| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Dean (West MI)

Orange Level

Joined: 12 Sep 2009

Location: West Michigan

Points: 1277

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Parts needed to rebuild 43 B hydraulic pump? Topic: Parts needed to rebuild 43 B hydraulic pump?

Posted: 07 Jan 2013 at 8:35pm |

Hi,

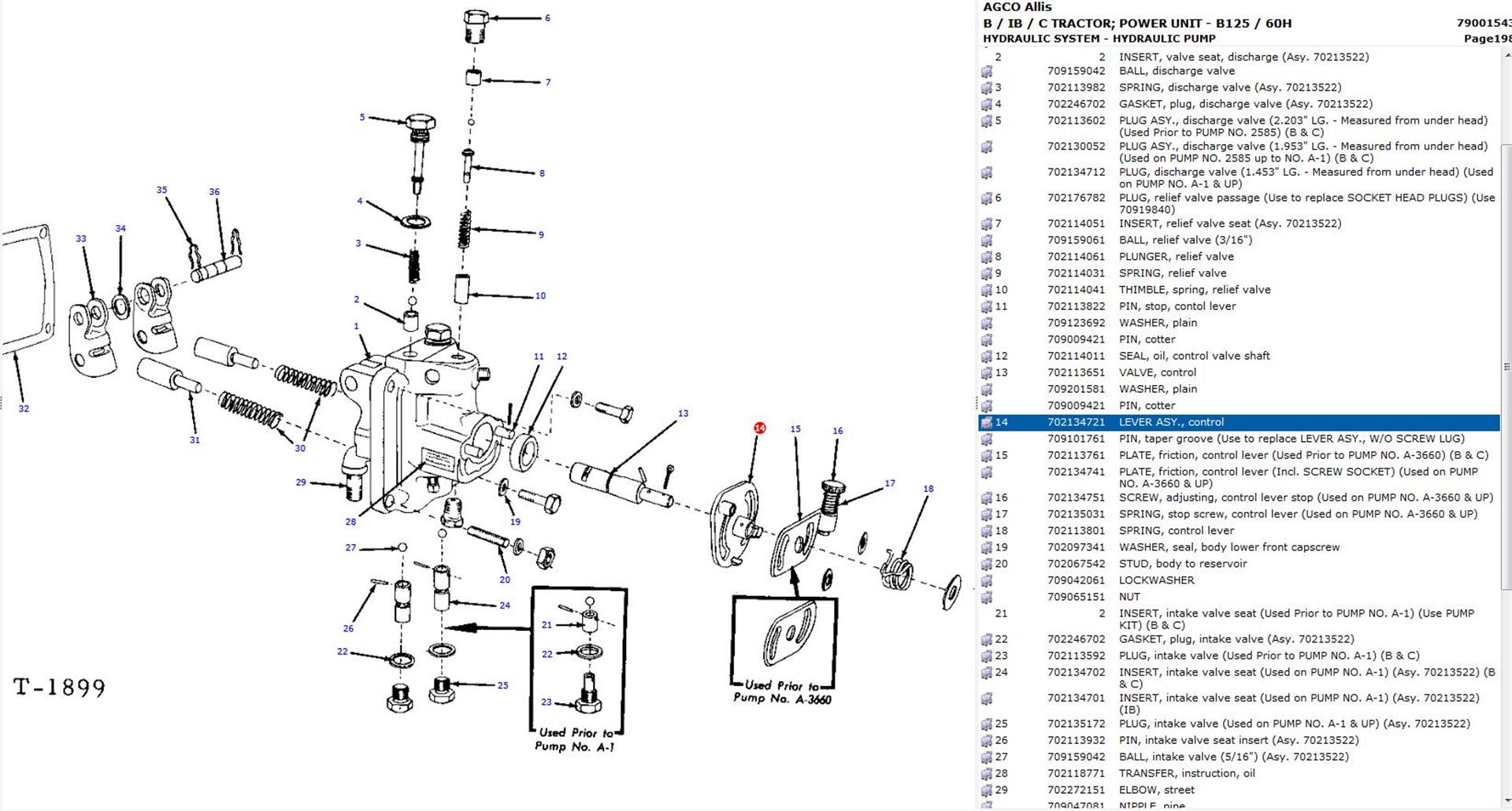

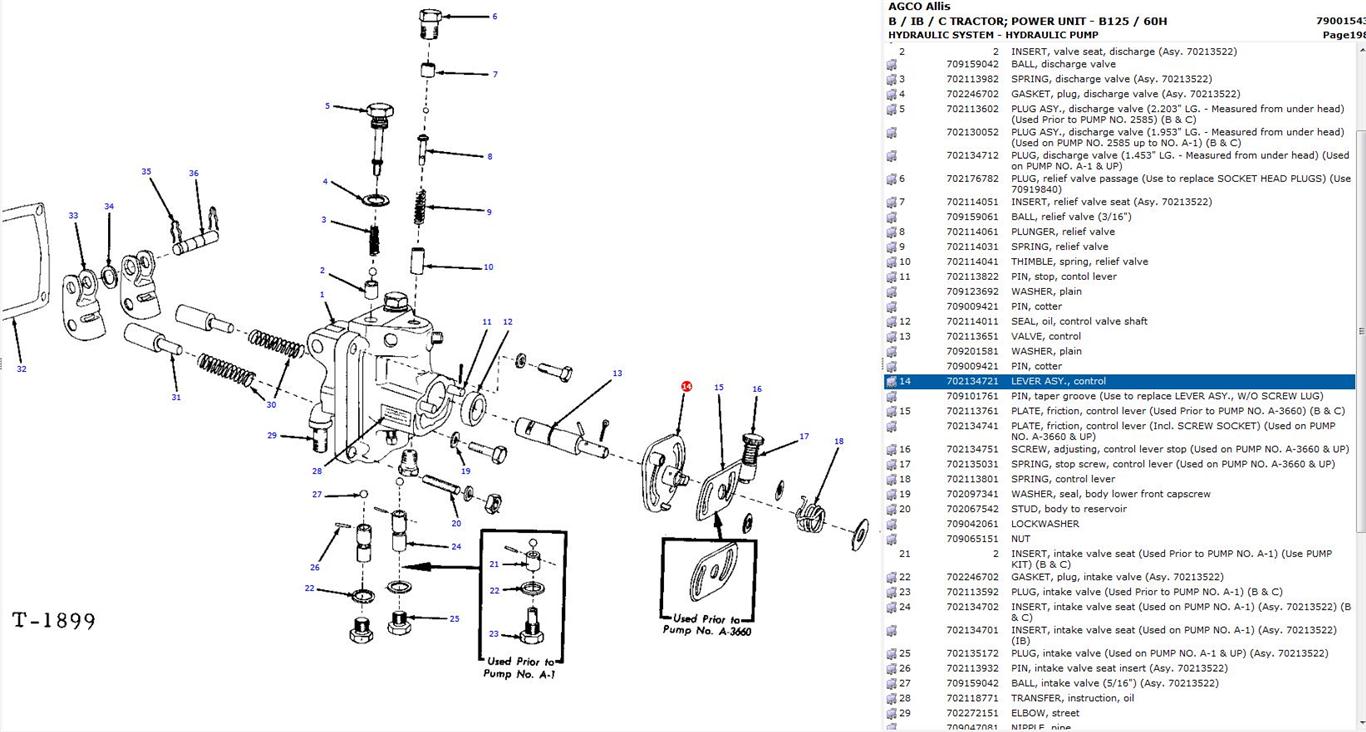

Another item on my winter tractor list is to rebuild the hydraulic pump on my 1943 B. It has always lifted slow, but it will no longer hold implements attached to the three point. Before I could come back a week later and the implement would still be up in the air, now I'm lucky if it makes it 60 seconds. Can someone please take a moment to look at the parts diagram and let me know what I need to replace to fix this (example numbers 6, 9, etc.)? Thanks in advance, your help is greatly appreciated! I found the parts diagram on Agco's website, select guest login, Ago-Allis and Model B. http://www.agcopartsbooks.com

|

|

|

Sponsored Links

|

|

|

norm[ind]

Orange Level

Joined: 29 Oct 2010

Location: bourbon,ind

Points: 2992

|

Post Options Post Options

Thanks(0) Thanks(0)

![Quote norm[ind] Quote norm[ind]](forum_images/quote.png) Quote Quote  Reply Reply

Posted: 07 Jan 2013 at 8:58pm Posted: 07 Jan 2013 at 8:58pm |

use an allis service manual for instructiondo as it says will be ok no it manual my 2cents hve repaired many 1-574-342-4545

|

|

wfmurray

Orange Level

Joined: 13 Sep 2009

Location: Bostic NC

Points: 1225

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Jan 2013 at 9:20pm Posted: 07 Jan 2013 at 9:20pm |

|

I had same trouble on my 49 B. Took apart and took relief valve seat to local machines and he refinished seat ,took off ten thousands. Works fine . that is part no 7. They recomend wash and flush good and you might not have to take apart . Might be just some crud.

|

|

Dean (West MI)

Orange Level

Joined: 12 Sep 2009

Location: West Michigan

Points: 1277

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Jan 2013 at 7:45am Posted: 08 Jan 2013 at 7:45am |

Thanks. I will look on ebay for an OEM service manual as the I&T manual is lacking in specifics. The problem is I have no tools to measure things to see if they are within specs, so I thought it would just be easier to order the few parts needed to fix and install instead of spending money on the tools and the parts.

Thanks wfmurray. The pump and inside of the housing looked really clean, but just to make sure I washed everything down in carb cleaner. I think I'll order part number 7 and nine and see how that works. I hate the idea of just cleaning it, putting in a new gasket, refilling with oil, putting the tire back on, just to find out it did not work. Can anyone think of any other parts that I should order?

|

|

CTuckerNWIL

Orange Level

Joined: 11 Sep 2009

Location: NW Illinois

Points: 22810

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Jan 2013 at 8:53am Posted: 08 Jan 2013 at 8:53am |

|

You need a few 3/16 ball bearings. I sorted some out from a box we had at work.

The leaking down is from one of those balls not seating properly. The repair is to get 2 new balls, use the first one to re-seat the mating part. Throw that ball away and put a new one in. If you do that to number 8 in the picture, you can change the pressure output of the pump. I used a porta-power set up to adjust the relief when I had everything back together.

You need about 3500 psi for proper operation.

If your 3 point has a large diameter cylinder, it will always be slow raising. By large I mean 2 inches or more. The original B cylinder only pushes the rod for movement so it takes less oil to move the length of the cylinder.

Edited by CTuckerNWIL - 08 Jan 2013 at 8:55am

|

|

|

|

rodney.pentecost

Bronze Level

Joined: 06 Mar 2017

Location: Indiana

Points: 8

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Mar 2017 at 6:28pm Posted: 13 Mar 2017 at 6:28pm |

|

Can this pump only be used on a one way cylinder or can I hook a two way cylinder too it. The cylinder on it now relies on the weight of the implement to lower it, it only uses hydraulic pressure to lift it. Can I put a two way cylinder on this pump so it works both ways?

|

|

CTuckerNWIL

Orange Level

Joined: 11 Sep 2009

Location: NW Illinois

Points: 22810

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Mar 2017 at 10:56am Posted: 14 Mar 2017 at 10:56am |

|

If you buy a single spool 2 way valve and plumb the pressure line to it, then run a return from the new valve to the tranny, you can run a 2 way cylinder.

Most 2 ways are meant for lower pressure and higher volume though, so reaction time may be slow and you'll want to make sure your 2 way valve has a relief in it set somewhere near 1200 psi.

|

|

|

|

rodney.pentecost

Bronze Level

Joined: 06 Mar 2017

Location: Indiana

Points: 8

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Mar 2017 at 3:31pm Posted: 14 Mar 2017 at 3:31pm |

|

Ok do you have an illustration of what you're referring too, I don't have much experience with hydraulic systems. Thanks.

|

|

Bill Long

Orange Level

Joined: 12 Sep 2009

Location: Bel Air, MD

Points: 4556

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Mar 2017 at 4:08pm Posted: 14 Mar 2017 at 4:08pm |

|

Before you order or start anything else you may want to do a complete and through cleaning. Sometimes after long use - remember these units are pushing 75 years - can get some dirt clogging the seats that may cause leakage.

Pay close attention to what is said above. It it very accurate.

When new we did not have much trouble with these pumps.

Good Luck!

Bill Long

ps: Take good care of my favorite

Edited by Bill Long - 14 Mar 2017 at 4:09pm

|

|

wfmurray

Orange Level

Joined: 13 Sep 2009

Location: Bostic NC

Points: 1225

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Mar 2017 at 8:56pm Posted: 14 Mar 2017 at 8:56pm |

|

Worked in a plant where we had check valves with working psi up to 15000 lbs. I reseated several and I call it a land that the ball sets against . It needs to be almost a square corner. If the ball sets against it. is to wide it will not hold .Might be the reason Bill Long did not have trouble when they were new.

|

|

Gerald J.

Orange Level

Joined: 12 Sep 2009

Location: Hamilton Co, IA

Points: 5636

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Mar 2017 at 9:13pm Posted: 14 Mar 2017 at 9:13pm |

I have a G, B, C and CA service manual on my web site. http://www.geraldj.networkiowa.com/Trees/Allis-Chalmers-G-B-C-CA-Service.pdfand military B manual http://www.geraldj.networkiowa.com/Trees/BMilitary.pdfThe first one is a 11MB download and the second one 1.6 MB. Gerald J.

|

|

rodney.pentecost

Bronze Level

Joined: 06 Mar 2017

Location: Indiana

Points: 8

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Mar 2017 at 11:47pm Posted: 14 Mar 2017 at 11:47pm |

Thanks that service manual is really helpful. However on the Model B and C hydraulic pump section it is showing a three way valve that is attached to the hydraulic pump with hose. Mine does not have the three way valve, there is one hose coming from the side of the hydraulic pump that leads to a hydraulic ram. The illustration in the manual shows the hose going to the three way valve is coming out of the top right side of the pump, but the hose on mine is coming out the side, If I put a three way valve on it do I need to move the hose to the top of the hydraulic pump housing to run the three way valve. I really appreciate your guys help on this, I was raised on a farm but we had an International 666 which has a completely different hydraulic set up on it. Thanks Rodney Pentecost

|

|

Gerald J.

Orange Level

Joined: 12 Sep 2009

Location: Hamilton Co, IA

Points: 5636

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Mar 2017 at 8:43am Posted: 15 Mar 2017 at 8:43am |

|

I'm not a B/C expert. I just collected the manual because it was hard to find sometimes. I don't find a date. The B and C were made over a considerable number of years prewar and post war and its likely lots of details changed like my JD4020 made over 10 years has so much change between the '68 and previous to the '69 and later that the parts books and shop manuals are kept separate and many parts like hydraulics and engine blocks do not interchange. I can see that being true for the B especially for options like hydraulics.

Gerald J.

|

|

CTuckerNWIL

Orange Level

Joined: 11 Sep 2009

Location: NW Illinois

Points: 22810

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Mar 2017 at 9:00am Posted: 15 Mar 2017 at 9:00am |

The splitter valve was mainly used for the 2 way plows. You had to flip it from one side to the other to operate either the left hand or the right hand plow. Unless you have a 3 point and want to use the hydraulics for something else, or you have a 2 way plow set up, you don't NEED that. As far as adding a 2 way hydraulic valve, plumbing would depend on what you want to be able to do with the hydraulics. If you want to be able to use the system as designed for original equipment, but also want to run a 2 way cylinder, you need a diverter valve in line ahead of the 2 way valve. If you only plan to use the 2 way valve, just run the pressure line from the pump to the input of the new valve and add your connections, run a return line and you're done. https://www.youtube.com/watch?v=vBkfO6CsVag

|

|

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)