| Author |

Topic Search Topic Search  Topic Options Topic Options

|

TomYaz

Orange Level

Joined: 14 Sep 2009

Location: PA

Points: 10341

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: 175 Brakes part II Topic: 175 Brakes part II

Posted: 30 May 2021 at 4:37pm |

Ok new thread to "reset dicussion"...

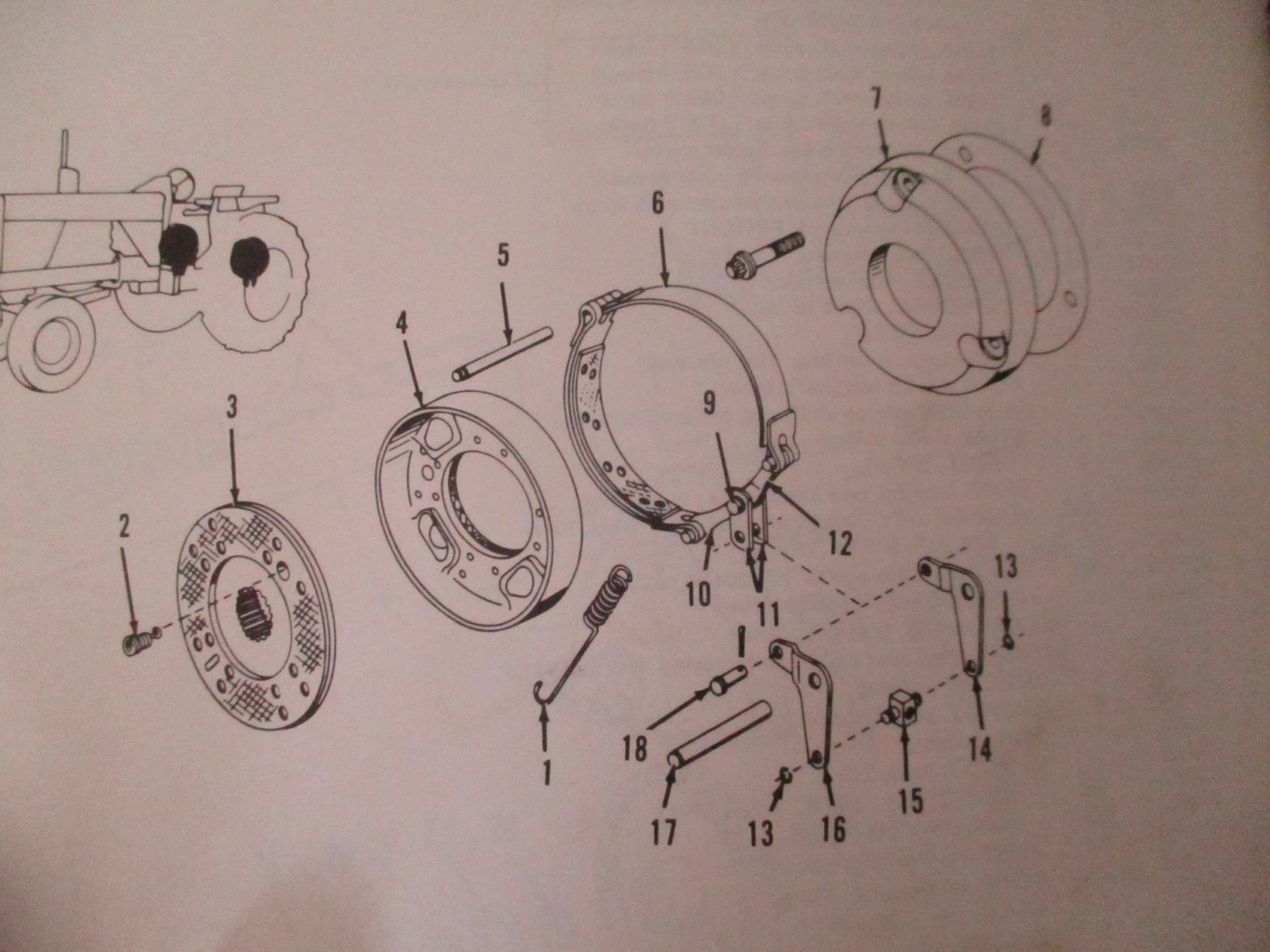

So I got a pic of the existing arrangement. So what is the gap supposed to be between the line arrows?

|

|

If its not an All-Crop, it all crap!

|

|

|

Sponsored Links

|

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22285

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 May 2021 at 7:31pm Posted: 30 May 2021 at 7:31pm |

|

When fully assembled on the tractor and rust free and able to slide side-tp-side, no less than .020" and ideally no more than .030". Feeler gauge works just fine.

|

|

TomYaz

Orange Level

Joined: 14 Sep 2009

Location: PA

Points: 10341

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 May 2021 at 7:34pm Posted: 30 May 2021 at 7:34pm |

DrAllis wrote: DrAllis wrote:

When fully assembled on the tractor and rust free and able to slide side-tp-side, no less than .020" and ideally no more than .030". Feeler gauge works just fine. |

So thats less than 1/32"...looks like we are WAAAYYY off in the pic no?

|

|

If its not an All-Crop, it all crap!

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22285

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 May 2021 at 8:14pm Posted: 30 May 2021 at 8:14pm |

|

A mile off.

|

|

Alex09(WI)

Orange Level

Joined: 15 Mar 2012

Location: CECIL WI

Points: 1768

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 May 2021 at 8:57pm Posted: 31 May 2021 at 8:57pm |

|

You will need some shims behind the friction plate to take up the gap to the proper spec. They are the same shims as in the differential bearing carriers. Should be a lot of them out there.

|

|

www.awtractor.com

A&W TRACTOR 920-598-1287

KEEPING ALLIS-CHALMERS IN THE FIELDS THROUGH THE 21ST CENTURY

|

|

TomYaz

Orange Level

Joined: 14 Sep 2009

Location: PA

Points: 10341

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Jun 2021 at 6:51am Posted: 01 Jun 2021 at 6:51am |

Alex09(WI) wrote: Alex09(WI) wrote:

You will need some shims behind the friction plate to take up the gap to the proper spec. They are the same shims as in the differential bearing carriers. Should be a lot of them out there.

|

Alex,

Can you draw me on the pic where you are talking about....

|

|

If its not an All-Crop, it all crap!

|

|

Lynn Marshall

Orange Level Access

Joined: 13 Sep 2009

Location: Dana, Iowa

Points: 2434

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Jun 2021 at 6:55am Posted: 01 Jun 2021 at 6:55am |

|

It's the piece below the brake drum in your picture. It will either need to be replaced or surfaced. And those bolts are going to be a problem too.

|

|

TomYaz

Orange Level

Joined: 14 Sep 2009

Location: PA

Points: 10341

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Jun 2021 at 6:56am Posted: 01 Jun 2021 at 6:56am |

TomYaz wrote: TomYaz wrote:

Alex09(WI) wrote: Alex09(WI) wrote:

You will need some shims behind the friction plate to take up the gap to the proper spec. They are the same shims as in the differential bearing carriers. Should be a lot of them out there.

|

Alex,

Can you draw me on the pic where you are talking about.... |

Edit...ok see what your saying...Weird though,,,you have to unbolt the friction plate, install the shims, then bolt back on...to what torque? Then if not right, rinse and repeat..sounds like a pain in the ass....Wonder why this was soooo way offf? Factory or someone who doesnt know what they were doing (like me)??? Going to take a LOT of shims I guess...

Edited by TomYaz - 01 Jun 2021 at 6:56am

|

|

If its not an All-Crop, it all crap!

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22285

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Jun 2021 at 7:54am Posted: 01 Jun 2021 at 7:54am |

|

It looks to me like your brake drum assembly is stuck on the splines, if it is holding itself that far away from the outer friction surface. You've got to have clean splines on the shaft and drum so things can slide freely. If this was a non rust bucket, that drum would be sitting clear down and there would be zero gap in the picture.

|

|

TomYaz

Orange Level

Joined: 14 Sep 2009

Location: PA

Points: 10341

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Jun 2021 at 8:02am Posted: 01 Jun 2021 at 8:02am |

DrAllis wrote: DrAllis wrote:

It looks to me like your brake drum assembly is stuck on the splines, if it is holding itself that far away from the outer friction surface. You've got to have clean splines on the shaft and drum so things can slide freely. If this was a non rust bucket, that drum would be sitting clear down and there would be zero gap in the picture. |

Yep the whole wheel was frozen. I think the opposite end of the drum was frozen to its mating piece marked with X

|

|

If its not an All-Crop, it all crap!

|

|

TomYaz

Orange Level

Joined: 14 Sep 2009

Location: PA

Points: 10341

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Jun 2021 at 8:04am Posted: 01 Jun 2021 at 8:04am |

|

Yes the drum wont budge manually. Advice on how to free? dare I say crowbar?

|

|

If its not an All-Crop, it all crap!

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22285

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Jun 2021 at 8:08am Posted: 01 Jun 2021 at 8:08am |

|

Large bearing puller with long legs a crossbar and a screw to pull against the end of the shaft. Never seen anything that rusty. It's like it's been laying on the bottom of a salt water ocean.

|

|

TomYaz

Orange Level

Joined: 14 Sep 2009

Location: PA

Points: 10341

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Jun 2021 at 8:26am Posted: 01 Jun 2021 at 8:26am |

DrAllis wrote: DrAllis wrote:

Large bearing puller with long legs a crossbar and a screw to pull against the end of the shaft. Never seen anything that rusty. It's like it's been laying on the bottom of a salt water ocean. |

Where the heck do I find a gear puller that large?!

Yeah this tractor was/is derelict. Not sure if even proceeding is worth the trouble. I got it and the loader for $800.00

|

|

If its not an All-Crop, it all crap!

|

|

Alex09(WI)

Orange Level

Joined: 15 Mar 2012

Location: CECIL WI

Points: 1768

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Jun 2021 at 8:55am Posted: 01 Jun 2021 at 8:55am |

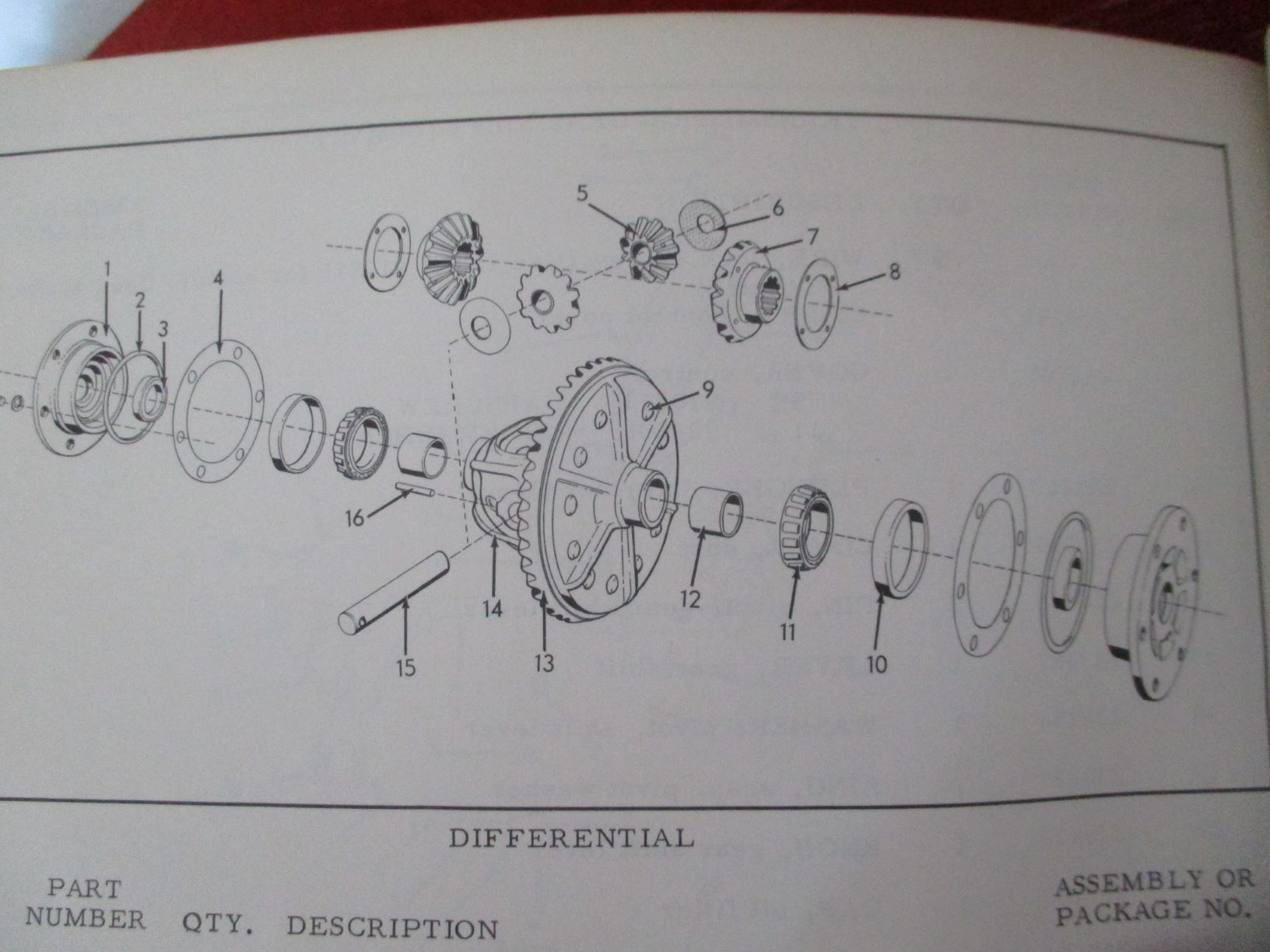

For $800, the tractor is worth the trouble. The shims you will need are #8 in 1st pic and #4 in second pic. Same from WD through 185 and 190. They come in different widths, .005, .007, .010, .020. You have to measure the new & remachined parts before final assembly to determine how thick of shims you need.

The spec where you see the inside micrometer should be 2.034-2.044". OR- with Dr's method, .020-.030" of combined clearance with brake drum installed.

|

|

www.awtractor.com

A&W TRACTOR 920-598-1287

KEEPING ALLIS-CHALMERS IN THE FIELDS THROUGH THE 21ST CENTURY

|

|

TomYaz

Orange Level

Joined: 14 Sep 2009

Location: PA

Points: 10341

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Jun 2021 at 9:15am Posted: 01 Jun 2021 at 9:15am |

>>>The spec where you see the inside micrometer should be 2.034-2.044". OR- with Dr's method, .020-.030" of combined clearance with brake drum installed.

Ohh man am I confused...Based on you pic, both sides of that friction(7) plate is exposed... the one side has a gap between it and the drum, supposed to be .020-030 per Doc, and in the other side per your pic show there is a 2.034" clearance....according to the illustration isnt a shim supposed to be on one of these sides. Also in the illustration, the face of part 7 faces the drum, but in your pic it is facing part #1 of the differential??

Edited by TomYaz - 01 Jun 2021 at 9:18am

|

|

If its not an All-Crop, it all crap!

|

|

TomYaz

Orange Level

Joined: 14 Sep 2009

Location: PA

Points: 10341

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Jun 2021 at 9:28am Posted: 01 Jun 2021 at 9:28am |

|

In my pic the bevel side of the friction plate faces the brake drum, while in your pic the beveled side of the friction plate faces the differential part 1....???

|

|

If its not an All-Crop, it all crap!

|

|

DSeries4

Orange Level

Joined: 12 Sep 2009

Location: Ontario, Canada

Points: 7564

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Jun 2021 at 9:36am Posted: 01 Jun 2021 at 9:36am |

|

Shims go behind #7 on the axle side, so you do not see it in the pictures. There are 2 ways to get the clearance. One is pictured above to get around 2.034 (without the drum in place). The other way is with the drum installed and using a feeler gauge to get .020 - .030" - I usually use this method.

|

|

'49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080

|

|

TomYaz

Orange Level

Joined: 14 Sep 2009

Location: PA

Points: 10341

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Jun 2021 at 9:44am Posted: 01 Jun 2021 at 9:44am |

DSeries4 wrote: DSeries4 wrote:

Shims go behind #7 on the axle side, so you do not see it in the pictures. There are 2 ways to get the clearance. One is pictured above to get around 2.034 (without the drum in place). The other way is with the drum installed and using a feeler gauge to get .020 - .030" - I usually use this method.

|

??? If you look at Alex pic, the other side of 7 would find the drum! Why is the beveled side faceing the differential while on my pic the bevel side faces the drum??

What am I not getting? Sorry guys I am just not the best wrench monkey like you are; this stuff doesnt come naturally to me.

|

|

If its not an All-Crop, it all crap!

|

|

TomYaz

Orange Level

Joined: 14 Sep 2009

Location: PA

Points: 10341

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Jun 2021 at 9:46am Posted: 01 Jun 2021 at 9:46am |

Wait a minute.....I suppose the drum goes where the micrometer is....

Geeezzzz like I said, this stuff aint easy for me....

|

|

If its not an All-Crop, it all crap!

|

|

DSeries4

Orange Level

Joined: 12 Sep 2009

Location: Ontario, Canada

Points: 7564

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Jun 2021 at 10:24am Posted: 01 Jun 2021 at 10:24am |

TomYaz wrote: TomYaz wrote:

Wait a minute.....I suppose the drum goes where the micrometer is....

Geeezzzz like I said, this stuff aint easy for me.... |

Yes, the drum goes where the micrometer is. Fit it together and take your measurements. Then remove the axle to adjust the number of shims as needed.

|

|

'49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080

|

|

TomYaz

Orange Level

Joined: 14 Sep 2009

Location: PA

Points: 10341

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Jun 2021 at 11:30am Posted: 01 Jun 2021 at 11:30am |

|

Given all the work to be done, no way in heck I will get this tractor done soon enuff for me to use. Think I will tear it down, get another 175 that is functional and put the loader on it. Use this unit for parts or make it a leisurely rebuild someday....I would have the other 175 to help tell me how to put it together!! Thanks for all the help fellas. I am going to offload this thread for future use.

|

|

If its not an All-Crop, it all crap!

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

DrAllis wrote:

DrAllis wrote: