| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Rugerben

Bronze Level

Joined: 09 Sep 2016

Location: Alden, NY

Points: 18

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Allis B 3 pt conversion questions Topic: Allis B 3 pt conversion questions

Posted: 15 Apr 2017 at 7:02pm |

|

I got a kit from ok tractor and am having issues with the ram lowering. Actually it wont lower at all. It did not come with any instructions so i dont know if i have the hose connected correctly. My old oem ram worked fine by the way, up and down. I believe with some research that this ram is a double acting and my pump is a single acting. So, am i missing a hose or is there some other way to connect this up? Do i need another hose for a return line? Currently i have the hose coming out of the ram hole on the back of the pump. Has anyone else installed one ofnthese on a B? Thanks!

|

|

|

Sponsored Links

|

|

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 54724

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Apr 2017 at 8:51pm Posted: 15 Apr 2017 at 8:51pm |

Might be fluid or air locked, if it has a plug in the other hose port.

Try one of these, and see if anything changes...

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89279

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Apr 2017 at 9:43pm Posted: 15 Apr 2017 at 9:43pm |

|

for a test, take the plug out of the top end of the cylinder ( rod end)... and then run it up and let it float down.. If that works, get a filter plug like Dave shows and install it on the rod end..........Other than that, that's all the cylinder effects the system.

|

|

Like them all, but love the "B"s.

|

|

PaulB

Orange Level

Joined: 12 Sep 2009

Location: Rocky Ridge Md

Points: 5197

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2017 at 7:49am Posted: 16 Apr 2017 at 7:49am |

|

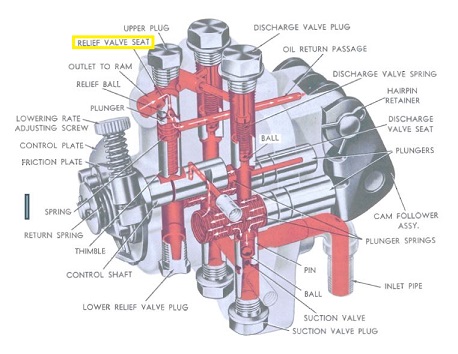

If the ball seat from the top plug is pushed down too far the side port gets cut off.

|

|

If it was fun to pull in LOW gear, I could have a John Deere.

Real pullers don't have speed limits.

If you can't make it GO... make it SHINY

|

|

Rugerben

Bronze Level

Joined: 09 Sep 2016

Location: Alden, NY

Points: 18

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2017 at 6:17pm Posted: 16 Apr 2017 at 6:17pm |

|

Update: so i pulled the plug on the rod end and ran the ram all the way up. It never settled down with a 5' rear blade on it. I checked the ball valves and actually ended up draining oil, removing pump, completely disassembling, reassembling, priming, and put back on tractor. Still no luck. It will raise fine all day but the only way to lower is by letting fluid out. Everything looked good in the pump. Nothing was worn and there was very little dirt or sediment. The only thing i can think is to replace the relief ball, plunger, and spring at this point. Anyone else have any ideas?

|

|

dt1050

Orange Level

Joined: 05 Jul 2011

Location: central pa

Points: 1078

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Apr 2017 at 4:28am Posted: 17 Apr 2017 at 4:28am |

|

you said currently you have the hose ran back to the pump? if I'm reading it right the one end of the cylinder has a hose from a lever to raise the 3pt and the other end of the cylinder is ran back to the pump. If it's hooked up that way the pump will be providing constant pressure to the cylinder (depending on what side of the pump it's plumbed into). I don't know what system you have or what it all looks like, but it sounds like you need a return line to allow the system to drain the fluid out of the cylinder.

|

|

Just cause it's orange don't make it a tractor, there's only one..Allis Chalmers

|

|

Rugerben

Bronze Level

Joined: 09 Sep 2016

Location: Alden, NY

Points: 18

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Apr 2017 at 9:00am Posted: 17 Apr 2017 at 9:00am |

I expect you are right about needing a return hose but everything I read online says just open the other port up on the rod side of the ram and it should be ok. I'll call OK tractor today to verify that. When I removed the pump I never checked the relief valve seat depth so I wonder if it got pushed down and is not allowing the fluid to go back into the pump? I'll check that as soon as i have time. Here is a picture from the manual about what I am talking about. I am also going to connect my original ram back up and see if it still works. Probably should have done that before messing with the pump but never thought of it until this morning!

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89279

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Apr 2017 at 8:58pm Posted: 17 Apr 2017 at 8:58pm |

you have an internal problem with your pump/ valve... lever should be pushed DOWN and allow internal port to open and cylinder pressure to go backward to sump....

one other thing to check is the two swivel plates on the side of the valve that the lever is connected to... If they don't slide good on each other, or the cotter pin is missing or broken, then your not stroking the shaft far enough to get the port to open and dump the oil............ look at the plates as you lower the lever and want to blade to drop... are the rotating ALL THE WAY ? Push one by hand and see if it has complete movement, and if blade will drop when PLATES moved by hand.

look at the return spring and friction plate movements...

Edited by steve(ill) - 17 Apr 2017 at 9:14pm

|

|

Like them all, but love the "B"s.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89279

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Apr 2017 at 9:04pm Posted: 17 Apr 2017 at 9:04pm |

|

are you sure you have the hose screwed into the correct port on the valve ? Has anything been changed at that point ?

|

|

Like them all, but love the "B"s.

|

|

Rugerben

Bronze Level

Joined: 09 Sep 2016

Location: Alden, NY

Points: 18

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Apr 2017 at 8:00pm Posted: 18 Apr 2017 at 8:00pm |

|

Yeah it is plugged into outlet on pump and one ofnthe base ports on cylinder. I did confirm that cylinder needs a vent plug or a plug removed from tie rod end of cylinder. So it is definitely something with my pump. I should have time later in the week to get back on it and ill let everyone know what i find if anything.

|

|

Rugerben

Bronze Level

Joined: 09 Sep 2016

Location: Alden, NY

Points: 18

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Apr 2017 at 3:33pm Posted: 24 Apr 2017 at 3:33pm |

Just a conclusion....I pulled the pump all apart and tapped the relief valve seat back up to spec, reassembled, and it works fine. I did have to back the screw out a little for lowering rate. So far it picks up my rear blade (about 250 lbs) and my 280lb body on it with no problems. So it was the relief valve depth although I don't know what pushed it down! Thanks for all your help guys! Ben

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)