| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Chilson450

Bronze Level

Joined: 03 Mar 2020

Location: Michigan

Points: 15

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: D14 rebuilt engine oil pressure Topic: D14 rebuilt engine oil pressure

Posted: 14 May 2025 at 5:48pm |

|

I installed a rebuilt engine in this tractor that we bought at a machine shop. The previous owner never returned to pay for it or couldn't afford it. It sat there for years so we got it cheap. I installed it in the tractor and got it running. I had roughly 15 psi oil pressure but realized I wasn't getting oil to the top end. Traced it back and found no oil coming out of the port in the side of the block. Later found out that the middle cam bearing was not installed correctly or even the right one. So we pulled the engine back out and got it to a guy that's built many engines. He tore it down and sent it to the machine shop to get the correct cam bearings installed and I think it got new rods bearings as well. So I now got the engine back from him and installed it in the tractor again. I now have oil going to the top end. But I have 5-7 psi oil pressure. I have not ran it much because of the low oil psi. I talked to the guy that put the engine together and he's thinking oil pump. Are the oil pumps common to wear out or have broken parts? Can it be installed incorrectly? I have oil coming into the filter tube. It seems to be moving oil just not much psi. Anyone have any ideas.

|

|

|

Sponsored Links

|

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88607

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 May 2025 at 6:00pm Posted: 14 May 2025 at 6:00pm |

I assume you have the BYPASS FILTER SYSTEM on this engine ? ... The filter is STUFFED WITH COTTON and has a mason jar type thread not an automotive center mount thread ?

The pump output goes to the FILTER and up thru a 1/4 inch center tube with a 1/8 inch hole in the top of it... About 15% of that oil goes thru that hole and thru the filter and dumped back to SUMP ( bupass system).... The OTHER 85% of the oil from the pump runs down thru the cam shaft and is spray lube thru holes to the pistons / connecting rods, and lubes the main bearings ..... this does NOT GO THRU THE FILTER.

Make sure you got the right filter , the center tube, and the 1/8 inch hole in the top of the tube, or you will LOOSE a lot of the oil and be dumping back to sump.... and LOW PRESSURE....... The PRESSURE you see is BACK PRESSURE caused by the filter and the 1/4 inch tube with the 1/8 inch hole..

|

|

Like them all, but love the "B"s.

|

|

Chilson450

Bronze Level

Joined: 03 Mar 2020

Location: Michigan

Points: 15

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 May 2025 at 6:23pm Posted: 14 May 2025 at 6:23pm |

|

Yes it does have the bypass style filter. I have a brand new center tube installed. I've tried a couple different filters.

|

|

HudCo

Orange Level

Joined: 29 Jan 2013

Location: Plymouth Utah

Points: 3951

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 May 2025 at 7:41pm Posted: 14 May 2025 at 7:41pm |

|

are you checking this with a gauge in the right range ? like a lower pressure gauge, like a 0 to 20 0r 30 ? not a 0 to 60 or 80

|

|

Chilson450

Bronze Level

Joined: 03 Mar 2020

Location: Michigan

Points: 15

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 May 2025 at 7:45pm Posted: 14 May 2025 at 7:45pm |

|

Yes I have multiple 30 psi gauges I have checked with. The tractor itself has a 0-80 psi gauge but I disconnected that and screwed the 30 psi gauge right into the filter base.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22166

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 May 2025 at 8:06pm Posted: 14 May 2025 at 8:06pm |

|

The oil filter absolutely must be a cotton string filter. NOT a pleated paper filter. I always replace the two vanes and their springs inside the oil pump making sure the vanes are installed the right way. Installed backwards would probably cause low oil pressure. I inspect the rotor for wear and the inside of the pump's housing for wear too.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88607

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 May 2025 at 8:25pm Posted: 14 May 2025 at 8:25pm |

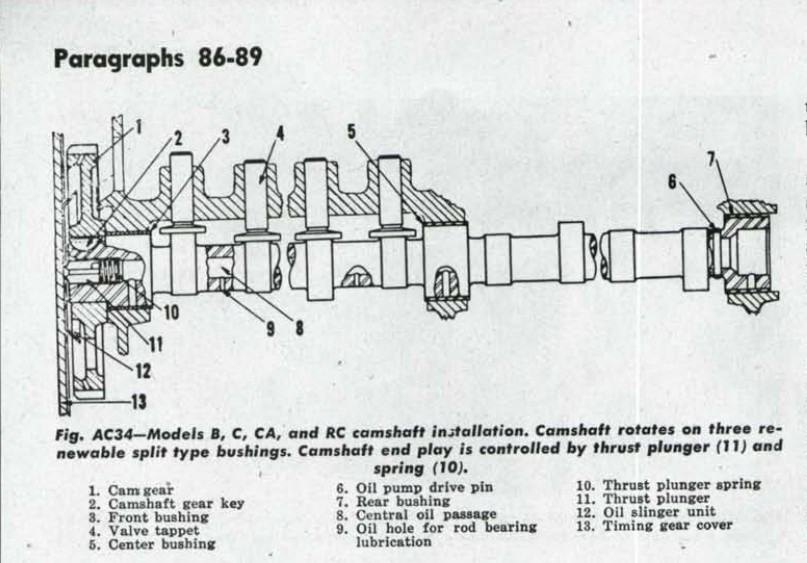

On the B-C engine, the hollow cam shaft has a restrictor plug at the front to keep the oil from dumping into the front housing on the gears.... Does the D14 engine have that same restrictor ? .......... Does YOUR engine have the restrictor in the cam ?

ITEM #10 - 11 ...

Edited by steve(ill) - 14 May 2025 at 8:28pm

|

|

Like them all, but love the "B"s.

|

|

Les Kerf

Orange Level

Joined: 08 May 2020

Location: Idaho

Points: 1394

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 May 2025 at 12:06am Posted: 15 May 2025 at 12:06am |

|

As a test you could temporarily block all of the oil going to the filter.

|

|

Chilson450

Bronze Level

Joined: 03 Mar 2020

Location: Michigan

Points: 15

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 May 2025 at 4:44am Posted: 15 May 2025 at 4:44am |

|

It does have the ball and spring in the front of the cam. I also tried the ball and spring out of the original engine because it looked to be in better shape.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22166

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 May 2025 at 4:49am Posted: 15 May 2025 at 4:49am |

|

Ball and 2 springs and a plunger ??

|

|

Chilson450

Bronze Level

Joined: 03 Mar 2020

Location: Michigan

Points: 15

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 May 2025 at 4:53am Posted: 15 May 2025 at 4:53am |

|

There was a ball, 2 springs and then a 4 sided piece that the spring pushed against and rode against the front cover. I dont remember a plunger.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22166

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 May 2025 at 6:21am Posted: 15 May 2025 at 6:21am |

|

You'e got it all.

|

|

tbran

Orange Level

Joined: 14 Sep 2009

Location: Paris Tn

Points: 3539

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 May 2025 at 8:14am Posted: 15 May 2025 at 8:14am |

|

We have found this several times - the pin in the back of the camshaft that drives the pump can be loose and a source of pressure loss. We have also had the cam brg issue - we just removed the fitting and carefully drilled through the side of the cam brg with a low angle sharpened bit. What we do on low pressure issues is insert an air fitting in one of the oil points in the block and put about 20 PSI in and LISTEN where the leakage is - might have to pull the pan. . That will show up a brg or drive pin issue but not a pump supply issue.

|

|

When told "it's not the money,it's the principle", remember, it's always the money..

|

|

HudCo

Orange Level

Joined: 29 Jan 2013

Location: Plymouth Utah

Points: 3951

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 May 2025 at 10:54am Posted: 15 May 2025 at 10:54am |

|

i have had two tractors that the pipe thread on the oil pick up tube had a crack on the pipe thread , fill it a gallon or so over full on oil may be jack it up to get oil leval above those threads and see if the oil pressure goes up

|

|

Alex09(WI)

Orange Level

Joined: 15 Mar 2012

Location: CECIL WI

Points: 1759

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 May 2025 at 10:14pm Posted: 17 May 2025 at 10:14pm |

Diagnostic 101. If the oil pump wasn't messed with when the engine was taken apart again, then its not the oil pump. The oil pressure changed from 15psi to 8psi. What else was changed at the same time the oil pressure changed? Bearings, right?

The original problem is easily solvable like Tbran said, just remove the cam, drill a small hole through the hole for the t fitting in the block, then make sure it lines up with the small hole in the center cam journal when you reinstall the camshaft. The aftermarket center cam bearings are made with the small oil hole on the opposite side of where it should be.

|

|

www.awtractor.com

A&W TRACTOR 920-598-1287

KEEPING ALLIS-CHALMERS IN THE FIELDS THROUGH THE 21ST CENTURY

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22166

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 May 2025 at 6:52am Posted: 18 May 2025 at 6:52am |

|

He has never confirmed the use of a cotton string filter versus the incorrect pleated paper filter which can cause low oil pressure. The filter MUST be cotton string. All he has said is "I've tried a couple different filters", which could still be the wrong types.

|

|

Chilson450

Bronze Level

Joined: 03 Mar 2020

Location: Michigan

Points: 15

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 May 2025 at 6:59am Posted: 18 May 2025 at 6:59am |

|

Sorry. All of the filters I have are the cotton string type. I have a Baldwin t300m. And also a wix that I don't remember the number on right now. But it does have the cotton inside.

|

|

Chilson450

Bronze Level

Joined: 03 Mar 2020

Location: Michigan

Points: 15

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 May 2025 at 7:06am Posted: 18 May 2025 at 7:06am |

|

I haven't had time recently to work on it but my plan is to try the air pressure to see if I can hear a large leak. Probably pull the pan off to listen and inspect the pickup tube area that was mentioned above.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)