| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Ray54

Orange Level Access

Joined: 22 Nov 2009

Location: Paso Robles, Ca

Points: 4840

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Dec 2012 at 10:08am Posted: 07 Dec 2012 at 10:08am |

|

The rollers were always called 1000 hour rollers.The grease from the day was a off white,put the pipe in and pump the new grease in until old brown grease was out and the new white was coming out around the pipe.I would guess that would be 1/4 to 1/2 tube of grease.We only did it once a year.For the us you are talking as long as there is anything in there you should be ok.

As for the filters many have been changed to the spin on.With the bigger better element you could get away without the secondary element as modern equipment only uses one filter.They can be a little hard to prime some time,so it helps to pressurize the fuel tank.A old inner tube cut with the valve stem and a large hose clamp put it on the fuel tank filler works really well.

For the temperature gauge you want a mechanical with a short capillary tube.As it is only a foot or so from rear of engine to the dash.

Ray

|

|

|

Sponsored Links

|

|

|

Coke-in-MN

Orange Level Access

Joined: 12 Sep 2009

Location: Afton MN

Points: 42194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Dec 2012 at 10:33am Posted: 07 Dec 2012 at 10:33am |

The manual was printed early in production or before - It stays the same all through the years . The parts manual is revised for the years of production so later manuals show the updated parts . As the 2-71 uses a engine driven gear pump to pressurize the injectors - no lift pump should be needed - if this pump is worn - you will not have right pressure to injectors and proper flow for cooling as well as for running. Should have around 40 PSI through system. I bought a mechanical gauge for a IH tractor from TSC and have had it in for 30 years now and still works fine. I replaced the fuel pressure gauge with a Stewart Warner mechanical gauge- You need a restriction in line (snubber) or the gauge will pulse as fuel moves through system. Some filters like the ones used on HD4 diesel have primary and secondary in same can but I would not do away with the 2 filters unless you are sure the new one has that . Rebuilt HV7 Detroit injectors can be expensive IF.

|

|

Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel.

|

|

heron

Silver Level

Joined: 01 Dec 2012

Location: Chattanooga, TN

Points: 109

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Dec 2012 at 11:14am Posted: 07 Dec 2012 at 11:14am |

|

With the 24770 fuel filter head there is no priming screw so I'm not sure how it will prime. Also, I'd like to remove the large canister on the right side of the machine and simply put the housing within that frame work but the priming is the issue.

Great idea on the tube, wondering if I could find a fitting at a big box store that would screw on to that and allow me to drill a hole for a shrader valve.

I'm wondering if I can find the "correct parts" for the secondary fuel filter. I'm missing the spring that goes on the bottom.

I'm wondering how that cork seal actually seals on the bottom of the fuel bowl. When you look at the bottom it's got dimples that would not allow it to seal up well...?

I found some 000 grease at a local lube store. Any idea how I can get that into the rollers without some specialized pump?

On that mechanical temp guage; will the sending unit that goes into the block hook right up?

My plan is to run a Cat 1R-0749 filter. It has an absolute micron down to a 4 and it's what I use as a primary on my truck. Very cheap and easily found. It has lots of room in it for water also.

|

|

Coke-in-MN

Orange Level Access

Joined: 12 Sep 2009

Location: Afton MN

Points: 42194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Dec 2012 at 11:48am Posted: 07 Dec 2012 at 11:48am |

|

I have run my machine dry many times and no problem priming or getting it to fire again . The fuel pump is not a injector pump it is simply a transfer pump. If you will notice in the picture of the filters I have on my HD5 the filters are inverted so priming them is hard to do but the machine will run and transfer fuel fine . I do fill the filter mounted on the engine (small honeycomb) with fuel, then use WD 40 or either to start the engine and run a few seconds until the fuel transfers.

|

|

Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel.

|

|

heron

Silver Level

Joined: 01 Dec 2012

Location: Chattanooga, TN

Points: 109

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Dec 2012 at 4:11pm Posted: 07 Dec 2012 at 4:11pm |

|

If I take off the canister on the right side of the machine and mount the fuel head and have the filter to where the bottom is almost at the bottom of the tank do you think it will still prime fine? Your is close in and there is no way I can get that in there on this machine. I'll try to get pic's on Saturday if it's not raining too hard. I can always use the secondary housing on the engine to prime it if it needs it.

Is there a better hose to run to connect everything up. I'll have to go and get fittings for the fuel head. I was going to use barbs and I guess 3/8 fuel line.

I've never heard of using WD40 for ether...wow. Yet another use for that stuff.

Edited by heron - 07 Dec 2012 at 4:12pm

|

|

Coke-in-MN

Orange Level Access

Joined: 12 Sep 2009

Location: Afton MN

Points: 42194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Dec 2012 at 4:17pm Posted: 07 Dec 2012 at 4:17pm |

When you talk of canister on RT side of machine - If a large round housing mounted to battery box - that is a LUBE-FINDER engine oil filter , Not a fuel filter . The machine used 2 canisters mounted on left side of engine for oil and fuel filters and 1 canister on right side of engine for fuel . The round canister on back Rt side is lube filter .

Edited by Coke-in-MN - 07 Dec 2012 at 4:21pm

|

|

Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel.

|

|

Coke-in-MN

Orange Level Access

Joined: 12 Sep 2009

Location: Afton MN

Points: 42194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Dec 2012 at 4:29pm Posted: 07 Dec 2012 at 4:29pm |

Here is a HD5B with the filter on the Left side (photos by John Ford Queensland AU)

|

|

Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel.

|

|

heron

Silver Level

Joined: 01 Dec 2012

Location: Chattanooga, TN

Points: 109

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Dec 2012 at 5:57pm Posted: 07 Dec 2012 at 5:57pm |

|

Nope...not on this machine. The oil is on the left and the fuel is on the right. There has never been two on the left. This is a 1955 machine. How old are the machines in the pic's...46..? I'll get some pic's on Saturday. It's nice to see that cable machine. I remember as a small kid the cable backhoes, northwest shovels..80d and 180d's. The first dump truck I drove was a Diamond T(reo) with chain drive. Grandfather push started me down a hill...couldn't turn the steering wheel and ran right into a pile of sand...luckily! I think I was 9. My grandpa had a little too much Jim Beam that day.

|

|

Coke-in-MN

Orange Level Access

Joined: 12 Sep 2009

Location: Afton MN

Points: 42194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Dec 2012 at 7:51pm Posted: 07 Dec 2012 at 7:51pm |

Mine is also a 1955 HD5G Srl # 26784 Both those machine are Down Under - AU

|

|

Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel.

|

|

heron

Silver Level

Joined: 01 Dec 2012

Location: Chattanooga, TN

Points: 109

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Dec 2012 at 9:17pm Posted: 07 Dec 2012 at 9:17pm |

|

Wow, wonder why it is different...? Cannot imagine why they did it other than maybe the one you have is some severe duty model that needed extra filtering...? I know for a fact this machine has never been hacked on by anyone except my dad who disconnected the fuel filter on the right hand side of the machine. He is trying to find the parts he took out of the canister this weekend. I'd put it back to stock if I had everything although I think if I can mount this new filter head and put the Cat filter on it that is 15" long it will do a better job than the original.

|

|

dadsdozerhd5b

Orange Level

Joined: 27 Sep 2009

Location: lansdale pa.

Points: 537

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Dec 2012 at 6:46pm Posted: 11 Dec 2012 at 6:46pm |

|

i have several of the canisters that you are talking about. i will look this weekend and see what is inside of them and will sell them to you cheap. i will post pics this weekend of what i have. i will also find the tube to grease the rollers. it looks like a 1/4" piece of pipe with a square block in the middle to put back pressure on the grease to force it into the bearings before it comes out. there is a pic of it in the back of the parts book but i will find mine and post it.

|

|

HD5B, HD5G, (2) FARMALL A's, CUB. DO IT RIGHT THE FIRST TIME, IGNORE THE LAUGHTER. FLANNEL IS ALWAYS IN STYLE.

|

|

dadsdozerhd5b

Orange Level

Joined: 27 Sep 2009

Location: lansdale pa.

Points: 537

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Dec 2012 at 7:12pm Posted: 11 Dec 2012 at 7:12pm |

here is a pic of the greaser. the gun goes on one end, the grease comes out the other and the squares put back pressure to get the new grease in where it goes while allowing the old grease to come out past it.

|

|

HD5B, HD5G, (2) FARMALL A's, CUB. DO IT RIGHT THE FIRST TIME, IGNORE THE LAUGHTER. FLANNEL IS ALWAYS IN STYLE.

|

|

heron

Silver Level

Joined: 01 Dec 2012

Location: Chattanooga, TN

Points: 109

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Dec 2012 at 8:10pm Posted: 11 Dec 2012 at 8:10pm |

Well, greased them up tonight with Corn Head Grease and a standard grease tube, pumped it in and as it came out I pulled out the tube so hopefully I got enough in there. Any ideas where I can get one of these?

dadsdozerhd5b wrote: dadsdozerhd5b wrote:

here is a pic of the greaser. the gun goes on one end, the grease comes out the other and the squares put back pressure to get the new grease in where it goes while allowing the old grease to come out past it. |

|

|

heron

Silver Level

Joined: 01 Dec 2012

Location: Chattanooga, TN

Points: 109

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Dec 2012 at 8:44pm Posted: 11 Dec 2012 at 8:44pm |

|

How many qts of oil does the 5 take? Book says 2 gallons. Put that in and nothing on the stick. Put in about 3 1/4 and she shows full...?

Also, big issue; the left steering clutch had about 5 gallons of water down in the sump. I vacuumed it out but there is all kind of rust down there. It was steering ok when I pulled it off the trailer but is there anything I can dump down there that will not hurt the fiber plates but yet clean everything up..esp. the moisture. Is there some type of drain plug under the machine? I could not see one.

Planning on going over to the dozer on Thursday and cutting a driveway in. First I have to replace the tranny check plug, make sure the transmission is filled up and then do a little dozing so hopefully working the clutch will keep it from freezing up.

FYI. if you guys like your tools I picked up a Kobalt (lowes) cordless 1/2" lithium impact. Unreal how handy this thing is on the dozer since I cannot get my compressor out to it.

Great investment!

Also, the Wix 54470 filter head works great and I now have a large Cat 2 micron spin on fuel filter along with water seperator under the seat.

Sorry, have to shrink my pic's... i'll get them on here later.

|

|

Dozer

Orange Level

Joined: 16 Aug 2011

Location: SW New York

Points: 689

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Dec 2012 at 2:53pm Posted: 12 Dec 2012 at 2:53pm |

|

There is a pipe plug under each steering clutch. Go back to August 19th on this forum "What is the tensil strength of a mouse nest?" It is about the steering clutch repair on my HD6G.

|

|

heron

Silver Level

Joined: 01 Dec 2012

Location: Chattanooga, TN

Points: 109

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Dec 2012 at 3:11pm Posted: 12 Dec 2012 at 3:11pm |

|

Great to hear! I'll be removing that tomorrow morning...if I can since it's probably been in there since 55!

Any ideas on where to get one of the grease tools for the rollers?

|

|

Dozer

Orange Level

Joined: 16 Aug 2011

Location: SW New York

Points: 689

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Dec 2012 at 3:34pm Posted: 12 Dec 2012 at 3:34pm |

|

Greese tool. Get some 1/8th pipe from your hardware store and a greese fitting with 1/8 NPT thread. When you are looking underneath for the steering clutch drain plugs, don't remove the center plug or you will get an oil bath. The plugs are supposed to be removed unless you are working in water.

|

|

DMiller

Orange Level Access

Joined: 14 Sep 2009

Location: Hermann, Mo

Points: 35310

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Dec 2012 at 4:13pm Posted: 12 Dec 2012 at 4:13pm |

Luberfiner is a brand for heavy equipment/trucks and available thru any major parts house, the canisters come in varied sizes and configurations but all work essentially the same, even the unit on the tractor now, it is a excellent fiter unit with a new cartridge. They also have filter base assemblies for other styles as fuel filters or spin on units.

|

|

heron

Silver Level

Joined: 01 Dec 2012

Location: Chattanooga, TN

Points: 109

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Dec 2012 at 4:30pm Posted: 12 Dec 2012 at 4:30pm |

Dozer wrote: Dozer wrote:

Greese tool. Get some 1/8th pipe from your hardware store and a greese fitting with 1/8 NPT thread. When you are looking underneath for the steering clutch drain plugs, don't remove the center plug or you will get an oil bath. The plugs are supposed to be removed unless you are working in water. |

Doesn't the standard grease gun tube with the coupler off work the same...b/c that is what I used. I would think the rectangular piece is needed to help pressurize the inside to get the grease into the bearings...? I'll have to check but if the plugs are removed there is probably too much junk in the bottom and the water could not drain out. Great to know! And yes, I do know about the tranny plug. My goal on Thursday is to top off the transmission oil, go on and do some dozing then drain the transmission and add GL-1 oil back into it. Can anyone confirm the tranny takes 5 gallons? Crankcase oil said 2 gallons and it was not.

|

|

heron

Silver Level

Joined: 01 Dec 2012

Location: Chattanooga, TN

Points: 109

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Dec 2012 at 4:30pm Posted: 12 Dec 2012 at 4:30pm |

DMiller wrote: DMiller wrote:

Luberfiner is a brand for heavy equipment/trucks and available thru any major parts house, the canisters come in varied sizes and configurations but all work essentially the same, even the unit on the tractor now, it is a excellent fiter unit with a new cartridge. They also have filter base assemblies for other styles as fuel filters or spin on units. |

I'm on hold with them right now...didn't know they were still in business.

|

|

heron

Silver Level

Joined: 01 Dec 2012

Location: Chattanooga, TN

Points: 109

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Dec 2012 at 7:36pm Posted: 13 Dec 2012 at 7:36pm |

|

Okay, ran the dozer for about 30 minutes today. Here are some issues:

The spool valve under the blade lever is leaking right under where it spins..."O" ring possibly...easy fix or not?

Also, right piston is dripping fluid down the piston shaft. Tried tightening "evenly" the two 3/4 inch bolts. Still dripping. Are the seals easy to find and replace with the piston on the machine?

Dropped the tranny fluid. Looked like brown water..Yuck. Poor fluid has probably not been changed in 45 years.

Shifter is definitely sloppy. Will have to open that up at some point.

I dropped about 3 gallons of diesel thru it and let it all drip out real well and added back

GL1 90wt gear oil. Hope that is the right stuff as I heard from the oil company that the GL1 is the same as the 50wt motor oil. (no detergents and that is what make it different...?) Hope that was the right advice.

Planning on changing out the water temp guage on Saturday. Any special fitting needed? I assume the stock guage is mechanical...hope so!

|

|

dadsdozerhd5b

Orange Level

Joined: 27 Sep 2009

Location: lansdale pa.

Points: 537

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Dec 2012 at 7:36am Posted: 15 Dec 2012 at 7:36am |

|

i have several of the blade controls if you need one but i have not had one apart. i would flush the tranny/bevel gear with the diesel only move it back and forth a few times to really wash it. check the gasket on top of the bevel gear as they dry out and allow water into the system. pistons use a packing that is available at a hydraulic shop. you can tighten them fairly tight until they stop leaking. used packig usually weeps. do the cylinders have pits or scores? you will have trouble if they do. i believe the water temp gauge threads into the head with pipe thread. a new gauge should come with the adapter. keep soaking and tapping the track adjusters to get some of the lube in there to free them up. it is some work to get them unstuck but use the time to your advantage and spray them as often as possible. i will find a pic of the packing and post it.

|

|

HD5B, HD5G, (2) FARMALL A's, CUB. DO IT RIGHT THE FIRST TIME, IGNORE THE LAUGHTER. FLANNEL IS ALWAYS IN STYLE.

|

|

dadsdozerhd5b

Orange Level

Joined: 27 Sep 2009

Location: lansdale pa.

Points: 537

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Dec 2012 at 7:47am Posted: 15 Dec 2012 at 7:47am |

here is a picture of packing. there are 3 sets in this pic as each cylinder uses 5 or 6 pieces.  the ram does not need to be removed to replace the ram end packing. if the cylinder leaks down, then the inside gland packing needs to be replaced whic requires complete cylinder disassembly.

|

|

HD5B, HD5G, (2) FARMALL A's, CUB. DO IT RIGHT THE FIRST TIME, IGNORE THE LAUGHTER. FLANNEL IS ALWAYS IN STYLE.

|

|

heron

Silver Level

Joined: 01 Dec 2012

Location: Chattanooga, TN

Points: 109

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Dec 2012 at 8:02am Posted: 15 Dec 2012 at 8:02am |

|

The piston has some scores but they have been there forever. I'll have to see today if tightening it had any positive effect.

On the tranny I did not remove the top plate, just removed the fill plug and dumped diesel down and out. I figured I would do that, run the new oil for a little bit and simply drain and refill again.

Yes, I will keep applying the PB blaster to the track adjustors. Not sure if it will free up those shims. My dad thinks the track has to come apart but we lack the right equipment and a really good mechanic.

Not sure on the blade control what has to be done. It works fine but just leaks. I may disassemble it and have a look. Seems like it would be some type of packing in there also as it's leaking out from underneath the swivel point of the lever.

There is no leak down in the blade so hopefully the packing will solve the issue. It's not so bad and it may seal up the more the dozer is used.

|

|

DMiller

Orange Level Access

Joined: 14 Sep 2009

Location: Hermann, Mo

Points: 35310

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Dec 2012 at 8:12am Posted: 15 Dec 2012 at 8:12am |

|

NAPA dealers should also have access to basic fuel filer spin of heads, the Allis head on my 7G is designed to draw thru the primary(vacuum or tank gravity), to the fuel transfer pump then from it to the secondary(pressurized) then to the injection system but mine has a Allis 4 stroke in it. The old Detroit style filters were similar on trucks, you could get a combination or separate head(s) from dealers that sold AC( not Allis Chalmers but General Motors AC) fliters and housings.

|

|

DMiller

Orange Level Access

Joined: 14 Sep 2009

Location: Hermann, Mo

Points: 35310

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Dec 2012 at 8:23am Posted: 15 Dec 2012 at 8:23am |

Found this site, go to filter bases, P/N FK1304, is a direct conversion set for Detroit cannister to spin on. Have others too as a OB1303 for spin on oil.

Edited by DMiller - 15 Dec 2012 at 8:41am

|

|

heron

Silver Level

Joined: 01 Dec 2012

Location: Chattanooga, TN

Points: 109

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Dec 2012 at 10:02am Posted: 15 Dec 2012 at 10:02am |

DMiller wrote: DMiller wrote:

NAPA dealers should also have access to basic fuel filer spin of heads, the Allis head on my 7G is designed to draw thru the primary(vacuum or tank gravity), to the fuel transfer pump then from it to the secondary(pressurized) then to the injection system but mine has a Allis 4 stroke in it. The old Detroit style filters were similar on trucks, you could get a combination or separate head(s) from dealers that sold AC( not Allis Chalmers but General Motors AC) fliters and housings. |

Yes, I put the Wix filter adapter on last week. Works great and allows me to run readily available Cat 1r-0749. Not sure on the oil filter though. The one on the left side of the machine is still working fine and the Napa/Wix are easy to get. I may convert that in the future to a spin on but for now I'm leaving it alone. Bigger fish to fry right now with this dozer. I'm just lucky the motor runs great! No smoke and she will push a full blade like nothing. If I can get the track adjustors freed up and the final drives sealed up the machine will be great.

|

|

heron

Silver Level

Joined: 01 Dec 2012

Location: Chattanooga, TN

Points: 109

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Dec 2012 at 9:34pm Posted: 15 Dec 2012 at 9:34pm |

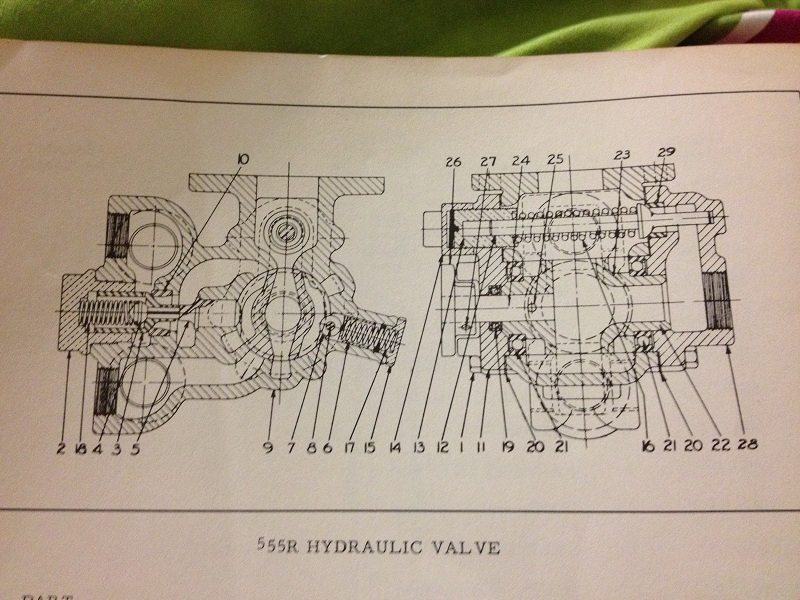

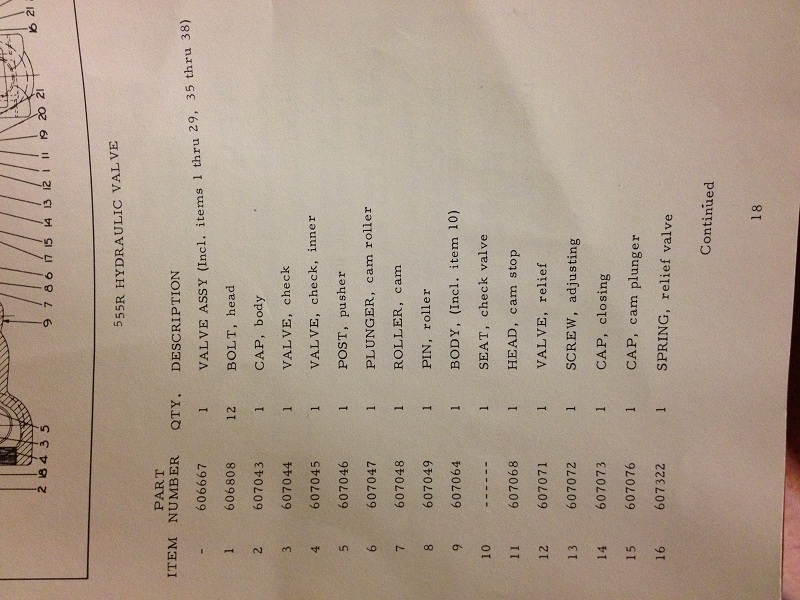

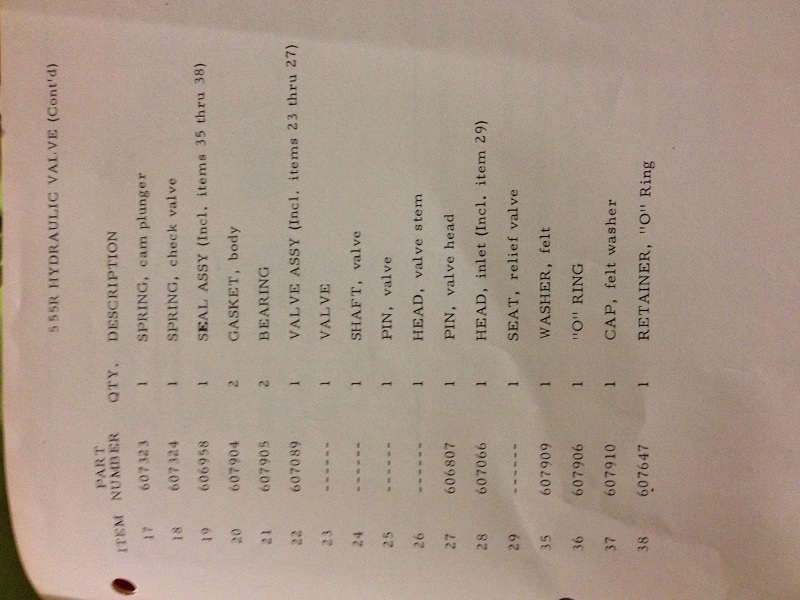

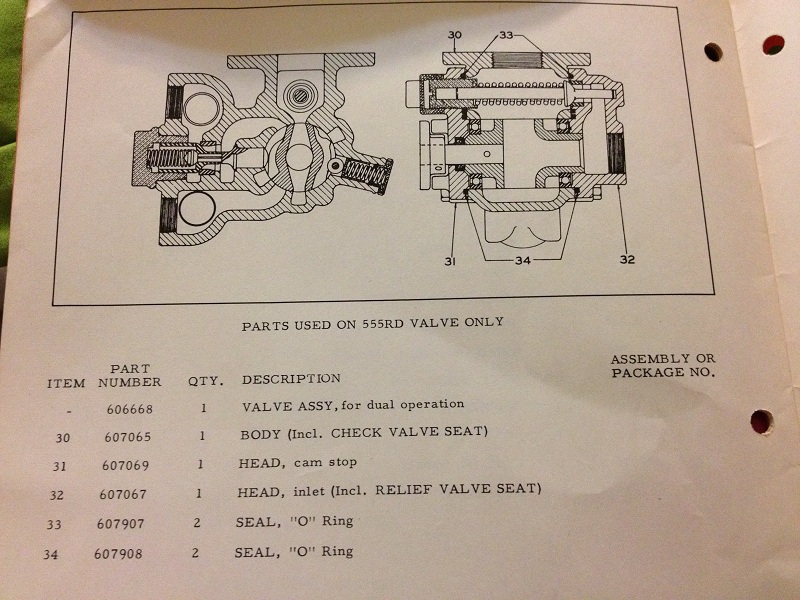

Hey guys, I began to take the 9/16" bolts off the top of the blade lever housing and it made the lever get really stiff so I stopped and screwed them back in. I'm afraid there are a bunch of springs etc..that will come apart as soon as I try to lift it off.  Does anyone have any illustrations or anything regarding the lever valve. The fluid is coming out right underneath where it spins. I'm hoping it's just a simple packing or "O" ring that needs to be replaced but I did not want to open up a can 9pm and rain coming in. Also, hooked up the temp guage tonight and lost some coolant. I'm puzzled because once I got the machine running and dozing the temp only went up to 160 and yet the fluid did not look down at all in the filler cap...? Could the thermostat be bad or water pump not circulating the coolant. It should have been down a half gallon or so. I'd think if the pump was bad the machine would heat up...  One thing I did not do is open the vent valve on the thermostat when I filled it up. It took almost 4 gallons so I thought it was good. Now I'm reading the manual and wondering if maybe I didn't close the vent valve and that is maybe why it's not heating up much.

Edited by heron - 15 Dec 2012 at 10:42pm

|

|

heron

Silver Level

Joined: 01 Dec 2012

Location: Chattanooga, TN

Points: 109

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Dec 2012 at 6:29pm Posted: 18 Dec 2012 at 6:29pm |

|

|

|

dadsdozerhd5b

Orange Level

Joined: 27 Sep 2009

Location: lansdale pa.

Points: 537

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Dec 2012 at 8:20pm Posted: 18 Dec 2012 at 8:20pm |

|

|

|

HD5B, HD5G, (2) FARMALL A's, CUB. DO IT RIGHT THE FIRST TIME, IGNORE THE LAUGHTER. FLANNEL IS ALWAYS IN STYLE.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

dadsdozerhd5b wrote:

dadsdozerhd5b wrote: