| Author |

Topic Search Topic Search  Topic Options Topic Options

|

GM Guy

Orange Level

Joined: 31 Jul 2012

Location: NW KS / S.C. ID

Points: 1988

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: 7580 PTO Driveline Removal Topic: 7580 PTO Driveline Removal

Posted: 03 Jun 2017 at 5:50pm |

|

Hey all,

I have a bad slip joint in my 7580's PTO driveline, and need to remove it to get it rebuilt.

I was wanting to ask you guys, do I need to have the tractor turned at all, or is straight ahead just fine?

Normally I wouldnt ask, but I have a bad leak in a hyd. oil cooler and i am removing at the same time, and I dont want to have it all apart and find out I needed to have it turned.

|

|

Gleaner: the properly engineered and built combine.

If you need parts for your Gleaner, we are parting out A's through L2's, so we may be able to help.

|

|

|

Sponsored Links

|

|

|

tbran

Orange Level

Joined: 14 Sep 2009

Location: Paris Tn

Points: 3545

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jun 2017 at 11:53pm Posted: 03 Jun 2017 at 11:53pm |

|

There used to be a cardan jack shaft kit for these to eliminate the CV joint. Might be worth checking into.

|

|

When told "it's not the money,it's the principle", remember, it's always the money..

|

|

victoryallis

Orange Level

Joined: 15 Apr 2010

Location: Ludington mi

Points: 2879

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Jun 2017 at 7:39am Posted: 04 Jun 2017 at 7:39am |

|

GM if you look into the cardan jack shaft let me know what you find out.

|

|

8030 and 8050MFWD, 7580, 3 6080's, 160, 7060, 175, heirloom D17, Deere 8760

|

|

GM Guy

Orange Level

Joined: 31 Jul 2012

Location: NW KS / S.C. ID

Points: 1988

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Jun 2017 at 3:47pm Posted: 04 Jun 2017 at 3:47pm |

|

The previous owners were quite proud they greased it daily, and I continue the trend. Amazingly the CVs are in great shape, just the slip joints are sloppy, so i think I will keep the CV setup and just have the slip joints replaced.

My dad picked up a 78 7580, and they converted it over to a home brew setup with a welded in crossmember and carrier bearing. I am not sure of what to think of it, probably better in flat land conditions, but at max turn and going through some terrain, I am worried it will have trouble.

Edited by GM Guy - 04 Jun 2017 at 3:49pm

|

|

Gleaner: the properly engineered and built combine.

If you need parts for your Gleaner, we are parting out A's through L2's, so we may be able to help.

|

|

Mike Kroupa

Silver Level

Joined: 02 Oct 2009

Location: pierce, ne

Points: 338

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Jun 2017 at 9:03pm Posted: 04 Jun 2017 at 9:03pm |

|

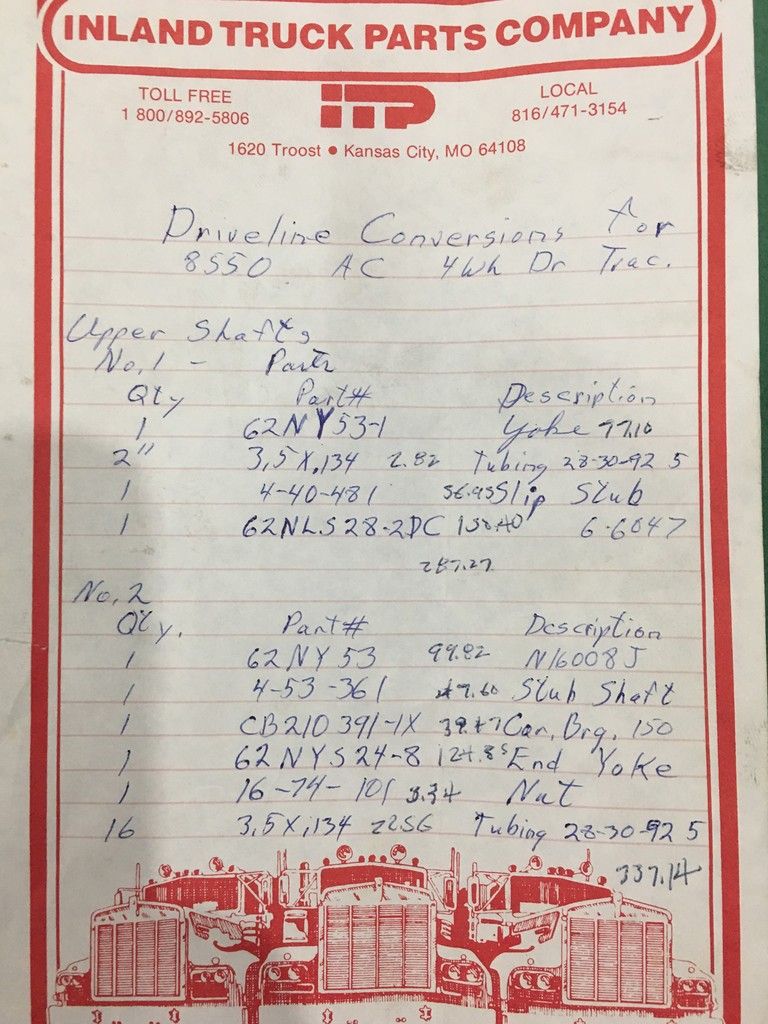

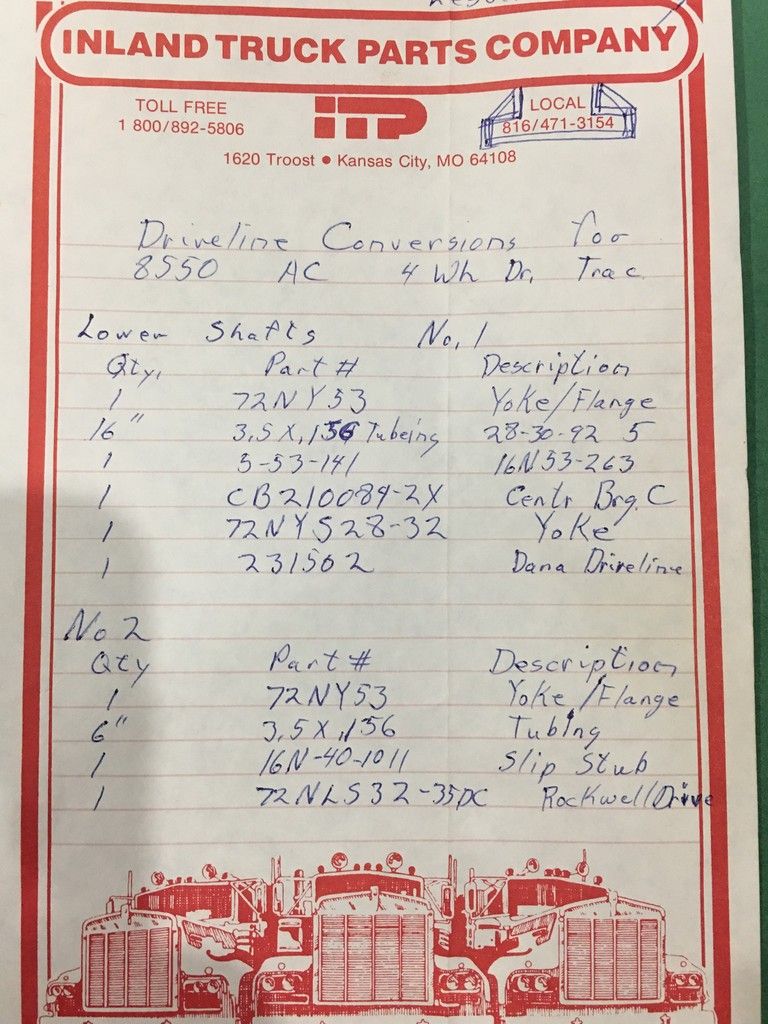

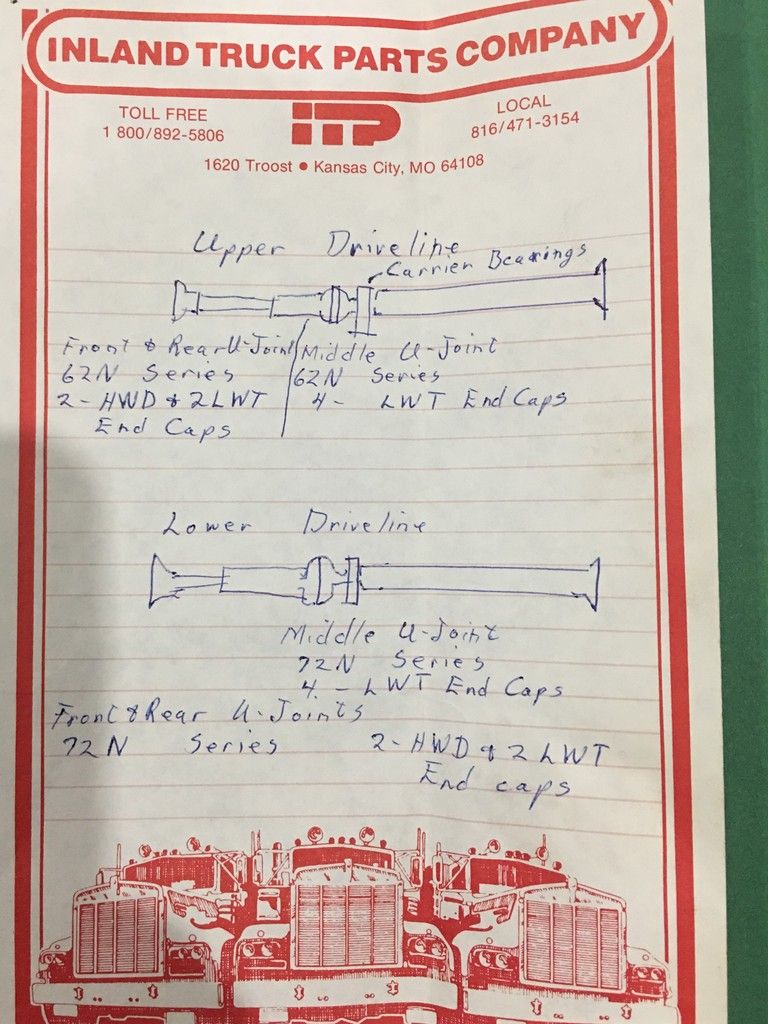

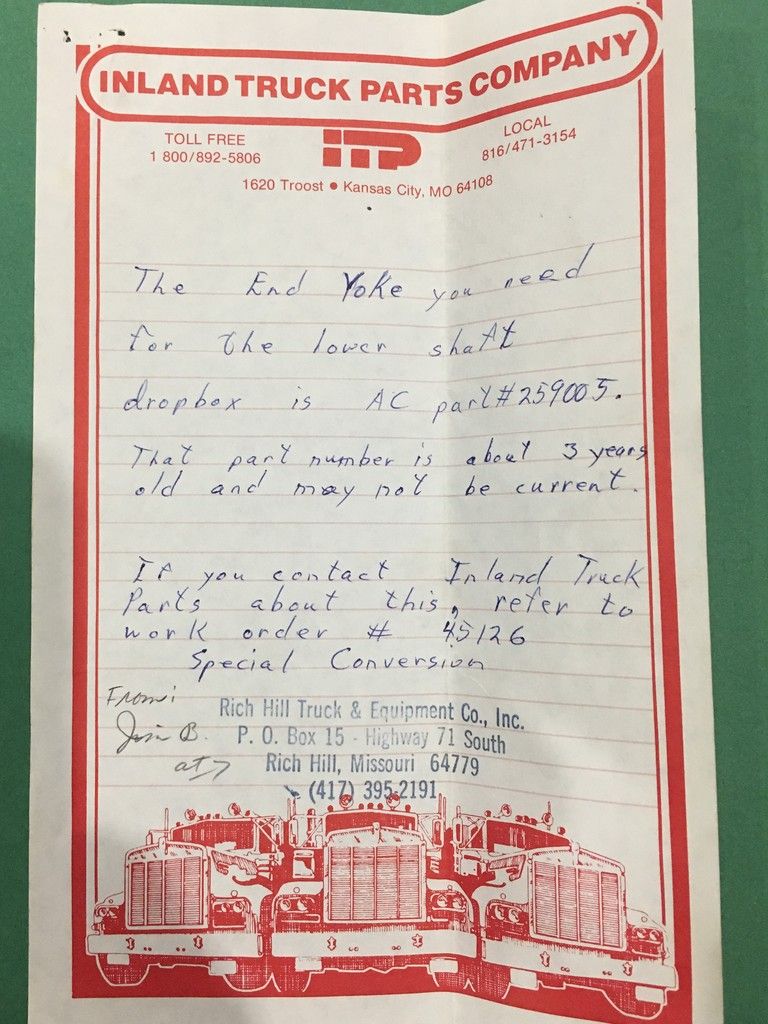

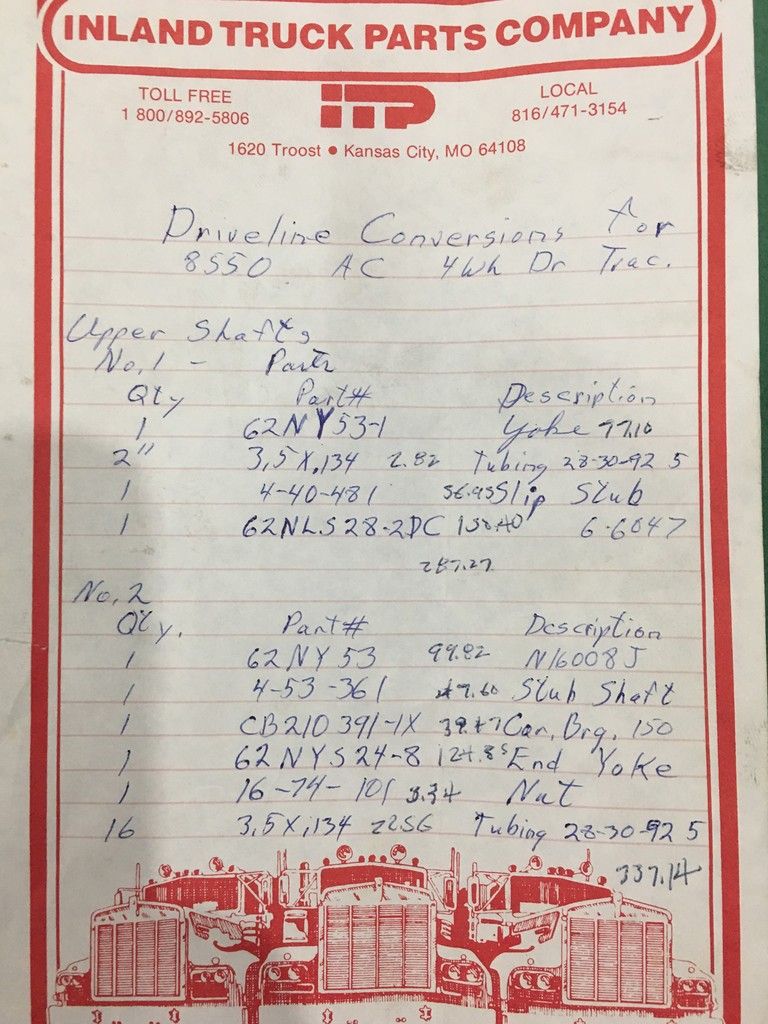

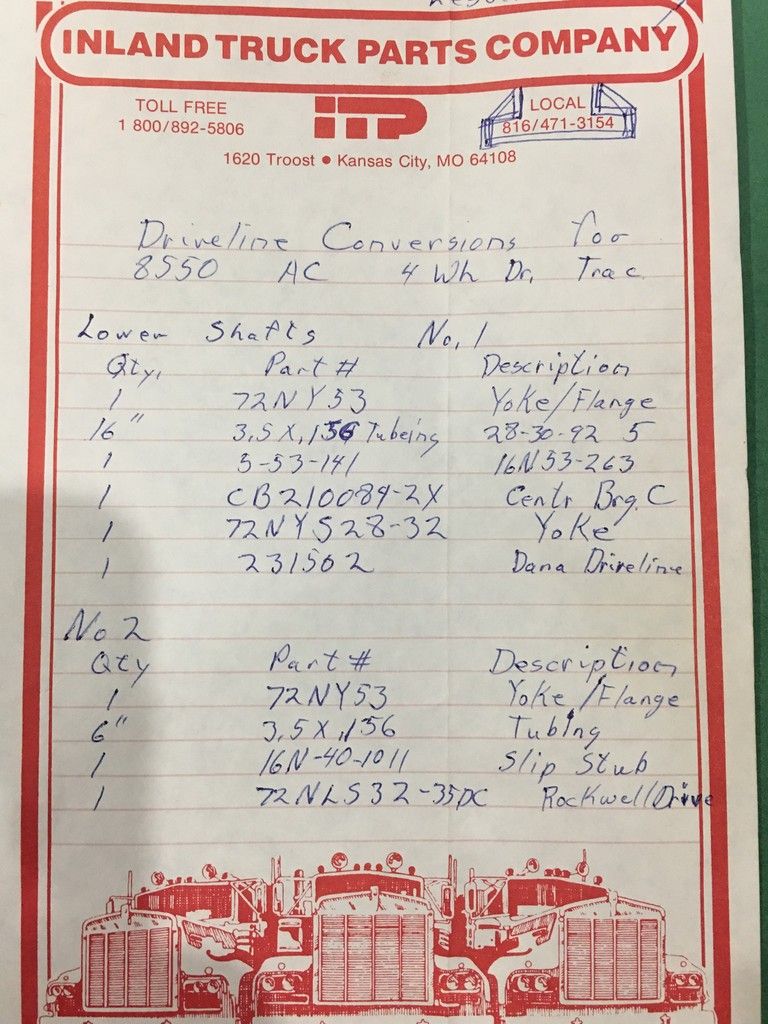

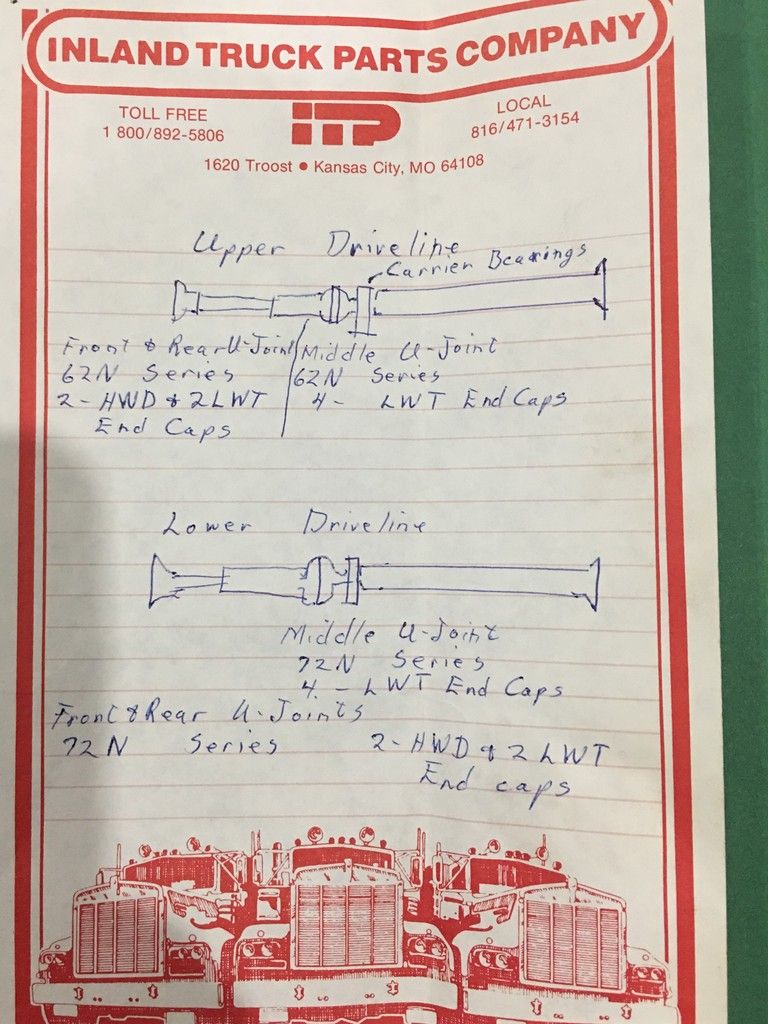

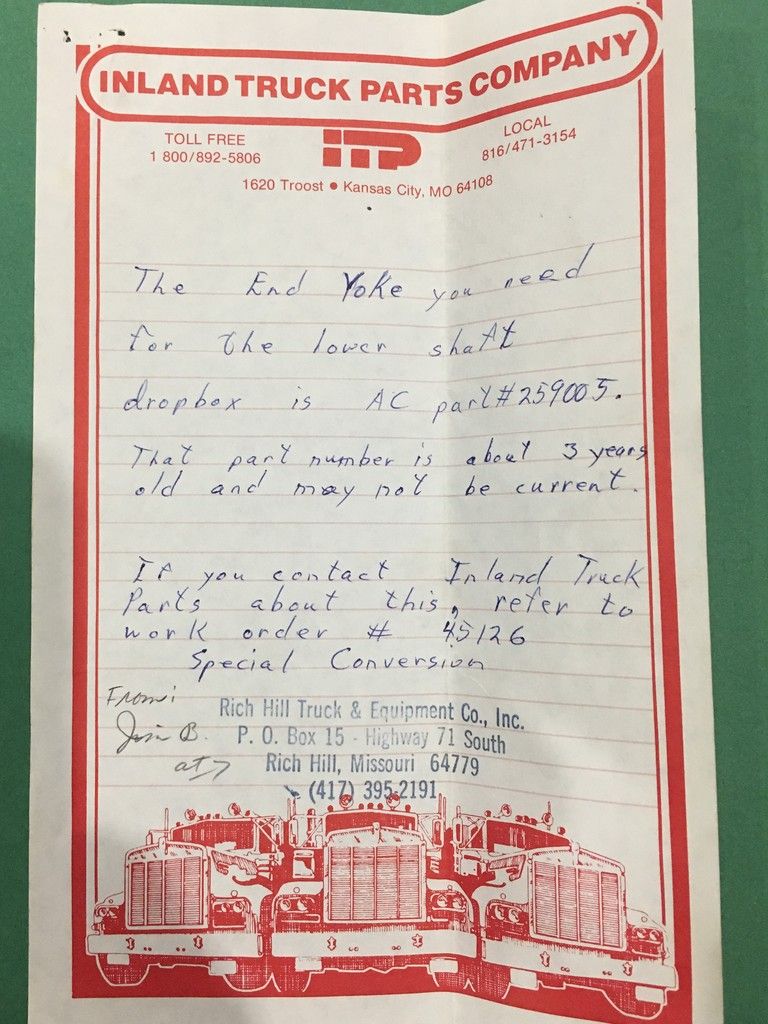

Most of the 7580/8550's around here locally had both drive shafts converted to the two piece hanger bearing style. I over greased both of the shafts on my 8550 but over time the slip yoke splines did wear. One important thing to note is that the two piece style runs a lot smoother and is less apt to affect the pto drop box bearings. I have the parts list somewhere if anyone is interested. , Mike

|

|

darrel in ND

Orange Level

Joined: 22 Nov 2009

Location: Hebron, ND

Points: 8755

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Jun 2017 at 7:29am Posted: 05 Jun 2017 at 7:29am |

|

I remember, years ago, helping a guy put the hanger bearing in on his 8550. I guess I didn't realize that when changing to a hanger bearing, you no longer use CV joints. Both my 8550, and 7580 still have CV joints. Guess in my mind, I'd have thought that CV joints would have been a better option. From what I'm hearing here, the hanger bearing with no CV joint is better? Right now, we are pulling the air seeder with the 8550, thus taxing the hydraulic pump pretty heavily, which in turn puts a steady load on the shaft going through the hinge, and we grease the drivelines daily, or else they start to chatter when turning. Wonder if changing over would be a good option for me. Darrel

|

|

GM Guy

Orange Level

Joined: 31 Jul 2012

Location: NW KS / S.C. ID

Points: 1988

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jun 2017 at 9:47am Posted: 06 Jun 2017 at 9:47am |

|

Mike Kroupa, so was this an Allis Campaign, or a home brew solution?

So does anyone know if the drivelines will come out without having the tractor articulated one way or the other?

|

|

Gleaner: the properly engineered and built combine.

If you need parts for your Gleaner, we are parting out A's through L2's, so we may be able to help.

|

|

JohnCO

Orange Level

Joined: 11 Sep 2009

Location: Niwot Colo

Points: 8992

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jun 2017 at 10:09am Posted: 06 Jun 2017 at 10:09am |

|

I hate to give advice when I'm not 100% sure but I seem to remember mine was straight when we installed the shafts. It might be easier if the machine is slightly turned, just to make working on it a bit easier. Personally, I think the drive line system is NOT one of AC's better ideas...

|

|

"If at first you don't succeed, get a bigger hammer"

Allis Express participant

|

|

Mike Kroupa

Silver Level

Joined: 02 Oct 2009

Location: pierce, ne

Points: 338

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jun 2017 at 8:44pm Posted: 06 Jun 2017 at 8:44pm |

|

They were advertised in the back pages of farm magazines. A-C did not design or promote it. When the 4W series came out, someone made their own version of that design. At the time parts for the driveline from A-C were very high and I suspect this also drove the need for a new design, with off the self components. The thing to remember though is on the 4W series the pto driveline turns considerably slower than the 75/85 series tractors. You will still get some vibration during full left or right turns but pulling "straight" the shaft runs true and no vibration. I have the handwritten parts list that I used to fabricate mine. I will try to post it sometime. , Mike

|

|

CAL(KS)

Orange Level

Joined: 18 Sep 2009

Location: Chapman, KS

Points: 3804

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Jun 2017 at 7:45am Posted: 07 Jun 2017 at 7:45am |

|

the splined sections of shaft and tube can be cut off and replaced by a truck or driveline shop much cheaper with common truck shaft than the oe splined sections. we are running the cv joints and replaced splines on our tractors. the 7580 had that carrier bearing driveline on the bottom and we replaced it with an original style when it went bad.

|

|

Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20

Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15

|

|

darrel in ND

Orange Level

Joined: 22 Nov 2009

Location: Hebron, ND

Points: 8755

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Jun 2017 at 12:40pm Posted: 07 Jun 2017 at 12:40pm |

darrel in ND wrote: darrel in ND wrote:

I remember, years ago, helping a guy put the hanger bearing in on his 8550. I guess I didn't realize that when changing to a hanger bearing, you no longer use CV joints. Both my 8550, and 7580 still have CV joints. Guess in my mind, I'd have thought that CV joints would have been a better option. From what I'm hearing here, the hanger bearing with no CV joint is better? Right now, we are pulling the air seeder with the 8550, thus taxing the hydraulic pump pretty heavily, which in turn puts a steady load on the shaft going through the hinge, and we grease the drivelines daily, or else they start to chatter when turning. Wonder if changing over would be a good option for me. Darrel |

Yesterday, I talked to the guy that I helped put the hanger bearing drive line into his 8550. He said he went away from the CV joint and to the hanger bearing type 100 per cent due to economics. The CV had gone out, and it was cheaper to put in the hanger bearing type driveline. He said it did not make an improvement, and if anything, chattered a little worse when turning. With that, I guess I am going to continue to grease the drivelines on mine very faithfully, and hope that they last. Darrel

|

|

CAL(KS)

Orange Level

Joined: 18 Sep 2009

Location: Chapman, KS

Points: 3804

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Jun 2017 at 2:22pm Posted: 07 Jun 2017 at 2:22pm |

|

whats silly is you can buy a new cv joint for less money than getting an old one rebuilt

|

|

Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20

Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15

|

|

SLee(IA)

Silver Level

Joined: 11 Sep 2009

Location: Polk City, Iowa

Points: 271

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Jun 2017 at 12:10am Posted: 08 Jun 2017 at 12:10am |

Here is the parts list from Mike Kroupa. Steve http://s290.photobucket.com/user/S53L/media/IMG_9048_zps52notxj6.jpg.html]  [/URL] http://s290.photobucket.com/user/S53L/media/IMG_9049_zpsefrttgir.jpg.html]  [/URL] http://s290.photobucket.com/user/S53L/media/IMG_9050_zpsbqswfhxr.jpg.html]  [/URL] http://s290.photobucket.com/user/S53L/media/IMG_9051_zpsfgyu1fq8.jpg.html]  [/URL] |

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

darrel in ND wrote:

darrel in ND wrote: [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL]