| Author |

Topic Search Topic Search  Topic Options Topic Options

|

tramiot

Bronze Level

Joined: 03 Jun 2016

Location: Crookston, MN

Points: 8

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: D17 Series IV Hydraulics and Loader Topic: D17 Series IV Hydraulics and Loader

Posted: 06 Feb 2018 at 2:50pm |

I have recently learned that there is a loader that is compatible with my '67 D17 Series IV. My question was how the hydraulics were controlled as my tractor only has two levers on the control bank (1 for hydraulics and 1 for 3pt). Some people have posted that their 17's came with 3 levers (2 hyd. and 1 3pt). Does anyone know if the "factory" second hydraulic lever and associated hoses, etc. are available for purchase or will I need to modify the hydraulic system by tapping into the existing single control and adding the joystick control that could operate both the loader arms and bucket? I would also appreciate any pictures of both setups (factory with the 2 hyd. controls and adding in the joystick).

The compatible loader I was referencing was a 417. As a second topic, does anyone know what other model loaders are compatible with my tractor?

Thanks! |

|

1938 Model B (Grandpa's first new tractor)

1967 Model D17 Series IV (Grandpa's last new tractor)

|

|

|

Sponsored Links

|

|

|

DSeries4

Orange Level

Joined: 12 Sep 2009

Location: Ontario, Canada

Points: 7564

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Feb 2018 at 4:49pm Posted: 06 Feb 2018 at 4:49pm |

|

Probably cannot get them new, but some people here would be able to get the second hydraulic controls for you. Both of my Series IVs have the second control and piping, but they are capped off. If I needed to use them, I would just have to screw on a couple of remote ends.

|

|

'49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080

|

|

Stan R

Orange Level Access

Joined: 03 Dec 2009

Location: MA

Points: 996

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Feb 2018 at 5:03pm Posted: 06 Feb 2018 at 5:03pm |

|

We have a d17 IV and tapped into the hydraulics and have a separate remote for the bucket (up/ down pressure & bucket tilt). Tractor remotes work work as-is.

|

|

MACK

Orange Level

Joined: 17 Nov 2009

Points: 7664

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Feb 2018 at 9:46pm Posted: 06 Feb 2018 at 9:46pm |

|

Go to salvage yard and buy another remote valve and linkage. Valve is same on series 4-D17-170-175-180-185-190-190xt-200-210-220 and 7000, but don't get one from a 7000.

I have some from 190 I would sell you. MACK

|

|

victoryallis

Orange Level

Joined: 15 Apr 2010

Location: Ludington mi

Points: 2879

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Feb 2018 at 5:39am Posted: 07 Feb 2018 at 5:39am |

|

Buy a hydraulic multiplier. Just plugs into your remote and wire it up.

|

|

8030 and 8050MFWD, 7580, 3 6080's, 160, 7060, 175, heirloom D17, Deere 8760

|

|

tramiot

Bronze Level

Joined: 03 Jun 2016

Location: Crookston, MN

Points: 8

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Feb 2018 at 8:46am Posted: 07 Feb 2018 at 8:46am |

|

DSeries4, do you happen to have any photos of how the hydraulic lines are tied into the pump, and also of the control panel?

Edited by tramiot - 07 Feb 2018 at 8:47am

|

|

1938 Model B (Grandpa's first new tractor)

1967 Model D17 Series IV (Grandpa's last new tractor)

|

|

tramiot

Bronze Level

Joined: 03 Jun 2016

Location: Crookston, MN

Points: 8

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Feb 2018 at 8:48am Posted: 07 Feb 2018 at 8:48am |

|

MACK, do you also have photos? I will also try to contact you seperate from the forms to discuss prices if you are indeed willing to sell.

|

|

1938 Model B (Grandpa's first new tractor)

1967 Model D17 Series IV (Grandpa's last new tractor)

|

|

Roger (NE)

Bronze Level

Joined: 14 Oct 2010

Location: Nebraska

Points: 186

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Feb 2018 at 10:58am Posted: 07 Feb 2018 at 10:58am |

|

If you remove the seat and the cover over the lines you should be able to see capped ports where the lines would connect. Our Series IV came new with all the valves...all we had to do was add couplers as wanted/needed. Shouldn't be much of a problem to get what you require from a salvage tractor and observe how it comes off in order to install it on yours.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22285

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Feb 2018 at 12:09pm Posted: 07 Feb 2018 at 12:09pm |

|

But, he doesn't have three levers in the console...only two levers. He needs an additional remote valve section.

|

|

Joe(TX)

Orange Level

Joined: 11 Sep 2009

Location: Weatherford. TX

Points: 1682

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Feb 2018 at 12:28pm Posted: 07 Feb 2018 at 12:28pm |

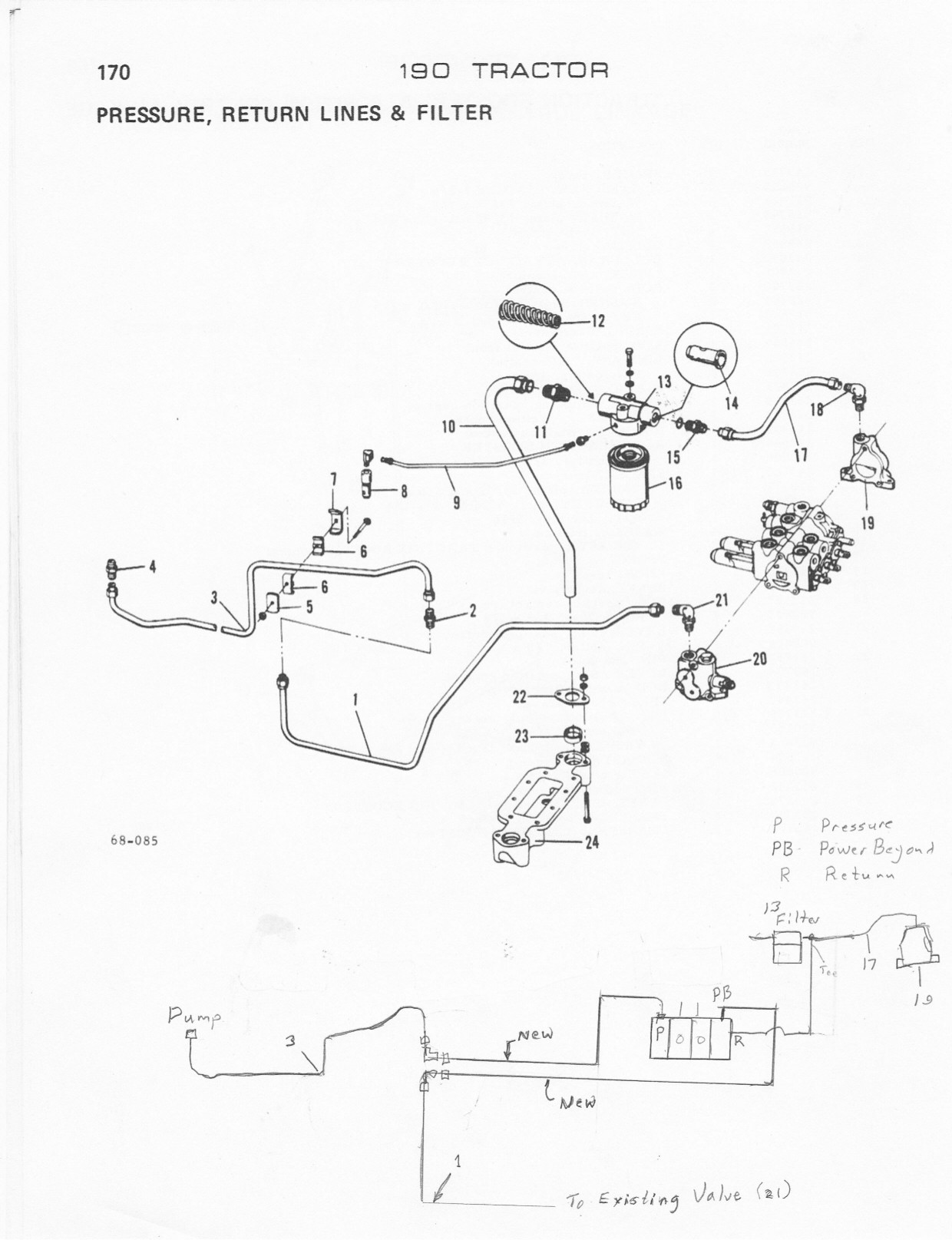

To add a separate joystick for the loader is not difficult. You need a power beyond joystick valve. The main pump output would be redirected to the new valve. The power beyond from this valve goes to the existing valve input (where you disconnected it). There would be a return from the joystick valve to the sump. There have been numerous post here on the subject. Posts about 170, 180, 190 etc. Here is a diagram for a 190.

|

|

1970 190XT, 1973 200, 1962 D-19 Diesel, 1979 7010, 1957 WD45, 1950 WD, 1961 D17, Speed Patrol, D14, All crop 66 big bin, 180 diesel, 1970 170 diesel, FP80 forklift. Gleaner A

|

|

Roger (NE)

Bronze Level

Joined: 14 Oct 2010

Location: Nebraska

Points: 186

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Feb 2018 at 1:31pm Posted: 07 Feb 2018 at 1:31pm |

|

Guess I didn't think it should be that difficult to add another remote valve and have the original factory style double outlets setup using parts from a salvage tractor. On many other brands you have the capability to add valve banks as needed but maybe not on AC. Our Series IV is one of the last one's and like stated above it came with double remotes installed from the factory new in 1967.

|

|

DSeries4

Orange Level

Joined: 12 Sep 2009

Location: Ontario, Canada

Points: 7564

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Feb 2018 at 9:22pm Posted: 07 Feb 2018 at 9:22pm |

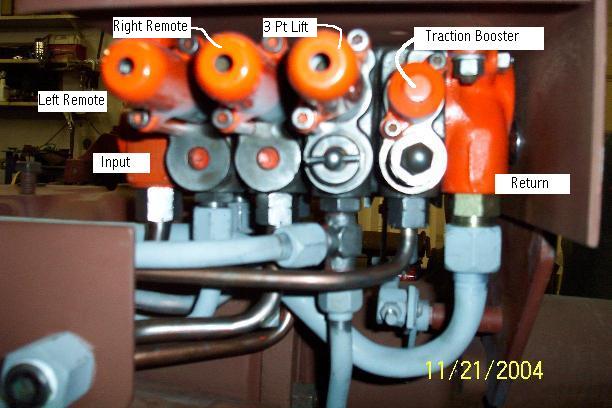

|

|

|

'49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080

|

|

tramiot

Bronze Level

Joined: 03 Jun 2016

Location: Crookston, MN

Points: 8

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Feb 2018 at 8:19am Posted: 08 Feb 2018 at 8:19am |

Roger, I agree! After thinking about it, I would prefer to have a "factory" looking second hydraulic control as compared to the joystick aftermarket option.

DSeries4, thanks for the pics. This is what I would like my final setup to be where the two inside levers are for hydraulics and the outside lever is for the three point. Can you, or anyone else, confirm that there is no additional piping to the hydraulic pump for this setup? My current understanding is that a person would just have to add another valve body and plumb lines to the rear of the tractor with nothing additional required from the hydraulic pump to the valve bodies.

Thank you everyone so far!

TRA

|

|

1938 Model B (Grandpa's first new tractor)

1967 Model D17 Series IV (Grandpa's last new tractor)

|

|

Dave H (NE)

Silver Level

Joined: 11 Sep 2009

Location: Western NE

Points: 288

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Feb 2018 at 8:34am Posted: 08 Feb 2018 at 8:34am |

|

Your understanding is correct.

|

|

Gatz in NE

Orange Level

Joined: 11 Sep 2009

Location: Lincoln, NE

Points: 1062

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Feb 2018 at 9:58am Posted: 08 Feb 2018 at 9:58am |

I added a remote valve to the stack on my D17sIV. It came from a 180. If you go this route, you'll need the longer tie-bolts that hold the stack together as the valves are 1 1/2" thick. These should be factory; DO NOT use Redi-Rod or All-Thread. You'll also need the outlet tubes/fittings that connect to the bottom side of the new valve. These are routed to the back plate for the couplings. The existing tubes on mine had bad leather rings and I had to make some backing rings to take up the space. When disassembling, have a clean area and pay close attention to the small valves & springs in between the valve bodies (items 4 & 5) below....you don't want to have a Roger Welsh moment. Note; "View from bottom of assembly"

|

|

DSeries4

Orange Level

Joined: 12 Sep 2009

Location: Ontario, Canada

Points: 7564

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Feb 2018 at 5:34pm Posted: 08 Feb 2018 at 5:34pm |

|

Gatz has provided great pictures and information for you. There is definitely no change in piping coming from the pump.

|

|

'49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22285

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Feb 2018 at 5:48pm Posted: 08 Feb 2018 at 5:48pm |

|

Yes, there is one change of lines. The short unpainted input line behind the seat is 1 1/2" shorter. That could easily be replaced with a hose. The two "new" lines to the left outlets could also be hoses instead of steel lines. My feeling on this matter is not everybody is talented enough to disassemble the original valve stack and add on an extra valve. When doing so, that is the best time to just reseal the whole stack and have it leak free for the next 30 or 40 years. I'd suggest just purchasing the open center "power beyond" type dual spool valve and mount it above the hand clutch area. This would be a dedicated loader only valve and leave the tractor valves just as they are. Mounting it to the right side leaves your left hand free to shift gears. This is what I'd advise to someone who might not be comfortable with the disassembly of the original tractor valve stack.

|

|

Stan R

Orange Level Access

Joined: 03 Dec 2009

Location: MA

Points: 996

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Feb 2018 at 5:56pm Posted: 08 Feb 2018 at 5:56pm |

DrAllis wrote: DrAllis wrote:

Yes, there is one change of lines. The short unpainted input line behind the seat is 1 1/2" shorter. That could easily be replaced with a hose. The two "new" lines to the left outlets could also be hoses instead of steel lines. My feeling on this matter is not everybody is talented enough to disassemble the original valve stack and add on an extra valve. When doing so, that is the best time to just reseal the whole stack and have it leak free for the next 30 or 40 years. I'd suggest just purchasing the open center "power beyond" type dual spool valve and mount it above the hand clutch area. This would be a dedicated loader only valve and leave the tractor valves just as they are. Mounting it to the right side leaves your left hand free to shift gears. This is what I'd advise to someone who might not be comfortable with the disassembly of the original tractor valve stack. |

Yup, that is what we did on our IV !!

|

|

Zahn7115

Bronze Level

Joined: 30 Oct 2018

Location: Solomon, Kansas

Points: 3

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Oct 2018 at 10:31am Posted: 30 Oct 2018 at 10:31am |

|

Hi Stan, I was wondering if you could send me some pictures of where and how you tapped into the system for your loader? I am wanting to do the same and need some ideas. Thanks

|

|

Leadoff

Silver Level

Joined: 14 Oct 2016

Location: Calgary

Points: 298

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Oct 2018 at 2:01pm Posted: 30 Oct 2018 at 2:01pm |

|

Tra it

Be sure to address the longer pivot shaft for the levers that will be required when you go from two to three (unless AC installed the three pivot shaft at the factory). Part no 242447 for D17 IV or 0250612-9 for 170 175 180 185. The pivot shaft has a shoulder as it enters the frame/fender area, is a smaller diameter and is threaded to support the hex nut on the fender. Pivot shafts for the D17 IV are a bit shorter than the 100 tractors due to fender/frame/bushings etc but are of similar diameters

Something to remember for your project. Hope it helps. Good luck.

|

|

1963 D17D Series III. 1965 D15 Series II. 1965 D17 Series IV. 1975 185. 1978 716H. 1979 716H. 1965 780 Harvester/1R&DC. 1957 Model 73 SC 4 Furrow Plow

|

|

Gatz in NE

Orange Level

Joined: 11 Sep 2009

Location: Lincoln, NE

Points: 1062

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Oct 2018 at 3:17pm Posted: 30 Oct 2018 at 3:17pm |

After having gone through the pains of doing it like I did, I would agree with what the Dr and others have suggested. Get a dedicated power beyond joystick and save some trouble....maybe even some $$

On the other hand, I will disagree with the good Dr, however .....there's really not enough room ahead of that mounting plate to get hoses and the necessary end fittings in there.

Edited by Gatz in NE - 30 Oct 2018 at 3:17pm

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

tramiot wrote:

tramiot wrote: