| Author |

Topic Search Topic Search  Topic Options Topic Options

|

TomYaz

Orange Level

Joined: 14 Sep 2009

Location: PA

Points: 10341

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: 175 Brake part Topic: 175 Brake part

Posted: 26 May 2021 at 11:58am |

Hi all,

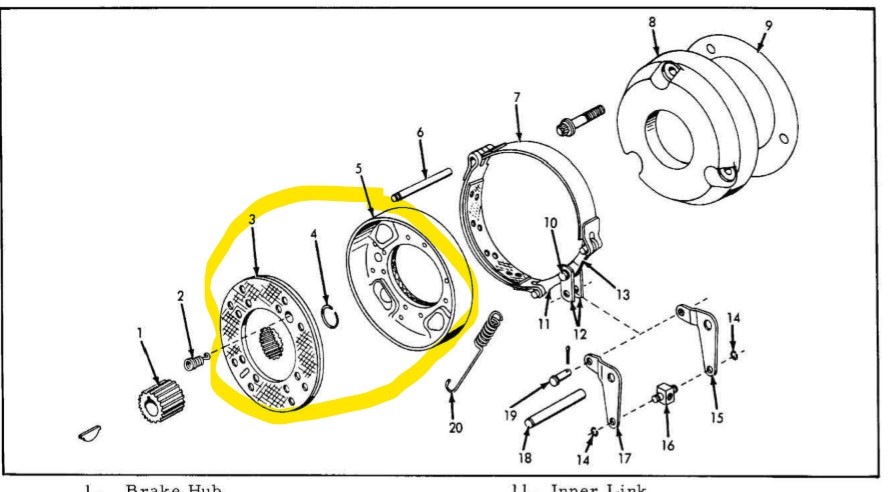

Anyone tell me the part number of the "X"?? Cant seem to find the part in my 175 parts catalog....also, helluva time getting the circled pin out. Seems frozen good....

|

|

If its not an All-Crop, it all crap!

|

|

|

Sponsored Links

|

|

|

Joe(TX)

Orange Level

Joined: 11 Sep 2009

Location: Weatherford. TX

Points: 1682

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 May 2021 at 6:45pm Posted: 26 May 2021 at 6:45pm |

Looks like the differential carrier. I had to make a puller for a small slide hammer. One end has 3/8 threads which are not labeled on the drawing.

|

|

1970 190XT, 1973 200, 1962 D-19 Diesel, 1979 7010, 1957 WD45, 1950 WD, 1961 D17, Speed Patrol, D14, All crop 66 big bin, 180 diesel, 1970 170 diesel, FP80 forklift. Gleaner A

|

|

TomYaz

Orange Level

Joined: 14 Sep 2009

Location: PA

Points: 10341

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 May 2021 at 6:52pm Posted: 26 May 2021 at 6:52pm |

Thats neat Joe!

Know someone who can make me one? $ for your trouble of course!

I dont understand 100% how these brakes work...so you got these bands similar to the wd45 and D17 that mount on this pin,,,they provide braking contact on the drum...but If i am understanding right the drum sides it self are a braking surface too?? Is this part I want to know about part of that??

|

|

If its not an All-Crop, it all crap!

|

|

Joe(TX)

Orange Level

Joined: 11 Sep 2009

Location: Weatherford. TX

Points: 1682

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 May 2021 at 7:05pm Posted: 26 May 2021 at 7:05pm |

|

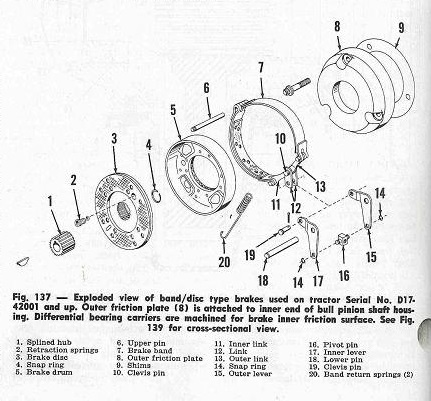

The band clamps on the drum. the drum has balls that spread the friction plates which press on the the friction discs on both side. friction plates are on the differential housing and the axle housing.

|

|

1970 190XT, 1973 200, 1962 D-19 Diesel, 1979 7010, 1957 WD45, 1950 WD, 1961 D17, Speed Patrol, D14, All crop 66 big bin, 180 diesel, 1970 170 diesel, FP80 forklift. Gleaner A

|

|

TomYaz

Orange Level

Joined: 14 Sep 2009

Location: PA

Points: 10341

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 May 2021 at 7:12pm Posted: 26 May 2021 at 7:12pm |

Joe(TX) wrote: Joe(TX) wrote:

The band clamps on the drum. the drum has balls that spread the friction plates which press on the the friction discs on both side. friction plates are on the differential housing and the axle housing. |

this part is a braking surface...but why the heck isnt it in the parts catalog???

Anyhoo,,,about that tool you made.....how can I get me one?

|

|

If its not an All-Crop, it all crap!

|

|

Lynn Marshall

Orange Level Access

Joined: 13 Sep 2009

Location: Dana, Iowa

Points: 2434

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 May 2021 at 7:53pm Posted: 26 May 2021 at 7:53pm |

|

Part# 70237183. It may or may not be available and the cost could be high. You could probably have your old one surfaced if that is the problem.

|

|

TomYaz

Orange Level

Joined: 14 Sep 2009

Location: PA

Points: 10341

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 May 2021 at 8:02pm Posted: 26 May 2021 at 8:02pm |

|

Thanks!

|

|

If its not an All-Crop, it all crap!

|

|

MACK

Orange Level

Joined: 17 Nov 2009

Points: 7664

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 May 2021 at 9:13pm Posted: 26 May 2021 at 9:13pm |

|

you can machine it down to bolt heads. Just add shims to axel side ware surface. MACK

|

|

DSeries4

Orange Level

Joined: 12 Sep 2009

Location: Ontario, Canada

Points: 7569

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 May 2021 at 9:22pm Posted: 26 May 2021 at 9:22pm |

|

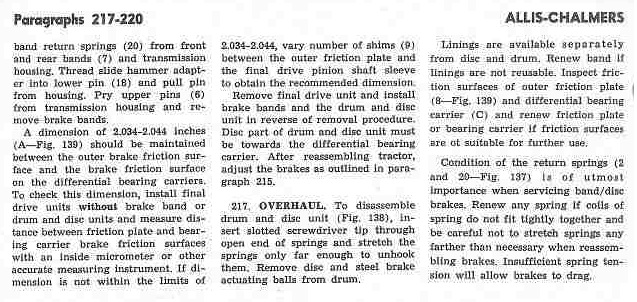

After you put the brake assembly back in the housing and put the axle on, you will have to check clearance between the brake disc and the bearing carrier. You may need to add shims to get proper clearance. The tolerance in the service manual - 33 to 88 thou rings a bell but I do not have it in front of me.

|

|

'49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080

|

|

TomYaz

Orange Level

Joined: 14 Sep 2009

Location: PA

Points: 10341

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 May 2021 at 7:23am Posted: 27 May 2021 at 7:23am |

DSeries4 wrote: DSeries4 wrote:

After you put the brake assembly back in the housing and put the axle on, you will have to check clearance between the brake disc and the bearing carrier. You may need to add shims to get proper clearance. The tolerance in the service manual - 33 to 88 thou rings a bell but I do not have it in front of me. |

I got the AC 175 service manual but there is nothing about brakes. Is it in the I&T?

So I dont get confused as I easliy do, can you tell me below what parts you are talking about?

|

|

If its not an All-Crop, it all crap!

|

|

MACK

Orange Level

Joined: 17 Nov 2009

Points: 7664

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 May 2021 at 7:52am Posted: 27 May 2021 at 7:52am |

|

Resurface #8 and shims are #9. Measure between #5 and 8. MACK

|

|

TomYaz

Orange Level

Joined: 14 Sep 2009

Location: PA

Points: 10341

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 May 2021 at 7:58am Posted: 27 May 2021 at 7:58am |

MACK wrote: MACK wrote:

Resurface #8 and shims are #9. Measure between #5 and 8. MACK |

Ok thanks...but part 5/3 slides freely off part 1....At least thats what it looks like as I am looking at it with whole thing taken off the tractor.. What keeps 5/3 in place?

Edited by TomYaz - 27 May 2021 at 7:59am

|

|

If its not an All-Crop, it all crap!

|

|

TomYaz

Orange Level

Joined: 14 Sep 2009

Location: PA

Points: 10341

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 May 2021 at 7:59am Posted: 27 May 2021 at 7:59am |

TomYaz wrote: TomYaz wrote:

MACK wrote: MACK wrote:

Resurface #8 and shims are #9. Measure between #5 and 8. MACK |

Ok thanks...but part 5/3 slides freely off part 1....At least thats what it looks like as I am looking at it with whole thing taken off the tractor.. What keeps 5/3 in place?

|

Lemme guess...the snap ring!

|

|

If its not an All-Crop, it all crap!

|

|

critter

Silver Level Access

Joined: 13 Nov 2013

Location: Ohio

Points: 254

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 May 2021 at 10:34am Posted: 27 May 2021 at 10:34am |

|

Joe is there a bolt in that puller to pinch it closed on the dowel?

|

|

DanWi

Orange Level Access

Joined: 18 Sep 2009

Location: wttn

Points: 1983

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 May 2021 at 12:00pm Posted: 27 May 2021 at 12:00pm |

|

3 and 5 have to float that is what expands to apply the brake the bands only actuate that part to push apart. You brake against no 8 and something on the side of 3. Your clearance would be with 3 and 5 together not spread apart and between 8 and the housing or cover on the other side. Not familiar with the 170/175 but the 190 just has a cover

|

|

JC-WI

Orange Level Access

Joined: 11 Sep 2009

Location: wisconsin

Points: 34430

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 May 2021 at 1:17pm Posted: 27 May 2021 at 1:17pm |

Tom, when I helped a friend get his 175 back to moving, he was short on dollars, thus the fix was as cheap as possible. We removed the wheel, and then the rear axle. Then made several measurements... some using a straight edge off of the mating surface of the axle and housing to surfaces. Measured the old brake assembly after putting new springs in (his had the #2 springs broke). Found the dimensions (2.423") of a new #8 friction plate.

Had a machinist resurface the friction plate face and had a plate made to take the place of many shims. That brought the tolerances back to what was needed to take the slop out of all the wear. Worked good until he sold the tractor.

Dimension between friction plates is suppose to be 2.034 - 2.044" . Had a gauge made with those two dimensions, sorta a go and no go gauge, if the narrow side didn't slip in, it was to narrow. and if the wide side slipped in, the area was to wide. Used it only once since it was made.

|

|

He who says there is no evil has already deceived himself

The truth is the truth, sugar coated or not. Trawler II says, "Remember that."

|

|

TomYaz

Orange Level

Joined: 14 Sep 2009

Location: PA

Points: 10341

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 May 2021 at 2:01pm Posted: 27 May 2021 at 2:01pm |

JC(WI) wrote: JC(WI) wrote:

Tom, when I helped a friend get his 175 back to moving, he was short on dollars, thus the fix was as cheap as possible. We removed the wheel, and then the rear axle. Then made several measurements... some using a straight edge off of the mating surface of the axle and housing to surfaces. Measured the old brake assembly after putting new springs in (his had the #2 springs broke). Found the dimensions (2.423") of a new #8 friction plate.

Had a machinist resurface the friction plate face and had a plate made to take the place of many shims. That brought the tolerances back to what was needed to take the slop out of all the wear. Worked good until he sold the tractor.

Dimension between friction plates is suppose to be 2.034 - 2.044" . Had a gauge made with those two dimensions, sorta a go and no go gauge, if the narrow side didn't slip in, it was to narrow. and if the wide side slipped in, the area was to wide. Used it only once since it was made.

|

Being a computer programmer I am very anal here....

"Dimension between friction plates is suppose to be 2.034 - 2.044" - you mean between parts 5/3 and 8 with 5/3 being closed?

Based on the other comment, there is a gap between the other side of 8 and the pictured part I posted? How the heck do you measure that gap??

|

|

If its not an All-Crop, it all crap!

|

|

Gatz in NE

Orange Level

Joined: 11 Sep 2009

Location: Lincoln, NE

Points: 1062

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 May 2021 at 7:04pm Posted: 27 May 2021 at 7:04pm |

The dimension given is shown in 2nd pic This is from an I&T manual for a D17s4 (and s3 if I'm not mistaken) You won't find this in an AC repair manual.

I think they used this basic design in the 175

BTW, Tom, I have made an extraction tool like Joe's to get that *@!*$#* pin out. I'll look to see if I had made an extra if you're interested.

Edited by Gatz in NE - 27 May 2021 at 7:06pm

|

|

Joe(TX)

Orange Level

Joined: 11 Sep 2009

Location: Weatherford. TX

Points: 1682

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 May 2021 at 1:46am Posted: 28 May 2021 at 1:46am |

critter wrote: critter wrote:

Joe is there a bolt in that puller to pinch it closed on the dowel? |

I made one like the earlier posted drawing Joe

|

|

1970 190XT, 1973 200, 1962 D-19 Diesel, 1979 7010, 1957 WD45, 1950 WD, 1961 D17, Speed Patrol, D14, All crop 66 big bin, 180 diesel, 1970 170 diesel, FP80 forklift. Gleaner A

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22307

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 May 2021 at 6:33am Posted: 28 May 2021 at 6:33am |

|

I assemble everything with new linings. You reach down thru the top hole and measure your disc lining clearance with a feeler gauge. One must assume the shim stack was pretty close to begin with. If you machine any part, you add that amount to the shim stack. I shoot for no less than .020" and no more than .030" with new disc linings. Suit yourself. You can assemble it and measure the distance with some sort of measuring tool, then take it back apart to correct things, or assemble it with real parts, measure and maybe be done the first time. Either way, you assemble and measure and correct if needed.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

Joe(TX) wrote:

Joe(TX) wrote: