| Author |

Topic Search Topic Search  Topic Options Topic Options

|

NE GA Allis

Bronze Level

Joined: 17 Feb 2019

Location: Georgia

Points: 139

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Roto-Baler endless belt idea Topic: Roto-Baler endless belt idea

Posted: 30 Apr 2020 at 8:42pm |

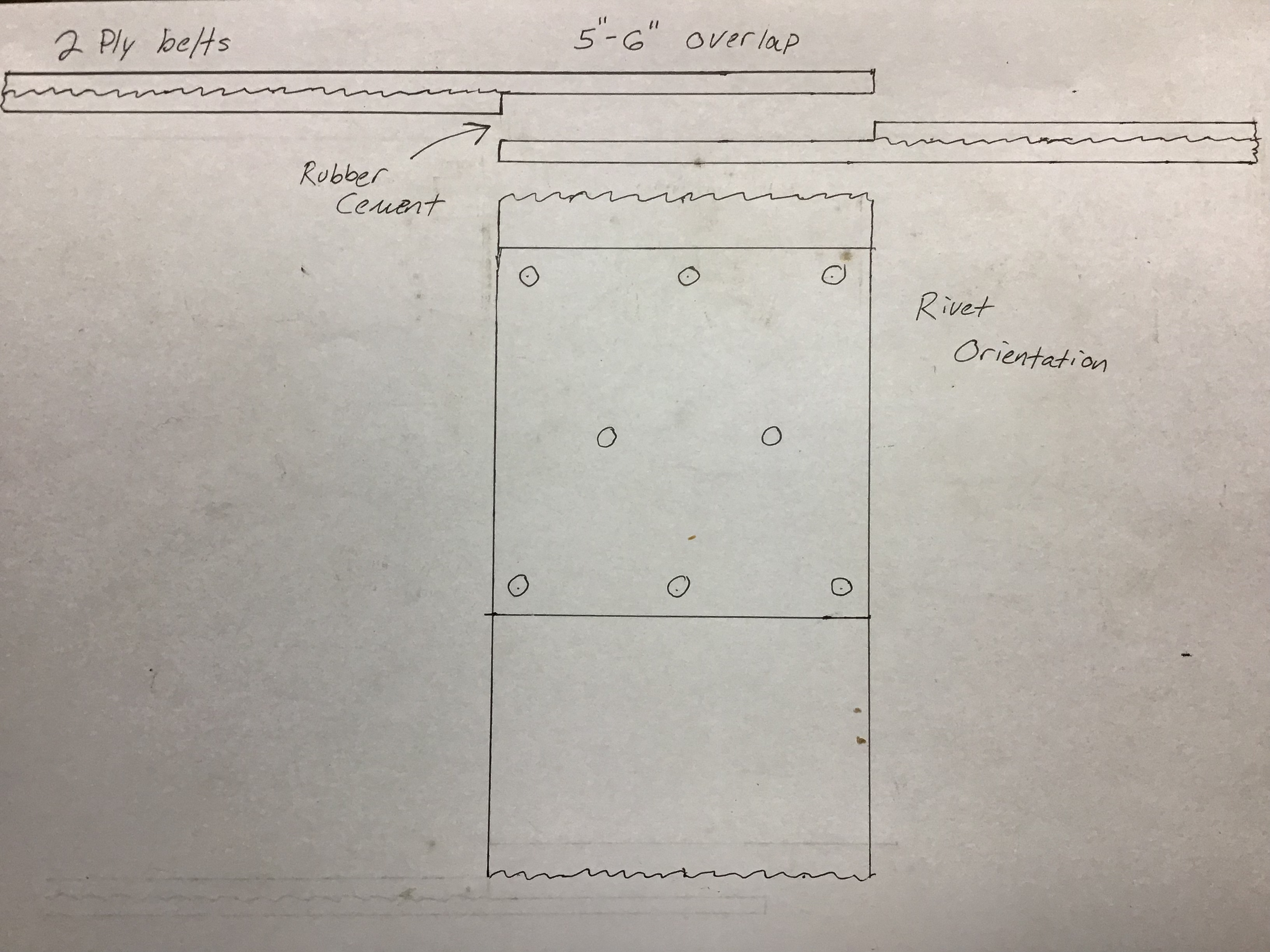

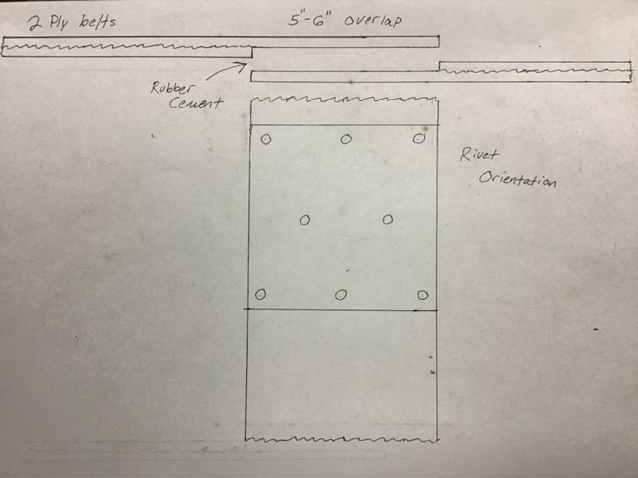

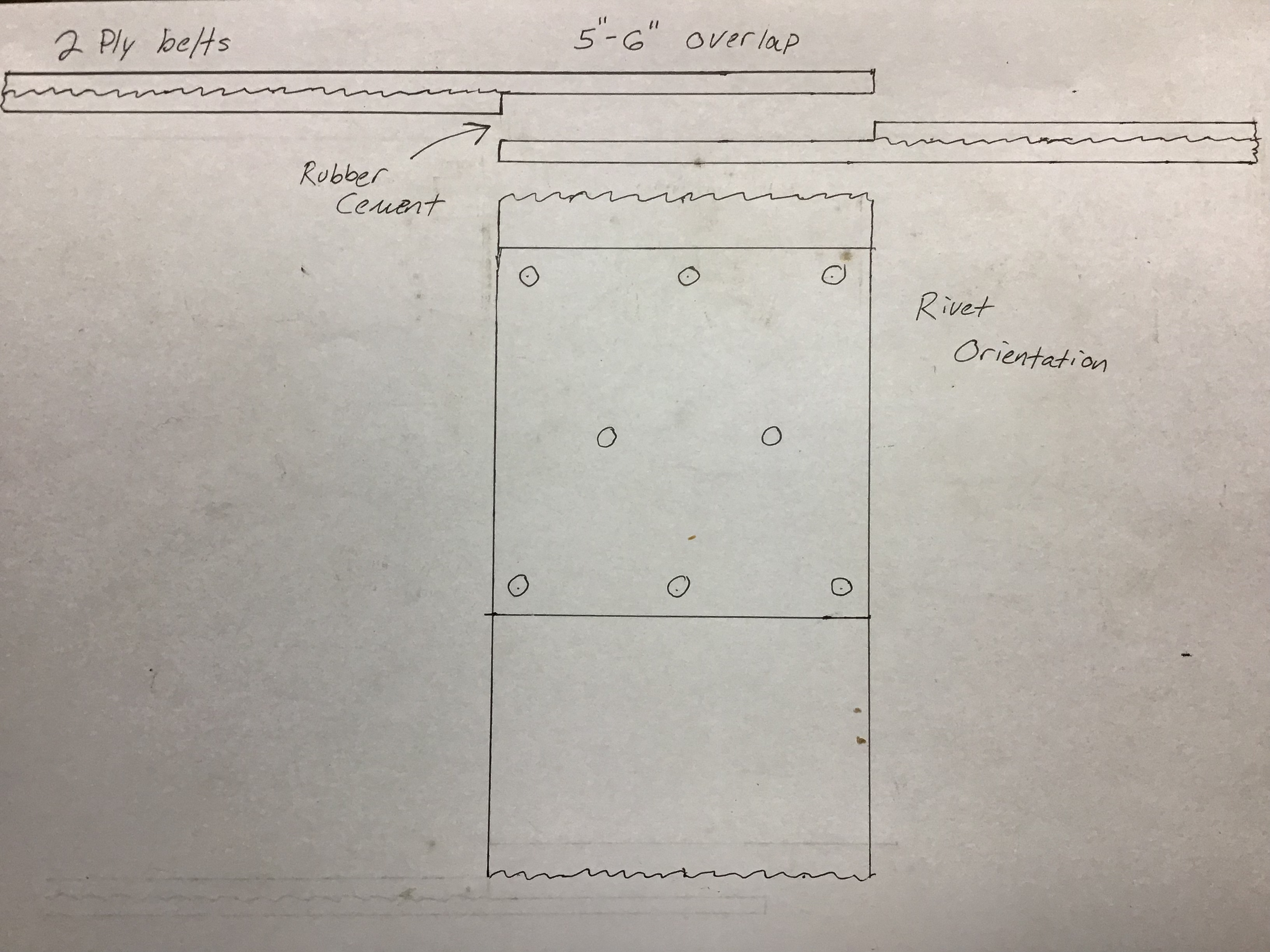

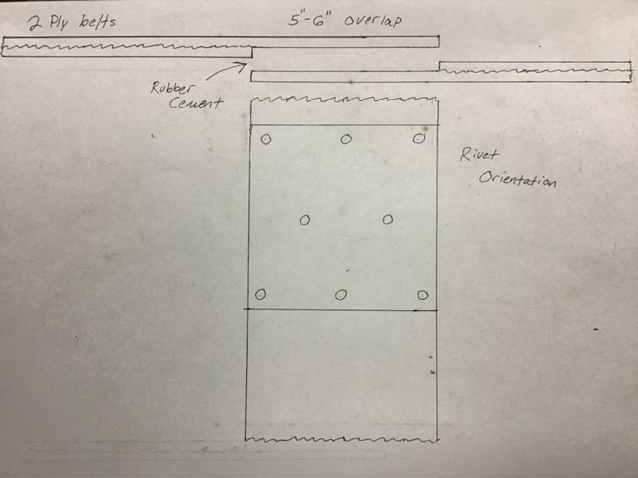

Anyone try this before? I had this idea last week (not sure if someone else thought about this but didn’t find it previously) From what I found out through the forum, the Roto-Baler belts were 2 ply. That being said, what if you took and shaved off one ply on each end, opposite side respectively, and glued them together with a heavy duty rubber cement and riveted them lightly. Some belt lacing systems use rivets instead of the clipper type system, so I would think rivets would be ok. Attached is a rough drawing. I am thinking about trying this on my next baler, since I just put new clipper belts on my current baler. Any thoughts?

|

|

Keeping Allis alive with:

2 B’s, 1 C, 6 CA’s, 2 WD’s,

1 WD45, 3 D15D’s, 1 D17

|

|

|

Sponsored Links

|

|

|

NE GA Allis

Bronze Level

Joined: 17 Feb 2019

Location: Georgia

Points: 139

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Apr 2020 at 8:47pm Posted: 30 Apr 2020 at 8:47pm |

Hopefully this photo is smaller.

|

|

Keeping Allis alive with:

2 B’s, 1 C, 6 CA’s, 2 WD’s,

1 WD45, 3 D15D’s, 1 D17

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Apr 2020 at 10:08pm Posted: 30 Apr 2020 at 10:08pm |

|

Interesting idea. Would this be less expensive than buying continuous belts - or are those no longer available? Or some other advantage?

|

|

WC, CA, D14, WD45

|

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 54698

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 May 2020 at 4:53am Posted: 01 May 2020 at 4:53am |

Problem with using a splice, other than the clipper type, on a AC rotobaler, is that the rollers are real narrow, and using a splice, that is long, subjects such a splice to a lot of stress, while the clipper type splice, simply bends with the stress. The longer splices such as the alligator, etc are only recommended for machines with a minimum roller diameter of 6".

That being said, try it on one belt, and see how long it lasts!  |

|

Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need!

|

|

NE GA Allis

Bronze Level

Joined: 17 Feb 2019

Location: Georgia

Points: 139

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 May 2020 at 6:28am Posted: 01 May 2020 at 6:28am |

Dave(inMA) wrote: Dave(inMA) wrote:

Interesting idea. Would this be less expensive than buying continuous belts - or are those no longer available? Or some other advantage? |

I don’t believe that the continuous belting is available any more, not unless you buy NOS.

DiyDave wrote: DiyDave wrote:

Problem with using a splice, other than the clipper type, on a AC rotobaler, is that the rollers are real narrow, and using a splice, that is long, subjects such a splice to a lot of stress, while the clipper type splice, simply bends with the stress. The longer splices such as the alligator, etc are only recommended for machines with a minimum roller diameter of 6".

That being said, try it on one belt, and see how long it lasts!  |

I would think that a glued overlapping splice, like drawn out, with a similar rivet orientation would be more conforming to the small rollers than any type of mechanical splicing. I still have enough belting left over to make one more belt. I might give it a try and throw it on my baler before we bale the wheat.

|

|

Keeping Allis alive with:

2 B’s, 1 C, 6 CA’s, 2 WD’s,

1 WD45, 3 D15D’s, 1 D17

|

|

Jim.ME

Orange Level

Joined: 19 Nov 2016

Location: Maine

Points: 964

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 May 2020 at 6:32am Posted: 01 May 2020 at 6:32am |

|

Chemical and vulcanizing belt splicing is a common thing in industry now. No rivets used, but there is a bit more to it than your plan. I won't say your plan won't work. I would suggest you talk with a company that does belt splicing they might give you some pointers or suggest an adhesive. They can make splices that are hard to spot in conveyor belts.

|

|

PaulB

Orange Level

Joined: 12 Sep 2009

Location: Rocky Ridge Md

Points: 5192

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 May 2020 at 6:44am Posted: 01 May 2020 at 6:44am |

You may be able to find some place that will make a wide belt, then have it cut it into 6 narrow ones, That's how the "endless" belts were made to begin with. It is very critical that all the belts are EXACTLY the same length or they won't run true. Most any place would want a number of belt to be made, so it all gets to how many set you could sell.

I no longer have NOS belts or any other NOS parts I had for Roto-Balers.

|

|

If it was fun to pull in LOW gear, I could have a John Deere.

Real pullers don't have speed limits.

If you can't make it GO... make it SHINY

|

|

Joe(OH)

Orange Level

Joined: 11 Sep 2009

Location: Montezuma, Ohio

Points: 999

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 May 2020 at 6:47am Posted: 01 May 2020 at 6:47am |

This guy probably has endless belts.

http://www.balerbelts.com/main.html

|

|

Life is simpler when you plow around the stump.

|

|

NE GA Allis

Bronze Level

Joined: 17 Feb 2019

Location: Georgia

Points: 139

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 May 2020 at 8:27am Posted: 01 May 2020 at 8:27am |

Jim.ME wrote: Jim.ME wrote:

Chemical and vulcanizing belt splicing is a common thing in industry now. No rivets used, but there is a bit more to it than your plan. I won't say your plan won't work. I would suggest you talk with a company that does belt splicing they might give you some pointers or suggest an adhesive. They can make splices that are hard to spot in conveyor belts. |

I’ll take a look into that!

|

|

Keeping Allis alive with:

2 B’s, 1 C, 6 CA’s, 2 WD’s,

1 WD45, 3 D15D’s, 1 D17

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

Dave(inMA) wrote:

Dave(inMA) wrote: