| Author |

Topic Search Topic Search  Topic Options Topic Options

|

BigGuy1000

Bronze Level

Joined: 06 Dec 2013

Location: NWIL

Points: 129

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: AC 175D Front Axle Kingbolt Topic: AC 175D Front Axle Kingbolt

Posted: 12 Nov 2021 at 10:34am |

We have an AC175D with oscillating wide front axle pivoting on a steel rod hung on 2 trunnions under the frame of the tractor. On one trunnion is a 3/8 Grade 8 kingbolt to keep the rod in place in the trunnion. This bolt breaks at the end of the threads quite often, may last 1 month or 3 months or a year, but always breaks at the end of the threads of the bolt. There are no grease fittings in the trunnions! We do oil often but apparently not enough, as it does not prevent breakage. I did try to drill 1/8 in hole in trunnion to install a fitting but there is a very hard bushing thru which I cannot drill with ordinary drills and hand tools. Does anybody have a proven solution to this problem which will keep the rod in place? This sort of wide front axle is common on many AC tractors. TNX in advance!!!!

|

|

|

Sponsored Links

|

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 21723

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Nov 2021 at 12:08pm Posted: 12 Nov 2021 at 12:08pm |

|

New Gr8 bolt and locknut. Weld the big pin to the axle on the front. Fixed.

|

|

BrianC

Orange Level Access

Joined: 16 Jun 2011

Location: New York

Points: 1619

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Nov 2021 at 12:23pm Posted: 12 Nov 2021 at 12:23pm |

Talking about axle failures here:

The online parts book appears to show that this bolt was upgraded to 1/2" diameter at some point. I don't have a clear view of the assembly. I imagine the bolt retains the pin in the front support, I just can't figure why it should break. You are talking about lubrication, is the pin all galled up and seized to bushings? My 160 has grease fittings.

Someone who knows will speak up.

|

|

MACK

Orange Level

Joined: 17 Nov 2009

Points: 7664

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Nov 2021 at 9:03pm Posted: 12 Nov 2021 at 9:03pm |

|

Use bolt like the Dr. Said with lock not but don't tighten it tight. MACK

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 21723

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Nov 2021 at 9:31pm Posted: 12 Nov 2021 at 9:31pm |

|

They eventually went to the larger 1/2" bolt because of the failures with the 3/8" bolt being sheared off. This is due to too much rotational drag on the large pivot pin, especially with a loader. What you don't want is the pin to fall out. You can probably drill it out to 1/2" if there's enough meat there to work with. But if you weld the pin on the front with a new bolt in the rear it will never fail. Why will you ever need to remove that pin ?? You won't.

|

|

BrianC

Orange Level Access

Joined: 16 Jun 2011

Location: New York

Points: 1619

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Nov 2021 at 11:43am Posted: 14 Nov 2021 at 11:43am |

Was the 1/2" bolt upgrade a sure fire fix? Lady farmer (35miles away) has a 175 and I would take a look for her. No loader, just some weights for plowing.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 21723

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Nov 2021 at 11:54am Posted: 14 Nov 2021 at 11:54am |

|

I'm sure they thought it was, but unfortunately who within the A-C company ever followed up on such a problem after they quit making the tractor ?? NO ONE did!! I'm sure it was an improvement regardless. They had the same issue on the 7000 series and finally went to a snap ring on the rear of the shaft instead of a thru bolt. On the front of the pivot shaft they welded a 1/4" x 3" x 3" square plate to it. Then, they welded a piece of keystock to the axle frame up against the square plate. This kept the pivot shaft tied to the axle framework as far as turning, but by removing the snap ring at the rear, one could remove the pivot shaft. That was a good fix. I have done that on some maroon chassis tractors while still leaving the bolt in the rear and I have welded many other solid to the axle frame at the front, while leaving the bolt at the rear. Again I ask...….why would anyone ever want to remove that pivot shaft ???????????

Edited by DrAllis - 14 Nov 2021 at 12:08pm

|

|

BigGuy1000

Bronze Level

Joined: 06 Dec 2013

Location: NWIL

Points: 129

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Jul 2022 at 8:43pm Posted: 10 Jul 2022 at 8:43pm |

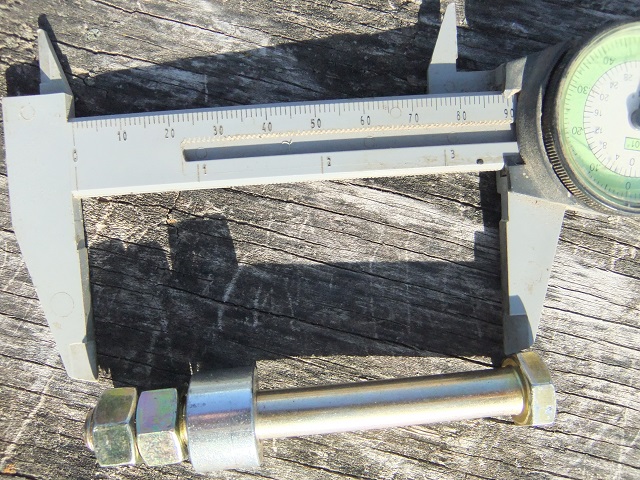

Applied the above bolt (3/8 X 3 1/2 GR8 NF, GR8 fine nuts with 1/2 in long bushing) to the ac175D trunnion. Bushing is next to the trunnion. Nuts are tight against each other, but are backed off one full turn from the bushing. The threads are entirely outside of the trunnion. It has not broken in more than 2 years now on loader duty! I will declare this fixed, WITHOUT needing to buy or learn a big expensive welder!!!!

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 21723

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Jul 2022 at 10:11pm Posted: 10 Jul 2022 at 10:11pm |

|

November 12th 2021 till July 2022 is only 8 months by my math.

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8565

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Jul 2022 at 12:50pm Posted: 11 Jul 2022 at 12:50pm |

|

....time flies??????

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)