| Author |

Topic Search Topic Search  Topic Options Topic Options

|

keith ashley

Bronze Level

Joined: 08 Nov 2011

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: ALIC B 3POINT LINKAGE Topic: ALIC B 3POINT LINKAGE

Posted: 09 Nov 2011 at 1:24am |

|

CAN ANY ONE HELP? I HAVE HYDRO LICKS FITTED TO ALICE B THAT I AM REBUILDING AS I AM IN THE UK. ITS HARD TO FIND SOME ONE TO HELP AS THEY ARE AS RARE AS HENS TEETH.THE PROBLEM IS THE ARMS ONLY GO UP VERY SLOWLY I HAVE CHANGED THE OIL TO HYDROLICK, THAT'S MADE NO DIFFERENCE I FILLED IT TO THE OVER FLOW PLUG BUT IT SAYS THAT THERE SHOULD BE 7 QUARTS 1 QUART TO POWER THE SYSTEM CAN ANY ONE OUT THERE GIVE ME SOME ADVICE ON HOW WE CAN MAKE IT WORK FASTER .KEITH

|

|

|

Sponsored Links

|

|

|

TramwayGuy

Orange Level Access

Joined: 19 Jan 2010

Location: Northern NY

Points: 11799

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Nov 2011 at 6:12am Posted: 09 Nov 2011 at 6:12am |

|

If you are using a standard (low pressure type) hydraulic cylinder/ram, 3 inches in diameter, you will have a problem because the flow out of the B pump is very low. Change the cylinder to the smallest diameter you can find.

|

|

CTuckerNWIL

Orange Level

Joined: 11 Sep 2009

Location: NW Illinois

Points: 22825

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Nov 2011 at 9:22am Posted: 09 Nov 2011 at 9:22am |

|

If you use a standard B hydraulic cylinder, cycle time should be OK. If you have an aftermarket cylinder, the bore is probably way to big for the high pressure low volume pump and will always be slow. You basically have 3 choices. Get the proper sized cylinders( which may limit your lifting capacity) , live with it slow , or add a live hydraulic system to the tractor.

Share so pictures of your set-up including pictures of the cylinders.

|

|

|

|

keith ashley

Bronze Level

Joined: 08 Nov 2011

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Nov 2011 at 2:57pm Posted: 13 Nov 2011 at 2:57pm |

|

Hi there thanks for advise but what size is a standard for the a/b as the one that was sent is one with the 4 long bolts could you tell me what size ram i would need to use on lifting a plough?regards Keith

|

|

CTuckerNWIL

Orange Level

Joined: 11 Sep 2009

Location: NW Illinois

Points: 22825

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Nov 2011 at 8:00pm Posted: 13 Nov 2011 at 8:00pm |

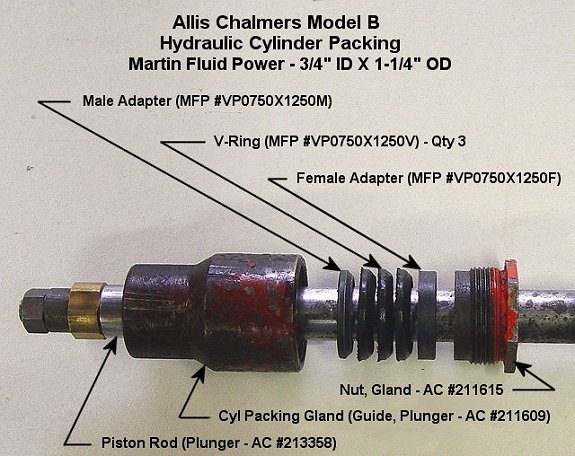

Here is the factory cylinder. The rod is approximately 3/4 of an inch in

diameter and there is no piston on the rod. If you have a 2,3, or 4

inch tie bar cylinder, it will be very slow acting because of the volume

of oil needed to extend the cylinder.

|

|

|

|

keith ashley

Bronze Level

Joined: 08 Nov 2011

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Nov 2011 at 2:36am Posted: 14 Nov 2011 at 2:36am |

|

I suppose they are as rare as hens teeth what kind of weight could they lift if we managed to get one??and how would it work on the new hitch? could you recommend a modern equivalent failing that is there some way i could i modify it thanks again for all your help as you have probably gathered i am no mechanic and your input is most helpful Regards Keith

|

|

Charlie175

Orange Level

Joined: 11 Sep 2009

Location: Shenandoah, VA

Points: 6369

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Nov 2011 at 5:25am Posted: 14 Nov 2011 at 5:25am |

The UK version of the B had a factory 3 point system which is different than the aftermarket units over here (If this one has the original 3 point)

|

|

Charlie

'48 B, '51 CA, '56 WD45 '61 D17, '63 D12, '65 D10 , '68 One-Ninety XTD

|

|

RockyBottomFarm

Orange Level

Joined: 16 Oct 2011

Location: Fall Creek WI

Points: 253

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Nov 2011 at 5:51am Posted: 14 Nov 2011 at 5:51am |

|

very nice cylinder pic! I now have 4 factory cylinders for my B. last night I installed the factory hydraulic lever and linkage, and factory hydraulic switching valve for 52 model plows (left and right). anybody ever put new packing or seals in thhe origonal cylinders?? I would like to go through a couple of my cylinders at somepoint. and what would a UK 3 pt look like?????

|

|

38 & 41 B, sickle mower, 2 way plows, rear field cultivator, 2 row drill planter

40 Combine

66 Combine

Roto Baler

|

|

keith ashley

Bronze Level

Joined: 08 Nov 2011

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Nov 2011 at 6:02am Posted: 14 Nov 2011 at 6:02am |

Click to enlarge

Click to enlarge

3 Point hitch adaptor for Allis Chalmers Models B an

|

|

keith ashley

Bronze Level

Joined: 08 Nov 2011

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Nov 2011 at 6:06am Posted: 14 Nov 2011 at 6:06am |

|

As you can see this is what i have on my uk model and you can see the ram as that's the type i have installed.would a new pump be a better option ??

|

|

CTuckerNWIL

Orange Level

Joined: 11 Sep 2009

Location: NW Illinois

Points: 22825

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Nov 2011 at 8:45am Posted: 14 Nov 2011 at 8:45am |

Keith, All kinds of things could be and have been done with adding "live" hydraulics to the B. I have seen a belt driven power steering unit added running off the fan belt and front mount hydraulic pumps run off the crankshaft. B cylinders should be available, a lot of them were made. Heck, I would bet you could remove the original pump, add a unit from a CA and get higher volume. Rocky Bottom, I have made a new cylinder rod and replaced the chevron packings in a B cylinder. It's not hard at all. The hardest part to explain is the fact the packings need to weep a little oil or they will self destruct. They aren't seals as such. The pictures I found by doing a google search.

Edited by CTuckerNWIL - 14 Nov 2011 at 8:47am

|

|

|

|

Lance/SC

Orange Level

Joined: 14 Sep 2009

Location: Lexington, SC

Points: 411

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Nov 2011 at 11:26am Posted: 14 Nov 2011 at 11:26am |

|

Keith, the Cross 3 point conversion is the one I bought from OK Tractor back around 2003. I used the same cylinder the picture shows and it performed much better than that small one that came on my 1948 B. Later on I purchased an L-59 belly mower, put a two way valve under the seat and used the small cylinder to raise and lower the mower. It worked well until the tractor spun a bearing. That was 8 years ago and all I have done is pull the oil pan.

I never claimed to work fast. LOL

Edited by Lance/SC - 14 Nov 2011 at 11:29am

|

|

CTuckerNWIL

Orange Level

Joined: 11 Sep 2009

Location: NW Illinois

Points: 22825

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Nov 2011 at 1:24pm Posted: 14 Nov 2011 at 1:24pm |

|

After reading Lance's post, I might think your pump isn't performing properly.

|

|

|

|

keith ashley

Bronze Level

Joined: 08 Nov 2011

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Nov 2011 at 1:55pm Posted: 14 Nov 2011 at 1:55pm |

|

Thanks for you help I shall have to give it some thought on which way to jump I did think about a different pump I know if i change the ram for a smaller one the lifting capacity will be lost. I only wanted to put a single furrow plough behind it? but over here there are very, very ,few Alice b `s with hydrolick s so i just cant have a look? any way thanks again guys and if you come up with any more advice please don't hesitate to pass it on.Regards Keith

|

|

keith ashley

Bronze Level

Joined: 08 Nov 2011

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Nov 2011 at 1:57pm Posted: 14 Nov 2011 at 1:57pm |

|

Thanks again for your advice any more please send it on Regards Keith

|

|

joegrgraham

Silver Level

Joined: 12 Nov 2009

Location: Wiltshire, UK

Points: 92

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Nov 2011 at 2:55pm Posted: 14 Nov 2011 at 2:55pm |

|

Keith, looking at your pic, that is not a UK factory fit system, looking at the welding, it looks like it is a homemade system. If that is the case, there is no telling the origins of the ram. Is it running the standard B pump? As others have said, either the ram is too big for the pump, or there may be an issue with the pump.

|

|

If it seems like a good idea, do it. It's easier to apologise than to get permission.

|

|

keith ashley

Bronze Level

Joined: 08 Nov 2011

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Nov 2011 at 4:46pm Posted: 14 Nov 2011 at 4:46pm |

|

No it was shipped over from the States i bought it with the tractor the guy had never unpacked it ,its getting a bit confusing as some one says its the pump while others say its the ram, i will strip the pump down and have a good examination of it ,trouble is trying to find a ram that will work well with the pump and give me the strength for the 3 point hitch

|

|

keith ashley

Bronze Level

Joined: 08 Nov 2011

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Nov 2011 at 2:10pm Posted: 15 Nov 2011 at 2:10pm |

|

Hi Guys a bit more advice if you have it. Its a normal twin cylinder pump and what i have been asked to ask you is what should the flow be through the pump pr min if the engine is running at 1000rpm we are hopping this will determine if both cylinders are working correctly. keith

|

|

SteveC(NS)

Orange Level

Joined: 12 Oct 2009

Location: Nova Scotia

Points: 663

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Nov 2011 at 2:32pm Posted: 15 Nov 2011 at 2:32pm |

Keith, You posted a picture of your 3 pt lift and it showed

a hydraulic cylinder considerably larger than the original AC B ram posted by CW Tucker.

It is normal that the B pump will take considerably

longer to displace a considerably larger volume. There is most probably nothing

wrong with the standard two piston pump on your B. It is a small displacement

high pressure pump it is going to be slower than one pressurizing a small

displacement ram that was originally supplied with AC B lift.

|

|

JimD

Orange Level

Joined: 11 Sep 2009

Location: Mounds, OK

Points: 2116

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Nov 2011 at 2:49pm Posted: 15 Nov 2011 at 2:49pm |

Since the picture looks to be from our website, I'll jump in. If it's the same ram as sold with our kits, it cycles reasonably quickly. Pretty short stroke to complete the cycle for our hitch. If it's another ram, then it could likely be setup for a much larger volume of fluid and yes, it would take a long time to cycle. How long in seconds does it take to get from full droop to top? With a load, and you hear it lug the engine when lifting? Any data on the ram at all?

|

Owner of OKtractor.com PM for an instant response on parts. Open M-F 9-6 Central. We have new and used parts. 877-378-6543

|

|

Tony.Or

Orange Level

Joined: 18 Mar 2010

Location: Oregon

Points: 1498

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Nov 2011 at 5:07pm Posted: 15 Nov 2011 at 5:07pm |

Keith !! No info on hyd flow, but found Pop off pressure at pump is supposed to be 3,200 Psi. Just like we figured.

Would be interesting to swap out the hyd cyl for a smaller dia one.

This is 1st hitch anyone has said anything about speed. Bet you have a weak pump. Tony

|

|

|

|

Scott(SC)

Orange Level

Joined: 11 Sep 2009

Location: Starr, SC

Points: 397

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Nov 2011 at 6:53pm Posted: 15 Nov 2011 at 6:53pm |

|

Keith, I replace the ram on my B with one off of a CA. The stroke is the same, but a bigger diameter. I'm only using 1 ram/cylinder and the arm it hooks to is a lot shorter than yours. Mine lifts pretty quick and strong.

|

|

CTuckerNWIL

Orange Level

Joined: 11 Sep 2009

Location: NW Illinois

Points: 22825

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Nov 2011 at 7:05pm Posted: 15 Nov 2011 at 7:05pm |

|

Scott touched on a point I was thinking of looking at the 3 point picture. If the connection between the rock shaft and the cylinder could be shortened, it would speed up you lift time using that cylinder.

|

|

|

|

keith ashley

Bronze Level

Joined: 08 Nov 2011

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Nov 2011 at 1:14am Posted: 16 Nov 2011 at 1:14am |

|

The ram id a HY- SPEC 20 AGU08 ASAE

|

|

SteveC(NS)

Orange Level

Joined: 12 Oct 2009

Location: Nova Scotia

Points: 663

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Nov 2011 at 2:34pm Posted: 16 Nov 2011 at 2:34pm |

What's the Dia. and stroke on the stock ram? From what I learned the HYS 20AGU08-ASAE-10 2X8 is 2" bore X 8" stroke. 2" bore means 3.14 sq.ins. that times 8 equals 25.12 cu.ins. If the stock ram is 1" D. that would mean .785 sq.ins. times 8 equals 6.28 cu.ins or 1/4 of the 2" bore cyl. So, the larger cyl. would take 4 times as long to extend than the smaller one. If it takes more time than that I would say yes there must be something wrong with the pump. I think the 2 pistons in the pump work in parallel for volume as opposed to in series for pressure, so if one piston is stuck the output volume of the pump would be halved so now we're looking a 8 times as long to pump up the lift. Keith, is there a noticeable pulse as the lift rises? There usually is some pulsing but if one piston were stuck the pulsing would be more noticeable and half as frequent.

Edited by SteveC(NS) - 16 Nov 2011 at 2:36pm

|

|

CTuckerNWIL

Orange Level

Joined: 11 Sep 2009

Location: NW Illinois

Points: 22825

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Nov 2011 at 4:46pm Posted: 16 Nov 2011 at 4:46pm |

SteveC(NS) wrote: SteveC(NS) wrote:

What's the Dia. and stroke on the stock ram?From what I learned the HYS 20AGU08-ASAE-10 2X8 is 2" bore X 8" stroke.2" bore means 3.14 sq.ins. that times 8 equals 25.12 cu.ins. If the stock ram is 1" D. that would mean .785 sq.ins. times 8 equals 6.28 cu.ins or 1/4 of the 2" bore cyl. So, the larger cyl. would take 4 times as long to extend than the smaller one. If it takes more time than that I would say yes there must be something wrong with the pump. I think the 2 pistons in the pump work in parallel for volume as opposed to in series for pressure, so if one piston is stuck the output volume of the pump would be halved so now we're looking a 8 times as long to pump up the lift. Keith, is there a noticeable pulse as the lift rises? There usually is some pulsing but if one piston were stuck the pulsing would be more noticeable and half as frequent. |

The stock ram is a tube with the rod going through it. There is no piston fit to a bore. I don't think the rod is more than 3/4 of an inch so you could stretch your differential of cycle time by some. Good point about the pulsing, it could very well have a piston stuck.

|

|

|

|

keith ashley

Bronze Level

Joined: 08 Nov 2011

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Nov 2011 at 5:35pm Posted: 16 Nov 2011 at 5:35pm |

|

After striping down the pump we found that a piece of spring had broken off and was jamming the ball in the valve chamber when put back it worked a lot better and yes there was some pulsing before strip down and after? but it cleared i think it was just clearing the air,as it seems ok now??But i feel like you guys that the ram is far to big and if poss could you recommend one that would poss give me that quicker lift and stronger enough to use with a plough . have done a small vid if i can get it on the forum ,and just to to say thanks again for all your help and input Keith

|

|

SteveC(NS)

Orange Level

Joined: 12 Oct 2009

Location: Nova Scotia

Points: 663

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Nov 2011 at 6:38pm Posted: 16 Nov 2011 at 6:38pm |

Charlie, I know what a B ram is that's why I tried to distinguish between a hydraulic ram and a hydraulic cylinder. I no longer have (or can find) mine so I guessed at an approx. Dia. All water under the bridge as it seems Keith has found his problem.

|

|

SteveC(NS)

Orange Level

Joined: 12 Oct 2009

Location: Nova Scotia

Points: 663

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Nov 2011 at 6:45pm Posted: 16 Nov 2011 at 6:45pm |

Keith, If your set-up is now performing to spec congratulations! I can't imagine why you'd want to go to further expense and work to gain a few seconds (or fractions there of). Your quest for "and stronger enough to use with a plough" is unwarranted, your present set up is WAY stronger (lifting force) than stock so enjoy it! And I'm glad you rectified your pump problem. Steve

|

|

CTuckerNWIL

Orange Level

Joined: 11 Sep 2009

Location: NW Illinois

Points: 22825

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Nov 2011 at 8:39pm Posted: 16 Nov 2011 at 8:39pm |

I wouldn't say it is performing well. Anybody know the gallons per minute, or is it pints per hour of the B pump? If the pump is putting out what it is supposed to, I would replace the arm between the rock shaft and the cylinder with a shorter one, just long enough that the cylinder doesn't bind on the linkage. Here is a video after the pump was fixed.

Edited by CTuckerNWIL - 16 Nov 2011 at 8:55pm

|

|

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

SteveC(NS) wrote:

SteveC(NS) wrote: