| Author |

Topic Search Topic Search  Topic Options Topic Options

|

CAL(KS)

Orange Level

Joined: 18 Sep 2009

Location: Chapman, KS

Points: 3804

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 19 Feb 2016 at 11:41am Posted: 19 Feb 2016 at 11:41am |

I'm just not familiar enough with this tractor or the vocabulary you are using above to make this assessment. If you can be more specific or if there are videos of these areas being examined or replaced, I would be better able to internalize what you are referring to as "undercarriage".

|

undercarriage refers to the following wear items of the tracks. front idler, truck rollers (bottom rollers), rear sprocket, rail (chain), and its parts contacting the sprocket (bushing and internal pins) and support rollers

|

|

Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20

Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15

|

|

|

Sponsored Links

|

|

|

split

Bronze Level

Joined: 18 Feb 2016

Location: Texas

Points: 18

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Feb 2016 at 11:55am Posted: 19 Feb 2016 at 11:55am |

CAL(KS) wrote: CAL(KS) wrote:

undercarriage refers to the following wear items of the tracks. front idler, truck rollers (bottom rollers), rear sprocket, rail (chain), and its parts contacting the sprocket (bushing and internal pins) and support rollers |

Ah, okay, I follow that. As far as I know this tractor was in operation at the time it blew...so the track system must have been operating. So its at least usable, though it might be worn out. Does anyone have good/bad pictures of these wear items item?

|

|

split

Bronze Level

Joined: 18 Feb 2016

Location: Texas

Points: 18

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Feb 2016 at 2:05pm Posted: 19 Feb 2016 at 2:05pm |

HD6GTOM wrote: HD6GTOM wrote:

Steering clutches might be stuck. 1 of mine did after I let it sit 2 years due to0 back and arm problems. Next time you are near it, post close up a picture of the sprocket teeth and the large front roller.

|

You are referring to the Track sprocket and roller?

HD6GTOM wrote: HD6GTOM wrote:

Is the floor pan, the 1 that your feet rest on somewhere close by?

|

I noticed that it appears to be missing in the picture. I did find a flat metal piece, which could be the pan, but I doubt it as the paint was too good on it. The pan may be missing

HD6GTOM wrote: HD6GTOM wrote:

The knob on the upper left of the dash is the fuel shutoff. The long lever leaning forward beside it is the clutch. When you pull it back does it snap good? It should take something like 35 lbs of force to make it snap back, going from bad memory here.

|

I never tried the controls....they all looked very unfamiliar to me. I will try it next time I'm there.

HD6GTOM wrote: HD6GTOM wrote:

If it is like mine it is a 24 volt system, looks like the top to the battery box is off, should be 2 12 volt batterys in it. .... |

It appeared to have two battery boxes on either side of the operators seat. The cover was off of both of them.

|

|

split

Bronze Level

Joined: 18 Feb 2016

Location: Texas

Points: 18

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Feb 2016 at 3:39pm Posted: 19 Feb 2016 at 3:39pm |

I found this picture which shows the pan or some sort of cover. It is sitting atop the track. Anyone know what this is?

|

|

nella(Pa)

Orange Level Access

Joined: 11 Sep 2009

Location: Allentown, Pa.

Points: 3141

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Feb 2016 at 4:28pm Posted: 19 Feb 2016 at 4:28pm |

[QUOTE=split] I found this picture which shows the pan or some sort of cover. It is sitting atop the track. Anyone know what this is?

It is the cover that goes over the starter.

|

|

Lee Bradley

Bronze Level

Joined: 13 Oct 2009

Location: Kingston, WA

Points: 120

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Feb 2016 at 2:29am Posted: 20 Feb 2016 at 2:29am |

|

It is a fender. Go on top of the frame and covers the starter. Probably had it off checking the starter when the engine wouldn't crank.

|

|

split

Bronze Level

Joined: 18 Feb 2016

Location: Texas

Points: 18

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Feb 2016 at 10:03pm Posted: 24 Feb 2016 at 10:03pm |

I had someone take a few more pictures. The first one is of the engine plate.  This is from the dash. The top plate is unreadable. The lower plate is subject to interpretation. It appears to be: 86P1780

there may be another digit in front of the first 8, but I can't make it out.

|

|

LeonR2013

Orange Level

Joined: 01 Jan 2013

Location: Fulton, Mo

Points: 3500

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Mar 2016 at 10:25pm Posted: 17 Mar 2016 at 10:25pm |

|

From the looks of the pads I would guess that the undercarriage is good. if the are, a motor change would be in order. Just my opinion, it,s you nickel. Leon Cmo

|

|

B26240

Orange Level

Joined: 21 Nov 2009

Location: mn

Points: 3866

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Mar 2016 at 2:45pm Posted: 18 Mar 2016 at 2:45pm |

|

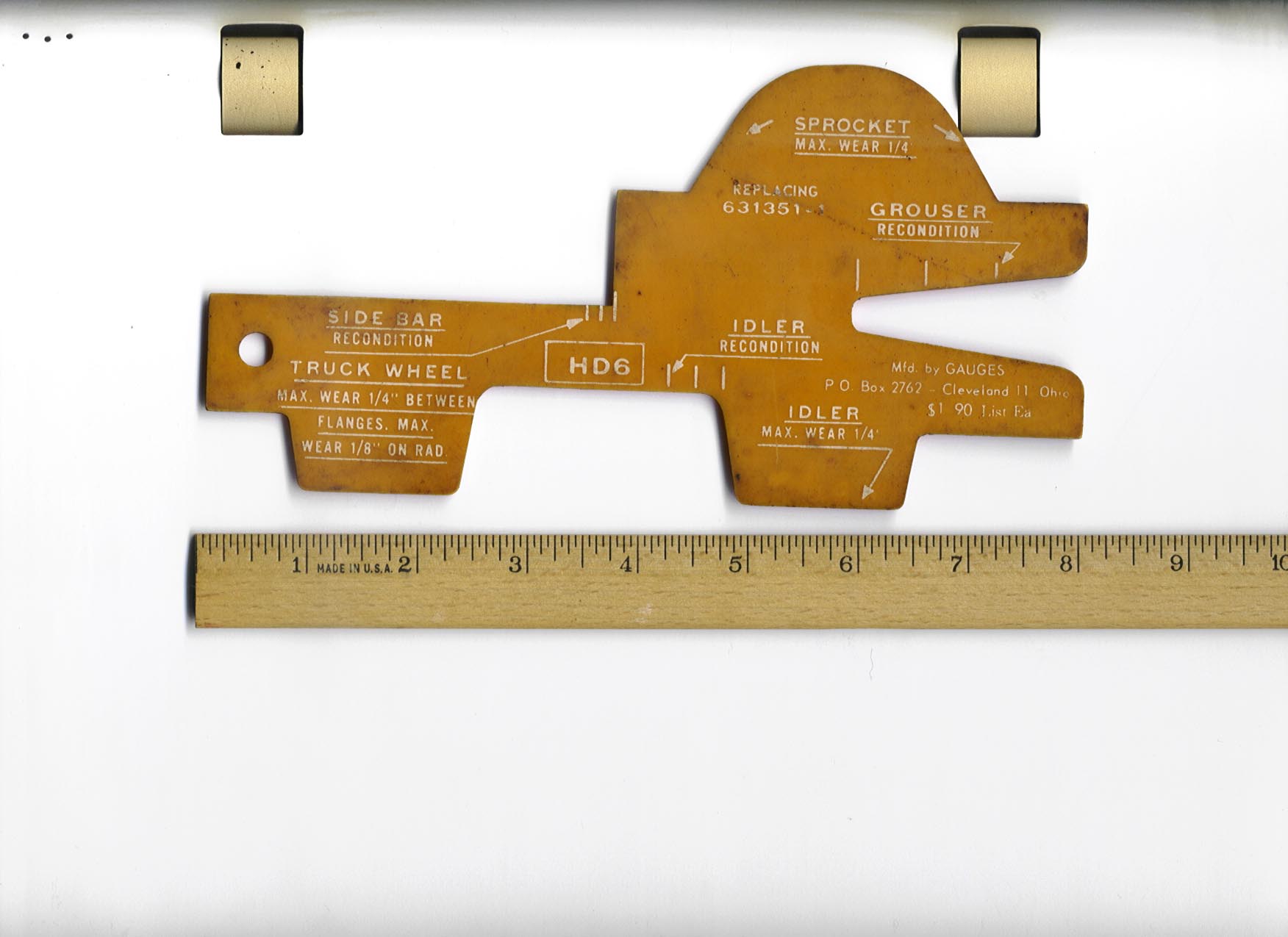

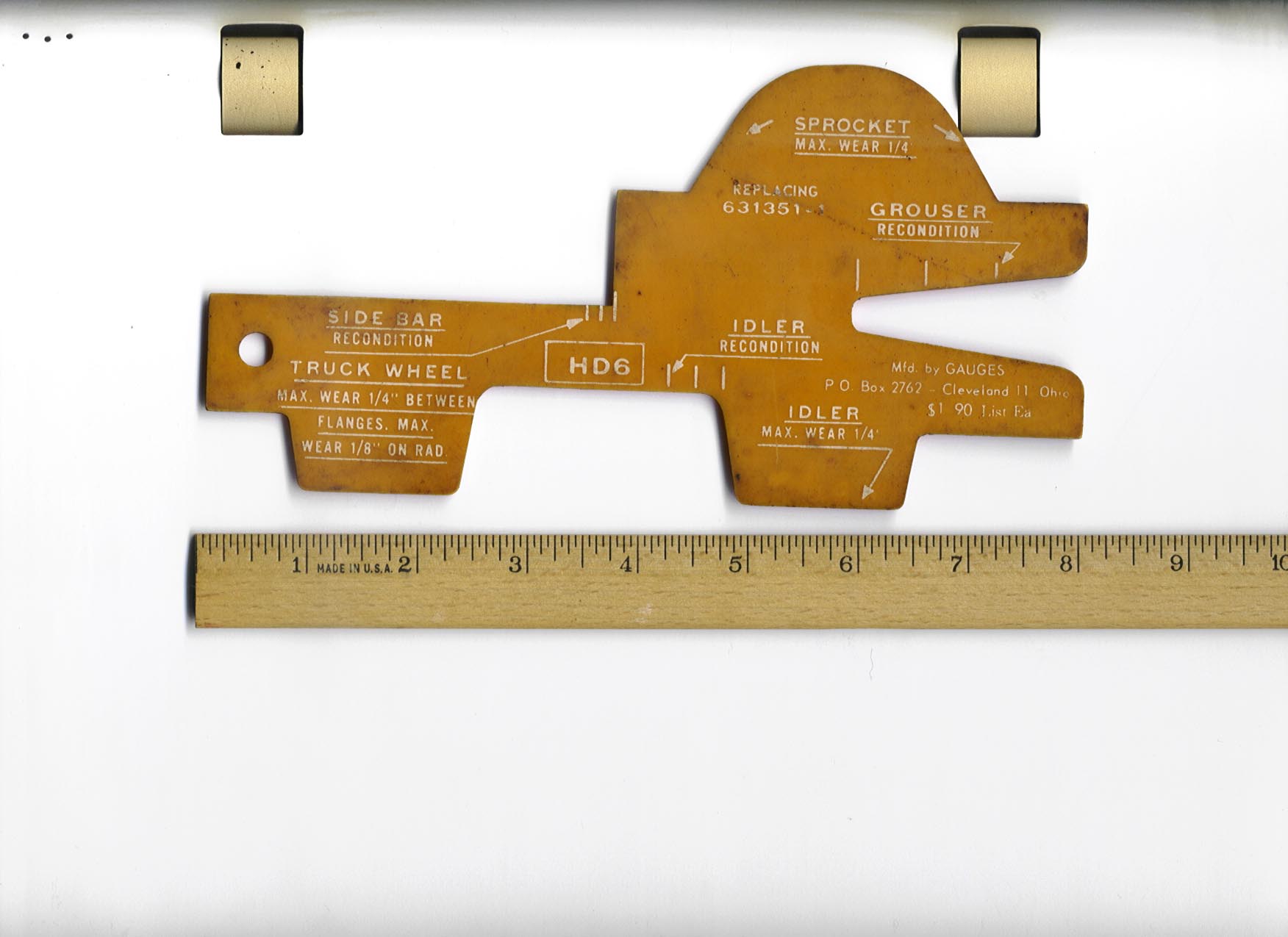

Split; If you can find someone on this site or else where that has a track gauge who would be willing to trace it out on some thick paper like poster type paper and mail it to you then you could determine the condition of the undercarriage. If the undercarriage parts are serviceable that will be the parts of the most value. Yes you could put another engine in it and use it on your property however it sounds like (pardon me for saying this) you aren't real mechanical and this old machine needs a real mechanic. I suggest you sell the machine for the value of track parts plus scrap price for whats left over. Not many people out there who have the skill and equipment to move a dead crawler and undertake a project of this size. JMO Mark

|

|

Coke-in-MN

Orange Level Access

Joined: 12 Sep 2009

Location: Afton MN

Points: 42171

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Mar 2016 at 4:43pm Posted: 18 Mar 2016 at 4:43pm |

I have posted a picture of the track gauge on here

|

|

Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel.

|

|

Dozer

Orange Level

Joined: 16 Aug 2011

Location: SW New York

Points: 689

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Mar 2016 at 8:07am Posted: 19 Mar 2016 at 8:07am |

|

It is sad whenever one of these GRAND OLD MACHINES is scrapped. The HD6 is one of the last crawlers that a mechanic can work on. Newer faster more productive crawlers are more complicated and difficult to keep running. If you are unable to transplant a motor find someone that can. The value is in the undercarrage however the HD6 can continue working until the track bushings are worn thru and the track pins are visible.

|

|

LeonR2013

Orange Level

Joined: 01 Jan 2013

Location: Fulton, Mo

Points: 3500

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Mar 2016 at 3:34pm Posted: 19 Mar 2016 at 3:34pm |

|

split, if you could take a picture of the sprockets, front idlers, maybe a roller you really wouldn't need a track gauge. Be nice to have but not mandatory. Then post the pic. here and the guys would have a better idea of their condition. Also if you can reach under the track at the top, feel of the bushing and see how much wear is on it. They can stand a lot of wear before needing to be changed. They can also be turned half a round and then you're pulling on a fresh side. You seem to have at least a moderate amount of mechanical ability or you would't be thinking about working on the machine. Be warned tho. that it is hard heavy work. But it's nothing a case of brew and four or five friends can't handle. Leon Cmo

|

|

JC-WI

Orange Level Access

Joined: 11 Sep 2009

Location: wisconsin

Points: 34528

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Mar 2016 at 3:49pm Posted: 19 Mar 2016 at 3:49pm |

And if you get it running, don't wait till they look like this to turn them pins and bushings... As seen on a TD18

or like these... on the HD5 I had bought as was/is.

|

|

He who says there is no evil has already deceived himself

The truth is the truth, sugar coated or not. Trawler II says, "Remember that."

|

|

LeonR2013

Orange Level

Joined: 01 Jan 2013

Location: Fulton, Mo

Points: 3500

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Mar 2016 at 3:55pm Posted: 19 Mar 2016 at 3:55pm |

|

Amazing! See how long they can run? Leon Cmo

|

|

LeonR2013

Orange Level

Joined: 01 Jan 2013

Location: Fulton, Mo

Points: 3500

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Mar 2016 at 2:18pm Posted: 25 Mar 2016 at 2:18pm |

|

By the way a set of pad bolts would save an unbelievable amount of time if you have to change out the rails. On this size I've taken a railroad spike hammer, set the track up on it's side and hit the nut on it's side a good hard lick. Go down one side of the track, turn the track over and repeat. It's a lot easier than fighting all those rusted together bolts. Oh, the bolts snap right off. Leon R Cmo

|

|

Dozer

Orange Level

Joined: 16 Aug 2011

Location: SW New York

Points: 689

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Mar 2016 at 7:01am Posted: 26 Mar 2016 at 7:01am |

|

If I owned this machine I would fix it. You should know that you should be able to purchase a working HD6 for less than it will cost you to replace the track and motor. I enjoy running equipment that I was able to repair and put back into service. I am proud to have saved heavy equipment from being melted down as scrap.

|

|

gemdozer

Orange Level

Joined: 17 Sep 2009

Points: 1072

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Mar 2016 at 1:42pm Posted: 26 Mar 2016 at 1:42pm |

|

Running with track like that you could brooked a final drive

|

|

LeonR2013

Orange Level

Joined: 01 Jan 2013

Location: Fulton, Mo

Points: 3500

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Apr 2016 at 2:46pm Posted: 02 Apr 2016 at 2:46pm |

|

I just wonder if the finals would hold up to a 90h.p. engine without being awfully careful? It sure would make a good machine and I'd jump on it like a duck on a june bug. Leon R Cmo

|

|

combinechris

Silver Level

Joined: 20 Jul 2015

Location: wittenberg,Wi.

Points: 424

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Apr 2016 at 5:23pm Posted: 02 Apr 2016 at 5:23pm |

|

I got some of my undercarriage parts from Cat.

|

|

35 combines and 15 forage harvesters. mostly allis combines and equipment.WTB 2 row cornhead for a 90

|

|

LeonR2013

Orange Level

Joined: 01 Jan 2013

Location: Fulton, Mo

Points: 3500

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Apr 2016 at 5:18am Posted: 09 Apr 2016 at 5:18am |

|

Hey split, what's the latest? We all interested(nosey).

|

|

split

Bronze Level

Joined: 18 Feb 2016

Location: Texas

Points: 18

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Apr 2016 at 3:14pm Posted: 15 Apr 2016 at 3:14pm |

|

I have yet to return to Oregon where the Tractor is located.

Lately, I have been thinking that even though there is a hole in the block, I might be able to weld or patch the hole....enough to seal in the oil, and then replace the lower bearings to get it running. This assumes the crank is not hammered....which it likely is.

I just don't want to dump a lot of time and $$$ into this old machine, which might have a host of other problems that may have existed prior to the failure and new issues resulting from sitting for an unknown number of years

|

|

LeonR2013

Orange Level

Joined: 01 Jan 2013

Location: Fulton, Mo

Points: 3500

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Apr 2016 at 10:37pm Posted: 21 Apr 2016 at 10:37pm |

|

Be a shame to not bring'er back to life, but it's yours to do with as you please, not somebody else. Leon R Cmo

|

|

Dozer

Orange Level

Joined: 16 Aug 2011

Location: SW New York

Points: 689

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2016 at 6:54am Posted: 22 Apr 2016 at 6:54am |

|

You have to understand that you are not going to be able to weld the block and get it running. Compared to working on automobiles everything on heavy equipment is about 5 times heavier, more expensive, and more difficult to replace. The least expensive repair will be to find another motor.

The worst thing you could do is to take it apart and not repair it. The HD6 is a grand old machine and should be repaired. Do not start the project unless you have the time and resources to complete it.

It is going to cost at least $3000. If you get it operational you might be able to sell it for $3000 to $5000

Comments please

|

|

michale34

Silver Level

Joined: 15 Mar 2011

Location: arkansas

Points: 472

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2016 at 8:07am Posted: 22 Apr 2016 at 8:07am |

|

the least expensive thing on these is the diesel it takes to run it . even a simple fan belt is 10x more than a car

|

|

Ferdinand

Orange Level

Joined: 31 Mar 2016

Location: North Carolina

Points: 1951

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2016 at 8:45am Posted: 22 Apr 2016 at 8:45am |

|

There is an AC 7000 engine for sale in Richmond, VA: $800.00 with turbo. If I understand correctly, this is the engine to convert HD6's.

I'd take on a project like that but, the dozer is in Oregon. 2500 miles away from me.

|

|

Dozer

Orange Level

Joined: 16 Aug 2011

Location: SW New York

Points: 689

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2016 at 7:01am Posted: 23 Apr 2016 at 7:01am |

|

The motor for sale for $800 in Virginia is the motor from an Allis Chalmers 7000 tractor. This is NOT the HD344, 6000, 7000 motor that would exchange with the HD6. I am looking for the 344 cubic inch (7000 series) diesel that fits the HD6 So far the cost of shipping has prevented me from purchasing one

|

|

Ferdinand

Orange Level

Joined: 31 Mar 2016

Location: North Carolina

Points: 1951

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2016 at 9:14pm Posted: 23 Apr 2016 at 9:14pm |

|

Sorry, didn't mean to mislead anyone. I"m still learning about AC equipment.

|

|

TimBinWV

Bronze Level

Joined: 05 May 2016

Location: West Hamlin, WV

Points: 3

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 May 2016 at 12:44pm Posted: 09 May 2016 at 12:44pm |

|

I have a good used 344 Buda in an HD6g loader, if interested.

|

|

serioussam

Silver Level

Joined: 21 Aug 2015

Location: Ontario

Points: 52

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 May 2016 at 10:16pm Posted: 13 May 2016 at 10:16pm |

|

Not sure how far this one is from you http://www.trademe.co.nz/business-farming-industry/industrial/earthmoving-machinery/bulldozers/auction-1079030320.htm

|

|

BenGiBoy

Orange Level

Joined: 11 Nov 2015

Location: Ashville, NY

Points: 705

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 May 2016 at 1:00pm Posted: 14 May 2016 at 1:00pm |

|

|

|

'39 Model B

Tractors are cheaper than girls, remember that!

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(1)

Thanks(1)