| Author |

Topic Search Topic Search  Topic Options Topic Options

|

BrianC

Orange Level Access

Joined: 16 Jun 2011

Location: New York

Points: 1619

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Advice repair this C fender Topic: Advice repair this C fender

Posted: 31 Jan 2012 at 12:35am |

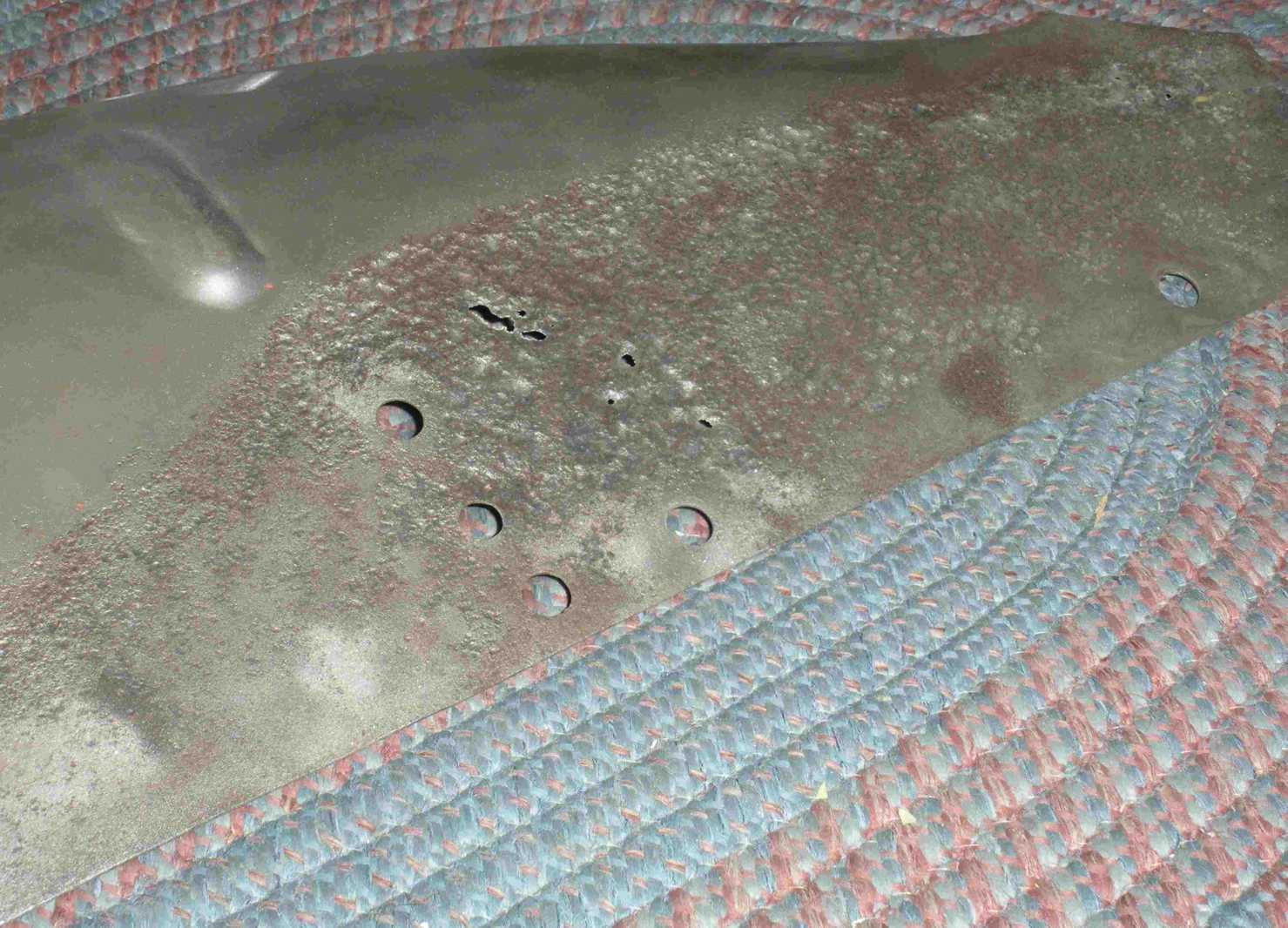

Need advice, approach to take to repair this fender. Rusted thru, pitted badly. C fenders are not on the market new. The B fenders are too different in my opinion.

|

|

|

Sponsored Links

|

|

|

Don(MI)

Orange Level

Joined: 15 Sep 2009

Location: Michigan

Points: 3893

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Jan 2012 at 5:06am Posted: 31 Jan 2012 at 5:06am |

Hmmm....thats a tough one. But it can be fixed, just depends on how much time you want to put into it.

I can tell you what we did with the WC fenders in a similar situation. We actually cut out square spots in the metal where it was rusted through, and TIG welded new metal in. Also, replace the inner fender walls with new metal.

As far as the pitting. I am not sure, you can fill that with filler, but that side of the fender bolts to the frame rail. I am not sure how that would hold up over the years, if it is tight on that side, there is a chance that could damage it.

Make sure you blast it well, looks like maybe you have in the past. Also, it would not hurt to zinc coat the steel, to help seal the metal and keep rust out.

Edited by Don(MI) - 31 Jan 2012 at 5:07am

|

|

Galatians 5:22-24

"I got a pig at home in a pen and corn to feed him on, All I need is a pretty little girl to feed him when I'm gone!"

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5087

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Jan 2012 at 5:29am Posted: 31 Jan 2012 at 5:29am |

|

|

|

David Maddux

Orange Level

Joined: 13 Sep 2009

Points: 2535

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Jan 2012 at 6:05am Posted: 31 Jan 2012 at 6:05am |

|

On small places like that, for a quick fix, I have used fiberglass fix. I use the short strand fiberglass type putty. Best fix is to cut out and replace like these boys say. Dave.

|

|

Steve in NJ

Orange Level Access

Joined: 12 Sep 2009

Location: Andover, NJ

Points: 11994

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Jan 2012 at 6:37am Posted: 31 Jan 2012 at 6:37am |

In the pitted area's (if its not peppered through) Duraglass works quite well for filling in the pits. And, even though the area is where the fender bolts to the framing, the Duraglass will protect the steel from rusting again if done correctly. After sandblasting or glassbeading, a coat or two of your favorite rust killer like POR15 or Extend (for examples) and then add the Duraglass over the top and sand nice n' smooth. You'll probably never have to worry bout' that fender rotting out or going through in that area again. I don't normally do body work, I just listen closely to my bodyman. He tells me this cool stuff, and I watch whether its Antique cars, trucks or tractors....

|

|

BrianC

Orange Level Access

Joined: 16 Jun 2011

Location: New York

Points: 1619

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Jan 2012 at 10:24am Posted: 31 Jan 2012 at 10:24am |

Thanks for replies. If I cut it out and replace I am faced with a long butt weld. I am afraid I might botch that. I have a small 115 volt flux core wire welder. I know skilled people can do it, but my skill level may not cut the mustard. I thought of welding or brazing the rust holes, then body solder over the pits. Someone at work suggested making a sheet metal doubler and epoxy together, or spot weld or braze or solder together. Another suggested zinc flame spray to build up area, sand flat? BTW the frame rail the fender bolts to is just as pitted. In one area, 50% thickness is gone. The seat back is shot. The front grill shroud is good, tool box good, battery box turned to dust, hood so so, but $320 gets me a new replacement hood.

|

|

EdK

Silver Level

Joined: 12 Sep 2009

Location: Newcastle, CA

Points: 223

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Jan 2012 at 10:37am Posted: 31 Jan 2012 at 10:37am |

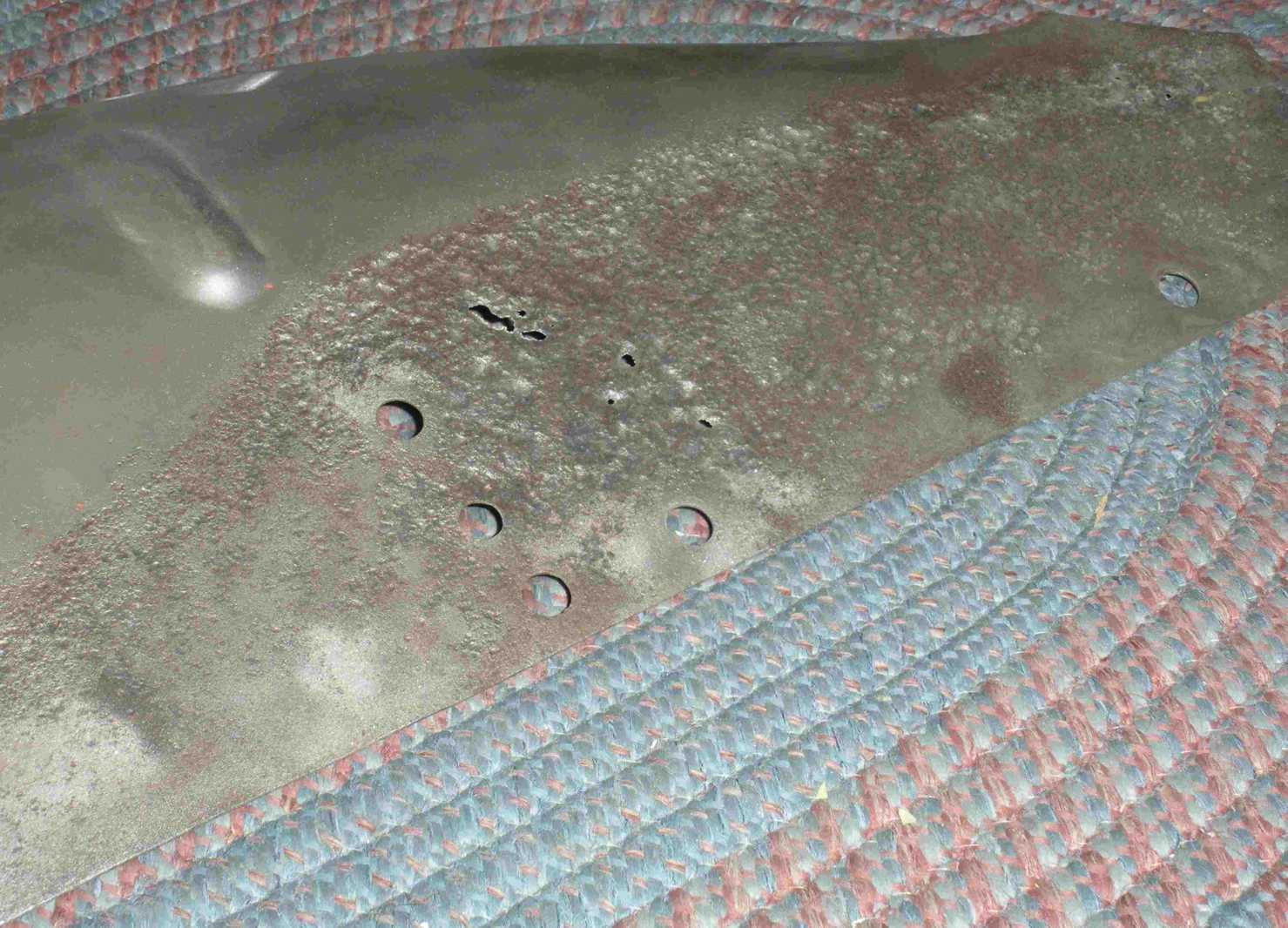

I did a Model C fender repair using some thin roof flashing metal, a lot of epoxy, a lot of "auto filler primer" and some Krylon, AC Orange spray paint. It actually turned out better than I expected and seems to be structurally stable.

Before:

After:

|

|

Dakota Dave

Orange Level

Joined: 12 Sep 2009

Location: ND

Points: 3971

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Jan 2012 at 11:26am Posted: 31 Jan 2012 at 11:26am |

|

just weld with you 115 flux core welder. weld short places along the lenghts. don't try one long weld it will warp out of shape. If It dosent look great grind the bad spots and weld again.by the time you finish the first one your welding will improve. welding metal in its place is realy the only good fix. bondo and fiberglass are only a good option if your going to get rid of it soon. When I did the grill shell on My WD45 I had to reweld the corners a couple times before I was happy. fortunatly this old metal is very tought and can stand a lot of welding and hammering before its past repair.

Edited by Dakota Dave - 31 Jan 2012 at 11:29am

|

|

GBACBFan

Orange Level

Joined: 11 Sep 2009

Location: Green Bay WI

Points: 2662

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Jan 2012 at 11:31am Posted: 31 Jan 2012 at 11:31am |

|

I would weigh the cost of a good used set vs. paying someone with the requisite welding skills to install a patch panel. Assuming $25/hr for a welder/craftsman to fix it, good used fenders will be the better value and are readily available, IMHO.

|

|

"The trouble with quotes on the Internet is that you can never know if they

are genuine." - Mark Twain

|

|

Don(MI)

Orange Level

Joined: 15 Sep 2009

Location: Michigan

Points: 3893

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Jan 2012 at 11:59am Posted: 31 Jan 2012 at 11:59am |

If you can, find someone to weld it for you. And beyond that, if you can do the work yourself its a great learning experience.

These fenders took us about 3 to 4 weeks of time to rebuild, on weeknights and weekends. Very time consuming, but the knowledge learned was worth it.

|

|

Galatians 5:22-24

"I got a pig at home in a pen and corn to feed him on, All I need is a pretty little girl to feed him when I'm gone!"

|

|

David Maddux

Orange Level

Joined: 13 Sep 2009

Points: 2535

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Jan 2012 at 1:23pm Posted: 31 Jan 2012 at 1:23pm |

|

Like Dave says: short welds: I would tack on each end then weld a 1/4" weld in the middle, then rotate from one end to the other end, then weld the center, about 1/4" welds til you have it all welded in, then do the back side the same way. Grind the weld down and a little finishing putty. Your done. Good place to test your skill.

|

|

orangeman

Orange Level

Joined: 12 Sep 2009

Points: 1855

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Jan 2012 at 3:15pm Posted: 31 Jan 2012 at 3:15pm |

There are a number of good ways to make the repair, depends on what hope to achieve from the outcome. Personally, I like the example the Dick L provided, a steel patch panel welded in place and carefully ground.

Overlays, additives, fillers and bondo's are Ok if that is what you want, however, my observation is that when there is variance between the coefficient of expansion of any two materials and exposure to a condensing environment and vibration, the two dissimilar products will separate and the result becomes obvious over time.

Guess it all depends on how fussy you are and what you expect in terms of short term or long term results. Nothing like metal on metal if it were me. Good luck on this effort.

|

|

BrianC

Orange Level Access

Joined: 16 Jun 2011

Location: New York

Points: 1619

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Jan 2012 at 4:54pm Posted: 31 Jan 2012 at 4:54pm |

In EdK's after picture, there is a part I don't have. It looks like a cover over the brake band and linkage. And my big arched drawbar has walked away. I can try welding the patch. The fender shown is the worst. If I destroy it I will look around for good used ones. Does anyone offer already reworked C fenders? As for # of hours I will end up putting in it, I bet I do more that 40. Just running around finding a sand blaster took some effort. Found a local machine shop that did what you see. What looks like rust is not, it is a jpeg artifact, I was trying to make the picure smaller. When done, if not too embarrassed, I will put up picture.

|

|

Chalmersbob

Orange Level

Joined: 11 Sep 2009

Location: Pennsylvania

Points: 2122

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Jan 2012 at 10:28pm Posted: 31 Jan 2012 at 10:28pm |

This is a great oppurtunity to improve on your welding skills. I have welded patches like Dick showed. I'm not a great welder, but I sure know how to use a grinder. Put it on, grind it off. Go slow, short 1/2" then skip 1 1/2" and 1/2" spot again. Go to the end and come back and add to the first 1/2" and work until the weld is complete. you can do it!!

Bob

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)