| Author |

Topic Search Topic Search  Topic Options Topic Options

|

CAL(KS)

Orange Level

Joined: 18 Sep 2009

Location: Chapman, KS

Points: 3804

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Model c main caps Topic: Model c main caps

Posted: 24 May 2017 at 8:43am |

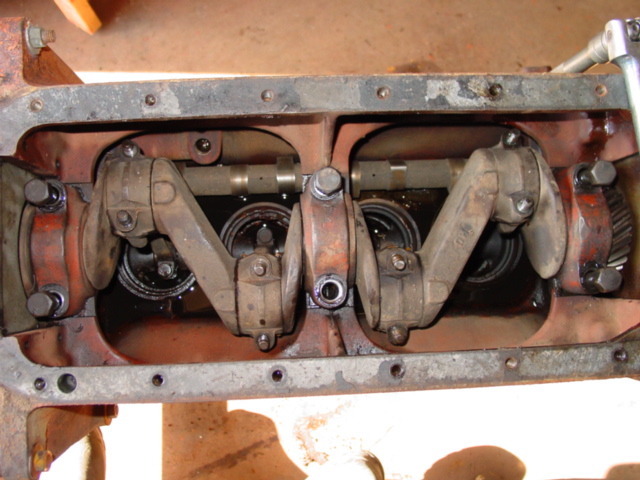

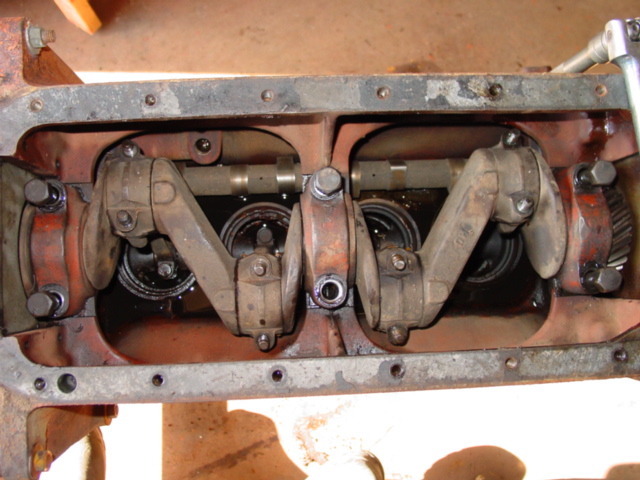

What is the correct orientation of the crankshaft main caps? i have 2 books and neither is specific, one says reinstall as they were originally. This engine has both bearing insert tab slots toward the camshaft side which i thought was correct. The issue is it turns hard. i have pulled all the mains, all look good. No abnormal wear, pitting or scoring but are obviously not new. If I loosen the caps it turns easy. All appear to be shimmed corrrectly so wondering if the caps are backwards from previous owner.

I bough this model c from a widow for scrap price. It was inside a building but the pan was off and one rod cap removed. I cleanup up, shimmed and reinstalled the rod bearing. the engine turns hard. check all the rods they arnt the problem. Cap bolt are wired and nicely done so pretty sure previous owner didnt touch them,by example of his other repairs, if you know what i mean. The problem is in the mains but i dont understand why with no abnormal wear, and the bearings arnt new.

Other than checking the shim thickness and adding is there something else i should be checking? engine is still in tractor so messing with the caps and shims is a real pain laying on the floor.

|

|

Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20

Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15

|

|

|

Sponsored Links

|

|

|

Brian Jasper co. Ia

Orange Level

Joined: 11 Sep 2009

Location: Prairie City Ia

Points: 10508

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 May 2017 at 9:34am Posted: 24 May 2017 at 9:34am |

|

Check your line bore for alignment. When I did my CA engine with proper clearance on a fresh regrind it would not turn with the caps tight. I forget how far out it was, but it doesn't take much misalignment to be a problem. I had the block line bored and did away with the shims in the process.

|

|

"Any man who thinks he can be happy and prosperous by letting the government take care of him better take a closer look at the American Indian." Henry Ford

|

|

CAL(KS)

Orange Level

Joined: 18 Sep 2009

Location: Chapman, KS

Points: 3804

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 May 2017 at 10:12am Posted: 24 May 2017 at 10:12am |

|

yes that would be the way to go but I am trying to get the thing together to evaluate the tractor to see if its worth spending money on. could be an oil burner with bad trans and hydraulic pump and clunky final drive lol

|

|

Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20

Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15

|

|

Gerald J.

Orange Level

Joined: 12 Sep 2009

Location: Hamilton Co, IA

Points: 5636

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 May 2017 at 10:13am Posted: 24 May 2017 at 10:13am |

|

Try turning the caps to the opposite orientation and see if they still bind when tightened. If the caps have been moved it will be harder to fit them. It would be easiest with the crankshaft removed and try cap and position and direction to line up the inserts in the bock and cap.

Gerald J.

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5093

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 May 2017 at 10:34am Posted: 24 May 2017 at 10:34am |

Here is a hint! The wide sides face each other between 1 and 2 cylinders as well as 3 and 4 cylinders. Nothing works better than making sure the rod is centered in the pistons at the same time it is centered on the crankshaft journals by watching as it is assembled.

|

|

CAL(KS)

Orange Level

Joined: 18 Sep 2009

Location: Chapman, KS

Points: 3804

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 May 2017 at 10:38am Posted: 24 May 2017 at 10:38am |

yes i checked that and they are correct and turn easily. trying to figure out if the mains are flipped around as that is when it gets tight

what i dont understand is how it could turn as tight as it does without damaging the bearings.

Edited by CAL(KS) - 24 May 2017 at 10:39am

|

|

Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20

Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15

|

|

Dakota Dave

Orange Level

Joined: 12 Sep 2009

Location: ND

Points: 3973

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 May 2017 at 9:53pm Posted: 24 May 2017 at 9:53pm |

|

You know in an hour you could have the engine in a rotating engine stand.four bolts in engine to trany and four bolts drop the whole front bolster off.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)