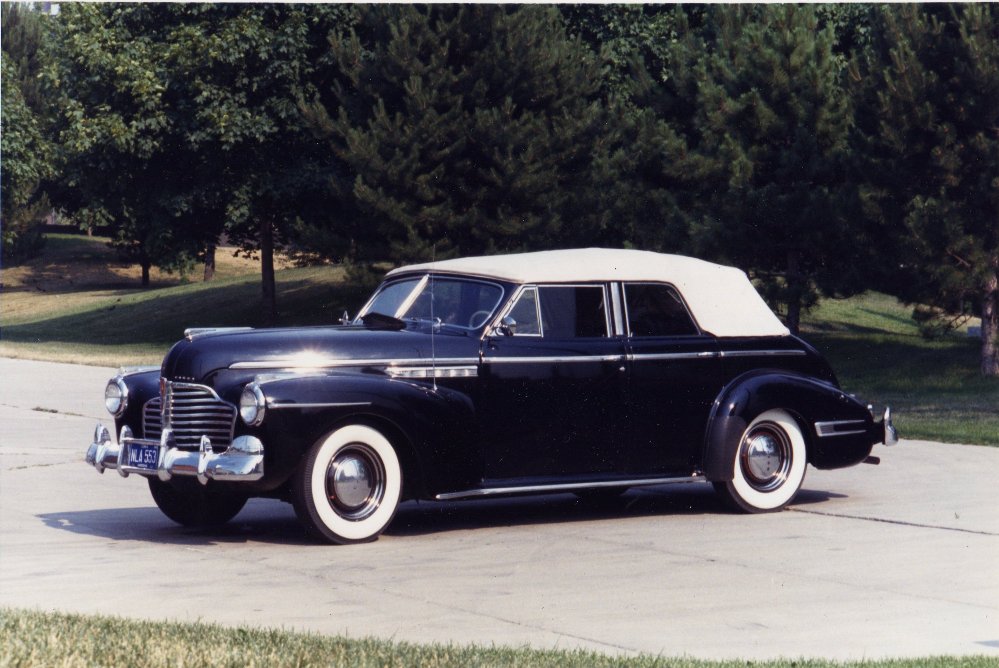

This is the wire I'm talking about. I don't see any solenoid that it'd be kicking in. Is this right? The moisture is from degreaser I just sprayed on it.

|

|

Leon B MO

Orange Level

Joined: 12 Sep 2009

Location: Old Monroe, Mo

Points: 2206

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Nov 2016 at 1:11pm Posted: 11 Nov 2016 at 1:11pm |

|

Do as Mack said above. Take that wire off, and run a temporary hot wire to that post. You'll here a click inside the pump, if so try to start the motor. You will have to disconnect the wire to kill it, might use an alligator clip on the battery end of the temporary wire. Could be mice got to some wiring behind the dash, might check that too.

Leon B

|

|

Uncle always said "Fill the back of the shovel and the front will take care of itself".

|

|

Lynn Marshall

Orange Level Access

Joined: 13 Sep 2009

Location: Dana, Iowa

Points: 2446

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Nov 2016 at 1:12pm Posted: 11 Nov 2016 at 1:12pm |

|

You need 12 volt power to that wire to make it start. There's a small solenoid under the pump cover to make it work.

|

|

injpumpEd

Orange Level Access

Joined: 13 Sep 2009

Location: Walnut IL

Points: 5156

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Nov 2016 at 1:44pm Posted: 11 Nov 2016 at 1:44pm |

|

Those two nuts sticking out the top of pump are the solenoid terminals. One side is the switched 12v, the other should be ground, most just have a small strap that goes right to the front cover attaching screw. Some safety switches use the ground side to kill the engine, so check the ground and hot sides of the solenoid terminals. Like said above, you should hear it "click" inside the top cover of the pump.

|

|

210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers!

|

|

McGatha185

Bronze Level

Joined: 10 Nov 2016

Location: Missouri

Points: 48

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Nov 2016 at 4:10pm Posted: 11 Nov 2016 at 4:10pm |

|

Sorry, that wasn't it. When I checked it last night, I grounded my meter on the painted loader. My meter didn't like the paint. I took the wire loose and set up wire with alligator clips from the battery to the post. It clicked, but when I tried to check the voltage, I got zero again. I grounded on the bare hydraulic cylinder and it showed the volts. I rechecked my wire and it showed me volts now too. So the wire is good. Sorry about that. I did hear the solenoid click too with the tractor's wire. Should I have a ground wire off this pump?

|

|

McGatha185

Bronze Level

Joined: 10 Nov 2016

Location: Missouri

Points: 48

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Nov 2016 at 4:24pm Posted: 11 Nov 2016 at 4:24pm |

|

I just checked on the ground strap Ed mentioned and it's still there. It looked like it was broken at first but it just has a 90 degree bend in it.

|

|

injpumpEd

Orange Level Access

Joined: 13 Sep 2009

Location: Walnut IL

Points: 5156

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Nov 2016 at 5:03pm Posted: 11 Nov 2016 at 5:03pm |

|

If you hear it click, then it's working. Like I stated in my earlier post, the pump internals are very likely gummed up from sitting in the old fuel, and the plungers are stuck.

|

|

210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers!

|

|

McGatha185

Bronze Level

Joined: 10 Nov 2016

Location: Missouri

Points: 48

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Nov 2016 at 3:53pm Posted: 14 Nov 2016 at 3:53pm |

Ok, I'm going to try and clean this up a bit. I'm going to take the fuel lines loose, and open the two screws on the timing tab to drain out the diesel. Then I'm going to pour in some Diesel Kleen and let it sit for awhile. Then I'll open it up again and drain it out. Maybe that'll un-gum it.

If this is good or bad or you have a better way, please let me know.

Thanks!

|

|

McGatha185

Bronze Level

Joined: 10 Nov 2016

Location: Missouri

Points: 48

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Nov 2016 at 3:56pm Posted: 14 Nov 2016 at 3:56pm |

|

Ah, another thought. There's a little screen just inside where the fuel enters the injector pump, right? Could that be blocked or gummed up? Can I easily disassemble this part and clean it up?

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22329

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Nov 2016 at 4:47pm Posted: 14 Nov 2016 at 4:47pm |

|

Tractor must have had a combine engine grafted into it. Tractors never had electric shut-off except the D-21.

|

|

McGatha185

Bronze Level

Joined: 10 Nov 2016

Location: Missouri

Points: 48

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Nov 2016 at 4:51pm Posted: 14 Nov 2016 at 4:51pm |

|

You know, there is something odd about this tractor. The paint on the engine is flaked off here and there, and it's yellow underneath. I assumed that either 1) it may be really faded Allis orange that they painted over or 2) the tractor may have been a road department yellow tractor back in the day. Maybe it does have a different engine. I don't know. How would I find out for certain?

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

Tracy Martin TN wrote:

Tracy Martin TN wrote: