| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Ewhitford

Bronze Level

Joined: 29 Apr 2018

Location: Mason MI

Points: 30

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: D17 Topic: D17

Posted: 15 Apr 2020 at 8:18pm |

|

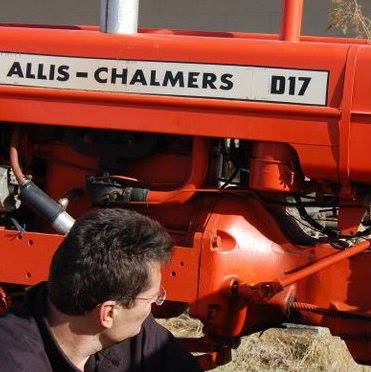

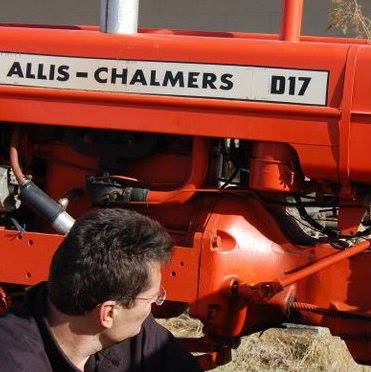

So I am looking at the possibility of purchasing a 1959 D17 or at least I believe it is the serial I was given is 224692. I believe that there might be 1 too many numbers unless I am reading it wrong. Anyway is there any thing good,bad or ugly on these. Comes with a loader,brush hog and a rear scraper blade that is missing 1 tooth. No seat. Dosen't look to be beat up. Looking for something like it for my hobby farm. I think the price might be right at $3,400. But I want to make sure I know what I am looking for when I go to check it out too. Was told it runs and is all operational. The only leak that he knows of is a cylinder leak on the loader.

Any information would be greatly appreciated.

Thank you.

|

|

|

Sponsored Links

|

|

|

DSeries4

Orange Level

Joined: 12 Sep 2009

Location: Ontario, Canada

Points: 7569

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Apr 2020 at 9:16pm Posted: 15 Apr 2020 at 9:16pm |

Yes, you do have one too many digits in your serial number.

D17s were one of the best tractors AC made. Highly respected by most people. Transmission jumping out of gear might be a very expensive repair is previous users ground the gears when shifting. Not much else. But remember that this tractor is over 60 years old. How it was used and how it was maintained will dictate how it works for you. They do not have live hydraulics, so they will not work with your foot on the clutch and they use a high pressure/low volume system rather than the standard high volume/low pressure system that modern tractors use.

|

|

'49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080

|

|

Gatz in NE

Orange Level

Joined: 11 Sep 2009

Location: Lincoln, NE

Points: 1062

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Apr 2020 at 10:05pm Posted: 15 Apr 2020 at 10:05pm |

It probably is one made in late 1959

take a look at the chart on the bottom of this page;

|

|

Brian G. NY

Orange Level

Joined: 12 Sep 2009

Location: 12194

Points: 2271

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2020 at 8:48am Posted: 16 Apr 2020 at 8:48am |

Whether the number is 22469 or 24692, it is likely to have the high pressure engine oil system which was a great improvement in these tractors. I believe the actual change took place in 1959 at "ENGINE" Ser. #19978 and is easily recognizable by the common F-1A Ford style oil filter used on these tractors. With a loader, you will appreciate the power steering if it is so equipped.

|

|

Ewhitford

Bronze Level

Joined: 29 Apr 2018

Location: Mason MI

Points: 30

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2020 at 9:34am Posted: 16 Apr 2020 at 9:34am |

Thank you for the answers. So if a deal can be had it should work out fine and dandy especially if the gearing moves nice and smooth . It looks as if it has a hydraulic pump in the front of the tractor how are those any issues.

Edited by Ewhitford - 16 Apr 2020 at 9:46am

|

|

Ewhitford

Bronze Level

Joined: 29 Apr 2018

Location: Mason MI

Points: 30

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2020 at 9:47am Posted: 16 Apr 2020 at 9:47am |

|

|

|

Ewhitford

Bronze Level

Joined: 29 Apr 2018

Location: Mason MI

Points: 30

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2020 at 9:49am Posted: 16 Apr 2020 at 9:49am |

|

|

|

Ewhitford

Bronze Level

Joined: 29 Apr 2018

Location: Mason MI

Points: 30

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2020 at 9:50am Posted: 16 Apr 2020 at 9:50am |

|

|

|

John (MO)

Orange Level

Joined: 16 Sep 2009

Location: NEMO

Points: 202

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2020 at 9:50am Posted: 16 Apr 2020 at 9:50am |

|

Almost 60 year old tractor, most likely it's gone thru many owners. I would count on every system needing work. It was a great tractor when new, and would be again if properly rebuilt. Cost to fix could be far more than purchase price. Might work with little work, but 60 years of use will have taken major toll on it. Good compression check will tell much about engine. Good test drive will tell much about transmission. Both will be costly to repair if repair is necessary. Check tractor carefully and buy cautiously. I'd strongly recommend inspection my someone very familiar with this vintage of AC tractors. You could easily be buying a money pit. Great tractor if it proves to be in good condition, but it will never be worth much more that the current asking price.

|

|

Ewhitford

Bronze Level

Joined: 29 Apr 2018

Location: Mason MI

Points: 30

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2020 at 9:51am Posted: 16 Apr 2020 at 9:51am |

Thats the one I am looking at

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22307

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2020 at 10:01am Posted: 16 Apr 2020 at 10:01am |

|

It's a good combination of a rugged tractor and rugged loader. It is old. Be sure to operate it for at least 30 minutes and wide open throttle as much a possible. Any blue smoke coming from the exhaust pipe means it is an oil burner.....beware.

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8625

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2020 at 10:12am Posted: 16 Apr 2020 at 10:12am |

Wishing you luck on your D17 purchase. As others have mentioned they can be good to poor condition? If you do get a chance to run it for a while that would tell you some things about how it operates too. When I bought mine, at a auction, I had time to check it out not running and then it was only started for about 10 seconds and shut down. I took a chance. Mine turned out good. I have gotten other tractors that were not very good at all. Tires are sometimes worth as much as the tractor. Those rears look good! Loader would be handy too. Let us know how you make out. Regards, Chris

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

AC7060IL

Orange Level

Joined: 19 Aug 2012

Location: central IL

Points: 3603

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2020 at 10:18am Posted: 16 Apr 2020 at 10:18am |

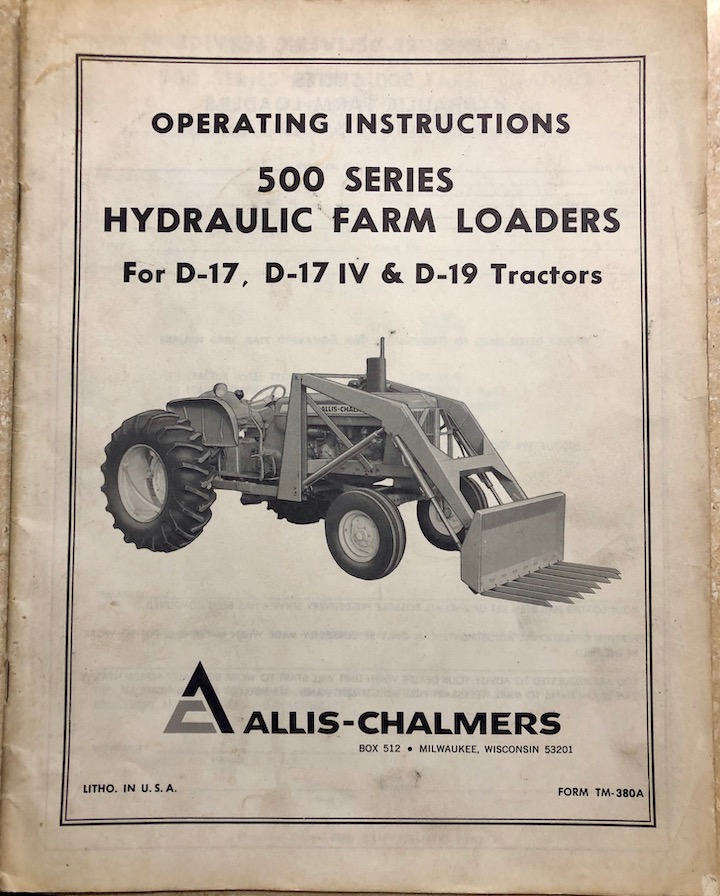

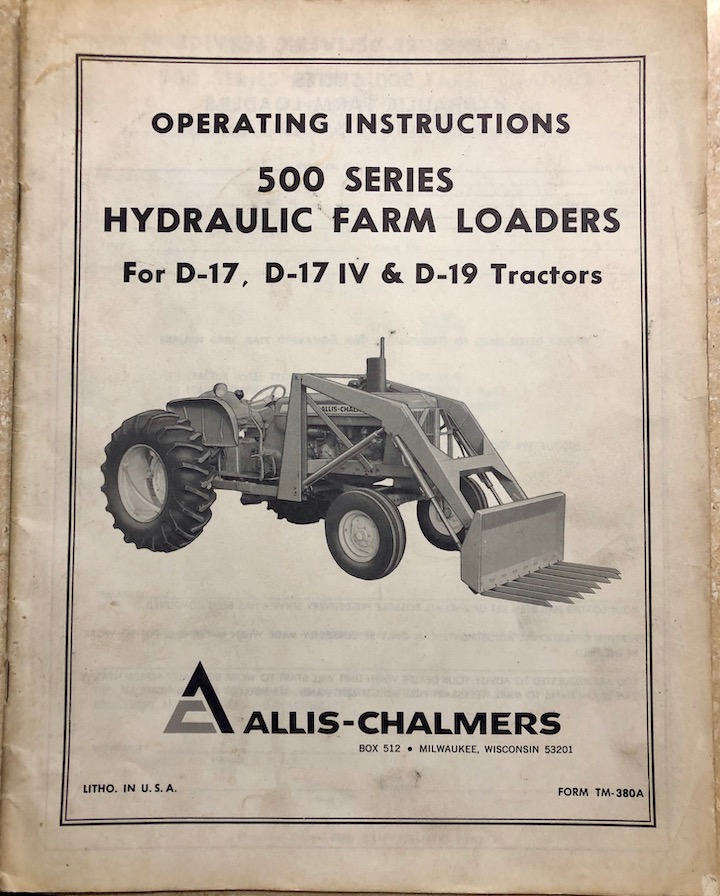

It looks like an AC 500 loader mounted on an early AC D17. That model loader could be outfitted for D17s, D17IVs, & D19s. For the early D17s, it was furnished with an optional separate hydraulic system(front hydraulic pump, oil reservoir inside left vertical frame, vavle bodies, & rear extended hydraulic valve levers. You can see these items in the later photos. The loader also was offered with maure buckets in 42", 60", & 72" sizes. Material buckets offered in 42" (10.75cu.ft) and 60" (17.5cu.ft) capacities. A light material bucket of 80" (23.65cu.ft) capacity. The dozer blade(heavy duty) is 80" width. Loader's pump capacity was 11gpm @1650rpms(D17 tractor's full throttle). Loader's front pump has 2000 psi max. Loader's oil screen is located in bottom of it's frame reservoir. Unless dealership installed an additional inline hydraulic filter, this screen is the system's only filter. For D17 model prior serial number 15931, the front mounted hydraulic pump is coupled by a chain coupler to an auxiliary pump drive shaft that splines into a 4 bolt hub that bolts to front of engine crankshaft pulley no. 230966. A pump guard covered to protect pump. Loader lift capacity: 2300lbs full lift, 3400lbs carrying @3' height, 4000lbs breakaway force.

For reference when you demo it, the loader cycle times are as follows: Cycle time up: 5.0 seconds, Cycle time down: 2.4 seconds To check loader oil level, raise loader to max height, then lower loader so its sets flat. Remove sump oil cap and add oil if required so oil level is at mark on dipstick in sump cap. Use SAE 10 oil, non foaming, high viscosity index, and high oxidation resistance.

Since its a loader tractor, it's rear tires are probably fluid filled for ballast. So check it's rear rims for rust, especially around valve stems. Best of luck. Good loader rig, if maintained & not abused.

Edited by AC7060IL - 16 Apr 2020 at 10:41am

|

|

Gary

Orange Level Access

Joined: 13 Sep 2009

Location: Peterborough,On

Points: 5909

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2020 at 11:36am Posted: 16 Apr 2020 at 11:36am |

|

That would be a 400 Series Loader since the Hyd. Oil Reservoir is in the L/H Frame.

You can see the Fill / Breather Spout and the 2 Hyd. Cylinder Control Levers.

Also the Front Mounted Pump and Pump Guard.

The 500 Series Loader was used on D-17 Series IV with Live Hydraulic.

Gary

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22307

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2020 at 11:59am Posted: 16 Apr 2020 at 11:59am |

|

I would say it is a 500 loader by how tall the towers are over the top of the hood.

Edited by DrAllis - 16 Apr 2020 at 11:59am

|

|

Brian G. NY

Orange Level

Joined: 12 Sep 2009

Location: 12194

Points: 2271

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2020 at 4:02pm Posted: 16 Apr 2020 at 4:02pm |

According to the manual I have, the frame is the same for both 400 and 500 series loaders.

I take that back........they do have different part numbers!

Edited by Brian G. NY - 16 Apr 2020 at 4:21pm

|

|

Gatz in NE

Orange Level

Joined: 11 Sep 2009

Location: Lincoln, NE

Points: 1062

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2020 at 4:16pm Posted: 16 Apr 2020 at 4:16pm |

400 loader on a 5040

On this loader, the oil reservoir/tank is on the right-hand column; black fill cap visible.

Maybe the difference from the 500 is in the Lift Arm length and corresponding Lift Cylinders & Bucket Cylinders length

Edited by Gatz in NE - 16 Apr 2020 at 4:17pm

|

|

Scott B

Orange Level

Joined: 14 Sep 2013

Location: Kansas City

Points: 1051

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2020 at 4:32pm Posted: 16 Apr 2020 at 4:32pm |

|

I've got a Series 1 D17 and enjoy it. I've had two major repairs: 1) Clutch issue required splitting the tractor and 2) the 3 pt lift seals are internal and will leak internally. Had to have the rear end part removed and the leak fixed. Check your hydro fluid levels by the seat and up in the middle by your hydros. Mine will sometimes jump out of gear when it's cold outside and until it warms up. Otherwise, great tractor.

|

|

D17 Series 1

Allis B- 1939

Allis B- 1945

|

|

AC7060IL

Orange Level

Joined: 19 Aug 2012

Location: central IL

Points: 3603

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Apr 2020 at 10:55am Posted: 17 Apr 2020 at 10:55am |

AC 400 loader - maybe? Ewitford, the previous AC 500 loader specs that I shared came directly from my genuine Allis-Chalmers 500 loader Operating Instructions book shown in the photo below. My AC 500 loader is mounted on an early AC One-Seventy. It's 500 loader completely shares the One-Seventy's hydraulic system, much like described in this book for the D17IV. So, it does not have the auxiliary front pump like the D17/loader that you're considering. My 500's lift cylinders leaked & a seal kits could not completely fix it's bent rams. Also some of it's pivot pin bushings wore too thin, probably not greased regularly. They are housed inside a casting that is welded into the ends of the loader arm rectangular tubes. A close inspection should offer insights of it's previous maintenance.

Norm's book says the 400/500 loaders were introduced in 1963. The 400 fit the One-Sixty,5040,5050,& 5045. The 500 fit the D17III, D19(with auxiliary pump), D17IV, and all hundred series from One-Seventy thru 200. But who's to say - things could get swapped?  |

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22307

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Apr 2020 at 11:16am Posted: 17 Apr 2020 at 11:16am |

|

But, a 400 loader on a D-17 has the crossbar just a couple of inches above the hood. The 500 like in your picture (and on the tractor/loader in question) is 6 inches above the hood.

|

|

Bob J (Wi)

Bronze Level

Joined: 12 May 2010

Location: Wisconsin

Points: 80

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Apr 2020 at 11:29am Posted: 17 Apr 2020 at 11:29am |

Here is my 200 with a loader. My retired AC dealer said it was a 500 loader.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22307

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Apr 2020 at 12:09pm Posted: 17 Apr 2020 at 12:09pm |

|

And he would be correct. A 400 loader doesn't fit D-19's, 180-185-190-200's.

|

|

Clay

Orange Level

Joined: 11 Sep 2009

Location: Udall, Kansas

Points: 10137

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Apr 2020 at 12:29pm Posted: 17 Apr 2020 at 12:29pm |

Our 1962 D-17 has a 500 loader. The local AC dealer put it on our D-17 in 1970. I know because I was there and have the paper work.

|

|

only AC orange

Orange Level Access

Joined: 06 Dec 2014

Location: Eastern Indiana

Points: 573

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Apr 2020 at 12:36pm Posted: 17 Apr 2020 at 12:36pm |

|

By all means, take D-17 for a test drive and check to see if it jumps out of any of the gears! In each of the 4 gears (high range), rev. tractor to full throttle, shove throttle to idle position (no braking) and see if it stays in that gear - best to do this on a downhill slope. With this being a loader tractor, it could be a prime suspect for gear jumping!

|

|

john(MI)

Orange Level

Joined: 12 Sep 2009

Location: SE MI

Points: 9262

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Apr 2020 at 1:36pm Posted: 17 Apr 2020 at 1:36pm |

|

It has a Saginaw three point adapter. Great stabilizer setup on it. Check around the valve stems on the rear rims for corrosion.

|

|

D14, D17, 5020, 612H, CASE 446

|

|

AC7060IL

Orange Level

Joined: 19 Aug 2012

Location: central IL

Points: 3603

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Apr 2020 at 4:12pm Posted: 17 Apr 2020 at 4:12pm |

DrAllis wrote: DrAllis wrote:

But, a 400 loader on a D-17 has the crossbar just a couple of inches above the hood. The 500 like in your picture (and on the tractor/loader in question) is 6 inches above the hood. |

I totally agree and appreciate your additional insights about them. Gary Yesterday’s reply seemed adamant about it being a 400. I’ve never owned a 400, so I have little to no comparisons to offer. That said, I Looked deeper into my AC literatures to help me understand any differences. What I learned was interesting & just wanted to share.

|

|

DaveKamp

Orange Level Access

Joined: 12 Apr 2010

Location: LeClaire, Ia

Points: 6108

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Apr 2020 at 10:35pm Posted: 17 Apr 2020 at 10:35pm |

I love my early D17. When I was a kid, my Grandfather taught me to drive on his D17... I raked and baled hay with it every summer. I acquired mine like you found yours... unknown history. I made my 3-point kit, and it's getting a loader with a front pump. I converted mine to 12v negative ground alternator, fitted it with LED lights, bought a new set of front tires and mounted some 18.4x26 combine tires/wheels to it. I've done a little work to seal up the exhaust manifold, rebuilt the carb, and replaced the original mechanical ignition points with a PerTronix electronic kit... but it still has the original seat.

Easy to work on, and regardless, you will NOT be able to find as capable a machine NEW for anywhere remotely close to what you could buy and maintain THIS one for.

If you can read and turn wrenches, it'll be just fine.

|

|

Ten Amendments, Ten Commandments, and one Golden Rule solve most every problem. Citrus hand-cleaner with Pumice does the rest.

|

|

Gary

Orange Level Access

Joined: 13 Sep 2009

Location: Peterborough,On

Points: 5909

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Apr 2020 at 4:26pm Posted: 18 Apr 2020 at 4:26pm |

|

Clay

Just curious. Where is the Hydraulic Oil Reservoir on your 500 Loader on your 1962 D-17?

|

|

Clay

Orange Level

Joined: 11 Sep 2009

Location: Udall, Kansas

Points: 10137

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Apr 2020 at 6:47pm Posted: 18 Apr 2020 at 6:47pm |

|

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

DrAllis wrote:

DrAllis wrote: