| Author |

Topic Search Topic Search  Topic Options Topic Options

|

AllisFreak MN

Orange Level Access

Joined: 07 Dec 2009

Location: Minnesota

Points: 1592

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Any tricks for joining baler twine? Topic: Any tricks for joining baler twine?

Posted: 24 May 2016 at 7:33pm |

|

Do any of you crafty old farmers have a good way to join the old roll of square baler twine to the new roll? I always seem to get a broken bale when the twine rolls switch over. My knots are either too big and plug up the knotters or if I try to make them smaller then it doesn't hold. Either way, broken bale. Any tricks to remedy this?

|

|

'49 A-C WD, '51 A-C WD, '63 A-C D17 Series III, 1968 A-C One-Seventy, '82 A-C 6060, '75 A-C 7040, A-C #3 sickle mower, 2 A-C 701 wagons, '78 Gleaner M2

|

|

|

Sponsored Links

|

|

|

norm[ind]

Orange Level

Joined: 29 Oct 2010

Location: bourbon,ind

Points: 2992

|

Post Options Post Options

Thanks(0) Thanks(0)

![Quote norm[ind] Quote norm[ind]](forum_images/quote.png) Quote Quote  Reply Reply

Posted: 24 May 2016 at 7:47pm Posted: 24 May 2016 at 7:47pm |

|

we tird a square knot in the 50s- new holland

|

|

Luke R.

Orange Level

Joined: 11 Sep 2009

Location: SE Iowa

Points: 1262

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 May 2016 at 7:47pm Posted: 24 May 2016 at 7:47pm |

|

Square knot, pull tight, trim tails, never fails

|

|

4-7030's,170G,220FWA,3-220's,210,D21II,D21I industrial,2-200's,3-190's,175D,2-D19D's,D19G,WD45,WD,CA,2-UCont.,5015FWA,917,B110,Gleaner F

|

|

Dan73

Orange Level

Joined: 04 Jun 2015

Location: United States

Points: 6054

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 May 2016 at 7:49pm Posted: 24 May 2016 at 7:49pm |

|

Square knot then when you have it tied roll it between your hands to make it smaller. Someone in here told me that last summer makes a big difference I still have trouble from time to time but alot better luck then before I started doing that.

|

|

KY poorboy

Orange Level

Joined: 16 Aug 2015

Location: West KY

Points: 933

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 May 2016 at 8:05pm Posted: 24 May 2016 at 8:05pm |

|

X2 on the square knot and trim the tails close. Then rub it between your hands some on a square baler, I don't have trouble with just a trimmed square knot on a roller. A square knot is the only knot that I have ever found that will hold. But you will still occasionally have one not tie on a square baler.

By the way,,, I like that,,,"crafty old farmers". LMAO

Edited by KY poorboy - 24 May 2016 at 8:07pm

|

|

Stan R

Orange Level Access

Joined: 03 Dec 2009

Location: MA

Points: 996

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 May 2016 at 8:08pm Posted: 24 May 2016 at 8:08pm |

baling knotThis is what we use and we have no problems with twine bale changes. We do it a bit neater but you get the idea.

Edited by Stan R - 24 May 2016 at 8:26pm

|

|

Pete from IL

Silver Level

Joined: 29 Dec 2009

Location: Beecher IL.

Points: 311

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 May 2016 at 8:41pm Posted: 24 May 2016 at 8:41pm |

|

A square knot. Also look at your needles. If the twine has wore down into the needle with a narrow slot the knots will not be able to go through. Use a die grinder with a 5/16 or 3/8 grinding tip on it and open up the narrow slot. Or new needles.

|

|

SHAMELESS

Orange Level

Joined: 13 Sep 2009

Location: EAST NE

Points: 29486

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 May 2016 at 8:46pm Posted: 24 May 2016 at 8:46pm |

|

wow...Stan...I've never seen a knot done like that....maybe i'll hafta try that!

|

|

thendrix

Orange Level

Joined: 04 Feb 2013

Location: Fairmount GA

Points: 5141

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 May 2016 at 8:49pm Posted: 24 May 2016 at 8:49pm |

Stan R wrote: Stan R wrote:

baling knot

This is what we use and we have no problems with twine bale changes. We do it a bit neater but you get the idea. |

I use a square knot as well but this is pretty interesting

|

|

"Farming is a business that makes a Las Vegas craps table look like a regular paycheck" Ronald Reagan

|

|

Gerald J.

Orange Level

Joined: 12 Sep 2009

Location: Hamilton Co, IA

Points: 5636

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 24 May 2016 at 9:03pm Posted: 24 May 2016 at 9:03pm |

|

When she pulled that overhand knot plus ends run together, it turned into a square knot with a thin second overhand knot making a thin square knot.

What worked for me most of the time was a standard square knot, then I rolled the knot between the palms of my hands with a rolling axis that of the two pieces of twine until there was hardly a lump at the knot location. That went through worn guides and needles as good as the bare twine on my MF-12 baler. I did have to replace worn ceramic guides once in the decade or so that I used it.

Gerald J.

|

|

JC-WI

Orange Level Access

Joined: 11 Sep 2009

Location: wisconsin

Points: 34416

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 May 2016 at 10:00pm Posted: 24 May 2016 at 10:00pm |

|

The knot tied in that video was not neat and clean...

I was taught

how to make those knots when I wasn't big enough yet to move a bale of

hay from the old 76 New Holland baler chute... Well they were about a

hundred pounds and if baling on big windrows so you weren't moving to

fast and dumping them on the ground, about 2/3 of the bales would stand

on their ends.

As for the knot, she didn't 'fluff' the ends real

good, and she did not pass the ends through very far and then you roll

the section between your fingers and then clamp your thumb and index on

the rolled section and hold the it tight then with you little finger

pressing the twin to your hand, pull the other end and work that knot

tight and it will be a clean splice, not all fryed like hers looked in

the vid.

Then some where along the way I learned another type

of knot that works good too, and it is basically a square knot but you

pass the end that sticks forward back down through the knot, but not so

far as to go under the leading loop and pull that tight and roll it

between your fingers and pull again and the following tails don't

bother a bit. and no trimming involved.

As for the wear in the twine guides, the porcelin insulators, I have turned them to get smooth surface again.

As for the needles that have worn slots, they can be filed to open the groove up, but best to use some good rod and weld and peen till the slot is filled. and don't weld them up in one pass, weld, chip, and peen and then let it cool... you can switch to the other needle and work that one and then go back to the first and do it again. Don't weld more than 3 seconds at a time.

|

|

He who says there is no evil has already deceived himself

The truth is the truth, sugar coated or not. Trawler II says, "Remember that."

|

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 54652

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 May 2016 at 4:49am Posted: 25 May 2016 at 4:49am |

Stan R wrote: Stan R wrote:

baling knot

This is what we use and we have no problems with twine bale changes. We do it a bit neater but you get the idea. |

Been tying that one for years. Yes, I like to tie it neater, too. I like about 3/4" ends meshed into each other, roll them back and forth, before pulling the knot tight. The knot will pass through insulators and the knotter, no problems...

|

|

HD6GTOM

Orange Level

Joined: 30 Nov 2009

Location: MADISON CO IA

Points: 6627

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 May 2016 at 8:47am Posted: 25 May 2016 at 8:47am |

|

square knot only on a 14t or 214t JD

|

|

tadams(OH)

Orange Level Access

Joined: 17 Sep 2009

Location: Jeromesville, O

Points: 11142

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 May 2016 at 2:57pm Posted: 25 May 2016 at 2:57pm |

If your needles have slots worn in them braze the slots so that all you have is around hole in the needle.

|

|

Longmeadow Farm

Silver Level

Joined: 30 Jul 2011

Location: Eastern NY

Points: 321

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 May 2016 at 3:38pm Posted: 25 May 2016 at 3:38pm |

|

square knot.. when my baler started having trouble.. I had to dig a little but discovered my hired hands actually didn't know how to tie a square knot. Come to find out, neither of them was a boy scout either.

|

|

steelwheelAcjim

Orange Level

Joined: 06 Dec 2009

Location: Blissfield,Mi

Points: 1257

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 May 2016 at 7:33pm Posted: 25 May 2016 at 7:33pm |

|

My Dad used to tie a square knot, then pound the knot with a hammer on a block of wood. It flattened it enough so it wouldn't get caught on the billhook in the knotter. It worked every time.

|

|

Pre-WW2 A-C tractors on steel wheels...because I'm too cheap to buy tires!

|

|

Gordy

Orange Level Access

Joined: 12 Sep 2009

Location: SWMI

Points: 2533

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 May 2016 at 8:22pm Posted: 25 May 2016 at 8:22pm |

|

Had an Amish guy show me a way that works good for me it is a square knot with the first twist of the knot the right side string goes left to right over the left string the second twist of the knot the left string goes over the right string so it makes the two twists of the knot opposite of each other always works for me.

|

|

“If you can't explain it simply, you don't understand it well enough”

|

|

Gerald J.

Orange Level

Joined: 12 Sep 2009

Location: Hamilton Co, IA

Points: 5636

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 May 2016 at 9:09pm Posted: 25 May 2016 at 9:09pm |

In a proper square knot each line and its tail are adjacent. Yes they twist in opposite directions. In a granny knot that is considerably weaker, they are not adjacent.  Square knot.  Granny knot. Gerald J.

Edited by Gerald J. - 25 May 2016 at 9:18pm

|

|

AllisFreak MN

Orange Level Access

Joined: 07 Dec 2009

Location: Minnesota

Points: 1592

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 May 2016 at 9:24pm Posted: 25 May 2016 at 9:24pm |

|

Holy cow, lots of good info about knots. I'll try 'em out until I find one that works for me. Thanks for all the info.

|

|

'49 A-C WD, '51 A-C WD, '63 A-C D17 Series III, 1968 A-C One-Seventy, '82 A-C 6060, '75 A-C 7040, A-C #3 sickle mower, 2 A-C 701 wagons, '78 Gleaner M2

|

|

desertjoe

Orange Level Access

Joined: 23 Sep 2013

Location: New mexico

Points: 13743

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 May 2016 at 10:21pm Posted: 25 May 2016 at 10:21pm |

YES,,,,!!!!this is a great subject bout knots,,  The knot I would like to learn is not so much a knot but a way of looping the end of a rope around a pipe that will not slip and actually gets tighter as you pull on it,,,,?? On the twine,,,I don't know if it would work,,but in my years in the oil fields, there were some folks that knew how to splice two ends of steel cable by unraveling each end bout a foot and then rewinding both ends together in a certain way and the finished product was no bigger around than either end before but the splice was just as strong as the original. Most of those dudes guarded their craft with a vengeance,,,anybody here seen that,,??

|

|

Gerald J.

Orange Level

Joined: 12 Sep 2009

Location: Hamilton Co, IA

Points: 5636

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 May 2016 at 10:02am Posted: 26 May 2016 at 10:02am |

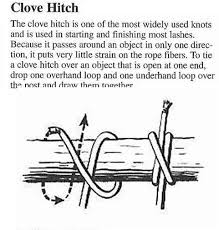

A bowline knot is strong to loop around a pipe or to make a loop in the end of a rope then run the free end of the rope around the pipe and through the loop and pull it tight. The standard knot for lifesaving operations. I used it to make and end loop on baler twine for retying bales with broken twine.  A clove hitch is another good pipe connection.  Then there's a more secure clove hitch plus two half hitches.  I recall the clove hitch plus a half hitch or two was the recommended tie for a boat line to a dock post when I took the course on small boat seamanship when I was in grade school. The Boy scout guide book on knots was encyclopedic back then and probably still is. Gerald J.

|

|

Dan73

Orange Level

Joined: 04 Jun 2015

Location: United States

Points: 6054

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 May 2016 at 12:11pm Posted: 26 May 2016 at 12:11pm |

http://howtowilderness.com/basic-knots/That is a pretty good site for knots of all who are interested. You can do amazing things with lashing it just takes longer then you might think.

|

|

desertjoe

Orange Level Access

Joined: 23 Sep 2013

Location: New mexico

Points: 13743

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 May 2016 at 2:30pm Posted: 26 May 2016 at 2:30pm |

Hey Gerald,,,Thanks Guy,!!!,,the clove hitch is the one I was thinkin bout and I needed to use one the other day but could not remember how to do it,,,but lookin at your pic,,,it seems so simple,,I'm kinda ashamed now,,,  I like the clove hitch with the extra half hitch for extra hold,,,many thanks,,,,  Back when I used to do a lot of fishing,,,I used to use an "Improved Clinch" knot on the lure eyes and was a very good knot,,just never tried it on rope or,,,???

Edited by desertjoe - 26 May 2016 at 2:33pm

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

Stan R wrote:

Stan R wrote:

Square knot.

Square knot.

The knot I would like to learn is not so much a knot but a way of looping the end of a rope around a pipe that will not slip and actually gets tighter as you pull on it,,,,??

The knot I would like to learn is not so much a knot but a way of looping the end of a rope around a pipe that will not slip and actually gets tighter as you pull on it,,,,??