| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Ranse

Orange Level

Joined: 11 Mar 2016

Location: Tennessee

Points: 782

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: B running rough Topic: B running rough

Posted: 11 Apr 2019 at 8:47pm |

|

I got my NH rake gearbox finished yesterday. I took it out in the pasture today and raked up some hay the cows didn't clean up. Rake did great. The B however spit, sputtered, and cut out like crazy. It's only been started two or three times all winter. It could use some fresh gas, but I don't think that's all of it. I cleaned the sediment bowl a couple of times. It didn't help, and I didn't really see anything in it. I put half a bottle of seafoam in it and pulled the rake around hoping it would straighten out-nope. Then I played around with the carburetor. Here's something I don't understand. It has a marvel carb with the fixed jet. I can turn that one screw all the way down as far as it will go, or I can turn it out till it's just about to come out and it doesn't do anything. I can't tell a bit of change from extreme to the other in the way it runs. Another strange thing, I can't choke it out. Pull the choke, it keeps running, no noticeable change. I put my hand over the breather-same thing. It doesn't seem to choke it down. This isn't the first time I've noticed these things, although it usually runs better. It always starts good. It's starting good now, just not running right. Any suggestions appreciated.

|

|

|

Sponsored Links

|

|

|

Gerald J.

Orange Level

Joined: 12 Sep 2009

Location: Hamilton Co, IA

Points: 5636

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Apr 2019 at 9:43pm Posted: 11 Apr 2019 at 9:43pm |

The shop manual may help though often carburetor adjustments are in the operator's manual: http://geraldj.networkiowa.com/Trees/Allis-Chalmers-G-B-C-CA-Service.pdf http://geraldj.networkiowa.com/Trees/BMilitary.pdf The slow speed idle mixture adjustment screw usually is only effective with the engine idling very slow. It could be that the internal choke plate isn't changing position even though the shaft or the choke cable is. My JD 4020 choke cable likes to get the outside not anchored near the carburetor and to cause such problems. Gerald J.

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5093

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2019 at 6:20am Posted: 12 Apr 2019 at 6:20am |

|

The screw adjust the air mixture for idle alone. When you have the throttle set above idle you can take it out and put it your pocket and go back to work. When you try to idle then it will die.

Any engine speed depends on the opening of the throttle plate!

The idle speed is set with (the throttle plate opening) the stop screw on the back side. The screw is adjusted for a fuel air mixture that makes the engine run smooth at the desired slow idle or how small the throttle plate opening. Your sputtering can be a dirty non adjustable power jet or it might even be dirty points.

|

|

Steve in NJ

Orange Level Access

Joined: 12 Sep 2009

Location: Andover, NJ

Points: 12036

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2019 at 6:35am Posted: 12 Apr 2019 at 6:35am |

Spitting and sputtering could be caused by a lot of things. The first thing I would do is inspect the Ignition system whether its a Mag or Distributor fired. As Dick mentioned, check the points for corrosion, change out the condenser, do an ohms check on the coil. The next thing I would do is drain the fuel tank of what fuel is in there, along with draining the Carb, and the fuel delivery system and start there with fresh fuel. If there's Ethanol in your fuel, that causes more problems than you think, and the Seafoam isn't gonna help a lot. Sometimes if the fuel isn't separated to much, an additive like Seafoam or dry gas may help, but there isn't any longevity to this lousy fuel we have. Lastly, if things haven't ironed out by then, check your valve lash at the rockers. Might have a tight valve or two causing the lousy running. You'll find it.

|

|

39'RC, 43'WC, 48'B, 49'G, 50'WF, 65 Big 10, 67'B-110, 75'716H, 2-620's, & a Motorhead wife

|

|

nella(Pa)

Orange Level Access

Joined: 11 Sep 2009

Location: Allentown, Pa.

Points: 3137

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2019 at 6:57am Posted: 12 Apr 2019 at 6:57am |

Ranse wrote: Ranse wrote:

I can't choke it out. Pull the choke, it keeps running, no noticeable change. I put my hand over the breather-same thing. It doesn't seem to choke it down. . |

Putting your hand over the breather should kill the engine. There might be a leak in the intake somewhere, possiably the hose between the air cleaner and carburetor. There might be dirt in the gas system somewhere because of no smoke. Take the valve with the gas bowel out of the gas tank and visualy check for dirt, if clean then go into the carb. Don't use air and blow back through the carb, that might collapse the float!

Edited by nella(Pa) - 12 Apr 2019 at 7:03am

|

|

Ranse

Orange Level

Joined: 11 Mar 2016

Location: Tennessee

Points: 782

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2019 at 9:30pm Posted: 12 Apr 2019 at 9:30pm |

|

Dick,

I didn't know it worked like that. I tried adjusting the screw at high engine speed and lower speed too, but probably not slow enough. If I throttle it down to much the engine will die. That's how I usually shut it off.

As for the choking down issue, that one confuses me. It should kill the engine, or at least make it run a lot worse. The breather pipe has very little suction on it. I don't know how much its supposed to have, but I suspect more than what it has. I thought about the hose between the carburetor and breather as well. It's a new hose and clamps, looked ok the last time I had the carb off. That's the only place it could be drawing air unless there's a big rust hole on the back side of the breather that I've never seen. I never had it off the tractor.

|

|

Ranse

Orange Level

Joined: 11 Mar 2016

Location: Tennessee

Points: 782

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2019 at 9:46pm Posted: 12 Apr 2019 at 9:46pm |

|

As for the ignition system, I've never opened up that magneto before. I could probably file the points and see if that helps. To be honest, I'm a little afraid to mess around in there to much. I might do more harm than good, like getting it out of time.

|

|

mdm1

Orange Level

Joined: 12 Sep 2009

Location: Onalaska, WI

Points: 2683

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Apr 2019 at 7:07am Posted: 13 Apr 2019 at 7:07am |

|

Check your plug wires. My C started running poorly and I did the carb and fuel stuff as that had been a problem in the past. One wire was shot. Did a tune up and it ran fine.

|

|

Everything is impossible until someone does it! WD45-trip loader 1947 c w/woods belly mower, 1939 B, #3 sickle mower 1944 B, 2 1948 G's. Misc other equipment that my wife calls JUNK!

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5093

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Apr 2019 at 8:27am Posted: 13 Apr 2019 at 8:27am |

Ranse wrote: Ranse wrote:

Dick,

I didn't know it worked like that. I tried adjusting the screw at high engine speed and lower speed too, but probably not slow enough. If I throttle it down to much the engine will die. That's how I usually shut it off.

|

The back stop screw and the air mixture screw will have to each be turned a little at a time alternating between the two to keep the engine runing as you reduce the speed. The slower the engine runs the more your on the idle circuit of the carburetor. When entirely on the idle circuit the more necessary it is to have the proper fuel air mixture to keep the engine running. Take it easy on filing the points or using sand paper. A piece torn off the corner of a poster board or even a business card will clean the points from just setting for a while. If the points have a spot on them that do not seem to clean with the paper they need changed. You can file them but soon will need changed or filed often. That depends on how much you filed off. The more compression the engine has the more suction you will have at the carburetor. The breather pipe can be letting air in thru the crimp in the pipe or at the cup. Remove the hose and check at the carburetor to feel the actual vacuum. Steve mentioned the tight valve lash/clearance which could cause lower vacuum which would also give problems with carburetor adjustments as well as sputtering. Valves not sealing from an improper valve job. I hesitate in saying valve grind as some think lapping is the same thing as a grind. Without grinding the proper angle on both the valve and seat is only temporary at best if a good seal is even achieved.

Edited by Dick L - 13 Apr 2019 at 8:30am

|

|

Stan IL&TN

Orange Level

Joined: 13 Sep 2009

Location: Elvis Land

Points: 6730

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Apr 2019 at 10:03am Posted: 13 Apr 2019 at 10:03am |

|

May be a long shot but I would check the intake manifold for a leak where it mates up with the block.

|

|

1957 WD45 dad's first AC

1968 one-seventy

1956 F40 Ferguson

|

|

CTuckerNWIL

Orange Level

Joined: 11 Sep 2009

Location: NW Illinois

Points: 22825

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Apr 2019 at 11:21am Posted: 13 Apr 2019 at 11:21am |

Ranse wrote: Ranse wrote:

It's a new hose and clamps, looked ok the last time I had the carb off. That's the only place it could be drawing air unless there's a big rust hole on the back side of the breather that I've never seen. I never had it off the tractor. |

That is NOT the only place it can draw air. If you have a leak in the manifold, whether it's where it mates to the head OR internally, it can and will draw air from the area of least resistance. You could have a rusted thru spot inside the manifold, letting exhaust gas be sucked back into the engine.

|

|

|

|

Ranse

Orange Level

Joined: 11 Mar 2016

Location: Tennessee

Points: 782

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Apr 2019 at 8:54pm Posted: 15 Apr 2019 at 8:54pm |

|

I haven't had a chance to tinker with the B since the other day. I'll probably drain the fuel tomorrow. That valve lash is something else new to me. I've heard of adjusting valves, but I don't know exactly what you are referring to when you say "valve lash".

I'm also going to check the suction at the carburetor to see if there's more vacuum there. I don't believe there's a manifold leak, not an obvious one anyway. If it's internal how can you tell? I have a suspicion the compression isn't good. It's just a suspicion, I have no way to check that either.

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5093

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2019 at 6:09am Posted: 16 Apr 2019 at 6:09am |

Ranse wrote: Ranse wrote:

I haven't had a chance to tinker with the B since the other day. I'll probably drain the fuel tomorrow. That valve lash is something else new to me. I've heard of adjusting valves, but I don't know exactly what you are referring to when you say "valve lash".

I'm also going to check the suction at the carburetor to see if there's more vacuum there. I don't believe there's a manifold leak, not an obvious one anyway. If it's internal how can you tell? I have a suspicion the compression isn't good. It's just a suspicion, I have no way to check that either. |

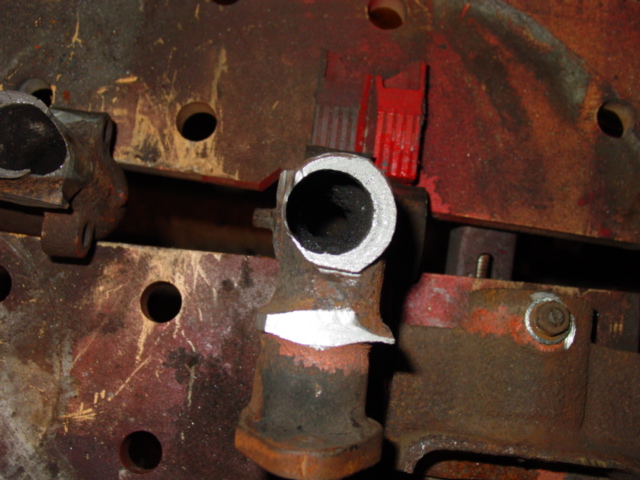

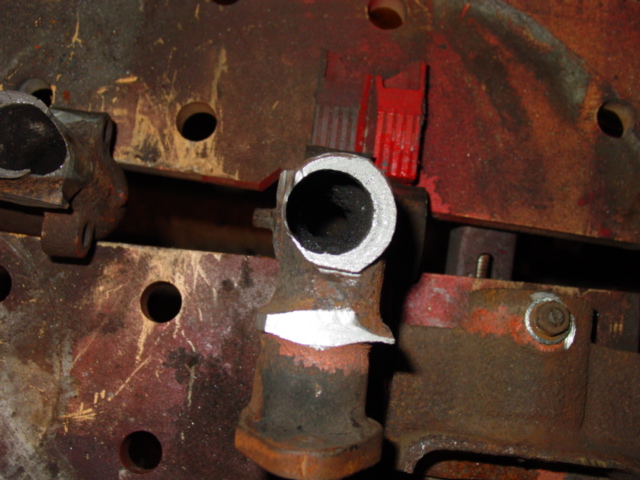

valve lash is the distance between the valve end that the rocker arm pad is allowed to move. Or the thickness of a feeler gage that will fit between the end of the valve stem and the rocker arm pad. To make checking the clearance when not have done it you can find TDC in the inspection hole and under the valve cover one cylinder will have both rocker arms up to where you can get a feeler gage of some thickness. I personally want .012 thickness. Every time the TDC is in the inspection hole one of the pistons are at TDC. Thinking this way about it takes the confusion on finding the compression stroke on number one that is most generally suggested. Any time TDC shows one of the pistons happens to be on the compression stroke even though it might not be number one. If the leak is internally in the manifold the tractor will most likely not start. That is caused by core shift when the casting is poured. It is also rare. Checking at the carburetor first will tell you if you need to look farther. Here is one I sectioned.

Edited by Dick L - 16 Apr 2019 at 6:12am

|

|

Ranse

Orange Level

Joined: 11 Mar 2016

Location: Tennessee

Points: 782

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2019 at 8:14am Posted: 16 Apr 2019 at 8:14am |

Dick L wrote: Dick L wrote:

valve lash is the distance between the valve end that the rocker arm pad is allowed to move. Or the thickness of a feeler gage that will fit between the end of the valve stem and the rocker arm pad.

|

I always called that the valve gap. I guess valve lash is the proper mechanic term. My Dad and I rebuilt the old original six cylinder motor in a 1955 Chevy pickup. We got the neighbor to adjust the valves because he was a better mechanic than us. Watching him was the only experience I've had with adjusting valves. I was 16 years old at the time. I remember he used a feeler gage, I don't recall him rotating the motor.

|

|

Gerald J.

Orange Level

Joined: 12 Sep 2009

Location: Hamilton Co, IA

Points: 5636

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2019 at 9:19am Posted: 16 Apr 2019 at 9:19am |

|

Valve lash or gap needs to be adjusted when the piston is at top dead center so the cam has the valves closed. The gap is there to make sure the valves close tight when pressure in the cylinder from combustion is greatest and to allow for heat expansion of the length of the valve stem, heat warp of the rocker arm, and heat expansion of the pushrod between the cam follower and the rocker arm. Lack of a gap leads to valve leakage which burns the valve and the valve seat and makes the engine run poorly, more so if its an intake valve pushing combustion products into the intake manifold.

Gerald J.

|

|

JaredC(WI)

Silver Level

Joined: 10 Apr 2019

Location: Birnamwood WI

Points: 106

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2019 at 9:50am Posted: 16 Apr 2019 at 9:50am |

|

I've got almost zero experience with engines other than the small ones so take that into account.

One thing that has consistently worked for me though is the KISS Principe.

Do the simple stuff first: check electrical connections. Make sure no wires are frayed and causing a short. Check spark plugs and their gaps. Drain a quart or so from the carb. Make sure the breather hole in the gas cap isn't plugged. Make sure the governor is moving freely.

My CA this winter was running horrible one day: cutting out on me occasionally and loosing power. Was convinced it was dirt or something in the fuel system. Ended up just finding a bunch of congealed oil and dirt where the oil tube goes into the governor and on the linkage there. Wasn't moving freely. Cleaned/scrapped that off with my pocket knife and the CA was snorting like a champ again.

Any time I ever started making carb adjustments or fiddling with other things on gas engines...especially if things had been working ok befor... I made more problems than needed.

Is it possible that your choke rod is binding up/catching on something or that the butterfly is stuck for some reason?

KISS it first.

Jared

Edited by JaredC(WI) - 16 Apr 2019 at 10:06am

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5093

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2019 at 10:29am Posted: 16 Apr 2019 at 10:29am |

Ranse wrote: Ranse wrote:

Dick L wrote: Dick L wrote:

valve lash is the distance between the valve end that the rocker arm pad is allowed to move. Or the thickness of a feeler gage that will fit between the end of the valve stem and the rocker arm pad.

|

I always called that the valve gap. I guess valve lash is the proper mechanic term. My Dad and I rebuilt the old original six cylinder motor in a 1955 Chevy pickup. We got the neighbor to adjust the valves because he was a better mechanic than us. Watching him was the only experience I've had with adjusting valves. I was 16 years old at the time. I remember he used a feeler gage, I don't recall him rotating the motor. |

I understand. He would have had to rotate it some or adjust them at idle. I also do not check for TDC on each valve adjustment. I was explaining how you could adjust them without wondering if you did it correct. You can only adjust correctly when both valves on one cylinder is closed. There exceptions to this rule when you fully understand what you are doing. As I stated above to not be (confused) this is the way I suggested. I was 17 when I learned how to adjust valve gap/ clearance/ lash! All being the same deal! That was at an Oliver dealers on a six cylinder with the engine at idle.

Edited by Dick L - 16 Apr 2019 at 10:31am

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5093

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2019 at 10:37am Posted: 16 Apr 2019 at 10:37am |

Gerald J. wrote: Gerald J. wrote:

Valve lash or gap needs to be adjusted when the piston is at top dead center so the cam has the valves closed. The gap is there to make sure the valves close tight when pressure in the cylinder from combustion is greatest and to allow for heat expansion of the length of the valve stem, heat warp of the rocker arm, and heat expansion of the pushrod between the cam follower and the rocker arm. Lack of a gap leads to valve leakage which burns the valve and the valve seat and makes the engine run poorly, more so if its an intake valve pushing combustion products into the intake manifold.

Gerald J.

|

Very Good!

|

|

Ranse

Orange Level

Joined: 11 Mar 2016

Location: Tennessee

Points: 782

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2019 at 8:35pm Posted: 16 Apr 2019 at 8:35pm |

Well I've got a ton more suction at the carburetor than I did at the breather pipe. I can choke it to death in an instant with my hand. I'm not sure if that's good news or bad. The tractor does seem to run better with fresh gas and no breather, but it's still sputtering. Especially at idle. The adjustment screw still don't seem to do much. I think it's safe to say at this point that it's not an adjustment issue. My question now is how was it getting air before? I still don't think that hose was the problem. Over condition of the canister looks good. It's made a little different than the one on the D10. How do you get the mesh out so I can wash it? It looks like this bottom flange is painted on, but it's hard to tell. It could be pressed on. I believe it will knock off, but I want to know for sure before I start whacking on it.

|

|

CTuckerNWIL

Orange Level

Joined: 11 Sep 2009

Location: NW Illinois

Points: 22825

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2019 at 8:44pm Posted: 16 Apr 2019 at 8:44pm |

|

The retainer for the wire mesh, is spot welded in. Gotta break the weld to get the mesh out, or soak the whole thing in diesel for a while and swish it out good. Maybe pressure wash it at the car wash? I removed mine on the old WC, because it was crumbling and I didn't want any of that going into my NEW engine.

|

|

|

|

nella(Pa)

Orange Level Access

Joined: 11 Sep 2009

Location: Allentown, Pa.

Points: 3137

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2019 at 9:01pm Posted: 16 Apr 2019 at 9:01pm |

|

Is there an o ring in the air cleaner for a seal so it wouldn't suck in air at the oil cup joint

Edited by nella(Pa) - 16 Apr 2019 at 9:02pm

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5093

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2019 at 10:46pm Posted: 16 Apr 2019 at 10:46pm |

|

You pretty much ruled out the valve problem. How slow is the idle? Have you turned the stop screw on the throttle plate until the engine died? If the mixture screw still does not change and stall out the engine you are either still not at slow idle or your idle circuit is plugged. Most likely could be both. The screw only has an effect at slow idle.

|

|

nella(Pa)

Orange Level Access

Joined: 11 Sep 2009

Location: Allentown, Pa.

Points: 3137

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Apr 2019 at 3:54pm Posted: 17 Apr 2019 at 3:54pm |

nella(Pa) wrote: nella(Pa) wrote:

Is there an o ring in the air cleaner for a seal so it wouldn't suck in air at the oil cup joint

|

I just checked my WD which has the same type air cleaner and it has a cork gasket(had tractor from new, 1950) where the oil cup fits into the air filter itself. If yours is missing, that is where it is getting air from when you held your hand on the intake and the motor didn't stop in about 3 seconds, if the hose had a good fit between the carb and air cleaner.

When you held your hand on carb intake did the exhaust smoke and tractor shut off in about 3 seconds, if not check the gas system starting at the gas tank valve for blockage. If there is dirt in the valve check the inside of tank.

Keep us up dated with your progress or questions.

Edited by nella(Pa) - 17 Apr 2019 at 5:38pm

|

|

Ranse

Orange Level

Joined: 11 Mar 2016

Location: Tennessee

Points: 782

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Apr 2019 at 9:40pm Posted: 17 Apr 2019 at 9:40pm |

Dick L wrote: Dick L wrote:

You pretty much ruled out the valve problem. |

Dick, Why do you say this? Are you saying because I'm getting good vacuum at the carburetor that eliminates the likelihood of it being a valve lash problem? If you are I will take your word for it, but I think I'm missing the connection. As for the stop screw, no I haven't touched it. I haven't because I can kill the engine by simply pulling the throttle all the way back. I just throttled it down as slow as I could without killing the engine while I turned the air mix screw. I could get the tractor to die by turning it all the way in. Other than that, little to no change that I could tell. I still think it's a carburetor issue. I think my next move is to take it a part again and clean it. I did this two years ago and put a kit in it. There was one jet I couldn't get out. I just sprayed carburetor cleaner thru it so I thought it would be fine. If this don't do anything I guess I will be forced to check for electrical problems. nella(PA), No I don't believe there was a O-ring or gasket on the oil breather cup. It don't take 3 seconds to kill the engine. You put your hand over that carburetor opening it will die almost instantly. No time to check for smoke. I do see white smoke sometimes while it's running.

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5093

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Apr 2019 at 6:23am Posted: 18 Apr 2019 at 6:23am |

|

First off you can never get the carburetor adjusted properly until you get it to idle with the lever all the way back. Something is wrong with the linkage as well as the stop screw setting if it closes the throttle plate enough for the engine to die at half throttle. My I suggest you remove the carburetor and while looking down at the throttle plate adjust the throttle plate stop screw so it will not close tight leaving about a 1/16" gap so you can see what it looks like.

What I would do if I was adjusting it is to run the tractor as slow as it would run where ever the lever is setting if it had the Zenith carburetor. I would then adjust the stop screw to hold the throttle plate so when moving the lever back the stop screw would keep it from killing the engine. I would then loosen the set screw at the throttle lever and move the lever back and tighten the set screw.

Since the linkage for the MS carburetor is most likely shorter or longer than the Zenith carburetor the linkage from the carburetor to your lever at the steering wheel might be out of adjustment at the cross over arm as well as at the steering wheel.

When you know that the throttle plate can not close when against the stop screw remove the connection at the cross over arm. With the linkage pulled forward and the throttle set wide open the linkage from the carburetor should just drop in or be 1/16" shy from dropping in. If is not in that position the arm needs to be bent until it is. From there you can see where the throttle lever is located and then can be adjusted if needed.

A person can get into the same problems using two different Zenith carburetors as well as they have different lengths levers operating the throttle plate on the back.

I have 5 of these engines running and none have ever had a gasket on the air cleaner cup. They might have had at one time but I have never seen one or put one on.

|

|

Ranse

Orange Level

Joined: 11 Mar 2016

Location: Tennessee

Points: 782

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Apr 2019 at 7:58pm Posted: 20 Apr 2019 at 7:58pm |

|

I took the carburetor a part yesterday and put it in to soak. I was going to put it back together today, but I ended up working at my daughter and son in law's place putting down base boards all day. I did take a look at it. All the paint is blistered and is going to come off. I expected that. I just put it back in the bucket. By the time I get to it tomorrow, it will have been in the solution close to 48 hours. It should be clean, I hope it don't do any harm. I don't believe I should take it out until I'm ready to finish cleaning it up.

|

|

Ranse

Orange Level

Joined: 11 Mar 2016

Location: Tennessee

Points: 782

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Apr 2019 at 8:47pm Posted: 24 Apr 2019 at 8:47pm |

|

I finally did a little more work on the B. I got the carburetor cleaned and back together. I'm telling you, if this carburetor gets any cleaner, someone else will have to do it. It is as clean as I can get it. It probably ain't perfect, but that's the way it is.

I put the carb on and it actually ran worse. It would only run a second or two at first. It would not idle at all, it would only run at half throttle or more. It spit, sputtered, and cut out worse than before. It smoked more and backed fired when the engine died. I even seen fire shoot from the muffler. It never done that before. It did seem to run a little more consistent with the choke pulled out. No way to adjust the carb with the tractor running like that.

I decided to clean the plugs. All four looked really bad. Number one and number three were dry with lots of dry powdery carbon build on them. Number two and four were wet and oily looking. I thought this was odd, but I don't know what it means.

After cleaning the plugs, the tractor ran better. I did as Dick suggested. I set the stop screw were the throttle plate would stay 1/16" open. By doing this I was able to run the tractor with the throttle all the way back (no linkage adjustment done). I then turned the stop screw until the engine died, then turn it back in just a touch. I restarted the engine and attempted to adjust the air mix screw. At times I thought it was helping, other times I couldn't tell.

In short, I'm still clueless. I think the tractor is cutting out to bad to tell what I'm doing to the carburetor. I think I may need to look else where. I bought new points and condenser. Any tips on installing them without screwing it up worse?

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5093

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Apr 2019 at 6:36am Posted: 25 Apr 2019 at 6:36am |

|

Were the jets easy to get out or did you have to heat them? Did you run drill bits with your fingers behind the power jet and down the discharge tube where the holes meet to get the scale out? Did the discharge tube have any of the little holes close to the bottom plugged?

|

|

Ranse

Orange Level

Joined: 11 Mar 2016

Location: Tennessee

Points: 782

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Apr 2019 at 11:26am Posted: 25 Apr 2019 at 11:26am |

Dick, The only jet that was hard to get out was the one below. That was mainly because of where it was at. Every screw driver I had small enough to go thru the hole above it was to small to grab the shoulders of the jet. I ended up grinding down a larger screw driver. I didn't heat anything. I didn't use drill bits, I used a tip cleaner for a cutting torch. The discharge tube I think you are referring to, I run the tip cleaner thru the center. However, that's a big tube and the cleaner wasn't tight. The tiny holes in the bottom part I could see daylight thru them, and I sprayed carb cleaner thru them freely. Everything was disassembled and soak in a bucket of carburetor solution for two days. Then I sprayed with carb cleaner and blew it out again and again. It all seemed free to me. I know its got to be cleaner than before. Like I said, if it gets any cleaner, I'll have to get a professional to do it. It ran worse at first, but I think it may be a little better now than before. It's a long way from being right.

|

|

chaskaduo

Orange Level

Joined: 26 Nov 2016

Location: Twin Cities

Points: 5200

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Apr 2019 at 2:46pm Posted: 25 Apr 2019 at 2:46pm |

|

If you could bum someone else's known to be good carb and try it, it might help you in deciding whether it is the carb or not. Got to be someone near you there in TN.

I myself suspect your coil is breaking down, or your condenser is, or both.

Edited by chaskaduo - 25 Apr 2019 at 2:49pm

|

|

1938 B, 79 Dynamark 11/36 6spd, 95 Weed-Eater 16hp, 2010 Bolens 14hp

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

Ranse wrote:

Ranse wrote: