| Author |

Topic Search Topic Search  Topic Options Topic Options

|

jollymon68

Bronze Level

Joined: 02 Jun 2014

Location: georgia

Points: 186

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Allis 160 Topic: Allis 160

Posted: 16 Dec 2019 at 10:39pm |

|

Guys got an issue that has got me stumped. Replaced the head on my 160 and now im trying to find top dead center on number one cylinder to set the valves. Any suggestions or tips would be great

|

|

|

Sponsored Links

|

|

|

Wes (VA)

Orange Level

Joined: 12 Sep 2009

Location: Elkton, VA

Points: 510

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 17 Dec 2019 at 6:23am Posted: 17 Dec 2019 at 6:23am |

|

Youll want to pull injector and watch rocker arms. When you rotate crank with a wrench, feel for compression coming out, both rockers should be loose when the air stops pushing out of the injector hole on #1 cylinder. There should be timing pointer to get it exact.

|

|

jollymon68

Bronze Level

Joined: 02 Jun 2014

Location: georgia

Points: 186

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Dec 2019 at 7:30am Posted: 19 Dec 2019 at 7:30am |

|

Ok...I got everything bled. Now cannot get it to fire up. Running 400lbs of compression in all three cylinders but still nothing not even a puff of smoke. The head was replaced with a new one with the valves preinstalled. Fuel is going to the injectors but nothing. She ran before the head was replaced. Im not sure where I went wrong though. I think I have the timing right but cannot find a place to check the timing. Injector pump was never removed from the tractor either.

Edited by jollymon68 - 19 Dec 2019 at 7:33am

|

|

lowell66dart

Orange Level

Joined: 10 Jul 2013

Location: Paulina La.

Points: 964

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 19 Dec 2019 at 7:33am Posted: 19 Dec 2019 at 7:33am |

|

I have had a few 160's and they are one of the worst to bleed air out of. I plumb in a temporary inline pump to get it to start. They actually make one for diesel. Got it on Amazon.

|

|

AC 6080 (8030,7060,200,175,D-17HC, 6040,160,6140 all gone) Farmall 1066 & 656 Hi-Clear (for sale), White 2-62 High Clearance, JD 4255 Hi Clear.

|

|

jollymon68

Bronze Level

Joined: 02 Jun 2014

Location: georgia

Points: 186

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Dec 2019 at 7:37am Posted: 19 Dec 2019 at 7:37am |

|

Do you remember the name of the pump you bought

|

|

injpumpEd

Orange Level Access

Joined: 13 Sep 2009

Location: Walnut IL

Points: 5148

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Dec 2019 at 8:15am Posted: 19 Dec 2019 at 8:15am |

|

If it's not smoking, it's not delivering fuel through the injectors. Whether it's out of time or not. If pump wasn't removed from engine, then it should not have gotten out of time all by itself. These have a 3 bolt drive gear with a dowel, and a chisel mark on the mountingflange of pump. So as long as the pump gear is in it's proper location, timing isn't your issue. As said above, CAV pumps can be tough to bleed. There is a bleeder screw right above the nametag. Takes a 5/16" wrench. If it still won't deliver fuel, the metering valve or pumping plungers could be stuck, and in that case it would be best to have it properly serviced. My bet is it has been a while since it last ran. Were injectors tested while head was off? I've seen people pull a head off and not pull the injector, and not even pay attention that the nozzle tips protrude through the head. Usually the tips get damaged and require injectors get rebuilt. If this is the case, the tips could all be smashed shut. Lots of issues possible here. Good luck!

|

|

210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers!

|

|

jollymon68

Bronze Level

Joined: 02 Jun 2014

Location: georgia

Points: 186

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Dec 2019 at 8:31am Posted: 19 Dec 2019 at 8:31am |

|

I did remove the injectors from the tractor before pulling the head. I had one replaced but the other I did not. I will get them tested but they were good when I took them off. I only replaced the one that was damaged due to me dropping a weight on it. the others were put in boxes by themselves. All the injector lines were delivering fuel to the injectors. When I hooked up the lines I get some spray of fuel around the injectors. I'll have to check the tips for any damage. Not a lot of diesel repair shops in my area unfortunately. Thanks

|

|

lowell66dart

Orange Level

Joined: 10 Jul 2013

Location: Paulina La.

Points: 964

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 19 Dec 2019 at 4:57pm Posted: 19 Dec 2019 at 4:57pm |

Here you go.

Handy little sucker.

|

|

AC 6080 (8030,7060,200,175,D-17HC, 6040,160,6140 all gone) Farmall 1066 & 656 Hi-Clear (for sale), White 2-62 High Clearance, JD 4255 Hi Clear.

|

|

BrianC

Orange Level Access

Joined: 16 Jun 2011

Location: New York

Points: 1619

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Dec 2019 at 7:05am Posted: 20 Dec 2019 at 7:05am |

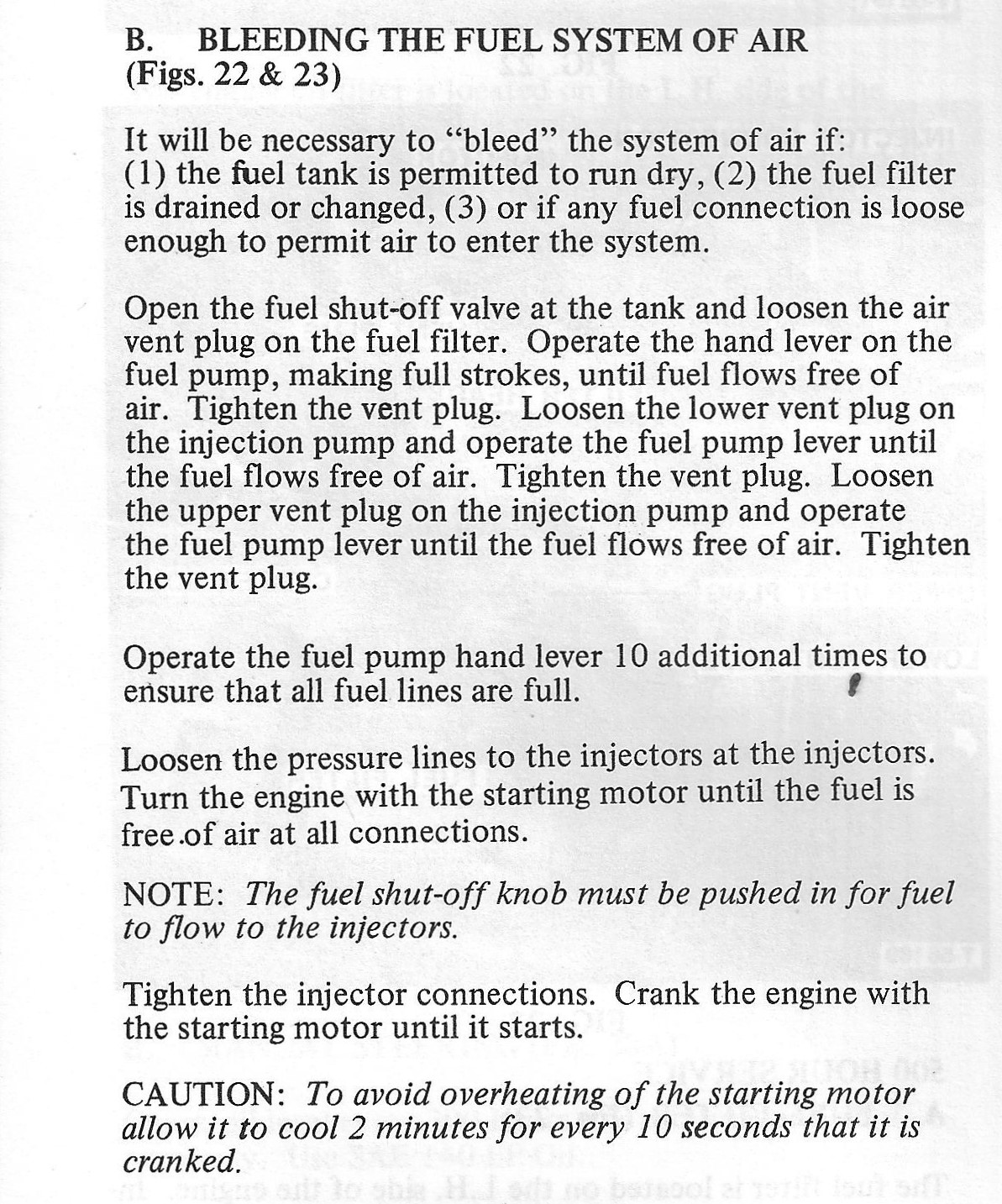

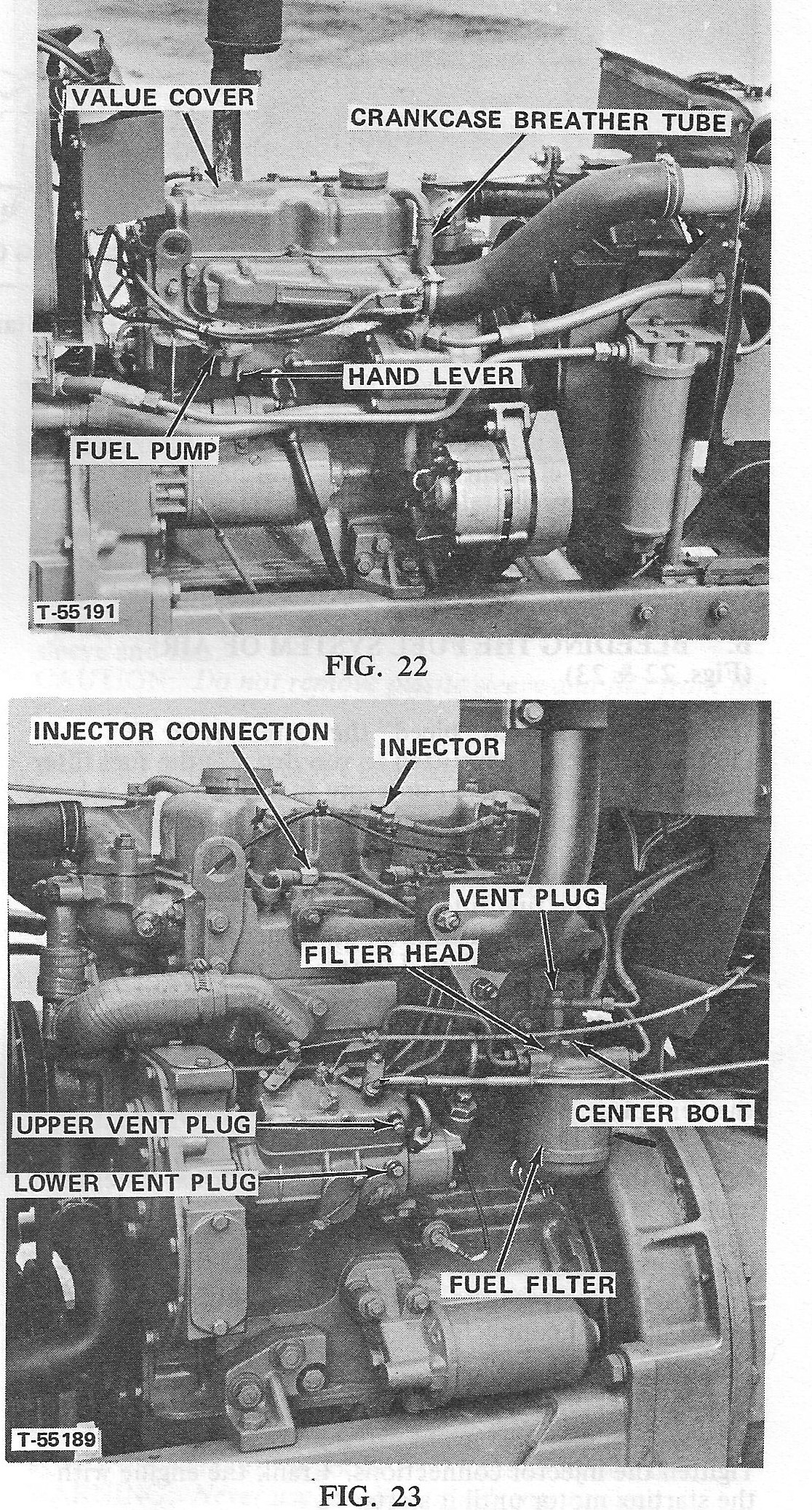

160 fuel system bleed procedure from the owners manual. When you try to manually pump the fuel lift pump handle and it doesn't seem like it is pumping, or has enough stroke to pump, rotate the engine some to get the camshaft eccentric off the high point. I agree doing this a time or two, out in the field, trains you to watch the fuel gauge.

Edited by BrianC - 20 Dec 2019 at 4:51pm

|

|

jollymon68

Bronze Level

Joined: 02 Jun 2014

Location: georgia

Points: 186

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Dec 2019 at 3:01pm Posted: 20 Dec 2019 at 3:01pm |

|

Thanks OrangeC that is a much better picture for me to go by...

|

|

BrianC

Orange Level Access

Joined: 16 Jun 2011

Location: New York

Points: 1619

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 20 Dec 2019 at 4:52pm Posted: 20 Dec 2019 at 4:52pm |

|

I just updated my post, I had forgot to add the instructions.

|

|

jollymon68

Bronze Level

Joined: 02 Jun 2014

Location: georgia

Points: 186

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Dec 2019 at 9:50pm Posted: 30 Dec 2019 at 9:50pm |

|

Gentlemen thanks for all the help with the tractor. Was able to bleed the whole system thanks to OrangeC for the diagrams and instructions. Unfortunately that was not the issue with the tractor. Apparently when I removed the head I should have measured the height of the three head studs that are just under the injector connections. These were just a bit higher than the previous studs and they were preventing the injectors from completely seating. I ground the three studs down a bit, reinstalled the injectors and she fired right up. Now I gotta fix all the little fuel line leaks.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)