| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Allis dave

Orange Level

Joined: 10 May 2012

Location: Northern IN

Points: 3085

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Installing WD45 engine sleeves question Topic: Installing WD45 engine sleeves question

Posted: 26 Mar 2016 at 9:02pm |

I started installing the sleeves on the WD45 engine this afternoon. I cleaning everything up good with a wire wheel and dropped the sleeves in with no orings. Sleeves turn by hand in the block. Problem is I've got .004 -.009 standout on all the sleeves. Usually in the .005-.006 range. When I spin the sleeves I only get about .001 change on the indicator. I can measure different spots around the sleeves and get from .004-.009 on the same sleeve. Just from the fingernail check I can tell it's different. Block deck isn't perfect but cleans up pretty good. I've cleaned the counter bores with break clean,a wire wheel and scraped with a razor blade. To measure I'm using a dial indicator and magnetic block.

What's my best options? Do I need to get the block decked and re-cut the counter bores? The service manual says to file the sleeves, but that doens't seem like it's help much when I get different readings when checking around the sleeves.

|

|

|

Sponsored Links

|

|

|

MACK

Orange Level

Joined: 17 Nov 2009

Points: 7664

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Mar 2016 at 9:23pm Posted: 26 Mar 2016 at 9:23pm |

|

Put the head on and go. The head will push them down. MACK

|

|

Bill_MN

Orange Level

Joined: 12 Sep 2009

Location: Sioux Falls, SD

Points: 1471

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Mar 2016 at 9:24pm Posted: 26 Mar 2016 at 9:24pm |

|

If you are using one of the good thick metallic head gaskets it should compress and seal just fine on .005 difference, I wouldn't worry

|

|

1951 WD #78283, 1918 Case 28x50 Thresher #76738, Case Centennial B 2x16 Plow

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22301

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Mar 2016 at 10:09pm Posted: 26 Mar 2016 at 10:09pm |

|

After you run it for a few hrs, retorque the head bolts when COLD and you'll have no issues.

|

|

Allis dave

Orange Level

Joined: 10 May 2012

Location: Northern IN

Points: 3085

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Mar 2016 at 7:00am Posted: 28 Mar 2016 at 7:00am |

|

Thanks guys This is my first full rebuild on my own and I want to make sure everything's right.

Would it be worth it to try filing down a couple of the high spots that are .008 after sleeves and O-rings are set in place?

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22301

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Mar 2016 at 7:40am Posted: 28 Mar 2016 at 7:40am |

|

File what?? the sleeves????????? The engine has run 70 years like that hasn't it ?? You'd better be bolting the sleeves in place with heavy flat washers to squeeze them down where they belong before you do any measuring.

|

|

Kevin in WA

Orange Level Access

Joined: 08 Feb 2010

Location: Lynden, WA

Points: 612

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Mar 2016 at 9:05am Posted: 28 Mar 2016 at 9:05am |

|

I have found that some aftermarket sleeves have a slightly thicker flange, about .002" Have seen it that too much standout on these engines can cause the head gasket to leak coolant on the right side,

|

|

Allis dave

Orange Level

Joined: 10 May 2012

Location: Northern IN

Points: 3085

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Mar 2016 at 7:01am Posted: 29 Mar 2016 at 7:01am |

|

Last night I compared the old M&W sleeves to the new reliance sleeves. Kevin's right. The new one's measure .247 flange thickness, but the old ones are only .245. SO that where my .005 standout is coming from.

I had the new sleeves tightened down with 2 bolts and doubled up 1/2 washers, maybe sunk the sleeves .0005. Still around .005 which I'm ok with

The only spot that bothers my is around the thermostat studs I'm getting .007-.008 standout on the 1 and 2 cylinders. Machine shop said it'd be around $300 to deck the block and recut the counter bores. There were some signs of coolant leakage but hoping that having the head surfaced will take care of it. I think I'm taking everyone's advice and giving it a good spray of copper coating and re-torqueing.

|

|

CTuckerNWIL

Orange Level

Joined: 11 Sep 2009

Location: NW Illinois

Points: 22825

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Mar 2016 at 10:37am Posted: 29 Mar 2016 at 10:37am |

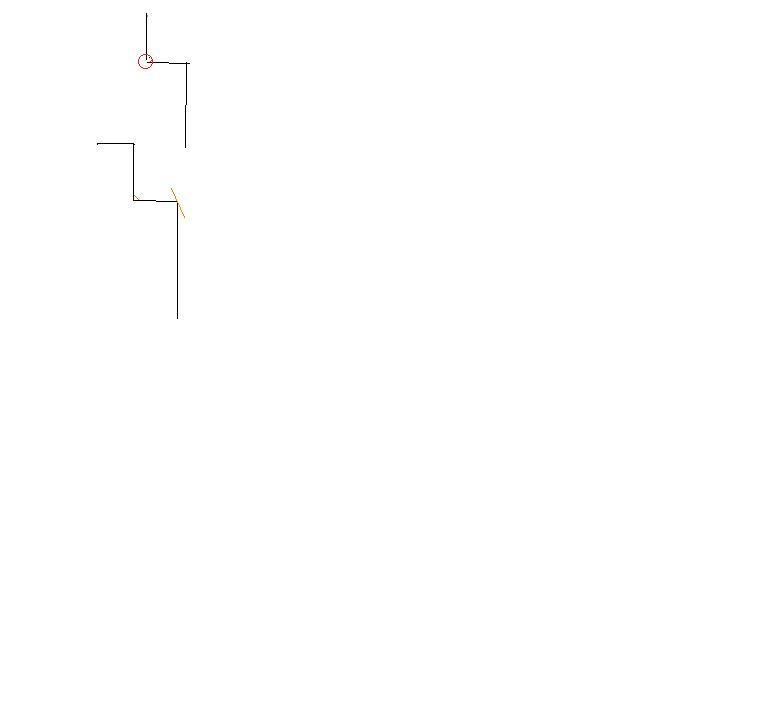

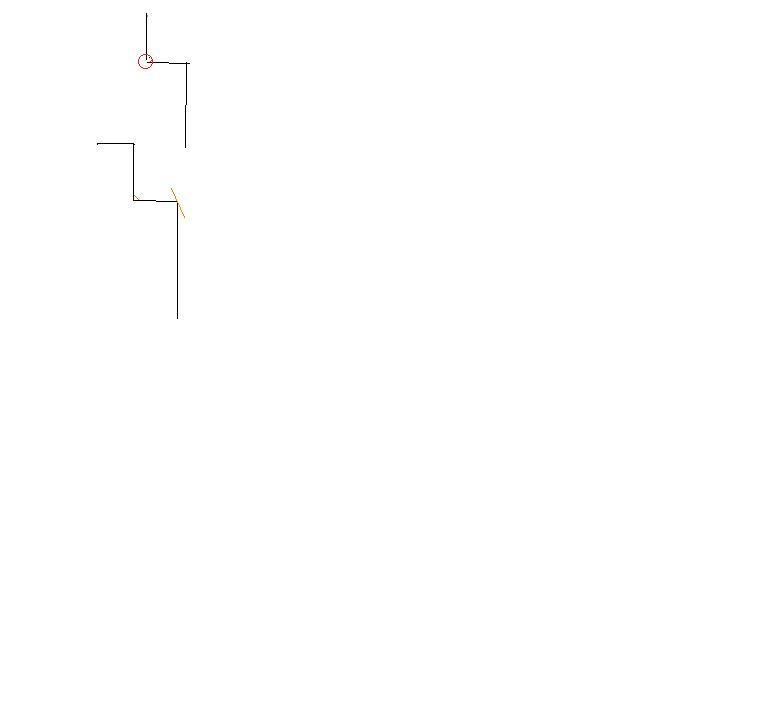

I would make sure the corner of the sleeve (red circle below) has a bigger radius, than what is in the corner of the c'bore and the top edge of the sleeve bore (orange angle) has a bigger radius than the inside corner of the sleeve.

|

|

|

|

Allis dave

Orange Level

Joined: 10 May 2012

Location: Northern IN

Points: 3085

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Mar 2016 at 7:59am Posted: 31 Mar 2016 at 7:59am |

|

Thanks for the suggestion Charlie. I checked last night and neither the counter bore nor sleeve flange has much of a radius. They are pretty square. I took a red sharpie marker and colored the bottom of the flange and spun the sleeve in the block and it looks like I'm getting pretty good sleeve to counter bore contact on all 4 cylinders. I had red ink deposited all the way around the counter bore as long as I pushed down on the sleeve correctly.

Hopefully I'll install the sleeves tonight or tomorrow with O-rings and clamp them down. Thanks for everyone's suggestions.

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8622

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Mar 2016 at 11:59am Posted: 31 Mar 2016 at 11:59am |

|

Dave,

If you have any pictures please post them. on my bucket list is to rebuild a Allis engine someday.

Regards,

Chris

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

Allis dave

Orange Level

Joined: 10 May 2012

Location: Northern IN

Points: 3085

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Mar 2016 at 12:28pm Posted: 31 Mar 2016 at 12:28pm |

|

Chris,

I'll be taking some as I work. Maybe that engine will be in a D17 ;)

|

|

B26240

Orange Level

Joined: 21 Nov 2009

Location: mn

Points: 3866

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Mar 2016 at 4:16pm Posted: 31 Mar 2016 at 4:16pm |

|

Keep us posted on how it turns out as this could be an issue for others. I had a antifreeze leak on the outside of a WD45 so I took the head off and cleaned everything up and put a new head gasket on coating it with aluminum paint. Used the tractor for about 10 years after with no leaks.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)