| Author |

Topic Search Topic Search  Topic Options Topic Options

|

WF owner

Orange Level

Joined: 12 May 2013

Location: Bombay NY

Points: 5136

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: D-15 Series 2 skipping Topic: D-15 Series 2 skipping

Posted: 03 Jul 2025 at 4:18pm |

Around Memorial Day, I found and bought a 1966 D-15 Series 2 (snap coupler). The guy I bought it from said his father bought the tractor new and he didn't think it ever spent a night outdoors. It had never had a loader on it and had 2780 (some) hours on it. It still has all original tires. The sheet metal is perfect on it, but the paint on the top of the gas tank is not very good. The rest of the paint is pretty good. It has a belt pulley and even the toolbox is in good shape.

Now the bad parts. He said the tractor had set in the toolshed for years. The battery was dead, so it never got started. He said it hadn't been started for 4 years. I think it may have been more. When they decided to sell it, they put a new battery in it and tried to start it but couldn't get any spark. (Several of you remember my post on the frustration of getting spark.) I paid, what I consider, too much for the tractor (especially with this problem)!

When I finally got spark, I had to rebuild the carburetor. When I got that done, it started right up but had a skip. I tried different plugs and wires and realized that cylinders 2 and 3 were the ones that were the problem.

Finally, I ran a compression check (per DrAllis directions - WOT, fully charged battery and a battery charger on while doing the compression check). I got about 160 psi on both #1 and #4 cylinders, but low 60's on #2 and #3. My initial thought was that the rings are frozen to the piston on #2 and #3, so I removed all the plugs and hand squirted some ATF fluid in the cylinders. I let it sit for about 3 weeks and intermittently turned the engine slightly (by the belt pulley). Yesterday, I put some paper towels in the sparkplug holes and turned it over with the starter (to blow the oil out), then replaced the plugs and started it. HOLY SMOKE!

Unfortunately, it was still skipping and after about an hour of running, a compression check revealed practically the same readings as before.

Am I on the right tract, thinking the rings are stuck to the pistons? Is it possible the head gasket is bad between #2 AND #3 (engine does not overheat or have any steam from exhaust)? Any other thoughts or advice?

|

|

|

Sponsored Links

|

|

|

Allis dave

Orange Level

Joined: 10 May 2012

Location: Northern IN

Points: 3105

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jul 2025 at 4:23pm Posted: 03 Jul 2025 at 4:23pm |

|

It could be as easy as the valves need adjusted or are stuck. Pull the valve cover and take a look

|

|

WF owner

Orange Level

Joined: 12 May 2013

Location: Bombay NY

Points: 5136

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jul 2025 at 5:14pm Posted: 03 Jul 2025 at 5:14pm |

Allis dave wrote: Allis dave wrote:

It could be as easy as the valves need adjusted or are stuck. Pull the valve cover and take a look |

I should have put in the post that I did take the valve cover off, checked the valve lash and all valves seem to be working as they should.

Edited by WF owner - 03 Jul 2025 at 5:15pm

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89871

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jul 2025 at 5:35pm Posted: 03 Jul 2025 at 5:35pm |

|

head gasket could be blowing between 2 and 3 and not have a coolant leak ??

|

|

Like them all, but love the "B"s.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22541

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jul 2025 at 5:47pm Posted: 03 Jul 2025 at 5:47pm |

|

Blown head gasket almost for sure. While taking it apart, check the valve lash and as long as there aren't any tight (#2 and #3) it's a blown head gasket. Best fix these days is use a G-149 gasket from a D-14 early D-15. Could also be stuck valves on those two cylinders, but again while disassembling a good Tech would check for that before just ripping the cylinder head off.

Edited by DrAllis - 03 Jul 2025 at 5:50pm

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89871

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 03 Jul 2025 at 6:29pm Posted: 03 Jul 2025 at 6:29pm |

|

Could you connect an air line into #2 spark plug port ,...... 100 psi... and see what comes out #3 ??? ......... of course the valves would have to be Closed.

Edited by steve(ill) - 03 Jul 2025 at 6:30pm

|

|

Like them all, but love the "B"s.

|

|

WF owner

Orange Level

Joined: 12 May 2013

Location: Bombay NY

Points: 5136

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jul 2025 at 6:31pm Posted: 03 Jul 2025 at 6:31pm |

I had it running with the valve cover off and the valves all seemed to be working right. I checked the (cold) valve lash. They were all very close to .015 .

I will pull the valve cover off again and turn the engine by hand and watch each individual valve.

By the way Doc, I don't have "a good tech" - just me!

|

|

WF owner

Orange Level

Joined: 12 May 2013

Location: Bombay NY

Points: 5136

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jul 2025 at 6:34pm Posted: 03 Jul 2025 at 6:34pm |

steve(ill) wrote: steve(ill) wrote:

Could you connect an air line into #2 spark plug port ,...... 100 psi... and see what comes out #3 ??? ......... of course the valves would have to be Closed. |

Great idea! I will try that.

Thank you all for the advice!!!

|

|

Tracy Martin TN

Orange Level Access

Joined: 11 Sep 2009

Location: Gallatin,TN

Points: 10889

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Jul 2025 at 10:42pm Posted: 03 Jul 2025 at 10:42pm |

|

I bought a D15 II that was like that. Blown head gasket. Make sure to get one that has fire rings on it. HTH Tracy

|

|

No greater gift than healthy grandkids!

|

|

ekjdm14

Orange Level Access

Joined: 20 Aug 2024

Location: Alsager UK

Points: 987

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Jul 2025 at 5:39am Posted: 04 Jul 2025 at 5:39am |

steve(ill) wrote: steve(ill) wrote:

Could you connect an air line into #2 spark plug port ,...... 100 psi... and see what comes out #3 ??? ......... of course the valves would have to be Closed. |

Beaten to the punch, a very basic form of leak down test. Proper way is with a set of gauges but with a problem as big as 100psi low on 2 cylinders you should be able to hear where the compression is going away.

First thought would be head gasket (air between #2 and #3 plug holes) but also listen at the exhaust, the intake and at the breather if it's not going between cylinders.

|

|

Stuck Farmer

|

|

JimD

Orange Level

Joined: 11 Sep 2009

Location: Mounds, OK

Points: 2116

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Jul 2025 at 9:53am Posted: 04 Jul 2025 at 9:53am |

Probably headgasket, but I would also pressurize the bad cylinders and try to hear. Is there a difference in testing with the cylinder wet? I had almost exact same situation with a D15 II. I finally fogged the cylinders and regained the compression. But having 2 adjacent cylinders does indicate a head gasket. I use the Victor Reinze that have the fire ring.

|

Owner of OKtractor.com PM for an instant response on parts. Open M-F 9-6 Central. We have new and used parts. 877-378-6543

|

|

WF owner

Orange Level

Joined: 12 May 2013

Location: Bombay NY

Points: 5136

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jul 2025 at 4:38pm Posted: 13 Jul 2025 at 4:38pm |

Well, it should be a surprise to no one that the Doctor and Steve(Ill) were right.

I hooked an air hose up to the fitting for my compression tester and hooked it to my air hose and it (turned the engine over) blew air from #2 out the plug hole of #3, so I was quite sure they were right.

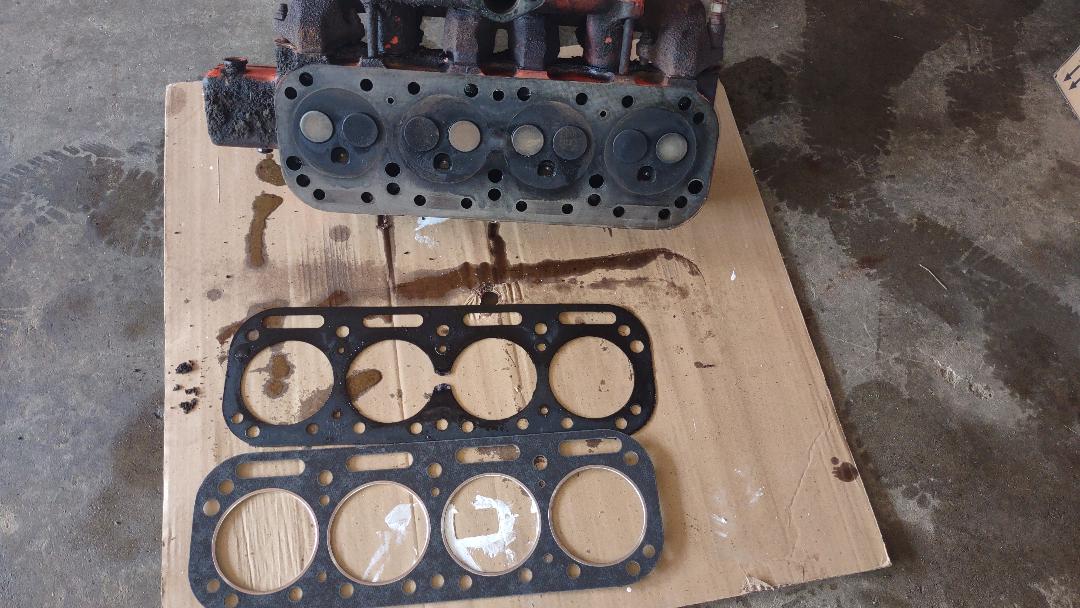

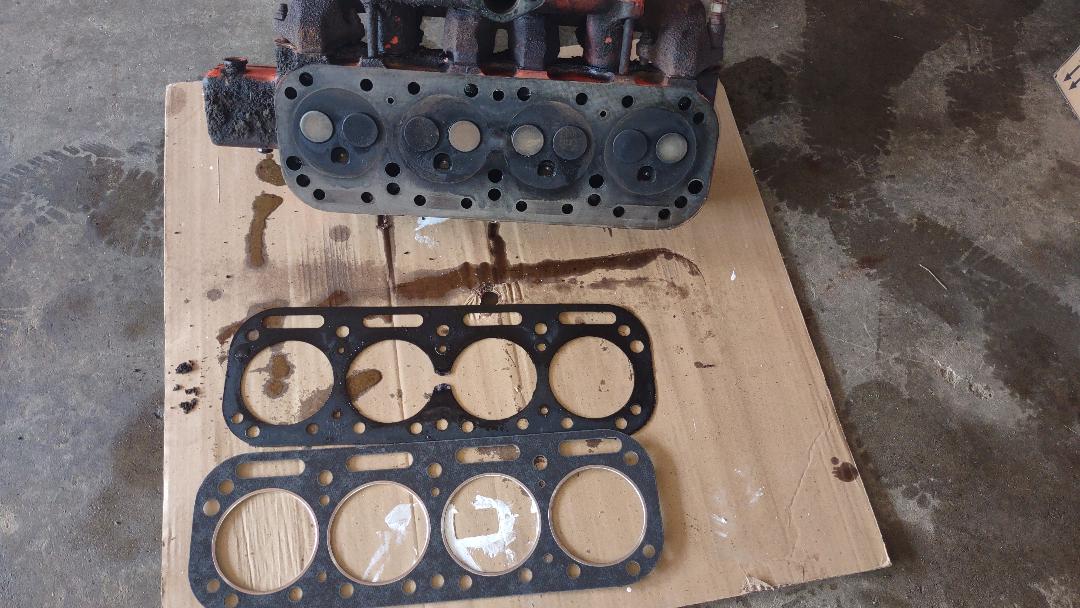

I finally got time to tear it apart today and the gasket had no fire rings and was blown between #2 and #3. I know I probably should have had the head flattened, but I put it back together without resurfacing. It runs much better!  |

|

WF owner

Orange Level

Joined: 12 May 2013

Location: Bombay NY

Points: 5136

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jul 2025 at 4:45pm Posted: 13 Jul 2025 at 4:45pm |

I should have added thank you to all for the help!!!

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22541

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jul 2025 at 6:24pm Posted: 13 Jul 2025 at 6:24pm |

|

If it was mine, I'd run it up to about 20 hrs and retorque the head bolts when the engine is stone cold. Hopefully you used some grease or oil on the head bolt threads.,

|

|

WF owner

Orange Level

Joined: 12 May 2013

Location: Bombay NY

Points: 5136

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jul 2025 at 6:46pm Posted: 13 Jul 2025 at 6:46pm |

I did have oil on all the head bolts. I used (the Permatex equivalent of) Hylomar on the block and the head side of the gasket. I set the valve lash at .015 cold on all valves. I will recheck that after a few running hours.

I torqued the head bolts to 80 ft. lbs. I can retorque in 20 running hours, but that will probably take years!

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22541

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jul 2025 at 7:26pm Posted: 13 Jul 2025 at 7:26pm |

|

So, make it in 6 months.

|

|

WF owner

Orange Level

Joined: 12 May 2013

Location: Bombay NY

Points: 5136

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jul 2025 at 7:55pm Posted: 13 Jul 2025 at 7:55pm |

What do you torque the rocker arm bolts to? I torqued them to 25 ft. lbs.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22541

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jul 2025 at 8:27pm Posted: 13 Jul 2025 at 8:27pm |

|

I never use a torque wrench. Prob 30-35 ft lbs. You can split those cast iron supports, but you don't want them coming loose either.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

Allis dave wrote:

Allis dave wrote: