| Author |

Topic Search Topic Search  Topic Options Topic Options

|

orangeman

Orange Level

Joined: 12 Sep 2009

Points: 1868

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Re-Engine Early HD6 G Shovel Part II Topic: Re-Engine Early HD6 G Shovel Part II

Posted: 07 Nov 2011 at 6:16pm |

Ok Guys: The saga continues on trying to re-engine the HD6G. I am had very little luck in finding either engine parts or a good running 344 block near me. So I was thinking about using a 2-71 out of an HD 5 to run in the HD6?

So has anyone used a 2-71 in a HD6 G shovel and what could I expect to encounter on swapping the 2-71 in place of the HD-344?

I am thinking that the radiator plumbing might be different along with the fan belt arrangements. Also maybe the hydraulic pump would need to be changed as well.

Any ideas or comments good/bad or otherwise are appreciated.

The machine would be for home use around the farm here and not for contracting work.

Thank -you Orangeman

|

|

|

Sponsored Links

|

|

|

Mactractor

Orange Level Access

Joined: 20 Jun 2011

Location: New Zealand

Points: 652

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Nov 2011 at 2:29am Posted: 08 Nov 2011 at 2:29am |

|

I would look for a 371 if you want to go GM. There are a number of HD6s here repowered with 371s. They are a snug fit. If you use remote mount oil filter, frame alterations are kept to a minimum. Bottom coolant pipes need some thought to get a tidy couple up around hydraulic pump feed. Top radiator pipe needs to turn over to point opposite diagonal. 371 likes a lot more air than a non turbo 344, so a bigger air filter needs to be adapted. Sounds like a lot of work, but they are a very happy tractor with a 371 under the hood

|

|

orangeman

Orange Level

Joined: 12 Sep 2009

Points: 1868

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Nov 2011 at 3:01am Posted: 08 Nov 2011 at 3:01am |

Mactractor- I was thinking the 2-71 would be an easier fit due to the fact that the 2-71 originally came in the HD5 and would slip right in.

Thank you for the points that you mentioned on the changeover to the 3-71.

Anyone running a 2-71 or 3-71 in the HD6?

|

|

Mactractor

Orange Level Access

Joined: 20 Jun 2011

Location: New Zealand

Points: 652

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Nov 2011 at 3:14am Posted: 08 Nov 2011 at 3:14am |

|

Although the rear ends are the same, HD6 has a different frame to HD5, and was produced for only Buda/AC 344, 6000, 7000 engines, so you would have to do all the alterations to a 6 for a 271 that you would have to do for a 371. For all the work, the 371 would make it seem more worthwhile

|

|

Kcgrain

Orange Level

Joined: 24 Sep 2009

Location: Wisconsin

Points: 805

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Nov 2011 at 8:49am Posted: 09 Nov 2011 at 8:49am |

|

I am not quite understanding the process here. You have an HD6 and the engine is bad, I guess I missed whats wrong with it, but unless the block imploded I cant see why it cant be repaired, but anyways you want to take out an engine that AC put in that worked beter than a Detroit, and find a detroit of unknown condition, go threw abunch of work to make it fit so you can go backwards in the design? I dont find the logic or economic sence it that. We have a truck here with a 8v71 detroit in it, its a good engine makes good power etc, but the noise is almost more than I can stand, and the torque is compensated by a million gears, this winter its coming OUT to be replaced by a Mack, which I know is going to be alot of work but at least the truck is being upgraded to something better, not to mention the value is increased. Your HD6 with a detroit is going to go backwards in value, not to mention all the work your going to do, and have less motor.

|

|

orangeman

Orange Level

Joined: 12 Sep 2009

Points: 1868

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Nov 2011 at 4:18am Posted: 10 Nov 2011 at 4:18am |

KCGrain: I posed the question on the premise that the frames of the 5 and 6 could take either engine without modification. Based on Macs information above, I now understand that is not the case. I have access to a running 2-71 at a considerable savings over the pistons and liner kit for the HD-344. The price I was quoted is $300 per hole or $1200 for four.

I see the merit in your comments and appreciate you posting your insights.

Guess I will continue to look for suppliers who have a rebuild kit for the HD-344 with hopefully better pricing. I have heard there is a vendor in Washington State that sells the kits but don't know the name, anyone have an idea what company offers the kits??

From calls made yesterday, Endurance Power advised - no longer available from their suppliers - Buda engine three emails and one phone call - no reply and Stephens equipment no reply.

Any insights on who(m) sells the HD-344 would be greatly appreciated. Thank-you Orangeman

|

|

Kcgrain

Orange Level

Joined: 24 Sep 2009

Location: Wisconsin

Points: 805

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Nov 2011 at 4:51pm Posted: 10 Nov 2011 at 4:51pm |

|

Is the engine a 13,323 or higher? which I am going to assume the lower number is probably a precup motor. If its 13323 or higher the kits are available. I dont remember the guys name in WA but I do remember calling him for parts for a guys HD16 he was alot of talk but no action, if its the same guy. Just remember a running Detroit doesnt make it a good one, if you go the detroit route, and find out the engine is need of an overhaul etc, the detroit will run into as much money to reapir as your 344 plus its getting harder and harder to find qualified detroit guys that actually know how to set them up to run properly.

|

|

orangeman

Orange Level

Joined: 12 Sep 2009

Points: 1868

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Nov 2011 at 8:17pm Posted: 10 Nov 2011 at 8:17pm |

Hello KCGrain: I need to check the engine serial number, now that I have the manuals for the machine, (thanks to Fred Lucabaugh) I can check the serial number and report back. Based on the serial number of the machine, it production was early 1958, so I am guessing here, but if the motor has not been touched I am assuming the HD-344's up to say serial number 13,323 were all flat top piston engines. By definition I am assuming that "cupped pistons" were either shallow thus 6000 engine with no turbo and deep dished = 7000 turbo engine???

All of you guys have been most helpful, am amazed at the knowledge on here and am very appreciative of your help. Since I am new to the diesel side of AC, I am kind of learning as I go. Hopefully, before too much snow sets in I will come up with a game plan to move ahead on this project. Thanks again - Orangeman

|

|

gemdozer

Orange Level

Joined: 17 Sep 2009

Points: 1072

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Nov 2011 at 3:44am Posted: 11 Nov 2011 at 3:44am |

I should have some good used 344 pistons and linners let me have your pistons parts#

I DISMANTLET 8 HD6G for parts

|

|

Kcgrain

Orange Level

Joined: 24 Sep 2009

Location: Wisconsin

Points: 805

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Nov 2011 at 11:17am Posted: 11 Nov 2011 at 11:17am |

|

Orangeman what is exactly wrong with the engine in your HD6 a 1958 is going to make it a precup, so I will be willing to bet thats the 13232 number break. Are you burning oil, loss of power spun bearing? Sometimes a new engine isnt needed other problems make one think its in need of an overhaul. Have seen alot of engines with a head job, and a fuel system come to life. Just curious as to what exactly is ailing yours.

Edited by Kcgrain - 11 Nov 2011 at 11:25am

|

|

Kcgrain

Orange Level

Joined: 24 Sep 2009

Location: Wisconsin

Points: 805

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Nov 2011 at 11:24am Posted: 11 Nov 2011 at 11:24am |

|

Actually the deep cup shallow cup has no exact meaning. We went round and round about this on a 745, and an HD11B. There seems to have been no rhyme or reason as to which engine had which piston. You can have a older direct injection with a shallow cup, and than you can find a newer engine that has the same cup. Some guys said its a newer version but that does not ring true, on the 516 we have worked on there is no telling whats inside untill you open it up. But the injectors are different, and if you have a shallow cup mixed with a deep cup injector they dont run worth a damm, and you cant assume the injectors in these old motors are correct to the bowl, becasue we have found that not to be the case.The only way to tell is lifting the head or sending a scope in to see what bowl you have.

|

|

gemdozer

Orange Level

Joined: 17 Sep 2009

Points: 1072

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Nov 2011 at 12:03pm Posted: 11 Nov 2011 at 12:03pm |

|

The HD6G have the big head with cell energy and the top pistons are flat and use 5 rings

|

|

Dozer

Orange Level

Joined: 16 Aug 2011

Location: SW New York

Points: 689

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Nov 2011 at 8:59pm Posted: 11 Nov 2011 at 8:59pm |

|

There are 2 Allis Chalmers 7000 engines on eBay. You can tell which pistons by the cylinder head and the engine tag. If the injectors are on the top of the head it is a direct injection engine with cupped pistons. The engine tag should say Allis Chalmers 6000 engine. If the injectors are on the side of the head with the pre combustion chambers on the other side of the head the engine tag should say HD344. The HD344 has flat top pistons. New sleeves and rings are available. Bearings are harder to find.

|

|

orangeman

Orange Level

Joined: 12 Sep 2009

Points: 1868

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Nov 2011 at 3:58am Posted: 12 Nov 2011 at 3:58am |

|

Gemdozer, Dozer and KC Grain: Thank-you for the good information. The engine is seized from water entry through the muffler. I do not have the engine apart as yet. Will be looking it over tomorrow if all goes as planned.

|

|

Kcgrain

Orange Level

Joined: 24 Sep 2009

Location: Wisconsin

Points: 805

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Nov 2011 at 9:56am Posted: 12 Nov 2011 at 9:56am |

|

Orange, if the engine is just stuck but you know it ran before,if I was you Id pull the head clean up the corrosion, make sure it didnt crack anything if your in a part of the world that freezes. These engines can be stuck but that doesnt mean shot, if you get the head off use a hone, or even just emery cloth by hand and get the cylinders freed up and cleaned up, have your head gone though, valve job, maybe check your injectors, and Id be willing to bet for less than $1500 you would be back in business. The fact of the matter is this tractor isnt going out on a job site to be pounded 10hrs a day 300 days a year chances are its going to be a toy to play with, so who cares if it does burn a little oil, or has some blow by, its never going to log enough hrs to make a bit of differnce. Thats my opinon, and from my expierence it doesnt take alot to hold an engine tight, and after it runs for 10 minutes on its own it will have the walls just as nice as can be. You could just try to unstick it with the head on, but if it were mine Id like to see whats inside, if you still have alot of cross hatches that cylinder wall is good.

|

|

TREVMAN

Orange Level

Joined: 04 Jan 2010

Location: Regina,Sask,Can

Points: 1635

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Nov 2011 at 10:57am Posted: 13 Nov 2011 at 10:57am |

|

Ive unstuck a few engines and had really good luck getting them running again without oil use or blow by, I think you are putting the cart before the horse here. Take kcgrains advice. Its amazing what can be accomplished by carefully disassembling things and cleaning them, lubricating and reassembling. I spend most of my shop time doing just that. Acetone and ATF 50/50 in those cyls to start with. There is a lot of engine experience/advice here, take it one step at atime, but start where kcgrain said above, keep us posted, Trev.

|

|

orangeman

Orange Level

Joined: 12 Sep 2009

Points: 1868

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Nov 2011 at 9:10pm Posted: 13 Nov 2011 at 9:10pm |

KCGrain, Trevman and Dozer: Will work on the engine using your recommendations. Was not able to get to the machine today, as I had yard chores, (getting lawn furniture in for the wife and started getting my wood supply in for the winter.

In close, very much appreciate everyones advice, will keep you posted as I proceed.

Orangeman

|

|

orangeman

Orange Level

Joined: 12 Sep 2009

Points: 1868

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Nov 2011 at 3:11pm Posted: 14 Nov 2011 at 3:11pm |

Todays Update: Went to look the engine over today. Head has not been off the machine, Nelson Muffler is in bad shape ( external part) which I would rebuild with Stainless steel. The attaching flanges of the muffler to the block are in real nice shape.

KC Grain or someone was asking about the engine

Here are the details from the side of the engine specification tag:

Allis Chalmers Manufacturing Corporation

344-G 6 - 8714

From Loader Plate - Tractoshovel TS-6 Serial Number 4994

From Rear Transmission housing upper right quadrant HD-6 8742

Believe this puts this machine as a 1958 close to mid year production. No leaks or seeps from the final drives, oil pan or radiator area. All areas dry underneath. Hour meter show 3606 hours. Has American Bosch Injection pump. There is more wear on the chains than I had originally thought front idlers are adjusted out to about 2.5"" from the end of C channel. Sprockets teeth have minimal wear, so I am thinking that I will use some 7018 rod and build up the chains.

Anybody here refabbed the track adjusters to make them hydraulic? The screw portion of the track adjuster appears to be B7 threaded - rod say - 1.750 inches, not sure though as I did not have my micrometer with me. Dang!

|

|

hilltop615

Silver Level

Joined: 23 Dec 2011

Location: Murfreesboro Tn

Points: 72

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Dec 2011 at 9:37am Posted: 23 Dec 2011 at 9:37am |

I'm new on here but just ran across this post and thought i would throw my 2 cents in. I had the exact same issue you've got. I know the dozer was driven to the exact spot it is at right now but over the past 6 years it leaked water through the exhaust and stuck the engine. I pulled the head 2 days ago and found a mess! I was able to use emery cloth (and a good deal of time) and clean them up. As i got each cylinder cleaned up i poured a mixed of marvels mystery oil/diesel and moved on the the next. when i got done with the last i used a wooden handled 2 pound hammer and let the end of the handle drop around the edges of the pistons (not to hard but enough to give them a little shock) this kind of broke up any crud in the rings a little before trying to turn it. Then i put a socket on the crank pulley nut with a breaker bar and just wiggled it back and forth until it was loose (didn't take much at all) Then run the pistons down in the bore and use emery cloth and clean up for the final time because there will be some more rust/corrosion that you couldn't get to before. mine spins over like a new one now. I realize this was what the guys above were telling you but i figure since i had done it in the last couple days i would share. I'm waiting on my head gasket to come in (hopefully today)

|

|

Dozer

Orange Level

Joined: 16 Aug 2011

Location: SW New York

Points: 689

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Dec 2011 at 6:59am Posted: 24 Dec 2011 at 6:59am |

|

Let us know the condition when you get the head off

|

|

Dozer

Orange Level

Joined: 16 Aug 2011

Location: SW New York

Points: 689

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Dec 2011 at 7:19am Posted: 24 Dec 2011 at 7:19am |

|

I thought of an alternate r3epair. Since the engine has taken on water thru the exhaust, Odds are that there is only one cylinder effected. Take the cylinder head and oil pan off. If the effected cylinder is close to the top of the stroke manually turn the engine backwards to re hone the bore. If the piston is near the bottom of the stroke, remove the rod cap and rotate the engine manually to pop the sleeve. Remove the sleeve, rod and piston as an assembly. The in frame rebuild will be much easier than removing the engine

|

|

hilltop615

Silver Level

Joined: 23 Dec 2011

Location: Murfreesboro Tn

Points: 72

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Dec 2011 at 8:41am Posted: 24 Dec 2011 at 8:41am |

It could be just one rusted i guess depending on if it was parked up/down hill but likely it will be at least two because, (lets see if i can get this right) The #1 reach TDC at the exact time each rotation as do #2. So if your lucky your engine was shut off last with two of them at the top. I was "lucky" enough to have all four of them about midway so all of them were pretty nasty. Another thing that i have found is that there is a lot of really coarse rust in the combustion chambers of the head. It's nothing that wouldn't clear out with a little running but i wouldn't want to process all that through my otherwise good valve train. I guess my point is pulling the head is super simple and i got a replacement gasket for $24 so i'm glad i went ahead and pulled my head because i think i would have wrecked mine had i have gotten it free'd up and just ran it. GOOD LUCK WITH IT!! MERRY CHRISTMAS ALL

|

|

Coke-in-MN

Orange Level Access

Joined: 12 Sep 2009

Location: Afton MN

Points: 42191

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Dec 2011 at 9:44am Posted: 24 Dec 2011 at 9:44am |

Using a 2-71 will drop HP about 1/4 of what the origonal engine had and you might find your way underpowered for what you want to use .

|

|

Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel.

|

|

orangeman

Orange Level

Joined: 12 Sep 2009

Points: 1868

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Dec 2011 at 10:39am Posted: 24 Dec 2011 at 10:39am |

Guys: Great information above, wanted to check with you and see if there were any markings on the bottom rollers that differentiated the Heavy Duty Rollers from the standard rollers. I see in the HD6 manual on page 234 calls out Heavy Duty Truck Wheels as optional equipment.

Were the HD6 G shovels equipped standard with heavy duty truck wheels?

Merry Christmas and Happy Holidays to each and every one of you!

|

|

hilltop615

Silver Level

Joined: 23 Dec 2011

Location: Murfreesboro Tn

Points: 72

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Dec 2011 at 10:48am Posted: 24 Dec 2011 at 10:48am |

|

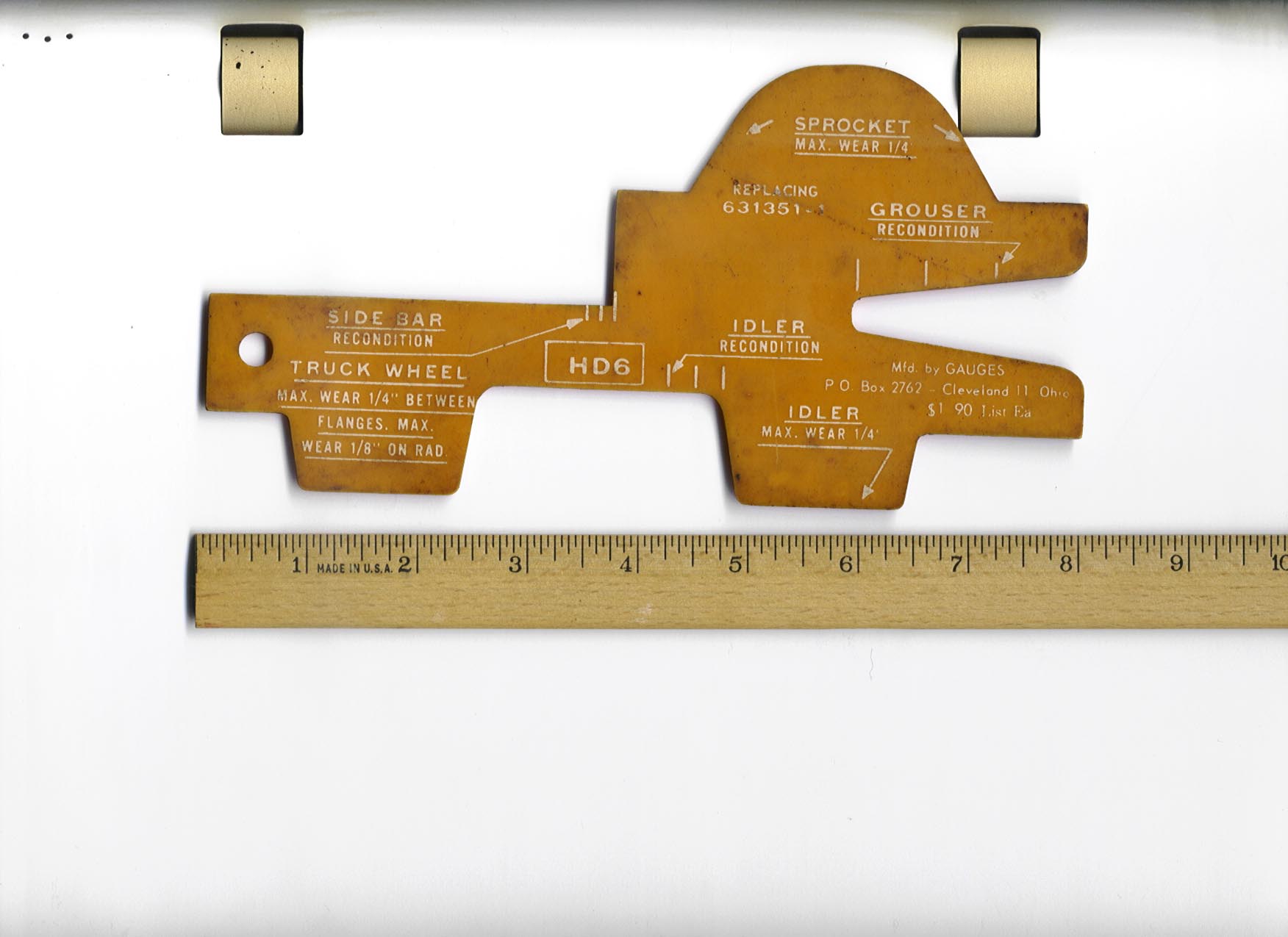

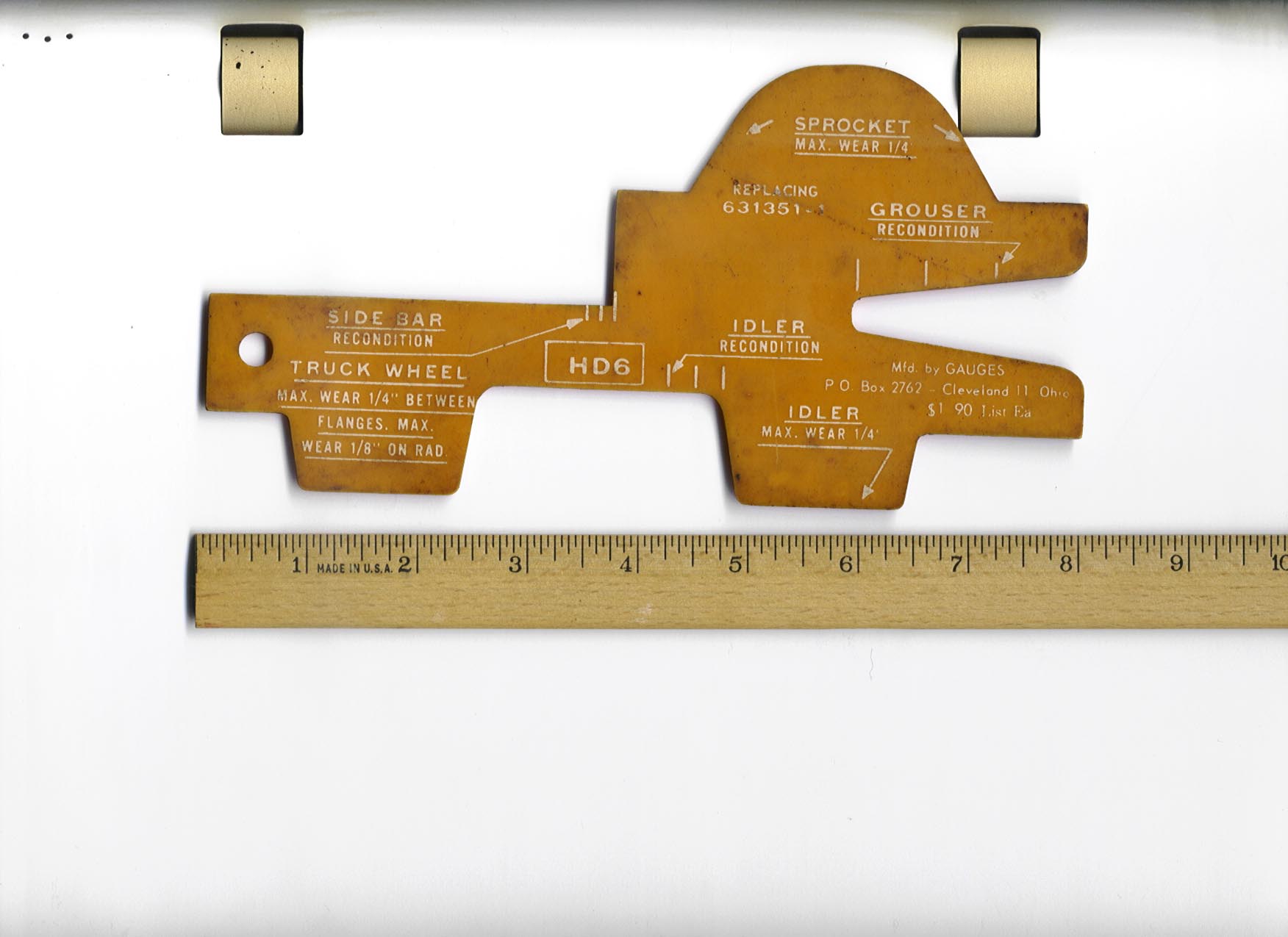

I am probably asking a dumb newbie question here but, is that gauge the same as the one for the HD-3?

|

|

Coke-in-MN

Orange Level Access

Joined: 12 Sep 2009

Location: Afton MN

Points: 42191

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Dec 2011 at 12:46pm Posted: 24 Dec 2011 at 12:46pm |

No it is for the HD5 and HD6 track .

HD3 and HD4 , 655 all used the same track and undercarrage, the 655 used a different stand for the top ideler but the ideler is the same

|

|

Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel.

|

|

orangeman

Orange Level

Joined: 12 Sep 2009

Points: 1868

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Dec 2011 at 4:26pm Posted: 30 Dec 2011 at 4:26pm |

Guys: You have mentioned using a 50/50 mix of acetone and ATF to use as a lubricant to free a stuck engine. I have both products in the shop.

Is there an additive that can be used to keep the both mixtures in suspension so they don't settle out?

Over on the farm section someone mentioned that the acetone and ATF separate after a little while.

Thank much for any thoughts? Happy New Year! Orangeman

|

|

orangeman

Orange Level

Joined: 12 Sep 2009

Points: 1868

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Jul 2012 at 5:34am Posted: 01 Jul 2012 at 5:34am |

OK Guys- Finally got the machine home, I have carefully read all the advice here and am very appreciative for all the input. I pulled the covers on the steering clutch housing and the pinion. Everything in there is in nice shape. There are new BERCO sprockets on the back of the machine and the bottom rolls are new.

Also got the valve cover off and determine that the intakes of 3 and 4 are stuck -so KC Grain you were right on. The head comes off today to inspect how much water intake has occurred.

Now since this is an early shovel 1958 does anyone have a source for the flat top pistons and liners besides Buda Engine Co. in Lousiana?

Allis made an excellent machine when they built the 6. Have a Great Day!

|

|

Dozer

Orange Level

Joined: 16 Aug 2011

Location: SW New York

Points: 689

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Jul 2012 at 8:12am Posted: 01 Jul 2012 at 8:12am |

|

I have some used sleeves that could be honed and re used. The sleeves for the HD344, 6000 & 7000 motor are the same. Ask gemdozer he might have some good pistons and sleeves. If you can't find flat top pistons you could convert your HD344 to a 6000 motor. This requires the 6000 cylinder head, pistons and connecting rods and dished pistons. If the pistons are stuck in the sleeve, turn the crankshaft to pop the sleeve out of the block with the piston.

Best wishes

|

|

orangeman

Orange Level

Joined: 12 Sep 2009

Points: 1868

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Jul 2012 at 8:56pm Posted: 05 Jul 2012 at 8:56pm |

Progress report - took the chain off that was holding the bucket in place that was slung over the top of the radiator cowl. Opened the radiator cover, much too my surprise no radiator cap! :( Jeepers doesn't anyone run these machines anymore as close to OEM as possible.

Does anyone have a parts number for a Gates or NAPA Radiator cap? Hoping to get the engine freed up or rebuilt but obviously want to run with a radiator cap. Thanks Guys... Orangeman!

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)