| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Warren(Oh)

Orange Level

Joined: 11 Sep 2009

Location: Jackson, Ohio

Points: 1127

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: G crank, been worked on before Topic: G crank, been worked on before

Posted: 24 Dec 2011 at 11:16am |

Finally got a chance to remove some parts from the G engine this morning, unfortunately I spent most of the morning looking for my harmonic puller. Never did find it, needed a 1 1/2 inch socket so headed to TSC, no pullers. Autozone had a small one, big enough.

Removed the carb and turned it over. Nasty oil screen ! Initials carved in the crank !? Deffinently ground before, probably not salvageable. Napa shop is closed till next week so it can wait. Time to get out and enjoy the weather.

|

|

|

Sponsored Links

|

|

|

Warren(Oh)

Orange Level

Joined: 11 Sep 2009

Location: Jackson, Ohio

Points: 1127

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Dec 2011 at 7:22am Posted: 25 Dec 2011 at 7:22am |

Pulled a rod bearing from the cap, .030, maybe I'll get lucky... The front 3 don't look as bad as #1.

Got the timing cover off this morning, two dowels had it held tight. Everythig looks good in there.

|

|

darrel in ND

Orange Level

Joined: 22 Nov 2009

Location: Hebron, ND

Points: 8755

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Dec 2011 at 7:37am Posted: 25 Dec 2011 at 7:37am |

Thanks for pics. Are you giving this G a complete restoration? Darrel

|

|

JoeM(GA)

Orange Level

Joined: 12 Sep 2009

Location: Cumming,GA

Points: 4890

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Dec 2011 at 7:42am Posted: 25 Dec 2011 at 7:42am |

|

of course it's been into!! it's a 60+ year old throw-a-way engine!!

It'll be fine with a bit of work

Edited by JoeM(GA) - 25 Dec 2011 at 7:43am

|

|

Allis Express North Georgia

41 WC,48 UC Cane,7-G's,

Ford 345C TLB

|

|

Warren(Oh)

Orange Level

Joined: 11 Sep 2009

Location: Jackson, Ohio

Points: 1127

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Dec 2011 at 7:55am Posted: 25 Dec 2011 at 7:55am |

|

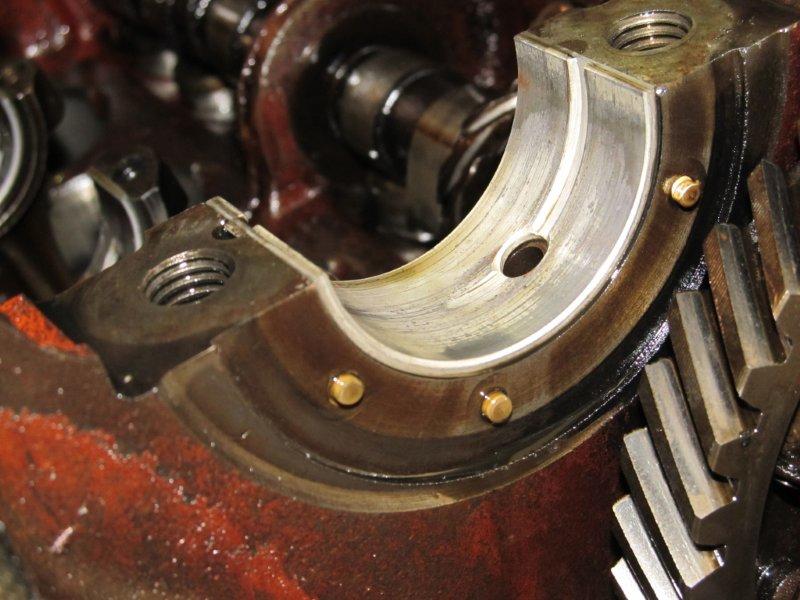

Got the main caps off, hardly any sign of wear in them at all. If possible, I think I'll only have the rod journals turned. There's not enough wrong with it to do a complete restore, it has good compression just a knock when revved up. Was told it was likely the rod bearings and certainly beleive it now. Gets me that none of the gaskets have torn up yet ! I don't suppose there's a chance the crank will come out of the front seal without removing that end ? I can see that won't work !

Edited by Warren(Oh) - 25 Dec 2011 at 7:58am

|

|

Warren(Oh)

Orange Level

Joined: 11 Sep 2009

Location: Jackson, Ohio

Points: 1127

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Dec 2011 at 8:42am Posted: 25 Dec 2011 at 8:42am |

Front cover came off easy enough, dispite the stand being in the way,crank ready to remove.

|

|

Warren(Oh)

Orange Level

Joined: 11 Sep 2009

Location: Jackson, Ohio

Points: 1127

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Dec 2011 at 9:42am Posted: 25 Dec 2011 at 9:42am |

Crank had other ideas ! Brass shim on rear was stuck, big time ! Rubber mallot convinced it otherwise. Hope I didn't mess it up !

OH HECK ! I see why it was stuck now ! Three little pins holding the shim in place ! Never seen nothing like that before. Don't look like I did any damage, would have been all the same...

|

|

Tracy Martin TN

Orange Level Access

Joined: 11 Sep 2009

Location: Gallatin,TN

Points: 10870

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Dec 2011 at 12:30pm Posted: 25 Dec 2011 at 12:30pm |

|

Warren,I would definitely clean all of the oil passages.Looks like you may have had a problem there. HTH Tracy Martin

|

|

Warren(Oh)

Orange Level

Joined: 11 Sep 2009

Location: Jackson, Ohio

Points: 1127

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Dec 2011 at 6:47pm Posted: 25 Dec 2011 at 6:47pm |

|

It'll get a good going through at the NAPA shop and if it's still usable, you better believe everything will get a good cleaning ! I don't know how big the bearings come but since they're already .030, probably .060 after they get done. Just won't know till they say.

|

|

norm[ind]

Orange Level

Joined: 29 Oct 2010

Location: bourbon,ind

Points: 2992

|

Post Options Post Options

Thanks(0) Thanks(0)

![Quote norm[ind] Quote norm[ind]](forum_images/quote.png) Quote Quote  Reply Reply

Posted: 25 Dec 2011 at 6:52pm Posted: 25 Dec 2011 at 6:52pm |

we have 4 .060 rod bearings in stock 1-800-254-3116 can ship visa-discover--

master cards

|

|

Warren(Oh)

Orange Level

Joined: 11 Sep 2009

Location: Jackson, Ohio

Points: 1127

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Dec 2011 at 7:15pm Posted: 25 Dec 2011 at 7:15pm |

|

Thanks Norm, soon as I know what it's gonna need, I'll be doing some shopping !

|

|

Ryan Renko

Orange Level

Joined: 12 Sep 2009

Location: Edwardsville, I

Points: 2338

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Dec 2011 at 7:40pm Posted: 25 Dec 2011 at 7:40pm |

|

I enjoy your photos Warren!! We have a G and its interesting to see the guts of the lil girl!! Ryan

|

|

Warren(Oh)

Orange Level

Joined: 11 Sep 2009

Location: Jackson, Ohio

Points: 1127

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Dec 2011 at 8:29am Posted: 27 Dec 2011 at 8:29am |

|

Guys at the shop weren't very optimistic about #1 rod journal staying inside .060, might have to replace the crank. Got another to tear down and test.

|

|

Warren(Oh)

Orange Level

Joined: 11 Sep 2009

Location: Jackson, Ohio

Points: 1127

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Jan 2012 at 6:30pm Posted: 25 Jan 2012 at 6:30pm |

If anyone is interested, a month later and the NAPA shop still hasn't gotten to my crank !!! Cranks, I took the one from the blown engine in, too.

But, I did find out why last night. Seems the guy that does the crank grinding is also a substitute teacher and has been filling in at the local vocational school for the past 6 weeks ! I guess 27 years at the shop earns him some time away but you'd think someone else could keep things done up !

And, I have since learned of another person who builds race car engines locally and does engine work on other engines as well. So, first day I have a minute, I'll be checking his place out.

I hope I can remember how to put it all back together ! Hang on to those .060 rod bearings Norm !

|

|

Tracy Martin TN

Orange Level Access

Joined: 11 Sep 2009

Location: Gallatin,TN

Points: 10870

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Jan 2012 at 7:09pm Posted: 25 Jan 2012 at 7:09pm |

|

Warren, grinding cranks is an art. If you watch one done sometime you will see. Not for the faint of heart. Tracy Martin

|

|

No greater gift than healthy grandkids!

|

|

RichinWis

Orange Level

Joined: 11 Sep 2009

Location: Deforest Wis

Points: 691

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Jan 2012 at 9:10pm Posted: 25 Jan 2012 at 9:10pm |

|

Those fat shims are the thrust washers for that engine thats why they have the pins in there to hold them in place. HTH Rich

|

|

Chalmersbob

Orange Level

Joined: 11 Sep 2009

Location: Pennsylvania

Points: 2122

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Jan 2012 at 10:43pm Posted: 25 Jan 2012 at 10:43pm |

Warren, I'm in the process of reassembling my G engine and just found out that the head bolts are all the same length. The parts book states that there should be short ones and long ones. Could you measure yours and send me the indivual lenghts so I can see which ones I need to replace?

I lucked out because the engine had a recent rebuild but the head was not torqued properly and leaked antifreeze into all of the cylinders. After a rebore and valve job, all of the other parts are like new. Just had to replace gaskets and seals. Thank you, Bob

|

|

Scott(GA)

Silver Level

Joined: 13 Sep 2009

Location: PeachtreeCityGA

Points: 407

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Jan 2012 at 8:06pm Posted: 26 Jan 2012 at 8:06pm |

Bob,

I've taken apart 3 engines and I found the same thing you did. All the head bolts have been the same size. I'm also pretty sure that the each of my engines had been worked on at least once.

I think I brought up this same question on this forum. To the best of my recollection, no one had ever seen different size head bolts on the G.

We'll see what answers are given this time.

Best regards,

Scott

Chalmersbob wrote: Chalmersbob wrote:

Warren, I'm in the process of reassembling my G engine and just found out that the head bolts are all the same length. The parts book states that there should be short ones and long ones. Could you measure yours and send me the indivual lenghts so I can see which ones I need to replace?

I lucked out because the engine had a recent rebuild but the head was not torqued properly and leaked antifreeze into all of the cylinders. After a rebore and valve job, all of the other parts are like new. Just had to replace gaskets and seals. Thank you, Bob |

|

|

Gerald J.

Orange Level

Joined: 12 Sep 2009

Location: Hamilton Co, IA

Points: 5636

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Jan 2012 at 8:39pm Posted: 26 Jan 2012 at 8:39pm |

|

There is a N62 manual by Continental. I have one, but I don't know it gets as detailed as the different length head bolts. If a bolt bottomed, I sure would torque find but let the head gasket leak. Maybe you could run a long bolt in each hole as deep as it goes without forcing it and see how far it sticks up above the block and compare that to the thickness of the head. That might show up where there needs to be short and long bolts.

Right now I don't know where that N62 manual is, I've moved and much is still in boxes.

Gerald J.

|

|

Scott(GA)

Silver Level

Joined: 13 Sep 2009

Location: PeachtreeCityGA

Points: 407

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Jan 2012 at 9:28pm Posted: 26 Jan 2012 at 9:28pm |

Took a few minutes to go through my notes regarding the Head Bolt issue.

The Dealer Parts Catalog for the G refers to the head having two different size Head Bolts - 10 short (Part # 013059) , 6 long. (Part # 058793). The short head bolt part # appears to be exclusively used by the G. The long head bolt part # is also used by at least the WC, WF & WD tractors. [Source: Master Numerical Index for Parts - Tractor Group].

All three of the engines I took apart had head bolts that were 2 1/4" long.

So what are the “correct” lengths for the short & long Head Bolts?

Best regards,

Scott

|

|

Chalmersbob

Orange Level

Joined: 11 Sep 2009

Location: Pennsylvania

Points: 2122

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Jan 2012 at 9:54pm Posted: 26 Jan 2012 at 9:54pm |

Thanks for the responses on the head bolt length. So maybe mine will be OK.

I'm certainly going to check the holes for depth. I know the ones in the center of the head are very shallow.

Warren, I pulled the gear forward to release the brass shims from the pins. You will need to have some space to realign the holes in the shim with the pins when you reassemble it. I put the shims in place and held them with a spring clamp, and then pressed the gear back against them as I tightened the pulley on the shaft. Bob

|

|

Warren(Oh)

Orange Level

Joined: 11 Sep 2009

Location: Jackson, Ohio

Points: 1127

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Jan 2012 at 5:38pm Posted: 31 Jan 2012 at 5:38pm |

|

OK, got my crank back today, the original from this engine. .060 rods journals and .020 mains. Waiting on bearings and seals now. Once they come I probably won't get a day off for another month ! haha

|

|

Warren(Oh)

Orange Level

Joined: 11 Sep 2009

Location: Jackson, Ohio

Points: 1127

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Feb 2012 at 8:11pm Posted: 02 Feb 2012 at 8:11pm |

|

Thank you Norm Steinman ! Got the bearings and seals today. Them's the cutest little things !! hahaha I know what I'll be doing while it's raining Saturday !

|

|

Gerald J.

Orange Level

Joined: 12 Sep 2009

Location: Hamilton Co, IA

Points: 5636

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Feb 2012 at 6:22pm Posted: 07 Feb 2012 at 6:22pm |

|

I found the N56/N62 owner's manual yesterday. I shows how to check for cylinder and ring wear with the head off, but doesn't mention head bolts of head bolt torque.

Last June I downloaded a Continental L Head Overhaul manual that covers four and six cylinder engines N56, N62, Y69, Y91 (on my Onan), Y112, F124, F135, F140, F162, and F163 and a similar list of six cylinder engines.

It lists torques by bolt size and function, not engine. It recommends the threads be lubricated with fresh engine oil.

It also shows how to time distributor with and without a light. Everything in the ignition chapter applies correctly to practically all tractor engines because so many use the same Delco distributor designs.

It has a detailed chapter on Zenith and Marvel-Schebler carburetors that applies to many tractors like AC with lots of details.

It should be in the computer of any one working on vintage gas engines with part printed for use at the engine side.

My search turned it up today at: http://www.wisconsinmotors.com:8080/wm/images/catalogs/continental/L-Head_Overhaul.pdf

Gerald J.

|

|

Warren(Oh)

Orange Level

Joined: 11 Sep 2009

Location: Jackson, Ohio

Points: 1127

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Feb 2012 at 6:35pm Posted: 07 Feb 2012 at 6:35pm |

|

|

|

Gerald J.

Orange Level

Joined: 12 Sep 2009

Location: Hamilton Co, IA

Points: 5636

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Feb 2012 at 6:49pm Posted: 07 Feb 2012 at 6:49pm |

|

Looking more at the Wisconsin web page on Continental, they have have three manuals that are probably good. The L-head quick reference doesn't cover N62.

http://www.wisconsinmotors.com/part_catalog/continental

I just found out that if you click on one, let it all down load, if you click on another it aborts the first download and starts the next one. Expensive on Verizon wireless if I let that happen too many times.

The larger repair manual comes in faulty according to my present adobe reader.

Gerald J.

|

|

Allis Barn

Bronze Level

Joined: 02 Jan 2010

Location: Virginia

Points: 42

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Mar 2012 at 8:26am Posted: 04 Mar 2012 at 8:26am |

More questions on G Head bolts. I also found that I only had 2.25 inch bolts ( total of 16 + 4 STUDS) used on the 49 G I am working on. Based on thickness of the head in the center I would think the 6 center bolts should be 2.5 inches long. Can anyone confirm? Is there a specification for this bolts? Potential for buying at NAPA? My Allis Chalmers G service manual says the head bolt torque is 55 ftlb. But the Continental manual that is mentioned in this thread says 35 - 40 ft lbs. Which is right? I think the 55 number is high for a 3/8 bolt! Does anyone have a good set of head bolts for a G they are willing to part with? Thanks Bob @ Allis Barn

|

|

Chalmersbob

Orange Level

Joined: 11 Sep 2009

Location: Pennsylvania

Points: 2122

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Mar 2012 at 8:18pm Posted: 04 Mar 2012 at 8:18pm |

|

I just went though what you are talking about. I checked with the Connential parts supplier, and they said 20 2 1/4" bolts. I stripped 1 bolt and 1 stud torquing it up to 55 lbs. I got a 2 1/2" grade 8 bolt and a 3" grade 8 stud, and they both torqued up. It does seem the 55 lbs is a lot for a 3/8" bolt, but my engine was not torqued properly when it was rebuilt before I got it. All 4 cylinder had antifreeze in them. LOL Bob

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

Chalmersbob wrote:

Chalmersbob wrote: