| Author |

Topic Search Topic Search  Topic Options Topic Options

|

DanD

Orange Level

Joined: 11 Sep 2009

Location: WI

Points: 856

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Gleaner F3 Torque value Topic: Gleaner F3 Torque value

Posted: 06 Aug 2017 at 10:37pm |

|

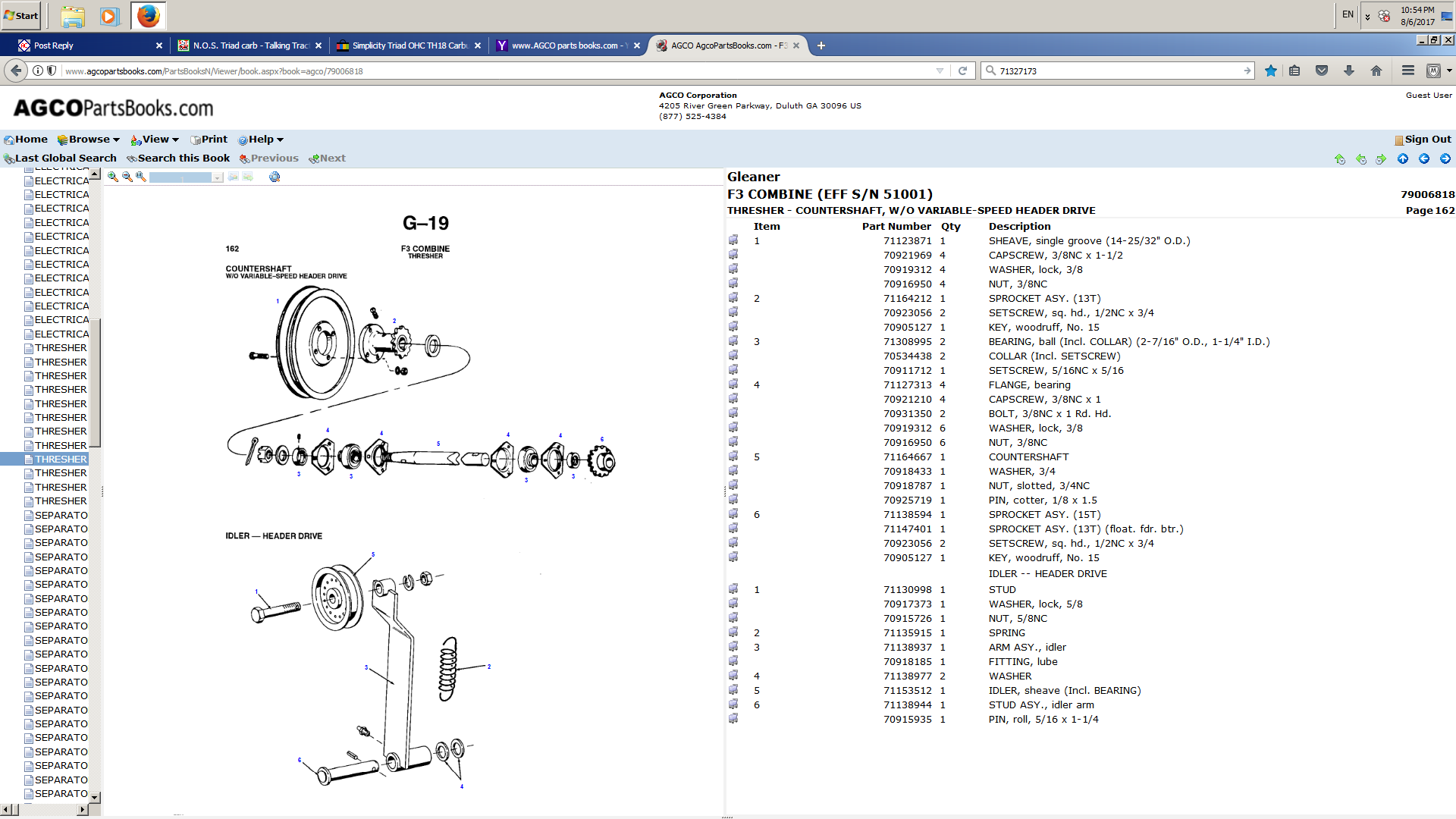

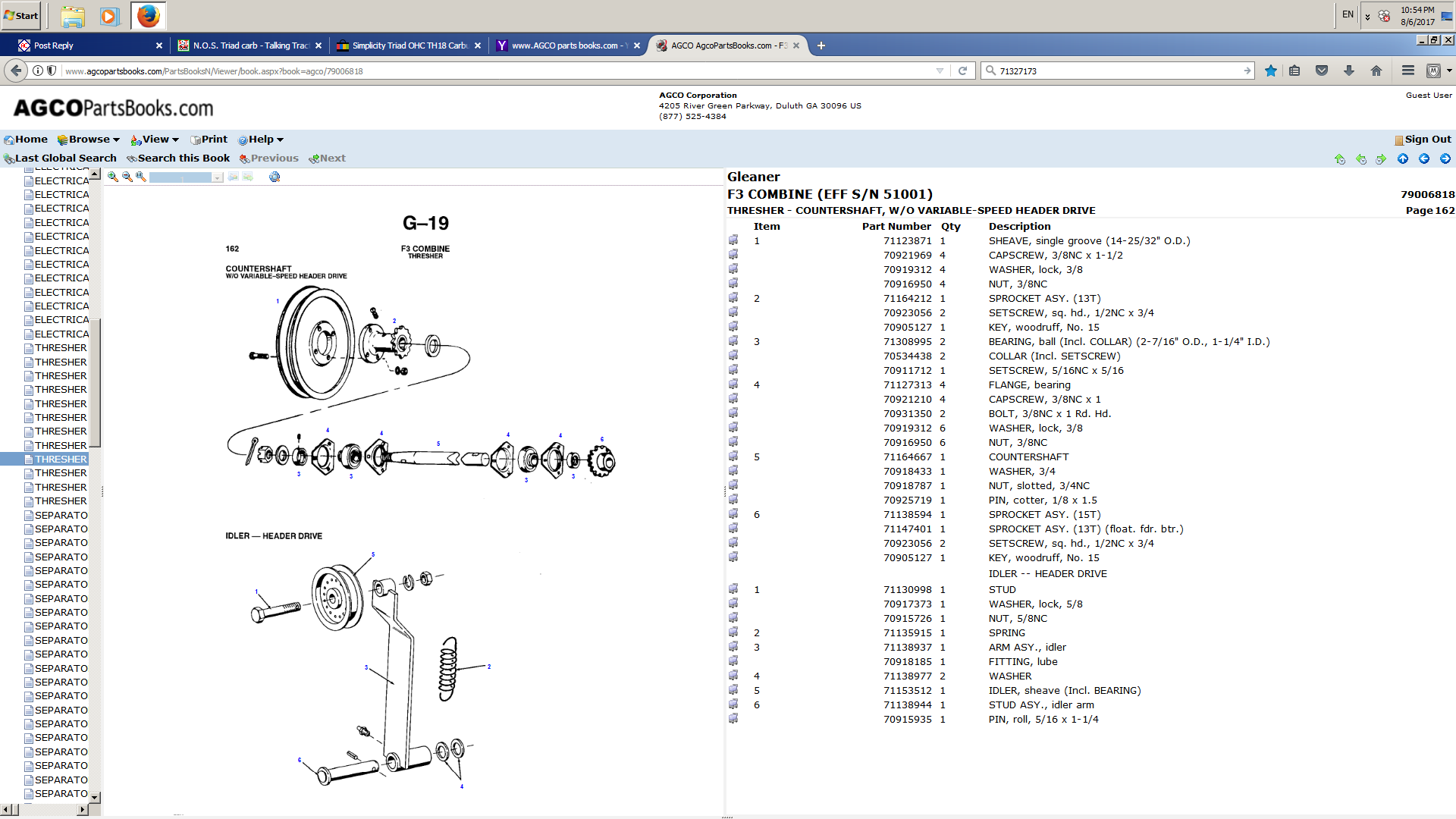

Anyone have any specs for what the torque setting should be for the nut on the left end of the thresher countershaft without the variable speed header drive on an F3? This is the shaft that drives the head and the feeder beater. Is there a torque spec or just do the German spec of Gutentite then just enough more to get the cotter pin the castle nut? I'm typically fussy on using the torque wrench whenever a value is given. Thanks.

|

|

|

Sponsored Links

|

|

|

MACK

Orange Level

Joined: 17 Nov 2009

Points: 7664

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Aug 2017 at 10:46pm Posted: 06 Aug 2017 at 10:46pm |

|

Just like adjusting wheel bearing. Tighten nut to where all slack is out of bearing, then loosen until it turns free, install cotter pin. MACK

|

|

DanD

Orange Level

Joined: 11 Sep 2009

Location: WI

Points: 856

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Aug 2017 at 10:58pm Posted: 06 Aug 2017 at 10:58pm |

MACK wrote: MACK wrote:

Just like adjusting wheel bearing. Tighten nut to where all slack is out of bearing, then loosen until it turns free, install cotter pin. MACK |

I'm a little confused. Are you perhaps thinking of the pivot shaft? It turns on tapered bearings. This shaft just turns on two sealed ball bearings.

|

|

FREEDGUY

Orange Level Access

Joined: 15 Apr 2017

Location: South West Mich

Points: 5396

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Aug 2017 at 6:56am Posted: 07 Aug 2017 at 6:56am |

|

We replaced that same shaft 2 years ago on a F2. Dad was in charge of that ends assembly and he doesn't own a torque wrench. I could ask him if he recalls how tight he made it if you want.

|

|

MACK

Orange Level

Joined: 17 Nov 2009

Points: 7664

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Aug 2017 at 8:23am Posted: 07 Aug 2017 at 8:23am |

|

You are right, I was talking of pivot shaft. MACK

|

|

allisrutledge

Orange Level

Joined: 30 Mar 2010

Location: SurgoinsvilleTN

Points: 1361

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Aug 2017 at 11:42am Posted: 07 Aug 2017 at 11:42am |

|

Put the shaft in both bearings in position allowing the same distance from the end of the shaft to the bearing as it was prior to taking it apart then tighten both locks on the bore race. Ball bearings don't like any thrust.just direct load. The shaft should turn free when the locks are set. Be sure pullys or cogs line up before installing belts/ chains. Clear as mud? Scott

|

|

Allis Chalmers still exist in my mind and barns

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8768

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Aug 2017 at 12:31pm Posted: 07 Aug 2017 at 12:31pm |

|

looks keyed and tapered...good and tight should be enough.Excessive tight may leave it not wanting to come off...EVER!!!

|

|

DanD

Orange Level

Joined: 11 Sep 2009

Location: WI

Points: 856

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Aug 2017 at 1:46pm Posted: 07 Aug 2017 at 1:46pm |

|

The shaft and sprocket are tapered. I'm asking because the old sprocket has been welded to the shaft some time in the past and it's either not square or the shaft is bent. The big pulley bolted to the sprocket wobbles a lot as a result. We just want to get it fixed. I was wondering if this was something that was prone to coming loose if not tightened properly and was just wondering if a shop manual would have a torque value. If not I'll just go pretty tight and then watch it. This should not have anything to do with the tightness of the bearings.

Edited by DanD - 07 Aug 2017 at 5:15pm

|

|

FREEDGUY

Orange Level Access

Joined: 15 Apr 2017

Location: South West Mich

Points: 5396

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Aug 2017 at 7:37pm Posted: 07 Aug 2017 at 7:37pm |

|

Are you sure that the "weld" isn't the sprocket welded to the tapered hub? That is exactly why we had to change our shaft AND that sprocket(ours is a double sprocket on a tapered hub-that part # is in a cornhead book),the pulley wobbled so bad it rolled and then threw the belt off. After closer examination, the tapered hub was wollered out,threads on end of shaft stripped and keyway slot in shaft ruined. Since this morning,I went out to the farm to look how snug that castle nut was and found that the pulley is loose on the sprocket hub!

|

|

DanD

Orange Level

Joined: 11 Sep 2009

Location: WI

Points: 856

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Aug 2017 at 9:14pm Posted: 07 Aug 2017 at 9:14pm |

|

I can assure you that the sprocket is welded to the shaft. Someone did that some time in the past. Ours has the double sprockets for the corn head too. Like you said you have to look in the corn head book to get their part numbers.

|

|

FREEDGUY

Orange Level Access

Joined: 15 Apr 2017

Location: South West Mich

Points: 5396

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Aug 2017 at 6:43pm Posted: 08 Aug 2017 at 6:43pm |

|

Ouch on the welded on sprocket

|

|

DanD

Orange Level

Joined: 11 Sep 2009

Location: WI

Points: 856

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Aug 2017 at 10:53pm Posted: 13 Aug 2017 at 10:53pm |

https://www.dropbox.com/s/mbl53g505h9nnny/2017-08-13%2013.05.56.mp4?dl=0I don't know if this link will work, but it shows the combine running today with a new shaft and bearings and sprocket installed. No wobble any more and sprockets and celts all are nice aligned.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

MACK wrote:

MACK wrote: