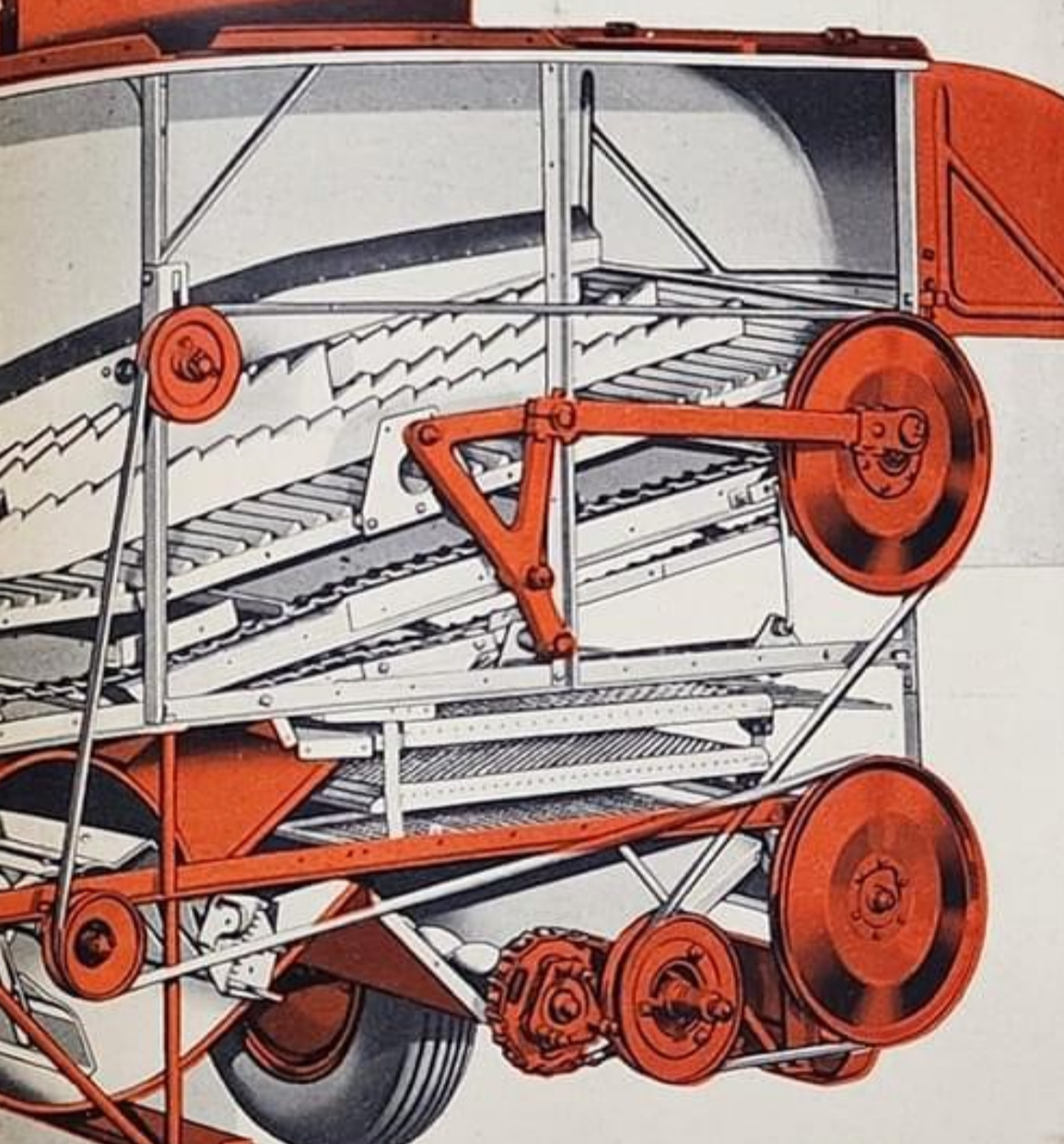

As others noted, it's a standard B-section belt - any Napa or industrial supply can order one. And the 66 does have a twist in it. It's also important to get the twist the correct way, or it'll keep walking off (see the diagram posted by dkatttau above, and note how the belt span between the fan and cross-auger is in front of the span from the slip-clutch to the shaker drive).

If it still keeps coming off, some other things to keep in mind:

- The two largest sheaves/pulleys are rather thin and chintzical - easily bent. If either of them is slightly bent/bowed, it won't keep the belt tracked and it will keep popping off. It's easy enough to bend them back because they're so thin and flimsy. And if you want an upgrade, buy a B-section sheave the same diameter with a weld-in hub from TSC: The ones from TSC (or anywhere else, for that matter) are much more rigid/stiff than the original Allis ones.

- On the 60 and 66, the large span between the tensioner and shaker drive can be a problem (and a rather poor design). A home-brewed flat tensioner/idler at the mid-span helps calm the belt down and stops it bouncing around and wanting to walk off. I've added idlers there to both my 66's.

- If it's been stored for a long time with tension on the belt, the twist may have become semi-permanent on the belt, and may be causing issue as it tries to go around the sheaves and un-twist as needed. You may need a new belt, but can hopefully just keep working the old belt to get it more pliable.

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)