| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Warren(Oh)

Orange Level

Joined: 11 Sep 2009

Location: Jackson, Ohio

Points: 1127

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Finally got my planters mounted Topic: Finally got my planters mounted

Posted: 17 Mar 2012 at 5:30pm |

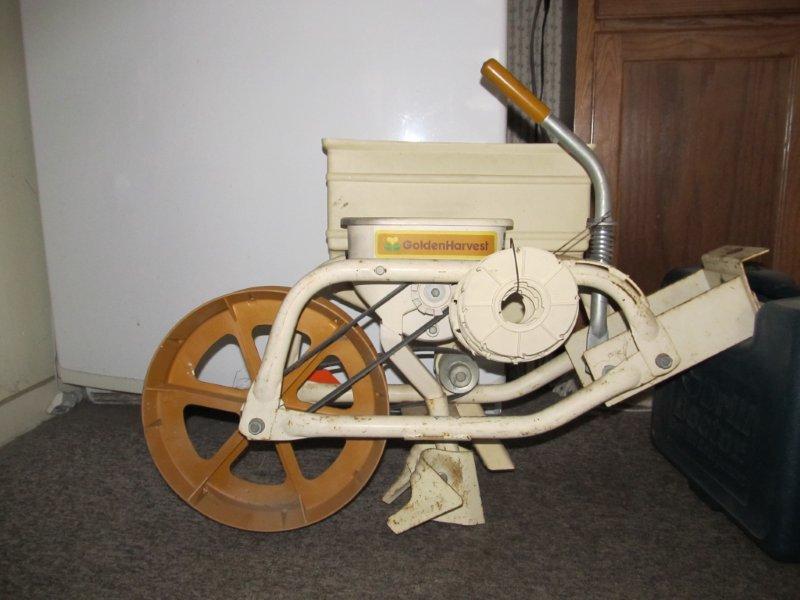

I bought these Jang Automation seeders from Columbus Irrigation Compant in Ashland, Ohio. Got to see one first at the Farm Science Review last summer and ordered these two a couple days later.This is the JP-1 model, here is their website. http://www.mechanicaltransplanter.com/seeder.html

Edited by Warren(Oh) - 07 Nov 2012 at 3:03am

|

|

|

Sponsored Links

|

|

|

Warren(Oh)

Orange Level

Joined: 11 Sep 2009

Location: Jackson, Ohio

Points: 1127

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Mar 2012 at 5:31pm Posted: 17 Mar 2012 at 5:31pm |

|

|

|

Redpower1456

Silver Level

Joined: 15 Mar 2010

Location: Central Texas

Points: 179

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Mar 2012 at 6:25pm Posted: 17 Mar 2012 at 6:25pm |

|

Interesting to see. Thanks for the pics and the link.

It looks as though your rig is sitting up on a porch of a house? Why is that? Is it in town? But still, why up on a porch???

Edited by Redpower1456 - 17 Mar 2012 at 6:28pm

|

|

D17 owner

Orange Level

Joined: 03 Jul 2010

Location: ladysmith Wi

Points: 225

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Mar 2012 at 7:25pm Posted: 17 Mar 2012 at 7:25pm |

|

Well it is nice and dry on the porch.

|

|

Warren(Oh)

Orange Level

Joined: 11 Sep 2009

Location: Jackson, Ohio

Points: 1127

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Mar 2012 at 7:37pm Posted: 17 Mar 2012 at 7:37pm |

HAHA, yeah, you must not have been on the forum when I first joined and posted pix of my 'Porch G'. You can find a picture of it while still being restored on Tony Carbaugh's site, here's the link. http://www.tonystractors.com/allis_chalmers.htm Yes, I live on the edge of town, less than .25 acre lot. I take the tractor to my Aunt's farm 6 miles out of town and work it. Cultivating and bush hogging. I have a 4 foot ATV bush hog I pull with it. I can seem to find the picture with the bush hog. Yes, the porch is dry, for the most part.

|

|

Warren(Oh)

Orange Level

Joined: 11 Sep 2009

Location: Jackson, Ohio

Points: 1127

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 May 2012 at 5:58pm Posted: 21 May 2012 at 5:58pm |

Well, got to try out the planters today. They need some work ! I didn't allow for enough float for uneven ground. They also wanted to twist, only being mounted at the rear allows for to much play. Sorghum seed is in the ground, though, so maybe next spring I'll get them working right. Probably put the push handles on to plant corn next weekend.

The G ran really good, though. No knocking now, throttle wide open. Used the hiller discs to make a ridge, got a furrowing plow on the rear tool carrier so taters were planted in the top of the ridge. Discs also covered them well. A month or so I'll hill them again, them we'll mulch between the rows with straw.

Edited by Warren(Oh) - 21 May 2012 at 6:07pm

|

|

DREAM

Orange Level

Joined: 06 Jan 2010

Location: Elberton,GA

Points: 1828

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 May 2012 at 6:21pm Posted: 21 May 2012 at 6:21pm |

|

Looks like you did some nice work mounting them. I wonder if it would help you some to put the mounts closer to the front, since that is where the drive tire is? Seems like that would help some with tracking. Put a little pressure on the drive tire and rig the lift handle to "float" up or down over rough ground. You would have to leave off the lift assist spring(if the G has one, i'm going on B hand lift knowledge.) and find a way to lock the lever latch open, but that might help. Just a thought. Might not work at all. You have a better view of things. Very nice work.

|

|

I didn't do it! It was a short, fat, tall, skinny guy that looked like me!

|

|

tadams(OH)

Orange Level Access

Joined: 17 Sep 2009

Location: Jeromesville, O

Points: 11151

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 May 2012 at 8:28am Posted: 22 May 2012 at 8:28am |

Yes, Dan at Columbus Irrigation is a buddy. Nice looking setup.

Tom

|

|

Orange Blood

Orange Level

Joined: 29 Nov 2010

Location: ColoradoSprings

Points: 4053

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 May 2012 at 10:52am Posted: 22 May 2012 at 10:52am |

|

As I see it, unless you add some cross bracing they will always twist, and that may still not stop it, anytime you push something through the field, it is going to want to twist when it hits a tough spot, even though your tool bar is ahead of the planter unit, it looks like you are mounted to the planter behind nearly the whole thing. If you can, find a place to mount the horizontal bar stock, ahead of the opener, but behind the drive wheel, and I bet you see a huge difference. You will still need cross bracing on the vertical pieces, and maybe even on the horizontal ones. Almost every planter I have seen, uses parallel linkage to keep the unit from twisting, that would allow for good float control as well.

|

|

Still in use:

HD7 WC C CA WD 2-WD45 WD45LP WD45D D14 3-D17 D17LP 2-D19D D19LP 190XTD 190XTLP 720 D21 220 7020 7030 7040 7045 3-7060

Projects: 3-U UC 2-G 2-B 2-C CA 7-WC RC WDLP WF D14 D21 210 7045 N7

|

|

Warren(Oh)

Orange Level

Joined: 11 Sep 2009

Location: Jackson, Ohio

Points: 1127

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 May 2012 at 6:28pm Posted: 22 May 2012 at 6:28pm |

I've got ideas on revamping the mount. Thinking of using a small bicycle front fork, mostly so I don't have to make yet another crooked piece !, to straddle the front drive wheel. A piece of rod or pipe for the fork to travel up and down on, spring pressure to hold it down, thinking shotgun magazine spring. The tool lift would only be used to lift it off the ground. Pipe frame across tractor frame and a T for the down rod or pipe. Still thinking...

Had a request for pictures of the hiller discs and rear furrower. The hillers came from agrisupply, 14" with 16" shank. I also have 12" on 22" shanks but they didn't do what I hoped. http://www.agrisupply.com/disc-hillers/c/4500013/c2c/sc/ They are on the standard cultivator frame. The plow on the rear tool bar looks like it belongs on a Troybilt tiller, I got it at an auction for, I think, $10. Made the mounting bracket, first use of my plasma cutter, still a long way to go before I brag about my abilities with it !

Now if the pictures will load right !

Edited by Warren(Oh) - 22 May 2012 at 6:31pm

|

|

Warren(Oh)

Orange Level

Joined: 11 Sep 2009

Location: Jackson, Ohio

Points: 1127

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 May 2012 at 6:30pm Posted: 22 May 2012 at 6:30pm |

Still only lets me post two pix at a time.

Here's the rear furrower.

Edited by Warren(Oh) - 22 May 2012 at 6:31pm

|

|

Warren(Oh)

Orange Level

Joined: 11 Sep 2009

Location: Jackson, Ohio

Points: 1127

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 May 2012 at 6:43pm Posted: 22 May 2012 at 6:43pm |

Yes, Tom, Dan is a great guy ! I met him at the Farm Science Review after emailing several times.

Orange Blood, go to the link in the original post, scroll to the bottom, look at the JPH-U model. I may have to duplicate this mount !

They also offer disc openers to replace the standard blade. I wonder if they would do any better when there is still grass in the tilled ground? Suggestions?? Anyone?

Oh, that big, open rear wheel ! It's gonna get enclosed somehow ! Dirt clod gets in there, it just drags !

Edited by Warren(Oh) - 22 May 2012 at 6:45pm

|

|

Orange Blood

Orange Level

Joined: 29 Nov 2010

Location: ColoradoSprings

Points: 4053

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 May 2012 at 11:20pm Posted: 22 May 2012 at 11:20pm |

Warren,

That is exactly what I am thinking, if you do duplicate that mount, keep the parallel linkage travel to around 4" max or so, because you won't have enough lift in your toolbar to get the whole unit off the ground when you need to transport.

|

|

Still in use:

HD7 WC C CA WD 2-WD45 WD45LP WD45D D14 3-D17 D17LP 2-D19D D19LP 190XTD 190XTLP 720 D21 220 7020 7030 7040 7045 3-7060

Projects: 3-U UC 2-G 2-B 2-C CA 7-WC RC WDLP WF D14 D21 210 7045 N7

|

|

SHAMELESS

Orange Level

Joined: 13 Sep 2009

Location: EAST NE

Points: 29486

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 May 2012 at 2:02am Posted: 23 May 2012 at 2:02am |

|

wish i could park my tractors on the front porch!!

|

|

Warren(Oh)

Orange Level

Joined: 11 Sep 2009

Location: Jackson, Ohio

Points: 1127

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 May 2012 at 3:23am Posted: 23 May 2012 at 3:23am |

OB, I've got so many ideas running wild through my head, it ain't funny ! That square mount, I'd want to fasten it to a stationary position and only use the tool carrier to lift it for transport. That could give a lot more lift, I'm thinking. Dang, that's a lot of little pieces to make AND have line up !!

Dale, I wish I could park all three of them on the front porch ! Heck, I'd settle for the other two on the back porch but it ain't strong enough.

|

|

tadams(OH)

Orange Level Access

Joined: 17 Sep 2009

Location: Jeromesville, O

Points: 11151

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 May 2012 at 6:37am Posted: 23 May 2012 at 6:37am |

Warren, could you send picture to Dan at Columbus Irrigation. He would like to ee it. I tried to copy and send him but it didn't work.

thanks

Tom

|

|

Jim Lindemood

Orange Level

Joined: 22 Sep 2009

Location: Dry Ridge, KY

Points: 2569

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 May 2012 at 6:45am Posted: 23 May 2012 at 6:45am |

|

Like the planter setup on the G - little more tweaking and it will be just the thing. Hanve to think about that for my G -- good idea.

|

|

Warren(Oh)

Orange Level

Joined: 11 Sep 2009

Location: Jackson, Ohio

Points: 1127

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 May 2012 at 6:02pm Posted: 23 May 2012 at 6:02pm |

Tom, I sent him the link to this page. He should be able to view and save the pictures if he wants.

Now I have a question for everyone. What size chain fits the ground drive sprocket on the G ? I want to put together a side dresser, if at all possible. I have a small fertilizer hopper, maybe some of you saw it on the little planter I got last spring. It mounts on 3/4" conduit and is belt driven. I just need to put a shaft across, sprocket on one end, pulley where ever the hopper ends up mounted and a couple bearings. Simple, huh !? Right...

OK, here it is, again

|

|

mmccarty

Silver Level

Joined: 06 Feb 2012

Location: SW Wisconsin

Points: 86

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 May 2012 at 6:31pm Posted: 24 May 2012 at 6:31pm |

I mounted a Jang seeder on my Allis G today and just ran across this post this evening. I removed the push handle and ran a 3/8" rod through through the lower mounting holes for the handle. I shimmed the seeder between the 3/4" mounting brackets with a stack of washers on each side and welded a strap across the back. The strap keeps the mounting bars parallel and acts as a stop so the front of the seeder doesn't pivot all the way down when the seeder is lifted.

|

|

Warren(Oh)

Orange Level

Joined: 11 Sep 2009

Location: Jackson, Ohio

Points: 1127

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 May 2012 at 6:48pm Posted: 24 May 2012 at 6:48pm |

That's the TD-1 for large seeds, nice simple mount. The JP-1 is made a bit different but that would work for a single unit. I probably ought to have only bought one but,no, I have to be more difficult...

Having uneven ground and hillsides to plant on, I think I need a lot more float/free travel. Let us know how it works.

|

|

mmccarty

Silver Level

Joined: 06 Feb 2012

Location: SW Wisconsin

Points: 86

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 May 2012 at 7:01pm Posted: 24 May 2012 at 7:01pm |

|

Yes, I have the JP-1 also, but I haven't used it yet. I used this one to plant a variety of green and dry beans, peas, sweet corn, and squash. I planted about 2 acres pushing it, but unless the soil is worked up perfectly it tends to a have a mind of its own as to which direction it wants to go. I have another one and a half acres of squash to plant so I figured I'd mount it and hopefully make things a little easier.

|

|

mmccarty

Silver Level

Joined: 06 Feb 2012

Location: SW Wisconsin

Points: 86

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 May 2012 at 7:16pm Posted: 24 May 2012 at 7:16pm |

Warren(Oh) wrote: Warren(Oh) wrote:

Having uneven ground and hillsides to plant on, I think I need a lot more float/free travel. Let us know how it works.

|

Do you need more float between the two units or the toolbar as a whole? I expect the weight of the assembly and the damper springs on the lift to keep it firm against the ground. I lubed everything up so the lift assembly can float easier.

I looked at the toolbar mount model but realized I didn't need the parallelogram mount for the single planter because it's built into the tractor.

|

|

Warren(Oh)

Orange Level

Joined: 11 Sep 2009

Location: Jackson, Ohio

Points: 1127

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 May 2012 at 7:34pm Posted: 24 May 2012 at 7:34pm |

|

Yes, more float between the units. I simply didn't allow enough. The short vertical piece at either side of the front wheel is only 4" long and the corner of the bracket sticks down a good inch, so only 3" of travel each. Many times when one was down working, the other was either in the air or being mashed and dragging the wheel.

|

|

mmccarty

Silver Level

Joined: 06 Feb 2012

Location: SW Wisconsin

Points: 86

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 May 2012 at 6:53pm Posted: 25 May 2012 at 6:53pm |

|

I planted an acre and a half of squash today. It worked fantastic. I widened the tractor's stance as wide as it would go and followed adjacent to my previous wheel tracks to plant in 6' rows. I went rather slowly, in creeper gear at half or three quarters throttle, just a slow walking speed. The double disc opener did its job. It only had trouble with some knotty alfalfa roots that were laying on the surface. Every now and again the opener would start pushing a ball of alfalfa roots and it would stop the drive wheel. It usually only took a pull on the lift handle to clear it. I only got off the tractor a handful of times to clear some nasty roots out of the opener or wheels.

|

|

Warren(Oh)

Orange Level

Joined: 11 Sep 2009

Location: Jackson, Ohio

Points: 1127

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 May 2012 at 7:51pm Posted: 25 May 2012 at 7:51pm |

That's good to hear Mac, glad it worked out. I use the creeper gear for most everything in the garden. I'll be getting the double disc openers before next spring, pricey little things but if they work, it'll be worth it.

Did you have any problems with clods or roots getting in the rear wheel and stopping it ?? I'll be enclosing it, duct tape if nothing else !

|

|

mmccarty

Silver Level

Joined: 06 Feb 2012

Location: SW Wisconsin

Points: 86

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 May 2012 at 8:26pm Posted: 25 May 2012 at 8:26pm |

|

I didn't get any clods in the rear wheel. I got clods in the rear wheel when I was pushing by hand because I was always sliding the rear end side to side trying to straighten it out, running true under the tractor none got in there. It did pick up a few roots between the rear wheel and the frame but it only stopped it once.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

Warren(Oh) wrote:

Warren(Oh) wrote: