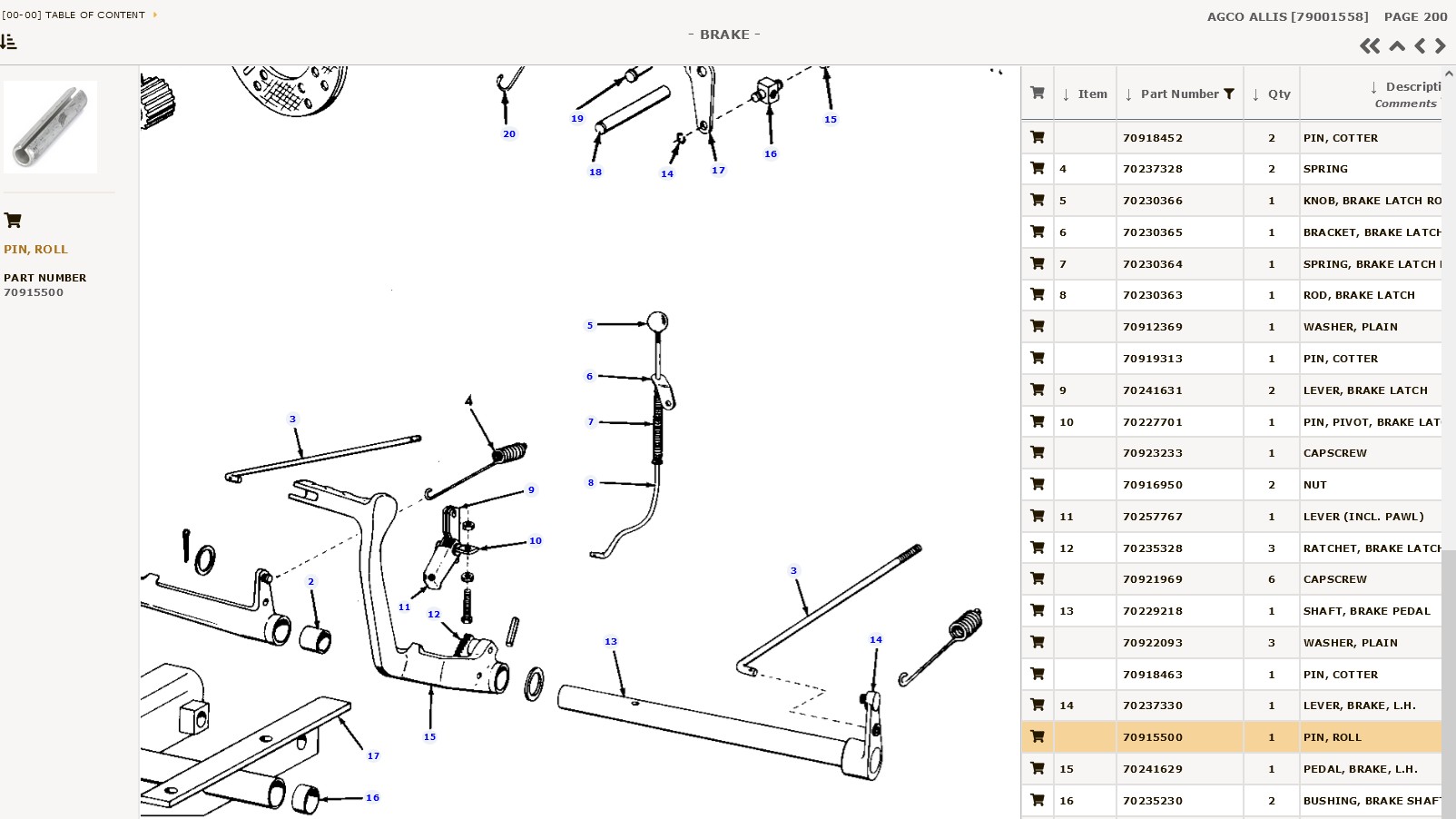

So the left brake started not returning back to its stop. Studying it, the spring on the left is intact and seems to be returning the actuating lever and rod back to its rest position. There appears to be slop in the pedal to the shaft. The Agco parts book shows a roll pin or something similar securing the left brake pedal to the shaft. It looks like I need to replace the roll pin in the left brake pedal to the cross shaft.

Can I just drive out the old, bent pin and replace it with new, or should I plan to pull both pedals off and kind of rework everything? Is there room for the old pin to be driven out leaving everything intact, which would sure make things simple. Also, is there an "upgrade" in that I should replace the pin with a hardened bolt, assuming I have enough clearance?

Thanks in advance for anyone who has done this before.

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)