| Author |

Topic Search Topic Search  Topic Options Topic Options

|

IBWD MIke

Orange Level

Joined: 08 Apr 2012

Location: Newton Ia.

Points: 4114

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Jan 2022 at 9:36am Posted: 11 Jan 2022 at 9:36am |

Nice work on the WD!

Fixing the shifter is one of the best things I did to the wide-front 45.

|

|

|

Sponsored Links

|

|

|

Eric B

Orange Level

Joined: 09 Feb 2012

Location: British Columbi

Points: 978

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Jan 2022 at 1:25pm Posted: 11 Jan 2022 at 1:25pm |

|

Justin, which connecting rods will you be using with the new crank? Maybe it's in the thread already and I have missed it...

|

|

Currently- WD,WC,3WF's,2 D14's B. Previously- I 600,TL745,200,FL9,FR12,H3,816 LBH. Earth has no sorrow that Heaven cannot heal!

|

|

Jtaylor

Bronze Level

Joined: 11 Oct 2021

Location: Barrie, Ontario

Points: 194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Jan 2022 at 1:38pm Posted: 11 Jan 2022 at 1:38pm |

Eric B wrote: Eric B wrote:

Justin, which connecting rods will you be using with the new crank? Maybe it's in the thread already and I have missed it... |

I will be using the original rods that came out of the WD engine that was already running.

|

|

Eric B

Orange Level

Joined: 09 Feb 2012

Location: British Columbi

Points: 978

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Jan 2022 at 10:05pm Posted: 11 Jan 2022 at 10:05pm |

|

Have you calculated what your compression ratio will be using the taller connecting rods on the 226 crank?

|

|

Currently- WD,WC,3WF's,2 D14's B. Previously- I 600,TL745,200,FL9,FR12,H3,816 LBH. Earth has no sorrow that Heaven cannot heal!

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22085

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 11 Jan 2022 at 10:16pm Posted: 11 Jan 2022 at 10:16pm |

|

Hold on here, Bunky !! The connecting rod LENGTH from a WC-WF-WD-WD45-D17-170-175 are all the same. Use the correct piston for what compression ratio you are trying to achieve with whichever stroke crankshaft you are using. Changing rods makes no difference.

|

|

Jtaylor

Bronze Level

Joined: 11 Oct 2021

Location: Barrie, Ontario

Points: 194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Jan 2022 at 10:30am Posted: 12 Jan 2022 at 10:30am |

DrAllis wrote: DrAllis wrote:

Hold on here, Bunky !! The connecting rod LENGTH from a WC-WF-WD-WD45-D17-170-175 are all the same. Use the correct piston for what compression ratio you are trying to achieve with whichever stroke crankshaft you are using. Changing rods makes no difference. |

This is correct. I believe i read this on the forum from Dr. Allis himself at some point.

|

|

Jtaylor

Bronze Level

Joined: 11 Oct 2021

Location: Barrie, Ontario

Points: 194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Jan 2022 at 10:39am Posted: 12 Jan 2022 at 10:39am |

made some progress last night on the shift forks. I have filled them back up with weld and used a couple tools to shape them back together. I will need to dry fit them to check and make sure they are going to function correctly. take a look at the changes below.

before:

After:

|

|

Eric B

Orange Level

Joined: 09 Feb 2012

Location: British Columbi

Points: 978

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Jan 2022 at 6:13pm Posted: 12 Jan 2022 at 6:13pm |

|

I'm sorry for having made a wrong assumption based on a thread to that effect that I read a long time back, I will have humble pie with my afternoon coffee break, (not my favourite pie)

|

|

Currently- WD,WC,3WF's,2 D14's B. Previously- I 600,TL745,200,FL9,FR12,H3,816 LBH. Earth has no sorrow that Heaven cannot heal!

|

|

Jtaylor

Bronze Level

Joined: 11 Oct 2021

Location: Barrie, Ontario

Points: 194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jan 2022 at 6:11am Posted: 13 Jan 2022 at 6:11am |

Eric B wrote: Eric B wrote:

I'm sorry for having made a wrong assumption based on a thread to that effect that I read a long time back, I will have humble pie with my afternoon coffee break, (not my favourite pie) |

It may not be your favorite pie, but its an honest pie!

it's all good here.

|

|

Jtaylor

Bronze Level

Joined: 11 Oct 2021

Location: Barrie, Ontario

Points: 194

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 13 Jan 2022 at 6:31am Posted: 13 Jan 2022 at 6:31am |

Made some more progress on the shifter forks. will be doing a test fit tonight without the detent balls and springs. Just enough to see how it shifts and make some adjustments if required.

before:

After:

Shifter ball also was helped a bit. Cleaned up the worn areas and made sure things slide nice. I still need to fill the shifter tower and re drill the hole for the square pin.

before:

After:

I also made up my hand clutch linkage. I got the clevis' from my local freightliner dealership as well as a 1/2-20 x6" bolt. cut the head off and welded it to one clevis. kept the other one free for adjustments. Just need to clean up the welds and install a jam nut into place and we are ready for primer!

|

|

IBWD MIke

Orange Level

Joined: 08 Apr 2012

Location: Newton Ia.

Points: 4114

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jan 2022 at 8:31am Posted: 13 Jan 2022 at 8:31am |

|

J, you can get oversize pins to fix the shifter. I used one on my 45 shifter, Think I reamed the hole .001" over pin size and fitted the square head to the shift lever.

|

|

Jtaylor

Bronze Level

Joined: 11 Oct 2021

Location: Barrie, Ontario

Points: 194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jan 2022 at 8:45am Posted: 13 Jan 2022 at 8:45am |

IBWD MIke wrote: IBWD MIke wrote:

J, you can get oversize pins to fix the shifter. I used one on my 45 shifter, Think I reamed the hole .001" over pin size and fitted the square head to the shift lever.

|

I looked into that, my shift tower only has one square pin. it looks like the previous owner put a bolt into the other side threaded. I will work some magic to get it working correctly. i think it might be easier (and cheaper) for me to repair the pin hole then get the pins from DJ's.

|

|

IBWD MIke

Orange Level

Joined: 08 Apr 2012

Location: Newton Ia.

Points: 4114

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jan 2022 at 8:49am Posted: 13 Jan 2022 at 8:49am |

|

J, my tower only has one pin, got it from the local AGCO dealer. About the same price as others, local pick-up, no shipping charges. I drive within about 1/2 mile of them on my way to work, kind of handy.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22085

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jan 2022 at 8:52am Posted: 13 Jan 2022 at 8:52am |

|

Later model WD45's had TWO square headed pins to help offset the curved shift handle that was twisting the lever when shifting. AGCO offers oversized pins !!!! The round part is oversize (drill tower to fit) and the square head is oversized (grind to size you want) to help make things like new again.

Edited by DrAllis - 13 Jan 2022 at 8:53am

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8543

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jan 2022 at 8:12am Posted: 14 Jan 2022 at 8:12am |

Justin, The 45 is going to be ready for work or show. Your giving it a new life. When i did my shifter repairs (There is a thread on here somewhere) I encountered a lot of the same issues of worn components. When I finally got the shift lever in I found it had worn the ball and socket allowing the ball to set down lower, which was allowing the bottom end of the shifter to have interference. I added material to the ball to raise this back up. Yours may not be that bad? Actually the socket was what was worn but it was much easier to add material to the ball. I also had the square pins on each side. and made custom sized and fitted pins. Must say that the improvements your making will last another life time! Good work and documentation. Regards, Chris

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

Jtaylor

Bronze Level

Joined: 11 Oct 2021

Location: Barrie, Ontario

Points: 194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Jan 2022 at 6:44am Posted: 17 Jan 2022 at 6:44am |

Made some progress on the shift tower yesterday. it went great until i lost an interlock detent ball (i think) ran out of steam yesterday to pull the tower apart to check.

I did end up tightening the shifter assembly ( also had to raise it up with some weld). installed the snap ring and collar for a nice tight fit.

also primed the shifter to prep for installation on the tractor once i find the interlock ball...

I also was able to sand down and prime the gauge cluster/console. primed it as well but did not get a good photo yet. nice and smooth! ready for paint.

Next up will be getting the frame rail insides painted and reinstalled onto the tractor. then we can start working on the front bolster assembly and getting it ready for some power steering (more on that later!) the back half of the tractor aside from the small odds and sods are ready to go. it should look more like a tractor very soon!

|

|

Jtaylor

Bronze Level

Joined: 11 Oct 2021

Location: Barrie, Ontario

Points: 194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Jan 2022 at 9:36am Posted: 18 Jan 2022 at 9:36am |

Here is a better set of photos on the battery console.

before:

After punching out the dents with a body hammer.

After body filler for the low spots:

After 2 coats of primer.

I also got the word back from the machine shop for the engine. Block is .002"-.003" low between cylinder 3 and 4. rest of the block is in good shape. he will deck it flat again then shave the liners to make it the correct protrusion. should be aiming for .003" or .004". I will then send him over the crankshaft for measuring and cylinder head for a valve job and flatness check.

|

|

Jtaylor

Bronze Level

Joined: 11 Oct 2021

Location: Barrie, Ontario

Points: 194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Jan 2022 at 10:59am Posted: 19 Jan 2022 at 10:59am |

Got a message from the machine shop this morning. Block is decked and flat again. it has a couple of low spots in between a couple of cylinders. we still have to shave the liners (currently sticking out .008")

here is some photos from the machine shop.

0

|

|

Jtaylor

Bronze Level

Joined: 11 Oct 2021

Location: Barrie, Ontario

Points: 194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Jan 2022 at 7:14am Posted: 26 Jan 2022 at 7:14am |

some slow progress over the last week. Very cold here now (-25*C) and hard to work on things outside. Inside i have been busy getting the odds and ends ready to go. Main progress has been made on the engine. Counterbores were cut so the liners are now 0.005" above the deck. Perfect height. Crank is being sent in tomorrow for polishing and sizing. Cylinder head is also going over at the same time to be surfaced. I pulled out all manifold studs and rocker studs. Ready for machining.

I also worked on getting the first bolt I broke when starting my disassembly. The exhaust pipe pinch bolt. I drilled and re-tapped the hole to 7/16 coarse thread just for simplicity.

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8543

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Jan 2022 at 6:13pm Posted: 26 Jan 2022 at 6:13pm |

The engine work is coming along nicely. Sound like about the same sleeve protrusion I had on the sleeves too. Thanks for the update! Keep hitting at it! Regards, Chris

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

Jtaylor

Bronze Level

Joined: 11 Oct 2021

Location: Barrie, Ontario

Points: 194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Feb 2022 at 8:03am Posted: 02 Feb 2022 at 8:03am |

A small update here. Got a bit tied up with work and other projects that have taken some time.

i cleaned and rebuilt the belt drive. pulled it apart and checked everything over. a nice couple of photos of the "live" belt setup. still do not know where it came from or what it was used for, but it is super simple and effective. check it out.

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8543

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Feb 2022 at 6:30am Posted: 03 Feb 2022 at 6:30am |

Justin, I had not seen the pulley engagement system. Heard about them. Is that a aftermarket item? Your doing good during the winter months! Lots of moves to make for sure. Give good attention to your oil pump. That was a area I had to go back and re-do. I think you will like how the transmission shifts with your repairs. Like factree!:) Dash looks great! I always customize mine to move the key switch up on top. I like the Sierra brand marine switches. Seem very durable and water proof. Regards, Chris

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

Jtaylor

Bronze Level

Joined: 11 Oct 2021

Location: Barrie, Ontario

Points: 194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Feb 2022 at 6:40am Posted: 03 Feb 2022 at 6:40am |

Sugarmaker wrote: Sugarmaker wrote:

Justin, I had not seen the pulley engagement system. Heard about them. Is that a aftermarket item? Your doing good during the winter months! Lots of moves to make for sure. Give good attention to your oil pump. That was a area I had to go back and re-do. I think you will like how the transmission shifts with your repairs. Like factree!:) Dash looks great! I always customize mine to move the key switch up on top. I like the Sierra brand marine switches. Seem very durable and water proof. Regards, Chris

|

It looks to be an allis part of some sort. stamping is indicative of Allis-type. it works well for sure! slowly getting things cleaned up and put back together. as much as possible anyways.. once i make some headway with the frame rails (next free day) they will be installed then i can paint the tractor again with all the new parts and pieces installed and prepare for its final assembly without sheetmetal.

|

|

Jtaylor

Bronze Level

Joined: 11 Oct 2021

Location: Barrie, Ontario

Points: 194

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 22 Feb 2022 at 6:38am Posted: 22 Feb 2022 at 6:38am |

Good morning Everyone, Been away from the forum and the tractor for a couple of weeks. Busy with my own business and tending to the snowmobile trails around the area

Just finished the top color change on this to add the black bandana

As well as running this guy during nights

BUT!

I was able to work on the tractor a bit over the long weekend. the main goal was frame rail prep. I wanted to have the tractor to the point the frame rails could be installed without the need for removal again. I finished the shifter assembly and sealed it to the tractor, as well as installed the belt drive with its cover sealed and tight. and all linkages i could think of was installed prior to the frame rails.

I installed the frame rails after that previous photo.

Then I started working on the front end, I pulled the bolster apart from the wide front for inspection and cleaning. lots of build up debris but not much in the form of wear.

I also got the front and rear pin plates removed, I will need to fill these in and machine them back to the correct size. the front is worn pretty good, Lots of time will be needed to reshape them back to original.

more updates to follow as the progress continues.

|

|

Jtaylor

Bronze Level

Joined: 11 Oct 2021

Location: Barrie, Ontario

Points: 194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Feb 2022 at 8:48am Posted: 24 Feb 2022 at 8:48am |

Another quick update. I have been pondering how to sucessfully complete a power steering conversion without purchasing the expensive char-lynn setup that some of these tractors came with.

I did have a pre-requisite that i wanted it to look as factory "in place" as it could as well as be between the frame rails and not externally mounted. I was originally thinking of a ford power steering pump and gear but after extensive searching for something to work, I was stuck with a right hand drive unit to mount between the frame rails. since i am in canada, right hand drive parts are hard to find and i wanted to stay away from an uncommon source in case something breaks in the future.

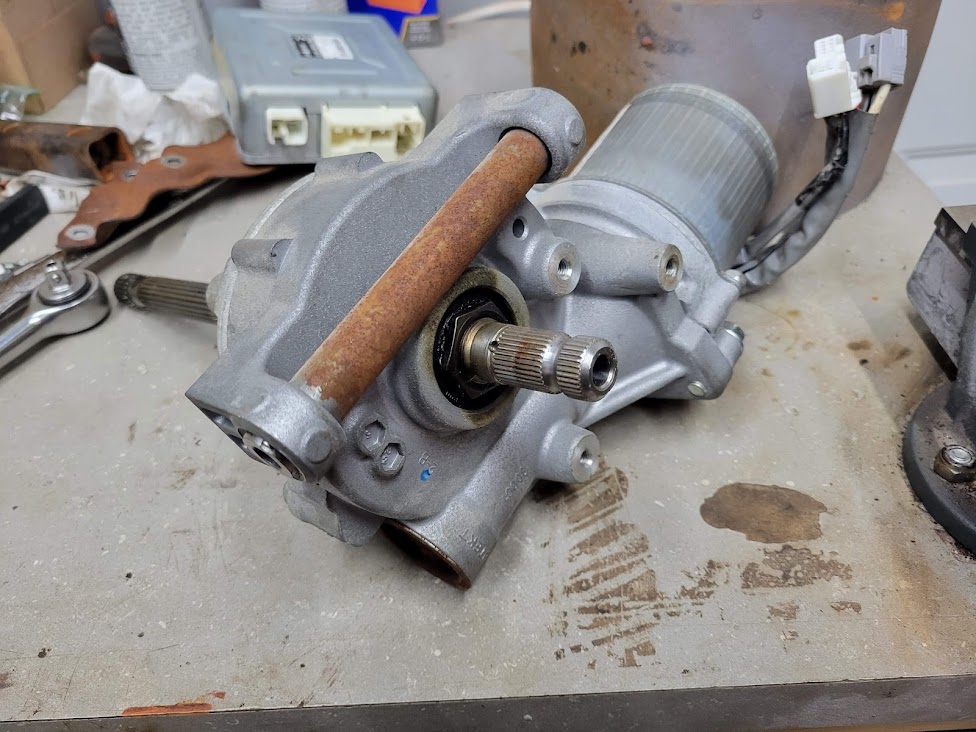

Here was my solution.

This was an ELECTRIC power steering pump from a 2007 saturn Vue SUV. these use a one piece steering shaft that fits in line of the original steering gear. it uses torque sensors to provide steering assistance but without the worry of leaking fluid or hiding another reservoir for nobody to see. PLUS.... the unit is very small. It will fit in the spot between the engine and bolster with plenty of room to spare. the bonus part is if the fuse blows or there is a malfunction, the unit will default to an "off" position and the unit will return back to manual steering. these units use 10AWG wire to power them from the battery, they also draw about 60 amps at full lock. it seems like a lot but with the newer technology of 100+ amp alternators we should be just fine running it off these tractors.

keep your eyes peeled for installation once the bracket is made up and this setup is painted persian orange!

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8543

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Feb 2022 at 8:57am Posted: 24 Feb 2022 at 8:57am |

Wow. Looking real good! interesting powersterring conversion too! Regards, Chris

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

IBWD MIke

Orange Level

Joined: 08 Apr 2012

Location: Newton Ia.

Points: 4114

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Feb 2022 at 10:05am Posted: 24 Feb 2022 at 10:05am |

|

Very interesting! Have heard of guys doing this kind of power steering conversion, will be nice to see it documented.

|

|

HudCo

Orange Level

Joined: 29 Jan 2013

Location: Plymouth Utah

Points: 3941

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Feb 2022 at 6:32pm Posted: 24 Feb 2022 at 6:32pm |

|

how many rounds from stop to stop on that steering gear ?

|

|

Jtaylor

Bronze Level

Joined: 11 Oct 2021

Location: Barrie, Ontario

Points: 194

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Feb 2022 at 6:43pm Posted: 24 Feb 2022 at 6:43pm |

HudCo wrote: HudCo wrote:

how many rounds from stop to stop on that steering gear ? |

Unlimited! Because it's not a steering gear. This is basically a torque generator but electric.

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 5246

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Feb 2022 at 9:00am Posted: 25 Feb 2022 at 9:00am |

|

That looks like a sweet solution. Will be interested in how that turns out.

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

Eric B wrote:

Eric B wrote: