| Author |

Topic Search Topic Search  Topic Options Topic Options

|

nowaktj

Orange Level

Joined: 13 Dec 2009

Location: Elk River, MN

Points: 735

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Allis UC Backlash on Ring and Pinion Topic: Allis UC Backlash on Ring and Pinion

Posted: 20 Jun 2023 at 10:29am |

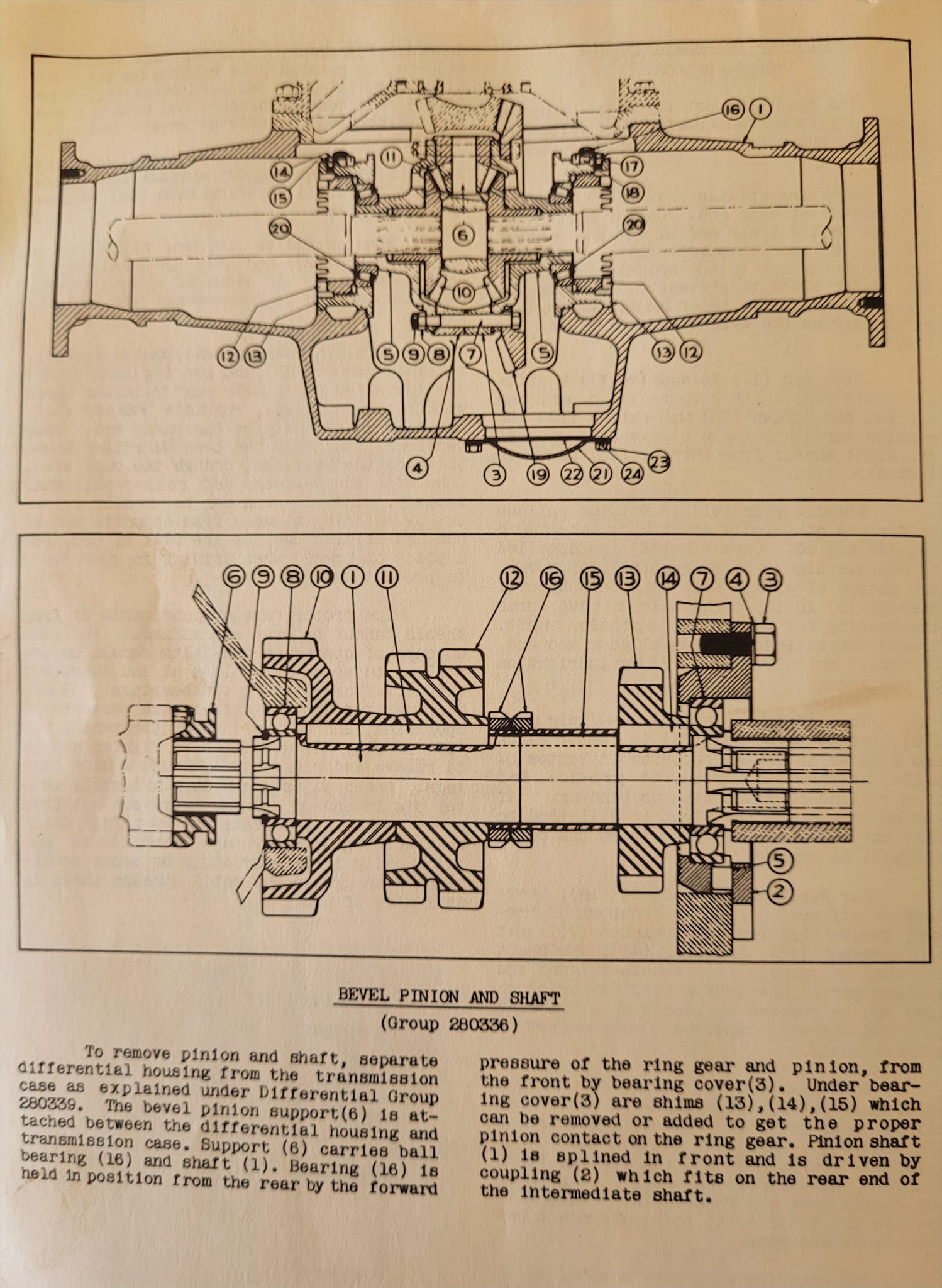

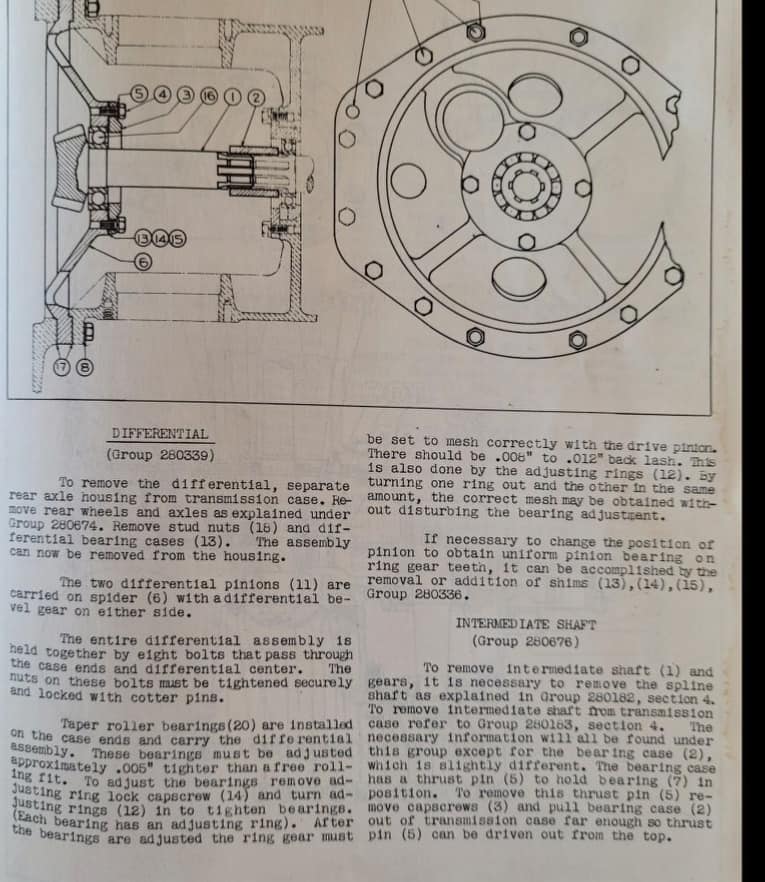

Anyone on here try adjusting the backlash on the ring and pinion of an Allis U? The adjusting nuts are used to push the races but my races appear to not budge one bit (See 1st image pictorial/2nd image text)

Edited by nowaktj - 20 Jun 2023 at 10:40am

|

|

D19D, D17D, WD, WC, Snobee, #83 Plow, SC Blade, 14' disk, 400 series planter, B , Terra Tiger, M Dozer w/Baker Blade, TL-12, 42S Grader, G

|

|

|

Sponsored Links

|

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88671

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Jun 2023 at 12:40pm Posted: 20 Jun 2023 at 12:40pm |

|

I would back one side out a couple turns,, then remove the nut on the other side.. Then PUNCH the race with a brass drift to get it to move.. When NEW, the nuts probably will push the race back and forth.. After setting for 70 years, a little SHOCK LOAD should help. ... Once they move a little, they will probably adjust with the nuts.

|

|

Like them all, but love the "B"s.

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8688

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Jun 2023 at 5:23pm Posted: 20 Jun 2023 at 5:23pm |

|

I can't tell how that's made but if it has brg caps tightened down on races,you may need to crack them loose to get things to move. Not floppy just not tight.

|

|

TramwayGuy

Orange Level Access

Joined: 19 Jan 2010

Location: Northern NY

Points: 11784

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Jun 2023 at 10:33pm Posted: 20 Jun 2023 at 10:33pm |

|

The cups will move. Like Steve says, they’ve been there a long time in one spot and will take a bit of encouragement at first.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22180

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Jun 2023 at 6:47am Posted: 21 Jun 2023 at 6:47am |

|

Are you intending on tightening up the gear backlash ?? Generally, decreasing backlash on old/worn gears like that will guarantee a noisey howl when in road gear, that may not have been there before. Just sayin........

|

|

nowaktj

Orange Level

Joined: 13 Dec 2009

Location: Elk River, MN

Points: 735

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Jun 2023 at 9:40am Posted: 21 Jun 2023 at 9:40am |

Long story...this was a sugar cane tractor. I flipped the differential around to get the forward gears in the normal forward position. That is the reason I want to reduce the backlash to the books spec.

In doing the flip, I torqued the 8 bolts that retain the differential to what I thought was the correct torque. I think I may have tightened them too much and that is preventing the races from moving.

I tried moving the races with a drift punch and they have no intent on moving!

I wonder what is the "correct" torque on those 8 nuts??

Edited by nowaktj - 21 Jun 2023 at 9:59am

|

|

D19D, D17D, WD, WC, Snobee, #83 Plow, SC Blade, 14' disk, 400 series planter, B , Terra Tiger, M Dozer w/Baker Blade, TL-12, 42S Grader, G

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88671

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Jun 2023 at 2:12pm Posted: 21 Jun 2023 at 2:12pm |

I dont see how torquing the bolts would effect the backlash or bearing position.. If the bearings are worn a little, its possible the BIG NUT is bottoming out on the case before it pushes on the bearing race ?

If you flipped the gear, you had to have the bearings out ?? Didnt you take out retainer #13 ?? If they dont move in far enough, then i would check the nut bottoming out on the case.... no good reason for the bearing race to not slide right in toward the bevel gear, unless it is hitting something ?

Edited by steve(ill) - 21 Jun 2023 at 2:14pm

|

|

Like them all, but love the "B"s.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)