| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Tenn allis

Bronze Level

Joined: 24 Nov 2016

Location: Tennessee

Points: 149

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Question on D17 Topic: Question on D17

Posted: 13 Mar 2023 at 9:14am |

|

A friend called me was wanting to add double remotes to a early series D17 with a single remote can someone tell us what we need to do and if this is doable

The tractor has a flywheel on the torque housing also. I haven’t been around a D series since I was a tiny fella in the early ‘70s

|

|

|

Sponsored Links

|

|

|

Allis dave

Orange Level

Joined: 10 May 2012

Location: Northern IN

Points: 3086

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Mar 2023 at 10:59am Posted: 13 Mar 2023 at 10:59am |

If I understand, you want to use your D17 on a 2-way cylinder correct?

Im in the middle of this same project myself

Edited by Allis dave - 13 Mar 2023 at 11:00am

|

|

Tenn allis

Bronze Level

Joined: 24 Nov 2016

Location: Tennessee

Points: 149

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Mar 2023 at 11:15am Posted: 13 Mar 2023 at 11:15am |

|

Yes that is correct

|

|

Allis dave

Orange Level

Joined: 10 May 2012

Location: Northern IN

Points: 3086

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Mar 2023 at 12:21pm Posted: 13 Mar 2023 at 12:21pm |

|

I can send you a picture when I'm done.

If the D17 has a transport valve you're almost there. The transport valve has a pressure and return line.

Get yourself a 2-way hydraulic valce wiht about 2000PSI relief. Feed it from the standard remote. Put a T into the return line and plump that into the valve return.

A D17 has a high pressure (3000PSI+) low volume system. So this setup will get you 2 way hydraulics, buy they will be much slower than a standard low pressure high volume tractor.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89179

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Mar 2023 at 12:39pm Posted: 13 Mar 2023 at 12:39pm |

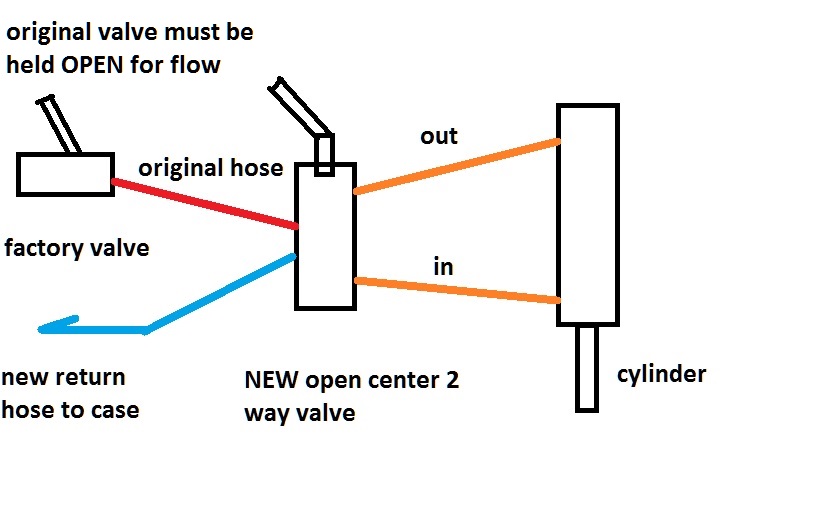

your NEW hydraulic valve should be OPEN CENTER so that the pump can recirc back to the tank ( case ) when not feeding the cylinder UP or DOWN...

Dave, i assume you put your FACTORY valve held OPEN position and feed constant flow to your NEW valve, and use it only ? something like this ?

Edited by steve(ill) - 13 Mar 2023 at 12:47pm

|

|

Like them all, but love the "B"s.

|

|

Tenn allis

Bronze Level

Joined: 24 Nov 2016

Location: Tennessee

Points: 149

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Mar 2023 at 3:34pm Posted: 13 Mar 2023 at 3:34pm |

|

Thanks for the info

|

|

Allis dave

Orange Level

Joined: 10 May 2012

Location: Northern IN

Points: 3086

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Mar 2023 at 12:35pm Posted: 14 Mar 2023 at 12:35pm |

Thats how I have it Steve. The hydraulic lever on the quadrant would need to be up all the time to keep supplying oil to the new valve. My "New valve" is actually an original Allis valve off an old d17 wiht this option. My setup will be like original, but an aftermarket open center center valve would be the same.

|

|

Allis dave

Orange Level

Joined: 10 May 2012

Location: Northern IN

Points: 3086

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Mar 2023 at 8:54am Posted: 28 Mar 2023 at 8:54am |

Picture of my valve installed as promised. Original Allis valve and bracket. Thanks to Lonn for the valve and Orange Knight for the bracket, transport valve, and return line!

Edited by Allis dave - 28 Mar 2023 at 8:56am

|

|

Clay

Orange Level

Joined: 11 Sep 2009

Location: Udall, Kansas

Points: 10143

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Mar 2023 at 10:02am Posted: 28 Mar 2023 at 10:02am |

Not sure I would hose clamps for that much pressure.

OOPSY, that line is the return line. Me bad.

Edited by Clay - 28 Mar 2023 at 5:03pm

|

|

Alvin M

Orange Level

Joined: 24 Jun 2018

Location: PA

Points: 815

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Mar 2023 at 10:45am Posted: 28 Mar 2023 at 10:45am |

|

That is the return

|

|

Tenn allis

Bronze Level

Joined: 24 Nov 2016

Location: Tennessee

Points: 149

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Mar 2023 at 10:46am Posted: 28 Mar 2023 at 10:46am |

|

Is the clamps I’m sure on the nonpressured return line

|

|

Lon(MN)

Orange Level

Joined: 11 Sep 2009

Location: Merrill Wi

Points: 2043

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Mar 2023 at 11:42am Posted: 28 Mar 2023 at 11:42am |

|

I have the factory set up but there is still pressure on the booster gauge. I checked the lines for damage and checked the valve to insure it is open center. I would think there should be no pressure when the valve is centered. Is this normal to have pressure? It has a transport valve.

|

|

http://lonsallischalmers.com

|

|

DSeries4

Orange Level

Joined: 12 Sep 2009

Location: Ontario, Canada

Points: 7570

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Mar 2023 at 3:51pm Posted: 28 Mar 2023 at 3:51pm |

There is a fair amount of work to do and at the end of the day the low volume system means your cylinders will move very slowly. You will also not have any hydraulics when you have your foot on the clutch.

|

|

'49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080

|

|

Allis dave

Orange Level

Joined: 10 May 2012

Location: Northern IN

Points: 3086

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Mar 2023 at 6:36pm Posted: 28 Mar 2023 at 6:36pm |

I just finished the plumbing this weekend. My disc is in the middle of what looks like a pond so I haven't actually tried it on a cylinder. I'll have to look at the Traction boost gauge when I start it next time. I put a gauge on both remotes and only got 900PSI. I wanted 1500 so I'll have to pull the valve apart some time, but it'll work for now. Mostly I wanted it to hook to our tandom rake hitch. Hydraulics just swing the hitch soo 900 should be fine for that. I has having trouble trying to figure out a return line. It was too close to make a hydraulic line and I didn't want to mess with trying to bend a 3/8 or 1/2 steel tube only 5" long. So i finally decided some fuel line with hose clamps might work easy enough.

Replaced the worn seat bushings and spring to while I was working on it. I don't bottom out now on every bump! Sure rides nice.

Edited by Allis dave - 28 Mar 2023 at 6:37pm

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)