| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: TSX 464 Rebuild - Problem SOLVED! Topic: TSX 464 Rebuild - Problem SOLVED!

Posted: 18 May 2020 at 4:02pm |

I wanted to give the WD45 the benefit of a carb rebuild. Gave the carb halves a good soaking in carb cleaner fluid and blew out all the passages - they all behaved as though clear. Used the Sandy Lake kit, then gave the carb a coat of the paint Steve NJ recommended followed by two coats of PO#1 from a Rustoleum rattlecan. After reinstalling the rebuild, there's good news and bad news:

1. The good news - the engine fired up and ran beautifully on the settings I used. Idles nicely and sounds great at full throttle. Then there's the sound it makes with that Nelson muffler when I pull the throttle lever from idle to full speed! Oh my.

2. The bad news - adjusting the high speed needle (it's a Type C carb) has zero impact on how the engine runs. Which was the case before I did the rebuild. And one reason why I did it.

3. More bad news - Rustoleum paint doesn't stand up to gas. A minor leak (fixed) ate that paint right off the carb where the gas hit it.

Any suggestions on what's causing #2 would be greatly appreciated! As would suggestions for gas-resistant paint.

Thanks much, guys. Dave

Edited by Dave(inMA) - 22 May 2020 at 1:00pm

|

|

WC, CA, D14, WD45

|

|

|

Sponsored Links

|

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2020 at 3:03pm Posted: 19 May 2020 at 3:03pm |

|

Anyone have any ideas about the high speed needle issue? Thanks!

|

|

WC, CA, D14, WD45

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8619

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 May 2020 at 6:47pm Posted: 20 May 2020 at 6:47pm |

Humm, Correct me if I am wrong but that should shut off gas when all the way in. Not sure I have the answer. You might call Bill at Sandy Lake if you done get any response. Regards, Chris

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 May 2020 at 9:03pm Posted: 20 May 2020 at 9:03pm |

Chris - I have had several emails/calls with Steve NJ. As always, he's a big help. I'm hoping to reinstall the carb tomorrow - hopefully my poking will have cured the problem. Or reinforced the definition of insanity!

Dave

|

|

WC, CA, D14, WD45

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 May 2020 at 12:58pm Posted: 22 May 2020 at 12:58pm |

I'm happy to report that the mystery of the non-functioning Power Adjusting Needle Assembly has been solved! After several calls/emails with Steve in NJ and then this morning with Bill at Sandy Lake, I traced the problem to the packing inside the assembly.

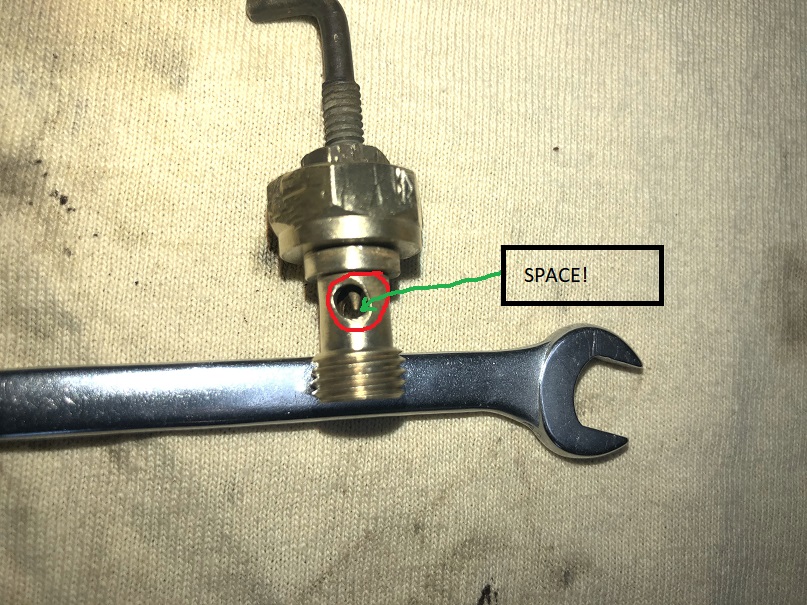

The assembly consists of an outer housing with a needle inside a packing nut and a packing washer. The packing nut compresses the packing washer around the needle to prevent fuel from leaking out and air from leaking in.

With the packing nut is tightened, the packing washer is compressed, reducing the diameter of the hole through which the needle must pass to the point that it acts as a seat - the needle can't pass through the hole. The result is that screwing the needle into the packing nut seats the needle on that washer, preventing the needle from crossing the open area in the middle of the assembly:

To function, the needle must be able to cross that open space and seat against the opening just before the threaded section:

The solution was absurdedly simple: loosed the packing nut enough that the needle will pass through the packing, then tighten the nut. I turned the needle out 1.5 turns, installed the carb on the tractor and slowly turned it in until the engine began to falter, turned it back out a half turn plus until the engine sounded happy again, then a bit more. Whew!

|

|

WC, CA, D14, WD45

|

|

garden_guy

Orange Level

Joined: 05 Jul 2013

Location: Illinois

Points: 1163

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 May 2020 at 5:24pm Posted: 22 May 2020 at 5:24pm |

|

So... If this is not assembled correctly, does fuel drip out of the adjustment screw? I'm working on one of these right now and am curious if I am putting that back together right after cleaning it.

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 May 2020 at 5:55pm Posted: 22 May 2020 at 5:55pm |

|

Well, I assembled it incorrectly and it didn't leak. That said, I bet there's at least one way to have it leak! Good luck with your project, GG.

|

|

WC, CA, D14, WD45

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8619

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 May 2020 at 7:20pm Posted: 22 May 2020 at 7:20pm |

Dave, Thanks for the update on your carb work! Since I have not installed mine on a tractor you are now ahead of me! Regards, Chris

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 May 2020 at 8:33pm Posted: 22 May 2020 at 8:33pm |

|

Well Chris, just make sure you get the power adjustment needle through the packing washer before you use the carb!

|

|

WC, CA, D14, WD45

|

|

ac45dave

Orange Level Access

Joined: 23 May 2015

Location: SE(IN)

Points: 1346

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 May 2020 at 8:22am Posted: 23 May 2020 at 8:22am |

|

Dave, I had a similar situation on the d17 I brought home a couple weeks ago.The packing was over tightened before the adjusting needle was through the packing thus not letting the needle through to the jet.Had black smoke and couldn't get it leaned out.Took the assembly apart and changed out the packing,starting the needle through the packing first before reassembling.Put it back in the carb and now it adjusts as it should.

|

|

54 wd-45gas ; 56 wd-45d N/F w/fact p/s ; 63 d-17 sIII N/F gas ; 60 D14 N/F ; 67 d-17 sIV N/F gas ; 63D15 sII W/F; 39rc#667 ; 2021 massey 4710 fwa ; gravely 2 wheel tractors

|

|

DaveKamp

Orange Level Access

Joined: 12 Apr 2010

Location: LeClaire, Ia

Points: 6108

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 May 2020 at 9:44am Posted: 23 May 2020 at 9:44am |

garden_guy wrote: garden_guy wrote:

So... If this is not assembled correctly, does fuel drip out of the adjustment screw? I'm working on one of these right now and am curious if I am putting that back together right after cleaning it.

|

What Dave experienced, was that either the trailing edge of the taper, or the outer surface of the needle was binding against the packing, making it 'feel' like the needle was seated. Of course, it was snug enough against the packing to not want to turn, it was clearly seated well enough not to leak... it was just about six-turns-shy of the orifice that the taper was supposed to control.

A leak from this valve is either coming from:

1) Lack of seal at the washer between the assembly and bottom of the bowl 2) Lack of seal in the packing of the needle (which Chris identified) 3) Loss of seal somewhere else, and it's deftly creeping down the outside of the bowl, over the valve, and 'lookin' like the valve is leaking, when it's actually something else.

For the category of 'something elses'... an overflowing float bowl (like damaged or swamped float, stuck or damaged/rotten float needle, crud jammed in needle seat, or improperly adjusted float height) is frequently one of the highest ranking in my experience. A cracked or loose fuel line fitting (and remember- there's a little catch-screen inside that inlet usually), or the last one...

A plugged up, or wasp-filled, or water-filled/frozen oil-bath air cleaner that is acting like full-choke when cranking...

Always remember- carbeurators are plumbing...

And PLUMBING (not money...) is the Root of All EVIL...

|

|

Ten Amendments, Ten Commandments, and one Golden Rule solve most every problem. Citrus hand-cleaner with Pumice does the rest.

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 May 2020 at 9:49am Posted: 23 May 2020 at 9:49am |

|

Very interesting, Dave! I'm glad to hear that I'm not the only one that has had this happen...in my case, the engine ran beautifully without the ability to adjust the carb. The only way I knew it was running a little rich was the condition of the spark plugs. It's running leaner now.

|

|

WC, CA, D14, WD45

|

|

tbran

Orange Level

Joined: 14 Sep 2009

Location: Paris Tn

Points: 3544

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 May 2020 at 10:03am Posted: 23 May 2020 at 10:03am |

|

We have received 2 'rebuild kits' with needle and seat that the seat hole was not drilled out completely - thus restricting flow at WOT - drilled out the hole for a cure - the rubber tip still sealed. .

|

|

When told "it's not the money,it's the principle", remember, it's always the money..

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 May 2020 at 11:17am Posted: 23 May 2020 at 11:17am |

|

tbran, initially I thought that was the issue, too. I'd removed the packing washer and ran the needle in to take some pictures to send to SL. I was expecting it would stop when it hit the (supposedly) undersized bore below the packing nut and was really surprised when the needle threaded right in there as it should - never would have thought that the washer was the issue.

|

|

WC, CA, D14, WD45

|

|

copyrite1972

Orange Level

Joined: 26 Feb 2016

Location: idaho

Points: 331

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 May 2020 at 9:56pm Posted: 25 May 2020 at 9:56pm |

Can anyone post a pick of what that packing looks like? I am rebuilding my TSX-869 (D15II) and don't have packing, or don't know what it is!

Thanks!

|

|

D15 Series II

|

|

Butch(OH)

Orange Level

Joined: 11 Sep 2009

Location: Lucerne Ohio

Points: 3842

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 May 2020 at 6:43am Posted: 26 May 2020 at 6:43am |

|

Next time you want to paint a carburetor go to NAPA and get a spray can of black lacquer. Dries in 5 minutes and gasomine won't touch it.

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 May 2020 at 9:05am Posted: 26 May 2020 at 9:05am |

copyrite1972 - I don't have a picture handy, but I can describe it: on the 464, it's a washer about 3/16" OD - just fits inside the hole that the packing fitting screws into; hole in the center is a bit less than 3/32" in diameter. It's about the size of the smooth shank behind the pointed tip of the needle screw. Maybe 3/32" thick, but it had been compressed by the packing fitting when I saw it so may come new a lot thicker. It's made of fiber - I had to be really careful picking it out of the assembly so I didn't ruin it. You might be able to use a small o-ring.

Butch - thanks for the paint tip!

Dave

Edited by Dave(inMA) - 26 May 2020 at 9:32am

|

|

WC, CA, D14, WD45

|

|

ac45dave

Orange Level Access

Joined: 23 May 2015

Location: SE(IN)

Points: 1346

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 May 2020 at 9:24am Posted: 26 May 2020 at 9:24am |

copyrite1972 wrote: copyrite1972 wrote:

Can anyone post a pick of what that packing looks like? I am rebuilding my TSX-869 (D15II) and don't have packing, or don't know what it is!

Thanks!

|

I don't think they come in the kits anymore but Roberts carb repair has them.I just got a few from them myself.They have about anything you need.Scroll down to Key #34.Be sure to read the description as to what it is compatible with. http://robertscarbrepair.com/carburetor-parts/marvel-schebler-tsx-m-40-320-330-420-430-440/?sort=featured&page=3

Edited by ac45dave - 26 May 2020 at 9:29am

|

|

54 wd-45gas ; 56 wd-45d N/F w/fact p/s ; 63 d-17 sIII N/F gas ; 60 D14 N/F ; 67 d-17 sIV N/F gas ; 63D15 sII W/F; 39rc#667 ; 2021 massey 4710 fwa ; gravely 2 wheel tractors

|

|

copyrite1972

Orange Level

Joined: 26 Feb 2016

Location: idaho

Points: 331

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 May 2020 at 10:11am Posted: 26 May 2020 at 10:11am |

|

Thanks!

|

|

D15 Series II

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

garden_guy wrote:

garden_guy wrote: