| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Rod Yowell

Orange Level

Joined: 01 Jun 2012

Location: St. Louis, Mo.

Points: 1182

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Cracks at Torque Tube & PTO area WD45 Topic: Cracks at Torque Tube & PTO area WD45

Posted: 12 Jun 2012 at 5:47pm |

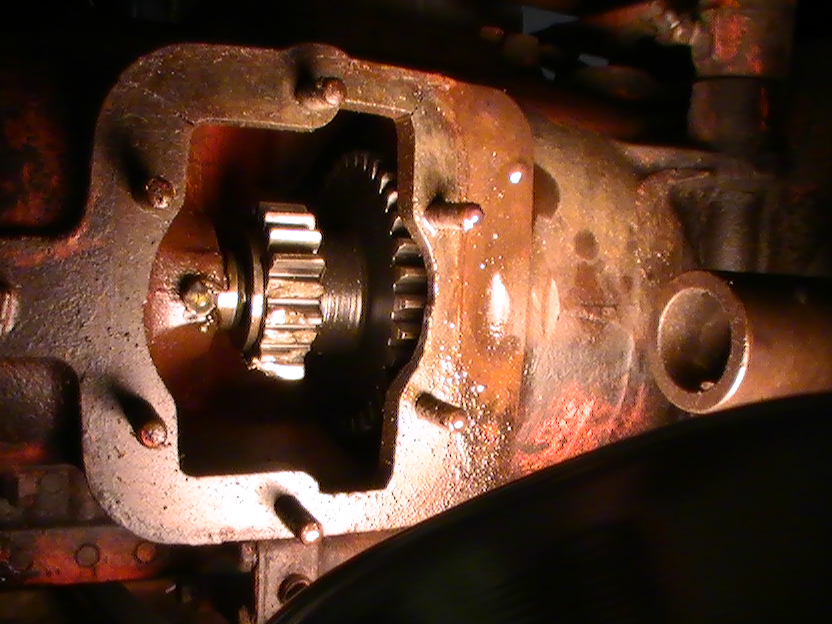

I was cleaning the part of the torque tube where the PTO bolts to it underneath. I am having to replace the PTO assembly because it was broken by the fellow I got this tractor from while he was brush-hogging. I just noticed two slight cracks in the torque tube housing that are about 2 inches on each side of 1 bolt. The cracks go up into the housing about 1 to 2 inches and I believe they either connect or at least go toward each other. The rest of the bolts on the housing and torque tube are fine. My questions are these. 1. Are these slight cracks enough of a problem that I should replace the torque tube now? 2. Will the PTO housing just snap off again when I start up the PTO and engage a brushhog? 3. Will tightening the bolt down on the PTO housing cause this part of the torque tube to snap off? 4. Is this something that can be welded or fixed with a JB Weld type of product? Thanks for any suggestions or comments you guys might have.

Edited by Rod Yowell - 12 Jun 2012 at 6:41pm

|

|

|

Sponsored Links

|

|

|

Rod Yowell

Orange Level

Joined: 01 Jun 2012

Location: St. Louis, Mo.

Points: 1182

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Jun 2012 at 6:48pm Posted: 12 Jun 2012 at 6:48pm |

Edited by Rod Yowell - 12 Jun 2012 at 6:52pm

|

|

Gary in da UP

Orange Level

Joined: 13 Sep 2009

Location: EUP of Mi.

Points: 1885

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Jun 2012 at 6:52pm Posted: 12 Jun 2012 at 6:52pm |

|

Replace it, they are plentiful, and cheap. Buy one close enuf to drive to pickup.

|

|

Bill_MN

Orange Level

Joined: 12 Sep 2009

Location: Sioux Falls, SD

Points: 1471

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Jun 2012 at 6:57pm Posted: 12 Jun 2012 at 6:57pm |

|

you will need to disassemble it to replace your intermediate gear anyway, just replace the whole works

|

|

1951 WD #78283, 1918 Case 28x50 Thresher #76738, Case Centennial B 2x16 Plow

|

|

CTuckerNWIL

Orange Level

Joined: 11 Sep 2009

Location: NW Illinois

Points: 22825

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Jun 2012 at 7:10pm Posted: 12 Jun 2012 at 7:10pm |

|

Replace the housing.

|

|

|

|

B26240

Orange Level

Joined: 21 Nov 2009

Location: mn

Points: 3866

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Jun 2012 at 7:29pm Posted: 12 Jun 2012 at 7:29pm |

Yes I agree - replace the housing, I had one in my junk pile that had the same brake and

had been welded and broke again -- get rid of it now and be done with it!!

|

|

Mike56073

Silver Level

Joined: 14 Nov 2010

Location: New Ulm

Points: 154

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Jun 2012 at 9:19pm Posted: 12 Jun 2012 at 9:19pm |

|

Everbody is right! You have to take it apart anyways to replace the gear. If you don't replace the housing it'll either break or you'll constantly worry about it breaking.

|

|

Rick

Orange Level

Joined: 11 Sep 2009

Location: Jonesburg,Mo.

Points: 3698

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Jun 2012 at 10:01pm Posted: 12 Jun 2012 at 10:01pm |

|

Rod, I sent you a private message. Rick

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8640

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Jun 2012 at 10:53pm Posted: 12 Jun 2012 at 10:53pm |

Just like me,the cart before the horse.He already replaced the intermediate gear....and you don't have to split to do it.They are plentiful and I agree replacing is best but man what a lot of work. Not hard,just time consuming.You said you're not a mechanic but you will be when you overcome this tractor,and you can,step by step.Chin up and dig in!

Chances are ole Rick has a complete,usable section that you can just swap in,and he will treat you right.

Edited by SteveM C/IL - 12 Jun 2012 at 10:56pm

|

|

Rod Yowell

Orange Level

Joined: 01 Jun 2012

Location: St. Louis, Mo.

Points: 1182

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jun 2012 at 7:13am Posted: 13 Jun 2012 at 7:13am |

|

Thanks to everyone for all the replies. I just knew I was going to have to replace the housing. I wanted someone to tell me what I was afraid of. I know your all right and I am going to bit the bullet and break the tractor and replace the torque tube. Rick I PM'd you back. Thanks again to all you guys. Your really great to help me out.

|

|

KGood

Orange Level

Joined: 17 Nov 2009

Location: Logansport,IN

Points: 955

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jun 2012 at 7:49am Posted: 13 Jun 2012 at 7:49am |

|

I just wonder if they are breaking because of being loose. The three different 45's we have used in our baling I have had to tighten the PTO housing when I was prepping them for work.

|

|

Rod Yowell

Orange Level

Joined: 01 Jun 2012

Location: St. Louis, Mo.

Points: 1182

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jun 2012 at 8:33am Posted: 13 Jun 2012 at 8:33am |

Kevin, I don't know if they were loose because the guy I bought this tractor from said he broke the PTO during brush-hogging. But I will remember to check these bolts on a regular basis to make sure they don't work loose. I only want to do this repair once. Thanks for the info.

Edited by Rod Yowell - 13 Jun 2012 at 8:34am

|

|

stu(ON)

Orange Level

Joined: 12 Sep 2009

Points: 377

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jun 2012 at 1:46pm Posted: 13 Jun 2012 at 1:46pm |

When you are remounting the PTO box to the torque tube, I encourage you to heed the instruction in the service manual regarding the clearance between the idler gear and intermediate gear. I don't know how to measure for the 0.004" backlash, but if it is hard to engage the PTO, you will feel it and you need a second gasket. I believe that the tolerances on these parts was fairly loose and it would not be unusual to find a tight fit when mixing and matching parts. I know that I did and that a second gasket brought things back to the way it originally felt. This could be one thing that puts pressure on the torque tube, intermediate gear and idler gear.

I also have spent too many hours repairing PTO damage incurred by brush hogging. All my fault.

|

|

TREVMAN

Orange Level

Joined: 04 Jan 2010

Location: Regina,Sask,Can

Points: 1635

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jun 2012 at 2:00pm Posted: 13 Jun 2012 at 2:00pm |

|

I dont think these tractors were designed for the torque of a heavy mower. I sure wouldnt use a very big one on my WD. Trev.

|

|

stu(ON)

Orange Level

Joined: 12 Sep 2009

Points: 377

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jun 2012 at 2:13pm Posted: 13 Jun 2012 at 2:13pm |

|

Trevman, you are right. They were designed for the rather steady load of a rotobaler, not the shock load of a brush hog. I doubt that hogs even existed in 1948. If you use a WD to actually hog brush, or even run over ant hills, you really want a slip clutch or use really soft shear bolts with the periphery scored. The PTO is the weakest link; just too easily damaged.

|

|

wfmurray

Orange Level

Joined: 13 Sep 2009

Location: Bostic NC

Points: 1225

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jun 2012 at 2:32pm Posted: 13 Jun 2012 at 2:32pm |

|

Help my dad put pto on a WC Instructions said if to tight it would whine , if to loose it will roar. Used that idea for a many a year. Also ! Pulled a 66 for year with a D/14 no trouble , used bush hog and twisted short shaft of pto . Took out and used 41/2 side grinder on splines and got it to work again . Put slipe clutch on . To check slip clutch rev engine up and drop foot clutch , you need to hear it slip just a little.

|

|

Rod Yowell

Orange Level

Joined: 01 Jun 2012

Location: St. Louis, Mo.

Points: 1182

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jun 2012 at 7:37am Posted: 14 Jun 2012 at 7:37am |

|

Well I picked up a 'new' torque tube housing and PTO gear box yesterday (along with a few other parts). So I am going to start on the splitting of my WD45 today. I will see if I am smart enough to do this repair or not. I let you guys know how it comes out. LOL

|

|

Socialism is the Philosophy of Failure, the Creed of Ignorance, and the Gospel of Envy

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8640

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jun 2012 at 8:00am Posted: 14 Jun 2012 at 8:00am |

|

Don't remember which end I blocked and which end I rolled but I unbolt frame rails from rearend and split trans off trq hsg,then pull trq hsg off clutch hsg. Take your time,be careful.

|

|

Rod Yowell

Orange Level

Joined: 01 Jun 2012

Location: St. Louis, Mo.

Points: 1182

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jun 2012 at 8:05am Posted: 14 Jun 2012 at 8:05am |

|

Thanks Steve, I will. That's the way I am going to do it also.

|

|

Socialism is the Philosophy of Failure, the Creed of Ignorance, and the Gospel of Envy

|

|

TREVMAN

Orange Level

Joined: 04 Jan 2010

Location: Regina,Sask,Can

Points: 1635

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jun 2012 at 10:10am Posted: 14 Jun 2012 at 10:10am |

|

Its just nuts, bolts, and time as a buddy of mine likes to say. If I was splitting a tractor, Id have someone with me to help, just stay safe, Trev.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)