| Author |

Topic Search Topic Search  Topic Options Topic Options

|

ac55tractor

Silver Level

Joined: 20 Oct 2012

Location: Raymond, Maine

Points: 240

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Crankshaft end play Topic: Crankshaft end play

Posted: 20 May 2022 at 2:02pm |

Steve

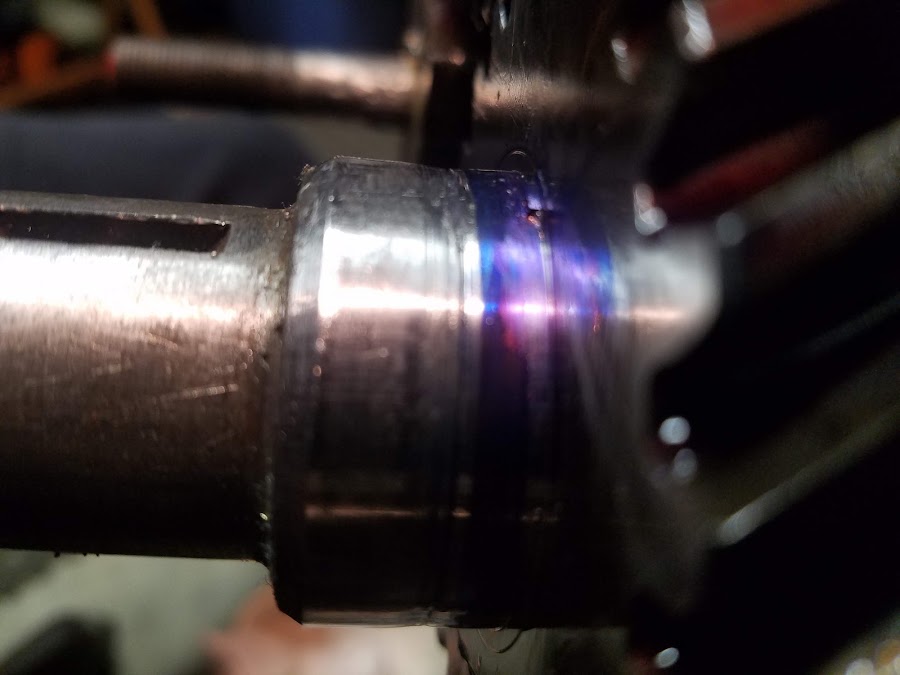

Maybe this will help. It was hard to get this

picture with my phone, but I'm sure you get the idea. I used a

Machinist's scale, from Starrett. Each line is .010. It shows roughly .040 from the old ware groove to the end of the blue. I only blued where

the old seal was up to the crank gear to check for seal contact. You are right, the

front seal that came with the gasket kit is not at all like the

original. The contact area on the new seal is also roughly .032. After some searching this morning the seal is for D10, D12, D14, D15 Allis. It does seem to fit the application without any interference from the lower belt pulley. All of the other gaskets from the kit fit just fine. The gasket kit was for a B so I got it. There were some extra gaskets with the kit that I didn't recognize, but the ones that I needed were included. I am not using the head gasket from that kit. It's marked China. I have a Fel-Pro head gasket kit Part # HS-7378B that I will be using. There was another thin front lip seal that came with the kit, it was larger in diameter than the original. I did come across some postings where some guys were using J.B. Weld. I just didn't know what would be best in this case. As always, Thanks

Steve (inME)

|

|

|

Sponsored Links

|

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 78086

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2022 at 10:51pm Posted: 19 May 2022 at 10:51pm |

Steve, i thought you had the face machined and the gear pushed on .037 inch to get the bearing thrust clearance back to spec... I can see the "groove" moving 30 thousands, but doubt you could see that... The photo looks like it move 1/4 inch , unless i am looking at the groove wrong ?? ......... I would be more inclined to believe the seal is setting different in the housing, or the seal is "different" than original ?

I dont think there is room in the block to move the crank 1/4 inch and still get the connecting rods installed ?

Edited by steve(ill) - 19 May 2022 at 10:53pm

|

|

Like them all, but love the "B"s.

|

|

ac55tractor

Silver Level

Joined: 20 Oct 2012

Location: Raymond, Maine

Points: 240

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2022 at 10:00pm Posted: 19 May 2022 at 10:00pm |

Steve Can you please look at the start of this post and I am sure it will all came back to you.

Thanks

Steve (in-ME)

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 78086

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2022 at 9:49pm Posted: 19 May 2022 at 9:49pm |

|

I would agree, no sleeve... the big question is WHY did the crank move that much ? It looks like a quarter inch ?

Edited by steve(ill) - 19 May 2022 at 9:50pm

|

|

Like them all, but love the "B"s.

|

|

ac55tractor

Silver Level

Joined: 20 Oct 2012

Location: Raymond, Maine

Points: 240

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2022 at 9:08pm Posted: 19 May 2022 at 9:08pm |

Thanks for your reply DrAllis. I have never heard of an easy sleeve until

just recently. Most of this is new to me. I really have struggled through a lot of this rebuild. I really just want this to be a one and done. I'm sure that you can

understand. Steve

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 19597

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2022 at 8:49pm Posted: 19 May 2022 at 8:49pm |

|

Only reason for a speedi-repair sleeve is to cover up worn in groove on a shaft. You've moved the groove out of the path of wear. Why would you need it ??

|

|

ac55tractor

Silver Level

Joined: 20 Oct 2012

Location: Raymond, Maine

Points: 240

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2022 at 8:43pm Posted: 19 May 2022 at 8:43pm |

Hi Everyone.

I just wanted to say how grateful I am

to the forum, to Steve(ill), Paul B, Steve M C/IL, and all the others. I

feel that their guidance is paying off. After my crankshaft was reground, roughly .040 was removed and cleaned up from the “thrust area” that had warn off,

on crankshaft.

After applying blue to the front seal journal. and with the front seal installed, I aligned the plate on the front of the engine and spun the crankshaft. From what I

can see, the seal is riding on a clean un-warn area of the seal journal. In the end the rework has appeared to have moved the

crankshaft forward making a new contact area for the front seal to ride. Or, is an easy sleeve still going to be needed here? Thanks Steve

|

|

ac55tractor

Silver Level

Joined: 20 Oct 2012

Location: Raymond, Maine

Points: 240

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Jan 2022 at 10:56am Posted: 29 Jan 2022 at 10:56am |

Thanks SteveM C/IL for your kind advice. I realize that the forum is not really the place for medical issues. All points are leading to what is called diverticula. You can Google it. I am feeling a little better this morning. I have some things that I want to pass along on the "Connecting rod "rework" page. I will try to post over there later on today or tomorrow. Sending my best to everyone at the Allis Chalmers forum.

Steve (inME) |

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8035

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Jan 2022 at 9:27pm Posted: 28 Jan 2022 at 9:27pm |

|

Take the time out to get your health back. Without that,nothing else matters much.

|

|

ac55tractor

Silver Level

Joined: 20 Oct 2012

Location: Raymond, Maine

Points: 240

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Jan 2022 at 12:19pm Posted: 28 Jan 2022 at 12:19pm |

Thanks, DrAllis One less thing to worry about, :)

Steve (inME)

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 19597

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Jan 2022 at 12:14pm Posted: 28 Jan 2022 at 12:14pm |

|

.010" crank endplay ?? I wouldn't lose one seconds sleep over that. Run it.

|

|

ac55tractor

Silver Level

Joined: 20 Oct 2012

Location: Raymond, Maine

Points: 240

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Jan 2022 at 12:03pm Posted: 28 Jan 2022 at 12:03pm |

steve(ill) wrote: steve(ill) wrote:

i had a similar problem on a B ... 15 years ago... cant give you exact numbers, but i took the gear off and machined a STEP on the back of the gear so i could push it on about .040 further to get the dimension right for the bearing... you want something small like .002 or .005 clearance .............. The gear is about an inch wide, pushing it on .040 further don't hurt the gear alignment to others. |

I have been very ill. It's not covid. Going for tests next week. Overhaul on hold for over a week now.

I wanted to take the time to say thanks to Steve (ill) for the heads up with my crankshaft gear and the rework that can be done. When I sent the crankshaft out, the guy who ground it assumed that the thrust bearing width was 1.625. So he machined a gap to 1.630. Come to find out, the thrust bearing was 1.620. That will give me .010 shaft end play. Instead of bringing the crank back to him, I am going to undercut the gear .005 - .007 and install the gear and call it good. Thanks again Steve(ill)

Steve (inME)

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8035

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Dec 2021 at 11:18pm Posted: 27 Dec 2021 at 11:18pm |

|

Around here rods are sent to the machine shop where they torque em down and hone the bore round. I don't think they generally have to remove any material at parting line. I'm no expert on this but that is my understanding.

|

|

ac55tractor

Silver Level

Joined: 20 Oct 2012

Location: Raymond, Maine

Points: 240

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Dec 2021 at 8:04pm Posted: 27 Dec 2021 at 8:04pm |

No worry''s, I have all the hard copy manuals.

Thanks for everything .

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 78086

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Dec 2021 at 7:45pm Posted: 27 Dec 2021 at 7:45pm |

I dont think anyone disagrees with your analysis... You need a couple thousandths clearance between the bearings and crank.. No matter how many SHIMS you add, you are not going to increase the horizontal dimension of the bearing.... Remachine is the only way.

How it got "TOO SMALL" is unknown at this point.. I did not look up the "factory" dimensions of the rod or crank to verify numbers... At this point it dont matter.

Edited by steve(ill) - 27 Dec 2021 at 7:47pm

|

|

Like them all, but love the "B"s.

|

|

ac55tractor

Silver Level

Joined: 20 Oct 2012

Location: Raymond, Maine

Points: 240

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Dec 2021 at 7:07pm Posted: 27 Dec 2021 at 7:07pm |

I do not disagree with you. I approached this with an open

mind today. After a lot of measuring, it seems that no matter what I do, I

cannot increase the distance shown with the arrow in the picture. This distance

remains at 1.925. I can add as much sim as I want, and it still won't increase

the 1.925 distance across. All the bearing journals on the crank shaft have

been ground down to 1.927 or -.010 from the original dimensions.

When I hand tighten the rod nuts to any of the rods, with

any combination of bearing, and matched shims to any of the journals on the

crank shaft, the area above and below the mating edges of the bearing will only

make contact and rub in the area shown in the picture. If I "snug"

the connecting rod to the crankshaft with a wrench, the rod will not move.

Please feel free to ask any questions. I want to get to the bottom of this

before I cut the bearing bores to fit the new bearings.

Respectfully

Steve

|

|

Joe(TX)

Orange Level

Joined: 11 Sep 2009

Location: Weatherford. TX

Points: 1682

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Dec 2021 at 2:18am Posted: 27 Dec 2021 at 2:18am |

|

All the rods will be egg shaped without shims. this will allow the shim thickness to be adjusted for bearing wear.

|

|

1970 190XT, 1973 200, 1962 D-19 Diesel, 1979 7010, 1957 WD45, 1950 WD, 1961 D17, Speed Patrol, D14, All crop 66 big bin, 180 diesel, 1970 170 diesel, FP80 forklift. Gleaner A

|

|

ac55tractor

Silver Level

Joined: 20 Oct 2012

Location: Raymond, Maine

Points: 240

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Dec 2021 at 10:26pm Posted: 24 Dec 2021 at 10:26pm |

Well, It’s Christmas eve. I have just

done some research. It seems that connecting rod and bearing bore stretching is

not uncommon. I found dozens of webpages describing how and why it happens.

Basically, it's all in the nature of an internal combustion engine. Pistons go

up and down and connecting rods, and bearing bores get stretched in the process. From what I've

found, it's been going on for over 100 years now. They say the best way to

correct a stretched connecting rod is to replace it. That leaves most of us vintage

Allis Chalmers owners in a bad place. I don't think that they are stamping out

any new connecting rods for our tractors in Milwaukee, Wisconsin or anywhere

else.:)

Okay, I know, I'm having a little fun,

and I am getting off topic here.

Fortunately, I received a message from a very wise

man tonight. He said, “This isn't a Nascar engine.” He’s right.

I will start a new post when I get started on reworking the connecting rods.

The crankshaft end play is fixed.

Merry Christmas and good night to all.

Steve from Maine

|

|

ac55tractor

Silver Level

Joined: 20 Oct 2012

Location: Raymond, Maine

Points: 240

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Dec 2021 at 2:40pm Posted: 24 Dec 2021 at 2:40pm |

Yes I have to re machine the bores. I am not an engineer, or at times the brightest bulb on the Christmas tree. There are a lot of things that I just don't understand, there has to be a reason why the bores on these rods become out of round. There is plenty of material there. I just checked them and they are all out of round at different amounts, within a few thousandths.

Lon(MN) said "All the rods I have sent out were egg shaped."

So it looks as if I am not the only one that have had this issue.

My guess is that Steve (ill) is right, they must be mounted together and machined to size. When this is done there is no real concern for how they go together, just as long as the bore is to size and perpendicular (square) to the outside machined edges of the bore. It's really just a cost savings for the factory.

I have a plan to repair the connecting rods. If anyone is interested, I will post it.

I have done quite a few things at work, in the shop, and I became really resourceful.

Fortunately, I have a good memory.

I am not a know it all. If I don't know something, I will be the first to tell you.

Steve form Maine

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8035

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Dec 2021 at 1:50pm Posted: 24 Dec 2021 at 1:50pm |

|

Uh ,yeah, you always make sure the cap and rod are marked as a set before separation. Many already are. Older stuff not so much.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 78086

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Dec 2021 at 12:17pm Posted: 24 Dec 2021 at 12:17pm |

YEP.... good idea to center punch the rod and cap near the bolt area prior to removal of each cap.. So, if you have the right caps on the right rods now, do the NUMBERS come out OK or do you still have to machine them ? I think factory "original" the cap was mounted to the rod and machined to size, so they have to be a "matched set".

Sounds like your on the right track now !!

|

|

Like them all, but love the "B"s.

|

|

ac55tractor

Silver Level

Joined: 20 Oct 2012

Location: Raymond, Maine

Points: 240

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Dec 2021 at 10:46am Posted: 24 Dec 2021 at 10:46am |

|

I found another set of connecting rods where the cap was mismatched. I numbered the piston rods as I pulled them out. I have just renumbered them. I can understand were people who do there best when working on their tractors can easily make a mistake and mismatch parts. This is not an easy process and nobody is any better than anyone else. I would have never noticed the mismatch without the support that I received here from the forum. This is an amazing resource. I feel very fortunate.

|

|

ac55tractor

Silver Level

Joined: 20 Oct 2012

Location: Raymond, Maine

Points: 240

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Dec 2021 at 7:40pm Posted: 23 Dec 2021 at 7:40pm |

|

|

|

ac55tractor

Silver Level

Joined: 20 Oct 2012

Location: Raymond, Maine

Points: 240

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Dec 2021 at 7:22pm Posted: 23 Dec 2021 at 7:22pm |

|

I have a Harbor Freight Mini Mill. Some might say that it's a P.O.S.. I like it. I got it when they were passing out 30% off coupons. I hope that I am not getting carried away here with a bunch of information. I paid $575.00 for it. Regularly $799.99. I have made some serious modifications to it. I have bypassed the cheep plastic gears in the head with a quieter "V" belt drive. I have X, Y, and Z digital readouts. I added a power feed on "X" (Long feed travel). The X has 12 inches of travel. The Y has just over 4 inches of travel. I have added an air piston on the "Z" (up and down travel) and removed the useless spring lever that came with the machine. I am in the process of making a stiffener plate for the back of the machine so I can use my boring head. I have a 6 inch rotary table for it. I made an adapter plate for a 6 inch, 4 Jaw chuck, and a 6 inch, 3 jaw chuck for it. So I can make "most" , but not everything that can be made on a lathe. I have a 4 inch angle lock vice, a 3 inch Hi-Precision Toolmakers Screwless Vise. I have a full set of collets. I have a full set of drill bits and many different size endmills, carbide and high speed. I have a bunch of other tools. Too much to list. I got the machine to keep my skills sharp. I know it's just a toy, But I make good use of it. I made some rings out of aircraft grade Aluminum with Copper bar inlays for gifts. I have made all sorts of parts with it.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 78086

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Dec 2021 at 6:01pm Posted: 23 Dec 2021 at 6:01pm |

|

just curious... what kind of lathe / mill machine you got ?

|

|

Like them all, but love the "B"s.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 78086

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Dec 2021 at 6:00pm Posted: 23 Dec 2021 at 6:00pm |

Most do not do that due to time and cost... Being a machinist and "you need the practice"  .. eliminating the shims and boring the rods to size is an excellent idea !

|

|

Like them all, but love the "B"s.

|

|

ac55tractor

Silver Level

Joined: 20 Oct 2012

Location: Raymond, Maine

Points: 240

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Dec 2021 at 4:52pm Posted: 23 Dec 2021 at 4:52pm |

You know that I wasn't going to quit until I had an answer. Now I do. There is a miss match in the bore on the connecting rod that I was using. So when I originally measured it, I got a "false" larger measurement than what was really there. The cap does not correctly match the rod. It sits off to one side. Maybe the bolts are slightly bent. I snugged the nuts down and I tapped it with a brass hammer until the bore was smooth. I remeasured the bore. It's .005 out of round. Looks like you guys had the right line of thinking. "Thank you". I am going to clean everything up, re-qualify the flats smooth, and re-cut the bores round with no shims. I will let you all know how I make out. I have been a Machinist for over 45 years. I started machining when I was 15. I Just turned 63. I'm sure that I can get it done. Thanks again

Steve from Maine

|

|

ac55tractor

Silver Level

Joined: 20 Oct 2012

Location: Raymond, Maine

Points: 240

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Dec 2021 at 1:07pm Posted: 23 Dec 2021 at 1:07pm |

Yes, I can enlarge the hole. Actually that may be a better way to go. I won't have to worry about thinning the Babbitt on the bearing. I really need a break. I have been putting a lot of thought into this since I got the crankshaft back 4 weeks ago. I wanted to be sure that I had all my ducks in a row before returning here with what I had found. I plan on seeing Jeff at the machine shop after Christmas. I have a lot of pictures to share. Is there a limit on the pictures that I can post? This has been a learning experience for me. There are a few things that I wanted to mention. The old front oil seal cut a groove in the crankshaft. By reworking the crankshaft as suggested by the forum, the oil seal will now ride on a fresh spot on the shaft. Also the dirt that came out of the coolant chamber after pulling the piston sleeves was quite a surprise. I know that this forum is the best resource for all things Allis

Chalmers tractors. I appreciate everyone's efforts in helping me out. I

will do my best to nail this down. I really don't want to assemble this

engine and end up with a bunch of parts in a basket. I have had my

Allis B for 30 years. It has been very faithful to me right up until I

pulled the engine last fall. Actually I am surprised that it ran as good

as it did with the warn crankshaft, the warn camshaft, a broken piston

ring in #3 cylinder, not to mention the leaking front and rear

crankshaft seals. Oh boy, did it smoke out of the exhaust. Kept the misquotes away for sure.

Merry Christmas everyone.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 78086

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Dec 2021 at 12:42pm Posted: 23 Dec 2021 at 12:42pm |

Steve, i think if you stop by and talk to the guy that machined the crank, he might have a good fix. Hopefully you dont have to do it on your milling machine.

Rather than cut a couple thousandths off the ID of the bearing, it might be a better idea to enlarge the hole in the rod so the bearings fit better. ?

Edited by steve(ill) - 23 Dec 2021 at 12:45pm

|

|

Like them all, but love the "B"s.

|

|

Alvin M

Orange Level

Joined: 24 Jun 2018

Location: PA

Points: 728

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Dec 2021 at 10:46am Posted: 23 Dec 2021 at 10:46am |

|

My machine shop line bores the block and does the rods then I don't need shims

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

steve(ill) wrote:

steve(ill) wrote:

.. eliminating the shims and boring the rods to size is an excellent idea !

.. eliminating the shims and boring the rods to size is an excellent idea !