| Author |

|

km5bq

Bronze Level

Joined: 02 Jul 2016

Location: El Dorado, AR

Points: 8

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: power director late 200 Topic: power director late 200

Posted: 02 Jul 2016 at 12:26pm |

|

Hi, all! I'm as new to this forum as I am to AC tractors, and could use some experience. This is my first AC, 200 Serial 7289. Had no PD neutral, no pto disengage. High pressure at the Tee back of the engine (250-300psi at any speed). I pulled the PD and PTO valves apart and found sticking shuttle/relief spools. Cleaned and reassembled. PTO stops and brakes now. Still no PD neutral. While I had the valve off, I opened the case to view the clutch and hub support. I applied air to the clutch apply tubes. air in one tube came out other tube and support. This indicates blown seals, I assume. with seals blown, the clutch should not engage either range, correct? The tractor drives! I don't know which range it's in, but if it moves and the seals are blown, i can only assume one of the clutches is jammed. Anyone agree? at any rate, it appears I'm going to split it. Anyone know how well balanced that back half is, in other words, how much support do I need under the transmission? I know I've been long winded, and I apologize. Thanks in advance to anybody with some input!!

|

|

|

Sponsored Links

|

|

|

screwloose

Orange Level

Joined: 06 Dec 2014

Location: maryland

Points: 361

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Jul 2016 at 4:39pm Posted: 02 Jul 2016 at 4:39pm |

|

Did you check the travel of the power director rod at the valve? If it is the same as a 190xtd there is a punch mark on the valve. You should have 9/16" travel from center of pin to punch mark in both directions. Once you get the travel correct take the 1/8" plug out of the side of the valve and hook your gauge there. Check both pressure at both plugs when you engage power director. If it's the same as 190xtd you should have I think 255 to 300 psi. In neutral you should have no more than 40 pounds if I remember correctly. You should have a couple thousand pound liquid filled gauge. If all that checks out ok you might have broken clutch plates.

Empty the fuel tank before you lift the platform. When or if you split it will want to tilt backwards not towards the transmission (at least mine did).

If you don't have a allis chalmers service manual get one, it's worth every penny.

|

|

MACK

Orange Level

Joined: 17 Nov 2009

Points: 7664

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Jul 2016 at 8:37pm Posted: 02 Jul 2016 at 8:37pm |

|

Snap coupler is heavy on front, Three point is heavy on back. Three point can be heavy on front if you

let it get over center forward. MACK

|

|

km5bq

Bronze Level

Joined: 02 Jul 2016

Location: El Dorado, AR

Points: 8

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jul 2016 at 8:56am Posted: 03 Jul 2016 at 8:56am |

|

Thanks, fellas! It has the three point. Crawling under it, I thought it looked like it might just about be balanced. The job may have to wait till the shop floor gets poured. Also waiting on a parts quote. It's going to be a bit like bush hogging with an 8N til I get it fixed, but at least whatever is broke broke solid.

|

|

km5bq

Bronze Level

Joined: 02 Jul 2016

Location: El Dorado, AR

Points: 8

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jul 2016 at 4:54pm Posted: 03 Jul 2016 at 4:54pm |

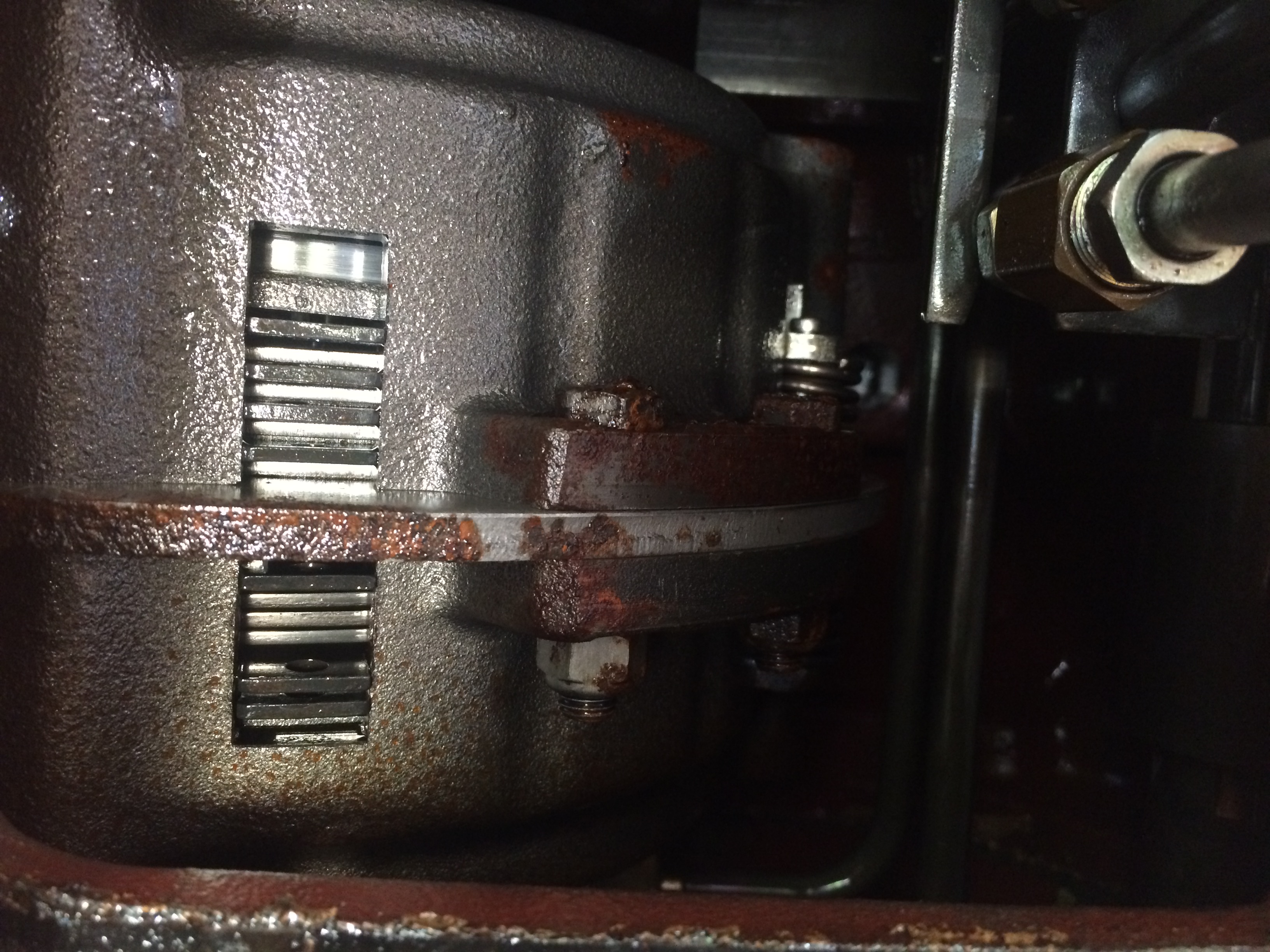

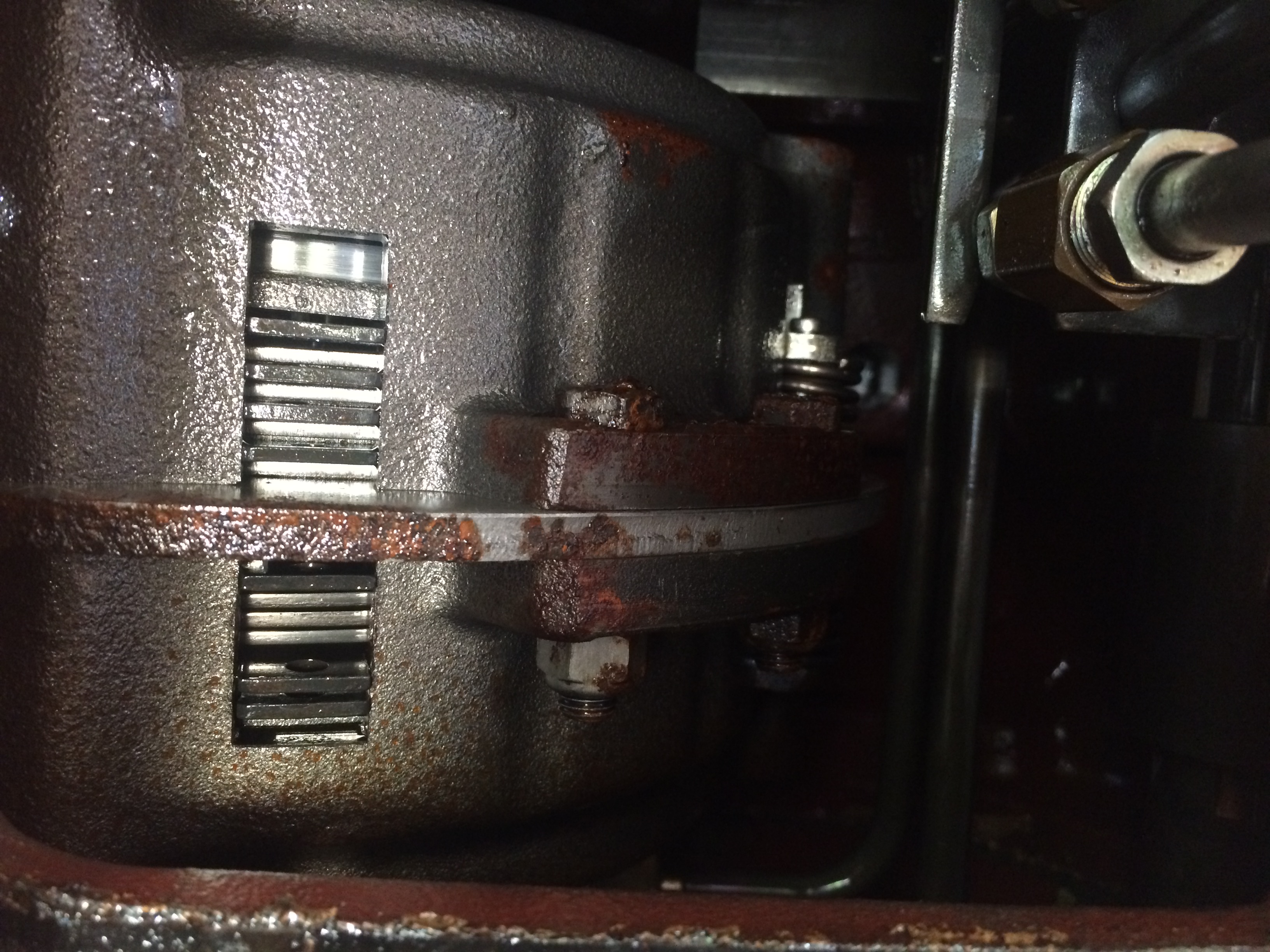

Ok, I got bored today so I locked the foot clutch down so I could rotate the PD assembly. YIKES! It's ugly in there. My guess is the back clutch came apart and the bits jammed in there in such a way as to fuse the thing. I pulled the sump and the gears look great. I suspect the splines are stripped out of the low range frictions. Hope the pic came through.

|

|

Lynn Marshall

Orange Level Access

Joined: 13 Sep 2009

Location: Dana, Iowa

Points: 2147

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jul 2016 at 9:20pm Posted: 03 Jul 2016 at 9:20pm |

|

That is a mess. It's a pretty simple clutch assembly to rebuild once you get it out.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 19519

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jul 2016 at 10:18pm Posted: 03 Jul 2016 at 10:18pm |

|

Be sure to replace all 9 discs with new 70261212 discs from a 7000.

|

|

firecowallis

Orange Level

Joined: 16 Mar 2012

Location: Helenville Wi

Points: 464

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Jul 2016 at 8:14am Posted: 04 Jul 2016 at 8:14am |

and re[lace the lock nut with a new one when the nut works its way of its a real expensive mess to fix 1.50 nut cheap insurance

|

|

allis g 7045 200 wd45 wd45d c ca 6080 u

|

|

km5bq

Bronze Level

Joined: 02 Jul 2016

Location: El Dorado, AR

Points: 8

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Jul 2016 at 10:03am Posted: 04 Jul 2016 at 10:03am |

|

Thanks, guys. I'll check, but I think that part number (70261212) is the one I sent to Schmidt & sons for a quote. Firecowallis, which not are you telling me to replace?

|

|

firecowallis

Orange Level

Joined: 16 Mar 2012

Location: Helenville Wi

Points: 464

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Jul 2016 at 3:21pm Posted: 04 Jul 2016 at 3:21pm |

|

lock nut on the main shaft that if i remember right the pto i will look on my old torque tube mine after replacing clutches in power director we used the old nylon locking nut and it worked off and took out pto box and power director again and ended up finding a late model torque tube pretty penny

|

|

allis g 7045 200 wd45 wd45d c ca 6080 u

|

|

km5bq

Bronze Level

Joined: 02 Jul 2016

Location: El Dorado, AR

Points: 8

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Jul 2016 at 12:05am Posted: 05 Jul 2016 at 12:05am |

|

Wow, ok, thanks, Firecowallis. Not anticipating removing that nut, but will remember your advice. It's looking like this may have to be put off a bit. I need to build a building to do the work in, but I need the tractor to clear the site for the building. Great catch 22, huh? It's appears that the carnage at least has the machine in a stably operable condition, for now.

|

|

DougG

Orange Level

Joined: 20 Sep 2009

Location: Mo

Points: 7946

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Jul 2016 at 5:45pm Posted: 05 Jul 2016 at 5:45pm |

|

Don't want to highjack this post, but Dr Allis , are these Powerdirector clutch plates good for the 7000 series too, 7000 up to 7080 ?

|

|

km5bq

Bronze Level

Joined: 02 Jul 2016

Location: El Dorado, AR

Points: 8

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Jul 2016 at 8:00pm Posted: 05 Jul 2016 at 8:00pm |

|

Wow, ok, thanks, Firecowallis. Not anticipating removing that nut, but will remember your advice. It's looking like this may have to be put off a bit. I need to build a building to do the work in, but I need the tractor to clear the site for the building. Great catch 22, huh? It's appears that the carnage at least has the machine in a stably operable condition, for now.

|

|

km5bq

Bronze Level

Joined: 02 Jul 2016

Location: El Dorado, AR

Points: 8

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Jul 2016 at 8:03pm Posted: 05 Jul 2016 at 8:03pm |

|

DougG, if I read the parts books and such correctly, that part number is the one for the 7000. It looks like maybe agco just went back and listed it to the 190 and 200, probably just to have one p/n for all. I'll stand corrected if anybody wants to do the honors.

|

|

DougG

Orange Level

Joined: 20 Sep 2009

Location: Mo

Points: 7946

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Jul 2016 at 8:08pm Posted: 05 Jul 2016 at 8:08pm |

|

Ok , yeah makes sence, I don't have much experience with the bigger 7000 series internals, thanks!

|

|

screwloose

Orange Level

Joined: 06 Dec 2014

Location: maryland

Points: 361

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jul 2016 at 10:25am Posted: 06 Jul 2016 at 10:25am |

|

Don't know if that part works for all the 7000 series. The difference is if I'm not mistaken is the original plates had about a 1/8th inch wide and about a 1 inch deep (from the outer circumstance) void/saw cut/gash, lol whatever you call it. The ones doc suggested is solid no gashes. The ones with gashes would break there.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 19519

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jul 2016 at 10:36am Posted: 06 Jul 2016 at 10:36am |

|

You'll never break/split a 70261212 disc in a 180-185-190-190XT or 200 like the old design discs. My first tractor I did this to was my Dad's 200 back in 1979, and have never worked on it again. Tractor was 5 years old and 3,000 hrs and had a broken disc in low range. Installed the 7000 discs and no problems ever again.

|

|

firecowallis

Orange Level

Joined: 16 Mar 2012

Location: Helenville Wi

Points: 464

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jul 2016 at 12:57pm Posted: 14 Jul 2016 at 12:57pm |

7000 will work in late 200 but if i remember right anything bigger than 7000 like 7045 or 7060 are different anyone on her am i correct or not

|

|

allis g 7045 200 wd45 wd45d c ca 6080 u

|

|

CAL(KS)

Orange Level

Joined: 18 Sep 2009

Location: Chapman, KS

Points: 3734

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jul 2016 at 1:22pm Posted: 14 Jul 2016 at 1:22pm |

|

Dr listed the part #. pretty sure that is 7000 model only as its basically a 200 with 7000 sheetmetal. bigger tractors have different drive train.

|

|

Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20

Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15

|

|

Orange Blood

Orange Level

Joined: 29 Nov 2010

Location: ColoradoSprings

Points: 4053

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jul 2016 at 8:03pm Posted: 14 Jul 2016 at 8:03pm |

firecowallis wrote: firecowallis wrote:

7000 will work in late 200 but if i remember right anything bigger than 7000 like 7045 or 7060 are different anyone on her am i correct or not

|

This is correct, anything bigger than the 7000, I.E. 7010-7080 has a completely different trans setup, P/S, or P/D. Similar clutch design principal, but very different none the less.

|

|

Still in use:

HD7 WC C CA WD 2-WD45 WD45LP WD45D D14 3-D17 D17LP 2-D19D D19LP 190XTD 190XTLP 720 D21 220 7020 7030 7040 7045 3-7060

Projects: 3-U UC 2-G 2-B 2-C CA 7-WC RC WDLP WF D14 D21 210 7045 N7

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

firecowallis wrote:

firecowallis wrote: