| Author |

|

IBWD MIke

Orange Level

Joined: 08 Apr 2012

Location: Newton Ia.

Points: 4120

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Jul 2019 at 8:28am Posted: 07 Jul 2019 at 8:28am |

Chris, great looking 147! Looks like you are having a good time with the toys and the family and it doesn't get much better than that.

Hope you get the CA, then we can have one of these threads for them.

|

|

|

Sponsored Links

|

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8544

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Jul 2019 at 11:08am Posted: 07 Jul 2019 at 11:08am |

Dave, JK, Mike, Folks, The oil thing is not great in my mind. I used a WD45 oil pump. I did not rebuild the oil pump. Looks like if your doing one of these that should be a priority too. Little frustrating at the moment. I dont want to run it much till I figure out if its ok as is or if I need to start taking it apart again. I guess my expectations were that I might have oil pressure near the upper end of the gage. The gage/s assuming they are ok are indicators the issue is somewhere else and the only thing I can determine is the oil pump may be not up to specs. Thanks for the positive comments too! Yea those great grandsons may have a shot at playing with this toy someday too!  Regards, Chris

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

IBWD MIke

Orange Level

Joined: 08 Apr 2012

Location: Newton Ia.

Points: 4120

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Jul 2019 at 8:54am Posted: 08 Jul 2019 at 8:54am |

|

Chris, you can shim that spring to bring up the pressure. Don't get too crazy with the amount of shim. A new from AGCO spring might be another alternative.

|

|

frnkeore

Silver Level

Joined: 07 May 2019

Location: Southern Oregon

Points: 362

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Jul 2019 at 10:46am Posted: 08 Jul 2019 at 10:46am |

|

Chis,

Did you find out what the actual oil pressure is?

My D17 didn't have a working gauge on it, when I bought it. I installed a SW gauge on it yesterday and got a high idle reading of 35 lb and a low idle of about 2 lb less, if that's any help.

I think 35 lb is fine for the RPM range that they work in but, I don't know the actual factory specs.

|

|

Frank

1959 D17 Series I #24001+, '59 D14

'55 & '59 Ford 850 & 861

Ferguson TO 35 Deluxe, Oliver 70 and 5 more.

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8544

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Jul 2019 at 9:48pm Posted: 08 Jul 2019 at 9:48pm |

Folks, Last night:

Today:

3/8 extension through these holes in the lower frame rails allow straight access to rad and shroud bolts! Got to try to learn a little each day!

Some oil from front crank seal??

Will check on oil pump parts tomorrow. Enough for one day. Should sleep good. Regards, Chris

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Jul 2019 at 10:26pm Posted: 08 Jul 2019 at 10:26pm |

|

Oh my. I'm sorry to see that lovely machine torn down like that. Hope the answers come quickly, Chris.

|

|

WC, CA, D14, WD45

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8544

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Jul 2019 at 8:18am Posted: 09 Jul 2019 at 8:18am |

Dave, Working on it. Could be a combination of things. Oil pump gears and clearance seem to be about normal for this age machine. Will try a couple improvements, and clean some things up. Regards, Chris

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8544

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Jul 2019 at 9:36pm Posted: 09 Jul 2019 at 9:36pm |

Folks, I was able to work on the WD45 a little today. A flat surface, 320 grit sandpaper, a little oil and lots of elbow grease and I removed the gear rings in the oil pump cover plate.

Checked the back lash and the shaft wear and spoke with Bill at Sandy Lake. Seemed to have some wear but nothing Bill had not heard of before. So continued the clean up of surfaces. added #2 gray permetex and the gasket and cover. Note that short screw goes at oil inlet position. light pressure on the screws then wait an hour and tighten up everything.

Took a trip to Sandy Lake and picked up the pan gasket set, and a Agco oil filter, a 9 spring pressure plate and this drawbar assembly. My drawbar parts had been cobbled together from WD pin hitch parts. I also got to look through some of their outside inventory!

Got the pan gaskets in place and the pan secured. Hope to set it back in the tractor tomorrow. The 9 spring pressure plate was what I had wanted for some reason, so that will be installed. I also got the spec on the pressure relief spring from Bill it is to be 3 inches long. That is the length of the second spring I installed and the oil pressure went up from the line to just past the N. Hoping this gasket on the oil pump solves some of the issue. Will know in a day or two.

Regards, Chris

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

Allis dave

Orange Level

Joined: 10 May 2012

Location: Northern IN

Points: 3073

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Jul 2019 at 7:20am Posted: 10 Jul 2019 at 7:20am |

Hi Chris, Hope that takes care of it. Only thing I see is isn't the pump supposed to have a screen around it? The tractor looks amazing. You've made fast progress over the last month. My mother-in-law got here from New York last week along with 2 1/2 gallons of NY maple syrup. We're set for another year.

|

|

sploke

Silver Level

Joined: 27 Jul 2015

Location: CT

Points: 113

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Jul 2019 at 9:55am Posted: 10 Jul 2019 at 9:55am |

Sugarmaker wrote: Sugarmaker wrote:

Folks,I was able to work on the WD45 a little today. A flat surface, 320 grit sandpaper, a little oil and lots of elbow grease and I removed the gear rings in the oil pump cover plate. |

good info...I suppose while I have my engine exploded all over my garage it would behoove me to take a look at this and possibly give the same treatment, just for insurance if nothing else.

|

|

frnkeore

Silver Level

Joined: 07 May 2019

Location: Southern Oregon

Points: 362

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Jul 2019 at 10:17am Posted: 10 Jul 2019 at 10:17am |

|

Chris,

I did a little research on gear pumps, last night and most specs run, .002 - .005/.006, for the clearance between the pump gears and cover.

You can measure that with a depth mic or Plastigauge. I've yet to find the spec for the gear to the housing but, I'm still looking. Can you measure your clearance for that, using a feeler gauge?

|

|

Frank

1959 D17 Series I #24001+, '59 D14

'55 & '59 Ford 850 & 861

Ferguson TO 35 Deluxe, Oliver 70 and 5 more.

|

|

TimCNY

Orange Level

Joined: 15 Apr 2014

Location: Upstate NY

Points: 1551

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Jul 2019 at 10:48am Posted: 10 Jul 2019 at 10:48am |

|

Chris, I see you've already got one on there (like you'd miss a single detail?!?! lol), but until the other day I never noticed my WD45 hasn't had a compensating spring since I've owned it. I used to think maybe not enough friction on the quadrant for the throttle lever to keep it where I wanted it. I've always had to hold the throttle more or less when operating the tractor before this. NOT pleasant... Then the other day while looking at parts diagrams, out of the blue I noticed a spring that, well, mine didn't have lol. Embarrassed but oh well. Bought one, just arrived today. Funny the little things we miss but >ahem< "compensate" for, isn't it?

Great job, you've been an inspiration for a LOT of us. Thanks!

- Tim

|

|

Lynn Marshall

Orange Level Access

Joined: 13 Sep 2009

Location: Dana, Iowa

Points: 2418

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Jul 2019 at 4:50pm Posted: 10 Jul 2019 at 4:50pm |

|

It's a little late now,but the drive shaft in the pump can wear below the spiral drive gear and cause pressure leakage .

|

|

JK in Pa

Bronze Level

Joined: 12 Sep 2009

Location: Dushore, Pa.

Points: 164

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Jul 2019 at 5:52pm Posted: 10 Jul 2019 at 5:52pm |

|

Lynn brought up a good point. The shaft is grooved full length so oil is forced up to lube that area under the gear. I have seen some shafts really worn in this area and some worn very little. I wouldn’t have used any sealer when installing the gear cover. Good luck Chris.

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8544

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Jul 2019 at 8:19pm Posted: 10 Jul 2019 at 8:19pm |

Folks, All good suggestions and comments. I did check the side wear of the oil pump shaft, (best I could) it was about at the .008 inches. Moved the driven gear over towards the idler gently and used a feeler gage between the gear and housing. Checked gear protrusion from the base with a straight edge across gears (no gasket) and the clearance under the straight edge was about .002 inches. I choose to use some sealer on both sides of the gasket. a very thin coat of gray premetex. This gasket and inspection are really the only things I did, time will tell if it made a difference. The original gasket was there but one corner looked like part of it might have been missing.

So sploke I would suggest that you give the pump at least a good inspection and a new gasket. BTW the gasket was in the kit and it just did not register that I needs replaced.

Yes there is a screen wired on to the pump.

When all said and done will see if it was worth it to do all that disassembly for a gasket! My thought was that the pump might have to have some additional work and that it would be eaiser to replace the pan gaskets too.

Engine is back in place. Just trying to get the rest of the details buttoned up. The engine leveler worked great. I had to put the crank engaged to roll the engine over just a smidge to get the clutch spline to align. Used 1/2 inch alignment dowels.

Lynn, guess I should have tried to check that too. Maybe we need a good thread on how to check and repair one of these WD or WD45 oil pumps?? The book has some of the words to disassemble and check, but is not very in depth, unless you have more on the ball than I do.

FYI WD gears are not as long as the WD45 pump gears.

Had a brain fart when installing the new pressure plate. I over torqued one of the bolts and it snapped off. I was lucky there was a little of the bolt sticking out and was able to unscrew it. Went and got new bolts and lock washers. And watched the torque the next time too. Not sure why the Harbor freight torque wrench was not clicking or I just wasnt paying attention?

I also noticed that the flywheel has two F marks and two score marks about 3 inches away too. I remember reading about flywheels with two F marks. Cant remember the logic? Regards, Chris

Edited by Sugarmaker - 11 Jul 2019 at 6:49am

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 10 Jul 2019 at 9:27pm Posted: 10 Jul 2019 at 9:27pm |

|

And may all those fixes work!

|

|

WC, CA, D14, WD45

|

|

Allis dave

Orange Level

Joined: 10 May 2012

Location: Northern IN

Points: 3073

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Jul 2019 at 9:47am Posted: 11 Jul 2019 at 9:47am |

|

My flywheel had 2 F marks also.

|

|

frnkeore

Silver Level

Joined: 07 May 2019

Location: Southern Oregon

Points: 362

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Jul 2019 at 11:59am Posted: 11 Jul 2019 at 11:59am |

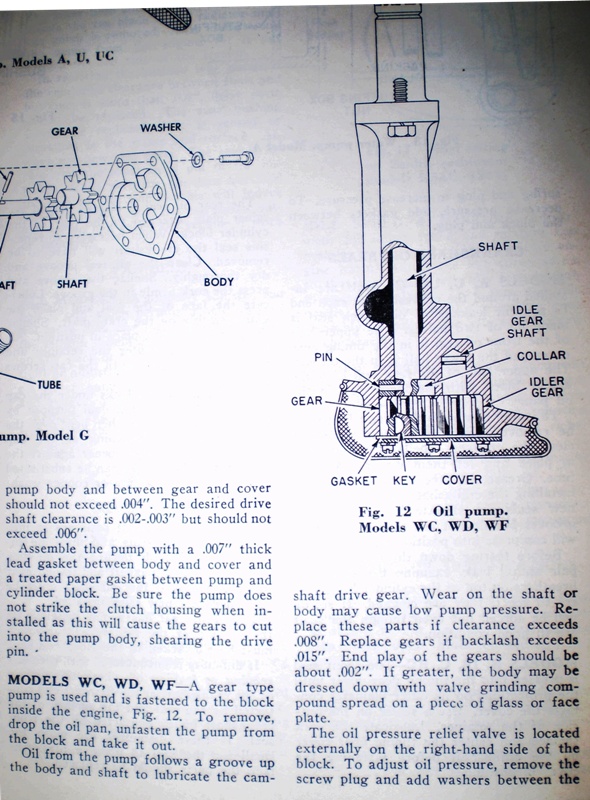

A little late to help Chris but, I found this info, on WC, WD and WF, oil pumps, in my 1949, Truck and Tractor, Motors Manual. It's my understanding that the major difference is the length of the gears and housing so, the clearances should apply to the 45.

|

|

Frank

1959 D17 Series I #24001+, '59 D14

'55 & '59 Ford 850 & 861

Ferguson TO 35 Deluxe, Oliver 70 and 5 more.

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8544

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Jul 2019 at 2:07pm Posted: 11 Jul 2019 at 2:07pm |

Frank, Never too late. I have that picture and words in my manual too. Someone else may be able to use that data! I just seen that the gears were longer in the WD45 than the WD oil pump.

Just installed the cross angle under the front of the engine and added a .017 shim. measured gap was .012 inches.

The air box and the manifold were hitting. I ground off a 1/4 inch chamfer on the corner of the manifold for some clearance between the air box.

Made 5 of the small angled clips for bolts through the frame. Just carved these from some steel in the scrap bin.

Regards, Chris

Edited by Sugarmaker - 11 Jul 2019 at 2:10pm

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

garden_guy

Orange Level

Joined: 05 Jul 2013

Location: Illinois

Points: 1153

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Jul 2019 at 5:11pm Posted: 11 Jul 2019 at 5:11pm |

|

Oh man sugarmaker, finally made it back on here today -- what an adventure! I have trouble finding the time to work on my front end, and look at all the stuff you're into, goodness. Hope to hear once you get it all back together that your oil pressure mystery is solved and everything looks good. Tractor lookin' mighty snazzy!

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8544

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Jul 2019 at 9:41pm Posted: 11 Jul 2019 at 9:41pm |

Folks, I hope its OK to say that the gasket and flattening of the oil pump plate did not seem to help much. So I added a spacer behind the pressure relief spring. What a pain that was getting the nut started with extra pressure on that spring. Anyway the pressure did go up a little. its about at the "R" in NORMAL. Then seems to fall off at idle. So I decided that I needed to re-torque the head and set the valve lash. Brought it up to operating temp. took the valve cover off and checked for oil coming to the head. Yes lots of oil while running the engine. Removed the rocker arm assembly. Torqued the head bolts in sequence to 90 ft lbs, and the small studs to 25 ft lb. Installed the rocker arm assembly, pulled the plugs and set the valve lash at .013 for with each cylinder at TDC. Valve cover back on and tractor started right up. I may get a 0 to 30 PSI gage for the oil pressure. just to see where its at with numbers. Tractor seems to run good and moves ok.

Have to work on the drawbar, cleaning, primer and paint, and assembly.

Thanks for all the support!

Regards, Chris

Next will be to think about break in.

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8544

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Jul 2019 at 9:27pm Posted: 12 Jul 2019 at 9:27pm |

Folks, Here was the start up oil pressure after installing a spacer behind the pressure spring.

Got new hydraulic hoses from NAPA today, and installed them. Lift went right up!'':

A shot of the finished WD45 other than drawbar:

Regards, Chris

Edited by Sugarmaker - 13 Jul 2019 at 8:09pm

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

IBWD MIke

Orange Level

Joined: 08 Apr 2012

Location: Newton Ia.

Points: 4120

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jul 2019 at 8:22am Posted: 13 Jul 2019 at 8:22am |

With that kind of pressure that 45 will outlast you, me , and most of the rest of this forum! We all like to see the gauge near the top but it isn't required. I should take a picture of the gauge on 'Grandpa's' WD. Got lots of hours on it, no one can remember the head even being off. The needle barely makes it to the 'N'. It's original and staying that way.

The 45 looks great!

|

|

FloydKS

Orange Level

Joined: 12 Sep 2009

Location: S E Kansas

Points: 8431

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jul 2019 at 9:20am Posted: 13 Jul 2019 at 9:20am |

Looks like congratulations for a job well done are in order...

|

|

Holding a grudge is like taking poison and expecting the other person to die

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jul 2019 at 10:52am Posted: 13 Jul 2019 at 10:52am |

Chris, I'm hardly an expert but I've often heard that getting a reading near the middle of the word "NORMAL" is just fine. You didn't say, but I gather that you were able to cure the other issues you mentioned.....

That WD45 looks magnificent! You do fine work. I hope this thread can get moved to the Knowledge section....   |

|

WC, CA, D14, WD45

|

|

Reindeer

Orange Level

Joined: 14 Sep 2009

Location: Calgary, AB

Points: 650

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jul 2019 at 5:31pm Posted: 13 Jul 2019 at 5:31pm |

|

This has been a very entertaining thread, and the tractor looks awesome! Thanks for taking the time to photograph each step, and for sharing it with us. Much appreciated and I for one learned a lot.😁

|

|

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8544

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jul 2019 at 8:29pm Posted: 13 Jul 2019 at 8:29pm |

Folks, Your kind words are greatly appreciated! As mentioned these tractors are a refurb/ clean and paint. Also they are not stock in some areas, like wheel color, wiring, dash, 12volt conversion, fasteners. I continue to learn on these old tractors, like I drove when I was a kid on the farm. We never did any of this stuff to the tractors they got the oil checked and maybe greased. (not often enough).

As you see I have a way of trying to document some of the details on these projects, hoping it will give someone the idea they can bring one of these back! This was a crank to drawbar project. It didnt start out that way, but when I got to the point that the engine needed overhauled it turned into a larger project. I will have some more pictures or the WD45 as I attempt to break it in, and also at our local tractor show this week too. Have a draw bar to clean, paint, and assemble.

I have two other oil pressure items I want to try. I bought a AGCO oil filter. I will swap out the NAPA #7011 (which looks identical). I also ordered a 0 to 30 PSI oil pressure gage from Stieners today too. That will allow me to get a approximate PSI number.

Regards, Chris

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

MDWilliams338

Silver Level

Joined: 19 Nov 2018

Location: NC

Points: 476

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jul 2019 at 11:38am Posted: 14 Jul 2019 at 11:38am |

|

Wait whut?!? I wasn’t gone that long....it was running then a tear down again?!?😳 Well it happens and sometimes things need to be addressed. I had to tear down one of our first B tractors ...3 times during a restoration,long story. I have to say though on all of our tractors with these non-numeral gauges at idle the needle sits on the ‘N’...at higher revs they all hang around in between the ‘R’’ and ‘M’ ... even our 45.You shouldn’t have to worry about it now.All in all ,I think you did a fantastic job with it....so worth it and rewarding in the end.

|

|

‘42B,’45B,’48C,’51CA,’52CA,’69170,1935WC,1936WC,WD,WD Highcrop,WD45,WF,D10/14/15/17/19

It isn’t how you die.It’s what you live for.-Daniel Boone

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8544

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jul 2019 at 9:12pm Posted: 14 Jul 2019 at 9:12pm |

MD, Folks, Thanks! We are preparing for our local tractor show July 19. Spent most of the day driving tractor for the crew picking up the barley shocks. Back at home tonight I prepped and painted the drawbar parts. Re-adjusted the clutch for some additional free pedal travel. Also adjusted the brakes to have about 3 inches of travel when pushing the pedals forward.

Took the 45 for a ride and it began missing. may have been something in the carb? Sediment bowl had some small chunks, removed and cleaned the glass bowl.

Regards, Chris

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

Allis dave

Orange Level

Joined: 10 May 2012

Location: Northern IN

Points: 3073

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jul 2019 at 11:39am Posted: 15 Jul 2019 at 11:39am |

Congratulations on a job well done! It looks great. I really like those tires on it and the narrow front.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

Sugarmaker wrote:

Sugarmaker wrote: