There are other folks on here who know these systems better than me. But having just done a pile of similar diagnosis & repair work on a 7045 (and having learned a lot from helpful folks on these forums), I can comment with some knowledge:

As you probably already know, the 'hydraulic pump' on these tractors is actually three pumps coupled axially together. Going from the rear of the tractor (where they're driven from) to the front, you have:

i) A geroter pump that pulls from the trans sump and puts trans fluid through the cooler, power-director (if a PD trans), and other tranny paraphernalia.

ii) Coupled in front of that is a gear pump with flow divider, which pulls fluid from the rear axle sump (through the LH suction filter) and puts fluid through the power steering, cooler, second (RH) fluid (and into the surge chamber), and lubricating/cooling oil for the brakes and PTO clutch (note: COOLING and LUBE oil for the brakes/PTO clutch. Not the pressure to run the brakes and PTO clutch themselves - just the cooling/lube).

iii) Coupled in front of that is a variable-displacement, pressure-compensated (closed-centre) piston pump. This runs the remotes, three-point, PTO, brakes, and diff lock.

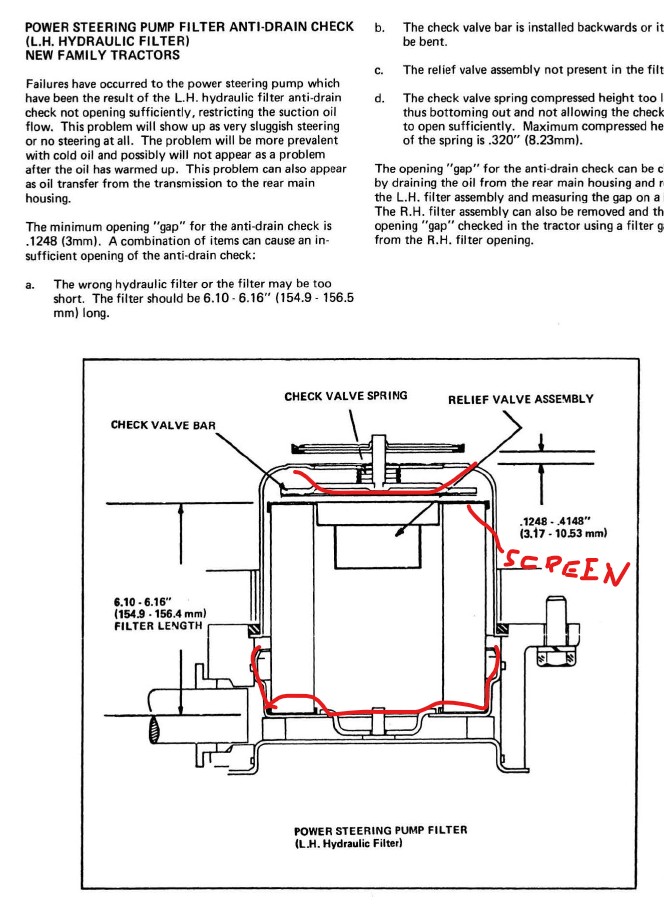

That's a bit over-simplified, but it gives the Coles-Notes version of everything. Now for your problem: A proper set of pressure gauges and checks is probably in order (which it sounds like you've started already). But because you periodically had brakes, three-point, and steering, I'm going to guess (/hope) that your pumps are whole and working in some capacity. It sounds like oil starvation problems, which are not uncommon on that series. The first thing to check is that you have lots of fluid in the rear end and (most importantly) the correct length filter in the LH housing. This was a well-known/common problem with these hydraulic systems. When installed, the filter 'should' be long enough to push the trap-door (called the 'anti-drain valve' in the manual) open and allow the LH filter cavity to fill. It doesn't push it open much - maybe 3/16" or so. A common problem was that these filters aren't all made the same. You really want to get the AGCO ones. The problem: All companies that make this size of filter make the metal filter-body length the same. But many manufacturers use different gaskets at either end. Most use thinner gaskets, and some use thin gaskets that also fit into a little recess in the end of the filter-body. The AGCO filters have much thicker gaskets adhered to the end of the filter body, making them about 1/8" longer than many/most other brands. If you use one of the other brands, they often aren't long enough to open the trap door and let the filter cavity fill (or rather, they only open it a smidge: They allow a little fluid to come through, but not enough to keep up with the flow demand and it will quickly/periodically starve for oil). Thus: A shorter or non-AGCO filter can cause hydraulic starving problems, resulting in intermittent or no hydraulics.

Coupled with this (I learned this from a local old Allis mechanic) is a problem that can happen to the filter housing components if it's used with the wrong filter: There's a lot of surface area around the trap door and filter end caps. If it's been run with a slightly short filter, it can create enough suction/vacuum on this surface area to bend the end caps in a little, which further compounds the problem as it effectively shortens things even more. When you disassemble the components in the LH filter housing, it's critical to make sure the removable end caps and the bar that pushes the trap door are straight/square. It's also abolutely critical that the screen be installed in the end of the LH filter, as its thickness/length is required to open the trap door sufficiently.

On my 7045 when I couldn't get an AGCO filter for the life of me, I got by for a little bit by making a second disc-shaped gasket our of some cork gasket maker to put in front of the filter and extend it a little, to make sure the trap door was opened sufficiently. I wouldn't want to run for a long period like this (when doing this, you're only relying on spring pressure to hold the filter against the gasket and keep everything in-place. It might last forever like this, but if anything ever went awry I wouldn't want it sucking the cork gasket into the pump). But worked dandy for a short test.

I like my Allis's, but this design (and relying on gravity pressure to keep the filter filled) is not my favourite design. Because you're relying on gravity to force fluid through the LH filter, it's also critical that you have enough fluid in there AND a clean filter. When the filters started to get old/plugged they would cause similar problems, and some folks compensated by just over-filling the rear-end. This created a little more gravity pressure to help force fluid through the LH filter.

So: First step (in my opinion) would be to ensure the LH filter is clean, has the screen on the end, and is the correct length/AGCO filter. At the same time, make sure all components of the filter (end cap, trap door pusher bar) are not bent in any way, to ensure that it's opening the trap door sufficiently far. Also make sure it's well topped up with enough fluid.

After that, I would be suspect of the compensator and priority valves for the piston pump. It's not uncommon for them (not only on Allis's, but on any similar hydraulic system) to get some gunkulence in them and be sticky/jammed. It's fairly simple to take them apart, clean them up, polish the spools, and re-assemble with new o-rings.

Take a look at this note and picture from the Allis manual. Note my sketches in red, which show how the T-Bar and end-cap can get bent over time (especially if the trap door hasn't been opening far enough and it's created a lot of suction pressure).

Edited by DanielW - 2 hours 14 minutes ago at 8:00am

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)